Abstract

Recently, the regenerative medicine has been introduced to promote self-restoration, replacement and regeneration of impaired bodily function of tissues or organs by delivering viable cells which are genetically appropriate to patients. In this study, porous matrices of nano fibrous collagen-HA were produced, and their affinity to human bone marrow derived mesenchymal stem cells (hBM-MSCs), human embryonic stem cells (hESC) and human induced pluripotnent stem cells (hiPSC) were evaluated through observing expression of specific proteins, DNA or RNA, to investigate possibilities of using the matrix in regenerative medicine.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

1 Introduction

Recently, the regenerative medicine has been introduced to promote self-restoration, replacement and regeneration of impaired bodily function of tissues or organs by delivering viable cells which are genetically appropriate to patients [1].

As cells are living by being attached on extracellular matrix (ECM) which is released from the cells and contains variable biological molecules necessary to provide favorable environment for cellular metabolism and structurally support tissue, mimicking the natural mammalian tissue by artificially hybridizing viable cells with biocompatible structural scaffold materials has been introduced [2, 3].

For scaffold, various biocompatible materials have been studied, as synthesized polymers or natural ECM components, according to the specific target tissue structure. An ideal artificial scaffold shall contain porous network that permits cell proliferation and entrapment, and transportation of oxygen, carbon dioxide, and nutritional substances [4,5,6].

By applying the ECM substances such as proteins and polysaccharides as scaffold components, as these are naturally synthesized, secreted and decomposed by enzymes in the body, less immunological events are expected after implantation [6,7,8,9]. Utilization of the signal transduction system in ECM is also possible. Additional vascular endothelial growth factor (VEGF) combined scaffold promotes neovascularization and infiltration of blood vessels, which are essential to provide vitality to the transferred cells, throughout the porous scaffolds after implantation [6].

In the ECM substances, collagen and hyaluronic acid (HA) have taken attention from numerous researchers for the scaffold materials [10,11,12,13,14,15].

Collagen occupies about 25% of the total body proteins and plays decisive role as structural scaffold for every tissue and organ, and the peptide sequences of RGD(Arg-Gly-Asp) in their molecules conduct cell attachment. Atelocollagen is an immune-free collagen molecule produced by eliminating telopeptides which exist in the both extremities of type I atelocollagen molecule that induce immune reactions, and has been recommended as the firstly chosen ECM substances for scaffold fabrications [2, 5, 9, 16,17,18].

In nature, glycosaminoglycan (GAG) is a polysaccharide existing in connective tissues as hydrophilic viscoelastic gel. Researches on various GAGs, such as chondroitin sulfate, heparin or HA, have reported that stiffness, chemical composition, and reaction against the growth factors of GAGs are affecting cell differentiation and proliferation [19,20,21].

HA consists of alternatively repeating β-D-glucuronic acid and β-N-acetyl-d-glucosamine molecules as one of the GAG. On HA matrices, cell attachment, migration and proliferation are promoted by the CD44 in molecules, and hydrophilic property affects mechanical strength and shape or structure of the artificial matrices made of HA [10, 14, 22].

Scaffolds designed to apply biological advantages of the collagen and HA revealed conduction of less immune reactions and wound healing through recognizing their ingredients dissolved in serum [20, 21]. Electrospinning method has been introduced to produce ultra-micro scaled fibers, and suggested as an appropriate tool to model ECM fibers with ranges about 50–500 nm in diameter. Nano-fibers have less diameter in comparison with length, and be easily fabricated to porous structure by controlling concentration of solute, as the diameter of the fiber increases as the solute increases, therefore, electrospun fiber is recommendable to model structural ECM [23,24,25].

For collagen-HA composites, collagen used to be dissolved by 1,1,1,3,3,3,-hexafluoro-2-propanol (HFP) through hydrolysis by disintegrating hydrogen bonds [26, 27], while HA is dissolved by formic acid or NaOH and N,N-dimethylformamide (DMF), and each solution is adulterated to produce electrospun nano-fibrous scaffold. For these methods produced collagen-HA scaffold, the residual organic solvents such as HFP, formic acid and DMF remained in body may have possibility to occur cytotoxicity [14, 15], high concentration of phosphate buffered salt (PBS) and ethanol are recommended as solvents for collagen to avoid organic solvents [28].

