Abstract

Recent developments and innovations in the field of P recovery and recycling from municipal sewage sludge claim to provide a sustainable and more efficient alternative to the traditional sludge valorization in agriculture. The method of life cycle assessment (LCA) offers a detailed analysis of the potential environmental impacts associated with different technologies, but it needs to be based on sound definitions and validated input data, not only for the specific technologies but also for the methodological framework. Since the relevant ISO standards 14040/44 provide methodological guidance without specifically fixed definitions, the application of LCA leaves a lot of potential for interpretation of results. Within the European research project P-REX, a methodological framework was developed to assess various available technologies for P recovery from sewage sludge, sludge liquor or incineration ash. Decisive definitions are the setting of adequate system boundaries and functional unit, the selection of LCA indicators and their interpretation. The following chapter discusses important definitions of the LCA methodology and provides recommendations towards a consolidated approach for future LCA studies in the field of P recovery from sewage sludge.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

A significant proportion of phosphorus (P) used for food production is contained in municipal wastewater and ends up in sewage sludge (Milieu 2010; van Dijk et al. 2016). Hence, the recycling of P from sewage sludge to agriculture has been realized for decades with the agricultural disposal of this sludge onto farmlands. However, recent years have seen a reduction of this recycling route in many EU countries due to concerns about inorganic and organic pollutants found in the sludge and also due to indications of limited plant availability of P in sewage sludge depending on its Fe content. Moving towards thermal disposal of sewage sludge in incineration plants (either as mono-incineration in dedicated facilities for sludge disposal or as co-incineration in power plants, municipal waste incineration plants or cement kilns), the direct recycling of P from sewage sludge into agriculture is usually not feasible with the residual ash from incineration due to limited plant availability of P and relatively high contamination of the ash with, e.g. heavy metals.

To overcome this drawback of limited P recycling with sludge incineration and close the P management cycle again, different pathways and processes of P recovery from sewage sludge or incineration ash have been developed in recent years. These processes claim to provide a sustainable and more efficient alternative to traditional sludge valorization in agriculture. However, they also require additional resources (e.g. electricity, chemicals, infrastructure) and will thus have indirect impacts on the overall environmental profile of the secondary P fertilizer products. Consequently, a comprehensive assessment of environmental impacts and benefits of these recycling processes should be targeted to identify and characterize potential benefits and drawbacks of the different routes, reveal potentials for optimization and direct future research and development activities towards promising routes of P recovery and recycling.

1.1 Using Life Cycle Assessment for P Recovery Processes

For assessing technical processes and systems in their potential environmental impacts, the method of life cycle assessment (LCA) has been developed and applied widely within research and industry (Klöpffer and Grahl 2009) and also in the field of wastewater and sludge treatment as reviewed in literature (Corominas et al. 2013; Yoshida et al. 2013). Taking the life cycle perspective into account, this method quantifies potential environmental impacts of a defined process or system based on quantitative information on resource needs and emissions of all relevant processes which are affected by the system under study. This includes on-site effects of the process or system (“foreground system”) and also indirect effects in the related production systems for upstream (e.g. electricity production) and downstream (e.g. waste disposal) processes (“background system”). Building on substance flow models of the foreground system and database information for the background system, all relevant inputs and outputs across the system boundary from or into the environment are quantified and summarized. This inventory information is then evaluated with a defined set of environmental indicators, relating to specific areas of environmental concern (e.g. anthropogenic climate change, acidification or ecotoxicity) and describing potential negative impacts of emissions and resource use.

The general framework and steps of an LCA are defined in the ISO standard 14040/44 (ISO 14040 2006; ISO 14044 2006) and include four distinctive working steps: (1) definition of goal and scope, (2) life cycle inventory, (3) life cycle impact assessment and (4) interpretation. The standard gives methodological guidance, but the LCA practitioner can freely choose adequate definitions to define the system under study depending on the respective goal and scope of the assessment, provided that they are well justified in the LCA report. Hence, LCA studies in the same field of technology often lack comparable definitions and may show divergent outcomes for the same processes, thus leaving a wide potential for contrasting interpretation of results, leading to low trust in their validity and credibility of the LCA results and method. This shortcoming may be overcome by a consolidated approach for LCA studies in a specific field of interest, so that future LCA can build upon a comparable and validated framework for environmental assessments and increase the credibility of their results.

1.2 Features of LCA

Per definition, the method of LCA can be used to compare different technical processes or systems in their potential environmental impacts, following a defined methodological approach. It quantifies the environmental profile of a specific technology in terms of emissions and resource use, revealing hotspots of environmental concern and optimization potentials towards reduction of emissions and resource consumption. However, the approach of LCA is characterized by specific features which have developed since its first application in the 1980s. Using LCA for a comparative environmental assessment of different processes or systems, these features have to be clearly identified and kept in mind while using the tool and interpreting its results.

LCA modelling of flows between the technical system and the environment is based on “steady-state” substance flow models of the technical system, typically describing a non-dynamic average operational state of the processes. In addition, flows of resources and emissions into the environment are aggregated over time and space, and these aggregates are used to characterize the potential environmental impact associated with a process or service. Hence, LCA does not provide any temporal or spatial resolution of emissions by definition. Consequently, effects of peak loads and temporal or spatial variations in emission profiles cannot be accounted for in LCA. Future developments in LCA data management and impact characterization may include more temporal and spatial aspects, but these are still under development.

Impact characterization in LCA is based on global or regional impact factors for emissions and resource use. For emissions, these factors take into account fate and effect of pollutants in multimedia transport and effect models, representing a generic environmental system. For resource use, impact factors typically relate available resources to consumption profiles to account for relative resource availability and potential scarcity. Hence, LCA indicator results are clearly identified as “potential” environmental impacts caused by these flows rather than actual predictions of local impacts on specific ecosystems. LCA is not useful for predicting if any specific environmental impact of a certain process or service is actually realized for a specific ecosystem (e.g. eutrophication in lake XY). This task has to include a localized environmental impact assessment, taking into account background concentrations, pollution loads and temporal and spatial aspects of emissions, which are not part of LCA.

Interpretation of LCA indicator results can be difficult to communicate to non-experts. Describing different potential environmental impacts on a global perspective, LCA will give information on multiple aspects of environmental concern based on quantitative input data. However, LCA will not tell the user automatically which process or system is to be preferred or rejected from an environmental perspective. As different categories of environmental impact are characterized in LCA (e.g. global warming, primary energy demand, eutrophication, ecotoxicity), there has to be a subjective weighting of the interested stakeholders between these environmental indicators to develop a conclusive decision. Although weighting schemes are proposed in selected LCA frameworks based on predefined weighting factors (e.g. using the scheme of Swiss eco-points Frischknecht et al. 2008), it is clearly recommended in the ISO standard to report the results of an LCA in non-weighted categories of environmental impact. Thus, each stakeholder can draw his/her own conclusions according to local, regional or other conditions and valuations.

Keeping in mind these inherent limitations of the LCA approach, it is clear that LCA cannot take the full responsibility for the decision from the user or stakeholder that is deciding between different processes or systems from an environmental point of view. However, LCA is based on a quantitative substance flow model of the relevant process or service, and it often serves as a focal point of process development and optimization, facilitating discussions on process improvements or optimization of the value chain, including relevant processes upstream and downstream of the core process or service. It can also draw attention to side effects or trade-offs in environmental impacts, for example, reducing a specific impact while shifting burden into another category of environmental concern.