Also, to produce scaffold made of atelocollagen and HA, cross-linking agents are necessary to control the biodegradable property which is induced by enzymes in body. In a previous study reported by Park and Suh [11], 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDC) demonstrates reasonable result as such a carbodiimide becomes a hydrolytic residuum and extracted from body without cytotoxicity [10,11,12].

In this study, porous matrices of nano fibrous collagen-HA were produced, and their affinity to human bone marrow derived mesenchymal stem cells (hBM-MSCs), human embryonic stem cells (hESC) and human induced pluripotnent stem cells (hiPSC) were evaluated through observing expression of specific proteins, DNA or RNA, to investigate possibility of using the matrix in regenerative medicine.

2 Materials and Methods

2.1 Materials

Type I atelocollagen (collagen) was extracted by pepsin treatment from porcine dermal skins and lyophilized under −40 °C [29]. Molecular weight of HA was from 120 to 150 k. Collagen and HA were stored under −20 °C before use.

2.2 Fabrication of Collagen-HA Nano-Fibrous Matrices

HA was dissolved in 20X PBS solution at pH 7.3, that contains NaCl 160.0 g/L, KCl 4.0 g/L, Na2HPO4 28.4 g/L, and KH2PO4 4.8 g/L in DW [28].

Collagen-HA solution with concentrations of 5, 10, and 15% (w/v) atelocollagen and 0, 0.25, 0.5, 0.75, and 1% (w/v) HA were prepared, and a self-designed electro spinner using 18 gauge nozzle was applied to produce the collagen-HA nano-fibers. Figure 1 shows procedures making collagen-HA solutions and a self-designed electro spinner, and Table 1 is the condition of electro spinning.

To crosslink the nano-fibrous matrices, 50 mM EDC was dissolved in 95% (v/v) ethanol. Each matrix was immersed in EDC solution for 6, 12, 18, and 24 h respectively at room temperature. To remove the residual EDC, matrices were washed by gradually diluted 20X, 10X, 5X PBS and DW in ultrasound chambers. Nano-fibrous matrices were collected on either cover glasses or aluminum foils.

2.3 Characterizations of Collagen-HA Nano-Fibrous Matrices

Morphological characterization of the fabricated matrices were observed by using a Field Emission Scanning Electron Microscope(FE-SEM) and diameter of nano-fibers was measured for more than 100 fibers randomly selected from each group, and the mean diameter was obtained depending on the conditions. Pore structure was defined as the space surrounded by more than 3 fibers, and diameter of pore was measured from more than 20 spots randomly selected in each group.

Alteration of chemical bonds in matrix by treatment of EDC was observed by a Fourier-transformed Infrared Spectroscope (FT-IR) at the wave length between 500 and 4000 cm−1.

2.4 Cell Cultures

2.4.1 hBM-MSCs

Human bone marrow was provided by the department of Orthopedics in Yonsei University Severance hospital and approved by the institutional review board of the Yonsei University Health System in Seoul, Korea. hBM-MSCs was isolated from bone marrow by conventional methods. hBM-MSCs was cultured using Dulbecco’s Modified Eagle’s Medium-low glucose (DMEM-lg) containing 1% penicillin/streptomycin/amphotericin B and 10% FBS. Cells were passaged when it reached confluence more than 90% by trypsin-EDTA treatment. Cell culture was conducted under an incubator under 37 °C, 5% CO2, 99% humidity conditions. Medium was changed every 3–4 days. Cells with passage number between 3 and 5 were seeded onto nano-fibrous matrices and checked the attachment, morphology and viability.

2.4.2 hiPSC, hESC

For feeder layer, STO cells were cultured in 10% FBS and 1% penicillin/streptomycin/amphotericin B added DMEM-high glucose (DMEM-hg) medium, and mitomycin C was treated to prevent STO cells proliferation.