Within the European research project P-REX (www.p-rex.eu), a methodological framework was developed to assess various processes and pathways for P recovery from sewage sludge, sludge liquor from dewatering or incineration ash (Remy and Jossa 2015). This chapter introduces this methodological framework defined in P-REX in terms of system boundaries, functional units, selection of LCA indicators and their interpretation. The following sections will discuss important definitions of the LCA methodology and provide recommendations towards a consolidated approach for future LCA studies in this field. It is structured into different parts according to the ISO framework for LCA to elaborate on important aspects of LCA goal and scope definitions and application within the context of P recovery in technical processes.

2 Definition of Goal and Scope

2.1 Goal of an LCA

The definition of a specific goal for an LCA study seems to be redundant at first; however it can provide valuable insights and help to formulate this goal in a precise way, so that the definitions can be set to fulfil this goal in an adequate manner. The goal will give information on the nature and purpose of the LCA study and the intended use of its outcome.

Some examples for proper goal definitions in the field of P recycling from municipal wastewater are listed below:

-

1.

The goal of this LCA is to analyse and compare potential environmental impacts of different P recovery technologies from sewage sludge, sludge liquor or mono-incineration ash against conventional phosphorus fertilizer production.

-

2.

The goal of this LCA is to analyse and compare potential environmental impacts of different P recovery technologies from sewage sludge, sludge liquor or mono-incineration ash and the recycling of obtained products against conventional P recycling via sludge application to arable land.

-

3.

The goal of this LCA is to analyse and compare potential environmental impacts of different P recovery technologies from mono-incineration ash and the recycling of obtained products to arable land against the usage of conventional phosphorus fertilizers.

Although all listed examples describe in principle the use of LCA for phosphorus recovery, the exact goal definition has decisive impact on LCA scoping such as the choice of adequate system boundaries, functions and functional units, LCA inventory, results, interpretation and conclusion that can be obtained from the LCA:

-

1.

The first goal definition allows comparability between different types of phosphorus recovery processes and fertilizer production; however the application of P products on arable land (e.g. environmental impacts of different heavy metal contamination or leaching of N and P into groundwater) is NOT within the scope of this LCA.

-

2.

The second goal definition allows comparability between different types of phosphorus recycling routes, including P recovery processes and traditional direct application of sludge on farmland. This LCA outcome focusses, e.g. on the question whether it is worth to invest energy, etc. for phosphorus recovery technologies compared to traditional sludge recycling from an environmental point of view.

-

3.

The third goal definition only considers technologies aiming for phosphorus recovery from ash; consequentially system boundaries will neither include sludge treatment nor ash production via mono-incineration. A comparison of ash-derived P products and conventional phosphorus fertilizers and the impacts of recovered and conventional phosphorus products on arable land can be included. However, no conclusion can be obtained if it is environmentally preferable to invest in sludge mono-incineration or not, since sludge disposal is not within the system boundaries.

The following sections show conclusive options which have to be considered by the LCA practitioner referring to the goal definition 1 (“compare P recovery processes and mineral fertilizer production”).

2.2 Scoping of LCA: System Boundaries, Functions and Functional Unit

LCA is based on two main principles: (1) account all relevant processes which are affected by the process under study (“life-cycle perspective”) and (2) account for all relevant environmental impacts to reveal synergies and trade-offs between different categories of environmental impact. To reflect these principles, the adequate definition of system boundaries is essential for developing a reasonable framework for the LCA. These system boundaries include all processes that will be modelled with their inputs and outputs towards the environment. They should be defined to include all relevant processes upstream and downstream of the core process, thus delivering a comprehensive picture of the process and its effects. This relates both to the “foreground system” and to the “background system” (e.g. electricity production in power plants, chemical production, disposal of wastes). For keeping the LCA model manageable, certain processes and material flows can be cut off from the assessment, e.g. by defining reasonable cut-off criteria in mass or relevance. However, this “cut-off” has to be carefully justified to prevent important system parts or flows to be excluded from the assessment.

For scenario definitions of comparative LCA studies, the systems under study should target the same system functions to allow for a fair comparison between systems of equal purpose. In case of a sludge treatment line of a WWTP, this function could be defined as “treatment and disposal of raw sludge from a 1 Mio pe (million population equivalents) WWTP per year”. To reach functional equivalency between systems, it is suitable to expand the systems with additional functions (“system expansion”) to reach comparability with other systems (e.g. recovery of secondary P from sewage sludge). Secondary functions can be accounted by subtracting the avoided process for secondary functions (i.e. the production of mineral P fertilizer) and thus crediting the avoided impacts (“avoided burden approach”).

Functional equivalency should also be reflected in the suitable selection of a functional unit (FU) to which all environmental impacts are related to. This FU has to be carefully defined, as it may affect the comparison between different processes or services. Following the system function and perspective of the study, different FU can be defined for P recovery from sewage sludge (Table 4.1):

-

The “system perspective” describes the total impacts of the entire system of sludge disposal (e.g. sludge disposal for a specific WWTP serving a defined number of inhabitants), giving information on the environmental profile of sludge treatment and disposal with or without P recovery options (e.g. scenarios A, B, C), including potential credits for substitution of mineral P production, electricity and heat. This perspective is useful to picture the overall environmental impacts of sludge treatment and disposal with and without P recovery, thus revealing also the contribution of P recovery processes to the total impacts of sludge disposal.

-

The “system change perspective” quantifies all changes in environmental impacts that can be associated with the introduction of a P recovery process in the defined system. For revealing these effects, a reference scenario (A) without dedicated P recovery should be compared against scenarios with P recovery (B, C). The difference between both scenarios (e.g. B-A. C-A) can then be fully attributed to the P recovery process, allocating all changes to the function of P recovery.

-

The “product perspective” describes the environmental impacts that are associated relative to the amount of recovered P. It should be calculated from the difference of the reference scenario (A) and the scenario for P recovery (B), related to the total amount of recovered P (e.g. (B-A)/mass of Precovered). The product perspective gives information about the environmental profile of the recovered P product, enabling the comparison of different secondary P products from different sites, pathways and processes.

All these perspectives can be useful for the interpretation of the LCA results. The LCA documentation should at least include suitable information to enable the transfer between these functional units, if not all results for these perspectives are reported explicitly. Thus, results from LCA studies with different functional units can be compared against each other.

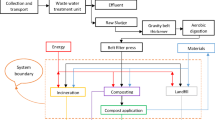

Regarding the definition of system boundaries of an LCA for P recovery from sewage sludge or incineration ash, the following system parts should be considered as a minimum to reflect all side effects of P recovery options on sludge treatment and disposal (Fig. 4.1):

-

Starting with raw mixed sludge coming from the WWTP (“reference flow”)

-

Sludge stabilization in digestion and valorization of products (e.g. sewage gas utilization in combined heat and power (CHP) plant)

-

Sludge dewatering

-

Treatment of sludge dewatering liquor which is usually recycled back to the influent of the WWTP (“return load”)

-

Sludge disposal (e.g. drying, transport, application in agriculture, incineration, disposal of incineration ash)

-

Credits from P recovery (e.g. avoided production of mineral P fertilizer) and energy recovery (avoided production of electricity, heat) in sludge digestion and disposal

-

All background processes relevant for the system function (i.e. production of electricity, chemicals, fuels and – if relevant – materials for infrastructure).

In particular, LCA of P recovery processes should include all processes downstream of the P recovery process which could be affected by the extraction of P. As P is often extracted from the liquid phase, the impact of the return of sludge liquor to the WWTP inlet (“return load”) is affected by P recovery and thus has to be included in the LCA definitions. Removing P and other substances (e.g. N, COD) from the return load will lead to a lower effort of treatment in the main line of the WWTP and can also affect WWTP effluent quality, which is naturally a major environmental effect of the system. The effect of changing return loads may be estimated by a simplified WWTP model (i.e. modelling only electricity demand and effluent quality of the mainline) to limit model complexity of the LCA.