Two types of cells were cultured on STO cell line. hiPSC and hESC were cultured using Dulbecco’s Modified Eagle Medium Nutrient Mixture F-2(Ham) (1:1) (DMEM/F12) medium. 20% Knockout Serum Replacement, 1% L-glutamine, 0.1% Non-essential amino acids, 1% β-mercaptoethanol 0.5% penicillin/streptomycin, and 4 ng/ml human recombinant basic fibroblast growth factor (bFGF) were supplemented in DMEM/F12 medium.

hiPSC and hESC were purchased from American Type Culture Collection (ATCC, University Boulevard, Manassas, VA, USA).

After dissociating the undifferentiated cells, cells were suspended in cryopreservation solvents and stored in LN2 tank before use.

2.5 Cell Seeding

Nano-fibrous matrices with dimensions of 2 cm × 2 cm collected on cover glasses were sterilized under 100, 70% ethanol for 30 min respectively. After sterilization, matrices were dried and washed with DW and 1X PBS and stored in medium before cell seeding. Matrices were placed upon a sterilized uncoated cover glasses.

2.5.1 hBM-MSCs

5 × 103 cells/cm2 were seeded on sterilized matrices. Firstly, small amount of cells suspension was seeded on the surface of matrices. After keeping matrices to be soaked in the cell suspension in incubator for 6 h, medium was added to fill the matrix for full immersion. Cell attachment efficiency was confirmed 24 h after seeding.

2.5.2 hiPSC and hESC

Matrices soaked in medium were washed with DMEM/F12 medium and hiPSC and hESC were seeded onto each matrix. Cells were seeded at the middle of the matrices which immersed in medium. 48 h after seeding, 4 ng/ml bFGF was added to the medium. Cell attachment was observed under light microscope on 4 days after seeding. Medium was changed every 5 days, and same volume of new medium was added to the previous one.

2.6 Evaluation of the Attached Stem Cells onto Collagen-HA Matrices

For morphological characterization, cells were fixed with 4% formaldehyde solution for 20 min at RT and observed by a light microscope.

CCK8 analysis was performed to investigate the viability of cells attached on each matrix. Optical density was measured by Enzyme-Linked Immunosorbent Assay (ELISA), and observed the effect of bFGF in culture media,

3 Results

3.1 Fabrication and Characterization of Collagen-HA Nano-Fibrous Matrices

To select the proper concentrations for fabrication of collagen-HA matrices, HA concentration was set 0, 0.25, 0.5, 0.75, and 1% (w/v). By increasing collagen concentrations, morphological and chemical characterizations were compared with.

In all collagen concentrations, nano-fibrous structure were observed by FE-SEM. In 5 and 10% (w/v) collagen specimens, nodes were randomly distributed, and diameters of fibers was measured including the nodes (Figs. 2, 3, 4 and 5; Tables 2, 3 and 4).

Diameter of porous structures was measured in 15% (w/v) collagen nano-fibrous matrices. Maximum pore size was 3.55038 μm in 0% (w/v) HA mixed group spun at 25 kV, and minimum was 1.9266 μm in 1% (w/v) HA mixed group spun at 20 kV (Fig. 6).

FT-IR analysis. (A) non-treated type I atelocollagen, (B) non-treated HA, (C) 15% (w/v) collagen-0% HA at 20 kV, (D) 15% (w/v) collagen-0.25% (w/v) HA at 20 kV, (E) 15% (w/v) collagen- 0.5% (w/v) HA at 20 kV, (F) 15% (w/v) collagen-0.75% (w/v) HA at 20 kV, (G) 15% (w/v) collagen-1% (w/v) HA at 20 kV

In FT-IR analysis, type I atalocollagen, HA dissolved in 20X PBS, Ethanol dissolved 15% (w/v) collagen containing 0, 0.25, 0.5, 0.75 and 1% (w/v) HA were surveyed. Amide peaks of collagen were appeared at 3300, 1600 and 600 cm−1, while HA were appeared at 3400 and 1600 cm−1. Peak of proteoglycan ring of HA was detectable from 1140 to 980 cm−1. Expressions of each collagen and HA peaks were revealed in entire concentrations [12, 28, 30] (Fig. 7).