Similarly, the dewatering and disposal of sludge can be affected by upstream P recovery due to changes in sludge properties (e.g. dewatering efficiency and dry matter content), affecting also transport volumes, incineration characteristics and related potential for energy recovery. Finally, disposal of any residuals from sludge incineration (e.g. fly ashes) or subsequent P recovery processes should also be included, as quality and quantity of these residuals can be affected by upstream P recovery from incineration ashes.

3 Life Cycle Inventory: Collecting Data for LCA

Quality of the inventory data for the LCA model will be decisive for the validity of the LCA results. In general, LCA input data should fulfil several criteria to meet the requirements of the study goal and scope. Particular attention has to be paid to the representativeness of the collected data for the system under study, the completeness in data collection so no relevant flows are overlooked and the consistency of the data collection procedure between different components of the analysis. In addition, information on uncertainty and precision (e.g. variation) of the collected data can be useful for sensitivity analysis and stability check of the LCA results. For the inventory, it can be distinguished between foreground data (process-specific flows and emissions of the system under study) and background data (resource use and emissions for background processes such as electricity production, chemicals production, transport, etc.).

3.1 Data Requirements for an LCA of P Recovery Processes

A minimum set of LCA foreground data for P recovery processes should include information on product yield (related to input flow of the process and P content), product quality (inorganic and organic pollutants, P content, content of important metals such as Fe), and demand for auxiliaries such as electricity, heat, fuels and chemicals. In addition, side effects of P recovery on upstream or downstream processes should be reflected as precisely as possible, e.g. changes in return load or sludge dewatering properties.

To adequately show potential effects of P recovery and the change in sludge properties, it is mandatory to consider the main parameters for sludge properties within flow modelling, which are at least volume, dry matter, organic dry matter (or COD), nitrogen and phosphorus. Further the consideration of inorganic matrix elements as calcium, silicon, iron, aluminium or magnesium is recommended. The consideration of further trace elements as heavy metals or trace organics is not necessary in terms of process performance. However a simplified approach for different contaminations of products should be considered if the application to arable land is within the scope of LCA.

3.2 Data Quality and Validation

In LCA studies of technical processes which are still under development and optimization (such as many evolving P recovery processes), input data has to be typically collected from process suppliers or operators based on test installations in laboratory or pilot scale. Here, it has to be kept in mind that results of lab or pilot tests may not reflect the actual technical full-scale realization in terms of energy and chemicals demand, product yield and product quality. Hence, upscaling of lab or pilot data towards a projected full-scale installation has to be carefully justified in close cooperation with suppliers and operators to end up with reasonable data for the LCA. Typically, process performance (product yield, product quality) and chemical demand (e.g. acids, complexing agents) of P recovery processes can be transferred from pilot-scale to full-scale process using suitable relations, whereas energy demand (electricity demand, heat management) has to be estimated or extrapolated from detailed engineering concepts. Potential biases between different processes with different stages of development (e.g. comparing lab-scale tests of process A with pilot or even full-scale results of process B) have to be addressed in the LCA documentation and also in the interpretation of the results of a comparative analysis.

For a comparative LCA of different P recovery processes, data collection will most probably include process data from different sites and treatment plants, thus introducing another potential bias in the comparison. In fact, sewage sludge composition and other relevant boundary conditions may vary in a wider range for important parameters (e.g. P concentration), which can have a high impact on efforts for P recovery as well as product yield and quality. To overcome this bias for comparative studies, LCA input data should be transferred to a reference model of a defined WWTP to enable the comparison of different processes based on the same boundary conditions such as sludge or liquor quality. For the transfer, a suitable relation of relevant process data to input characteristics (e.g. molar dosing of Mg as precipitation agent in relation to PO4-P content, P yield in % of dissolved P) should be targeted wherever possible.

For the background data, LCA databases should be used which reflect the current knowledge of resource use and emissions. A common database for this purpose is e.g. ecoinvent (Ecoinvent 2014), but there are other commercial and national databases available. The LCA report should contain precise information on which database and datasets have been used for the LCA. Comparability of different LCAs can be improved if similar datasets are used for the background processes.

After data collection has been finished, final validation of data with technology suppliers and operators is strongly recommended to have a common agreement on all input data for the LCA. Sending the input data for validation to the experts can help to track down errors in data transfer and processing (e.g. different units or relations) which are fairly common regarding the large amount of data to be collected for the LCA. Finally, data validation will increase validity of the LCA results and consequently the trust of all stakeholders into the final results of the LCA model. Calculation of LCA results can be started before final validation which helps to track down obvious errors in input data, but public communication of LCA results should not start until all input data has been finally validated by the data providers.

4 Life Cycle Impact Assessment: Calculating Environmental Indicators

In general, the ISO standard for LCA does not regulate the specific indicators and related impact models that have to be chosen for a specific LCA study. Hence, the LCA practitioner can choose from a variety of different indicators and impact assessment methods which are available in the LCA community. Recently, the Joint Research Centre of the European Commission published a review of available methods for LCA impact assessment and recommended the use of selected models (Hauschild et al. 2013). For an adequate selection of environmental indicators in LCA, two aspects have to be taken into account. First, the environmental impact category should be affected by the process under study. Second, suitable data should be available to allow for a meaningful characterization of this environmental impact in the respective LCA model. In practice, the selection of indicators will also rely on practicability and data availability in each LCA study.

4.1 Selection of Indicators

Most LCA impact assessment models calculate “midpoint” indicators which characterize the environmental impact with a physically measurable effect model at the midpoint of the cause-effect chain, using a representative substance as reference unit (e.g. CO2 equivalents for global warming potential). In addition, some methods also offer “endpoint” indicators which extend the modelling of the cause-effect chain towards the endpoint receiving the potential damage, i.e. the affected areas of protection (human health, ecosystems, resources). While enabling the comparison between different indicators and their relevance for a specific endpoint, the endpoint approach introduces a higher level of uncertainty in the evaluation, as the final impacts of environmental phenomena (e.g. impact of global warming on human health) are often difficult to estimate. For reasons of clarity and transparency, it is highly recommended to report LCA results using midpoint indicators, while endpoint indicators may be reported in addition if required by the study goal and scope.

For LCA studies of P recovery from sewage sludge or incineration ash, a selection of suitable midpoint indicators is recommended to reflect the most relevant environmental aspects of P recovery (Table 4.2). This list of indicators is based on previous experience of LCA studies in the field of sludge treatment and resource recovery and can serve as a minimum requirement in terms of environmental categories. Concerning the choice of indicator models, it is useful to stick to a consistent impact assessment method as far as possible (e.g. the ReCiPe model Goedkoop et al. 2009) and complement it with selected indicators of other methods, also for sensitivity analysis. Naturally, the list can be amended with selected indicators as necessary for the specific LCA study (e.g. ozone depletion, photochemical oxidant formation, land use, water footprint).

Impact assessment factors are influenced by the time horizon and other specific factors, which are reflected in ReCiPe by different sets of factors for different perspectives. Usually, the hierarchist perspective serves well for prospective LCAs and reflects a suitable timeframe for political decisions (e.g. global warming potential over 100a). The effect of long-term emissions (e.g. emissions from leaching at opencast mines or landfill sites >>100 a) can be deliberately excluded from the assessment to focus on effects within meaningful time frames.

Indicators can be normalized to a reference system, e.g. to the total environmental impact per person and year. Thus, the contribution of the P recovery system under study to the total environmental impacts of society can be quantified, indicating where the system of P recovery has significant or minor contribution to a specific area of environmental concern. Normalization factors are usually available on continental or national level and can be found in the impact assessment method (Sala et al. 2015; Sleeswijk et al. 2008).