15% (w/c) collagen-0% (w/v) HA at 20 kV nano-fibrous matrices after crosslinking by EDC. Upper: FT-IR analysis after (A) before crosslinking, (B) crosslinking for 6 h, (C) crosslinking for 12 h, (D) crosslinking for 18 h, (E) crosslinking for 24 h. Lower: FE-SEM view of nano-fibrous matrices after crosslinking by EDC. (×5000, scale bar: 1 μm)

Formation of amide bond by the EDC crosslinking was confirmed by appearance of the peaks near 1650–1400 cm−1. Also peak of ester bond was appeared at 1100 cm−1. At 1400 cm−1, peaks related to carboxylate salt were shown. Morphological characteristics were verified by the EDC crosslinking time through FE-SEM. Nanofibers were adhered each other after EDC crosslinking (Figs. 8, 9, 10, 11, 12, 13 and 14).

15% (w/c) collagen-0.25% (w/v) HA at 20 kV nano-fibrous matrices after crosslinking by EDC. Upper: FT-IR analysis after (A) before crosslinking, (B) crosslinking for 6 h, (C) crosslinking for 12 h, (D) crosslinking for 18 h, (E) crosslinking for 24 h. Lower: FE-SEM view of nano-fibrous matrices after crosslinking by EDC. (×5000, scale bar: 1 μm)

15% (w/c) collagen-0.5% (w/v) HA at 20 kV nano-fibrous matrices after crosslinking by EDC. Upper: FT-IR analysis after (A) before crosslinking, (B) crosslinking for 6 h, (C) crosslinking for 12 h, (D) crosslinking for 18 h, (E) crosslinking for 24 h. Lower: FE-SEM view of nano-fibrous matrices after crosslinking by EDC. (×5000, scale bar: 1 μm)

15% (w/c) collagen-0.75% (w/v) HA at 20 kV nano-fibrous matrices after crosslinking by EDC. Upper: FT-IR analysis after (A) before crosslinking, (B) crosslinking for 6 h, (C) crosslinking for 12 h, (D) crosslinking for 18 h, (E) crosslinking for 24 h. Lower: FE-SEM view of nano-fibrous matrices after crosslinking by EDC. (×5000, scale bar: 1 μm)

15% (w/c) collagen-1% (w/v) HA at 20 kV nano-fibrous matrices after crosslinking by EDC. Upper: FT-IR analysis after (A) before crosslinking, (B) crosslinking for 6 h, (C) crosslinking for 12 h, (D) crosslinking for 18 h, (E) crosslinking for 24 h. Lower: FE-SEM view of nano-fibrous matrices after crosslinking by EDC. (×5000, scale bar: 1 μm)

3.2 Characterization of Cells After Seeding on Matrix

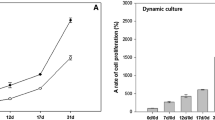

Analysis of cell viability was measured by CCK8 kit. hBM-MSC cells were seeded on 15% (w/v) collagen-0, 0.25, 0.5, 0.75 and 1% (w/v) HA matrices and compared with the control groups of culture flask. 4 days after cell seeding, 0.25% (w/v) HA containing 15% (w/v) collagen matrices demonstrated the highest value of cell viability, and cell viability decreased as the concentration of HA increased (Fig. 15).

Morphologies of hBM-MSC, hESC, and hiPSC seeded upon 15% (w/v) collagen-0, 0.25, 0.5, 0.75, 1% (w/v) HA matrices were observed 4, 10, 16, 22, 28 days after seeding (Figs. 16, 17, 18, 19, 20 and 21).