5 Interpretation: Using LCA Results for Decision Support

For interpretation of the LCA results and subsequent communication towards relevant stakeholders, transparency and reproducibility of LCA methodology both play a major role for building trust in the outcomes of an LCA study. Thus, LCA reporting should include a detailed documentation and justification of the LCA methodology and definitions, the used input data, the indicator results of the impact assessment and a detailed discussion on the final interpretation of the results. This documentation also includes information on data quality and an estimate of uncertainty or variability of input data affecting the stability of the results. It is recommended to check the influence of selected definition parameters with major influence on the results (e.g. dissolved PO4-P concentration in digested sludge or liquor for P recovery processes) in sensitivity analysis to be able to comment on the consequences of system definitions for the comparative results.

For communication of LCA results to stakeholders to support decision-making in political or municipal bodies, aggregation of indicators with endpoint methods or final weighting to end up with a single indicator result (e.g. “eco-points”) has the intrinsic danger of lack of transparency for the involved stakeholders. Single-score results are attractive for decision-makers because they pretend to be scientifically derived and thus enable “unambiguous” conclusions of which process or scenario is preferable from an environmental point of view. However, weighting of indicators against each other is always based on a subjective value choice and will depend on local and regional conditions, priorities of different actors or political targets. Consequently, the weighed and aggregated result of an LCA should only be communicated with explicitly describing the weighting method and result factors. In fact, the ISO standard explicitly recommends no weighting in comparative studies (“Weighting […] shall not be used in LCA studies intended to be used in comparative assertions intended to be disclosed to the public” ISO 14044 2006).

Therefore, it is recommended to report at least a defined set of midpoint indicators as results of the LCA and feed that into the discussion of the stakeholders about the different alternatives. In this manner, LCA can facilitate the discussion on potential environmental impacts associated with P recovery processes by giving quantitative information into the decision-making process. The LCA outcomes will not intrinsically lead to the recommendation of one process or pathway over another from an environmental perspective but can rather be seen as a defined framework in which process features can be revealed and environmental hotspots are identified. Finally, LCA does not take the decision on which process to choose based on the environmental profile but gives further that has to be correctly communicated and used by the relevant stakeholders. The responsibility for the decision and the overall evaluation of environmental relevance remains with the stakeholders.

6 Summary and Outlook

The present chapter discusses the specific features of LCA with relation to its application on P recovery processes from sewage sludge or incineration ash. Based on experience from the European research project P-REX, it proposes a methodological framework that can be adopted for future studies in this field to improve comparability between different LCA studies and increase the quality and validity of results. Recommendations are provided for a suitable definition of goal and scope of the LCA with regard to system boundaries, scenario selection and functional unit. Advice on data collection and validation is given to assure a high quality of input data as basis for the LCA. Finally, a defined minimum set of LCA impact indicators is proposed to improve the comparability of the results of future LCA studies and prevent the exclusive use of endpoint or single-score indicators in stakeholder communication. Using this methodological framework, future LCA studies in this field can follow a more harmonized approach which will increase trust in this tool and enable intelligent and meaningful use of its results towards an improved and more sustainable management of limited P resources.

References

Corominas L, Foley J, Guest JS, Hospido A, Larsen HF, Morera S, Shaw A (2013) Life cycle assessment applied to wastewater treatment: state of the art. Water Res 47 (15):5480–5492. S0043-1354(13)00540-X [pii] https://doi.org/10.1016/j.watres.2013.06.049

Ecoinvent (2014) Ecoinvent data v3.1, ecoinvent reports no. 1–26. Swiss Center for Life Cycle Inventories, www.ecoinvent.org

Frischknecht R, Steiner R, Jungbluth N (2008) Ökobilanzen: Methode der ökologischen Knappheit – Ökofaktoren 2006 (Life Cycle Assessment: Method of ecological scarcity – eco-factors 2006). Öbu – Netzwerk für nachhaltiges Wirtschaften, Zurich

Goedkoop MJ, Heijungs R, Huijbregts MAJ, De Schryver A, Struijs J, Van Zelm R (2009) ReCiPe 2008, a life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level; first edition report I: characterization. http://www.lcia-recipe.net

Hauschild MZ, Goedkoop M, Guinée J, Heijungs R, Huijbregts M, Jolliet O, Margni M, De Schryver A, Humbert S, Laurent A, Sala S, Pant R (2013) Identifying best existing practice for characterization modeling in life cycle impact assessment. Int J Life Cycle Assess 18(3):683–697. https://doi.org/10.1007/s11367-012-0489-5

IPCC (2014) Climate change 2014: synthesis report. Contribution of Working Groups I, II and III to the fifth assessment report of the Intergovernmental Panel on Climate Change IPCC, Geneva, Switzerland

ISO 14040 (2006) Environmental management – life cycle assessment – principles and framework. International Standardisation Organisation, Geneva

ISO 14044 (2006) Environmental management – life cycle assessment – requirements and guidelines. International Standardisation Organisation, Geneva

Klöpffer W, Grahl B (2009) Ökobilanz (LCA): Ein Leitfaden für Ausbildung und Beruf (Life Cycle Assessment: A guide for education and practice). Wiley-VCH, Weinheim

Milieu (2010) Environmental, economic and social impacts of the use of sewage sludge on land. Final report part I: overview report. Prepared for the European Commission, DG Environment under Study Contract DG ENV.G.4/ETU/2008/0076r. Brussels, Belgium

Remy C, Jossa P (2015) Comparative life cycle assessment of treatment-recovery paths (D9.2). KWB, www.p-rex.eu

Rosenbaum RK, Bachmann TM, Gold LS, Huijbregts MAJ, Jolliet O, Juraske R, Koehler A, Larsen HF, MacLeod M, Margni M, McKone TE, Payet J, Schuhmacher M, van de Meent D, Hauschild MZ (2008) USEtox-the UNEP-SETAC toxicity model: recommended characterisation factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. Int J Life Cycle Assess 13(7):532–546. https://doi.org/10.1007/s11367-008-0038-4

Sala S, Benini L, Mancini L, Pant R (2015) Integrated assessment of environmental impact of Europe in 2010: data sources and extrapolation strategies for calculating normalisation factors. Int J Life Cycle Assess 20(11):1568–1585. https://doi.org/10.1007/s11367-015-0958-8

Sleeswijk AW, van Oers LFCM, Guinée JB, Struijs J, Huijbregts MAJ (2008) Normalisation in product life cycle assessment: an LCA of the global and European economic systems in the year 2000. Sci Total Environ 390(1):227–240. https://doi.org/10.1016/j.scitotenv.2007.09.040

van Dijk KC, Lesschen JP, Oenema O (2016) Phosphorus flows and balances of the European Union Member States. Sci Total Environ 542:1078–1093. https://doi.org/10.1016/j.scitotenv.2015.08.048

VDI (2012) VDI-Richtlinie 4600: 2012-01: Kumulierter Energieaufwand – Begriffe, Berechnungsmethoden (VDI guideline 4600: 2012-01: cumulative energy demand – terms, definitions, methods of calculation). Beuth Verlag, Berlin

Yoshida H, Christensen TH, Scheutz C (2013) Life cycle assessment of sewage sludge management: a review. Waste Manag Res 31(11):1083–1101. https://doi.org/10.1177/0734242X13504446

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Remy, C., Kraus, F. (2019). Life Cycle Assessment of Processes for P Recycling. In: Ohtake, H., Tsuneda, S. (eds) Phosphorus Recovery and Recycling . Springer, Singapore. https://doi.org/10.1007/978-981-10-8031-9_4

Download citation

DOI: https://doi.org/10.1007/978-981-10-8031-9_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-8030-2

Online ISBN: 978-981-10-8031-9

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)