In control group of culture flask, hBM-MSCs reached 90% confluence after 4 days, and it reached 100% confluence after 10 days at the site of cell seeded. Control had larger growth area than matrices, and showed cells keep spreading across the surface of flasks.

hBM-MSCs flatly distributed throughout the surface, therefore, morphology of hBM-MSCs was hard to define by light microscope. On the other hand, colonies of hiPSC and hESC protruded from the surfaces of matrices. Spherically formed colony could be seen in both hiPSC and hESC on 10 days after seeding. But on the 4th day, hiPSC demonstrated flatly spreading differentiated cells. Particularly, 0.5% (w/v) HA contained matrices showed large sized colonies, and cells grew out of the colony and spread as time courses. This phenomenon was not seen in the other groups. Cell viability was confirmed by the CCK8 analysis. There were no evidences of proliferation of hiPSC but hESC showed signs of proliferation by increasing of optical density in comparison with the results at day 10 and 28. Morphological characteristic was not altered as time courses. And CCK8 results were not affected by the inclusion of growth factors (Figs. 19, 20 and 21).

4 Discussions

To produce optimal solvent condition for fabrication of collagen-HA nano-fibrous matrices, conditions suggested by Park and Suh were adopted [11]. This condition was used to solve the problem that HA has low solubility in organic solvents. Conventionally, binary solvents like NaOH/N,N-dimethylformamide(DMF) or HFP/formic acid were used to make collagen-HA nano- fibrous matrix. But, these works had some limitations because of the use of toxic solvents like formic acid, DMF, and HFP [8, 14, 27]. Therefore, benign solvents like PBS and ethanol were applied for this work to select the conditions to produce proper collagen-HA nano-fibrous matrix structures.

HA concentrations were set 0, 0.25, 0.05, 0.75, and 1% (w/v) in PBS and ethanol conditions. Gel was formed during solution making processes due to its hydrophilic property. And to solve the low solubility of HA in ethanol, HA was dissolved in PBS 24 h at room temperature before processing. Solutions were mixed by either vortex mixer or centrifuge to dissolve collagen and HA in solvents. After that, remained solutes were dissociated by ultrasonicator to remove the lump. When concentration of HA reached more than 1% (w/v), gel lumps could be remained in the solution even though sonication was applied, and 1% (w/v) was selected as the maximum concentration of HA. Collagen-HA solution was produced as the Fig. 1 and electro spun with the conditions of Table 1. In the pilot test to set the collagen concentrations, same collagen concentration of Dong et al. [28] was used by addition of HA. By comparing the structures of nano-fibers with each group, fixing HA concentrations were chosen, and collagen concentrations were set at 5, 10, 15% (w/v).

In 5% (w/v) collagen-HA matrices, there were fine nano-fibrous structures in all conditions, but it has some nodal structures. To figure out the effect of formation of nodal structures, distribution of diameter was observed. With including nodal structures, maximum value of diameter was 137.41 nm whereas minimum was 91.2794 nm. If nodal structures were excluded, every diameter was less than 100 nm. The standard deviations were also changed by addition of nodal structures in the distribution. Randomly generated nodal structures affected the diameter and standard deviation. But there was no significant relation of the effect of nodal structures to cells. Collagen concentration was increased to remove the nodal structures from the matrices.

In 10% (w/v) collagen-HA nano-fibrous matrices, occurrence of nodules decreased as collagen concentration increased. Also the surface of nano-fiber became smoothened. Maximum diameter was 302.575 nm (with nodes) and 293.625 nm (without nodes). And the minimum value was 172.049 nm (with nodes) and 143.682 nm (without nodes). Specifically, 0.75% (w/v) HA contained matrices showed decrease of diameters in every voltage, and it did not affected by the formation of the nodal structures.

There were no nodes in 15% (w/v) collagen-HA nano-fibrous matrices. Formation of nodal structures was affected by the concentrations of solutes. Since HA concentration was fixed, collagen played a more important part than HA in nodal formation. Maximum diameter was 768.537 nm and minimum was 490.152 nm. By increasing the collagen concentrations, diameter increased and that is referred to characteristics of electro spinning [31, 32]. And attachment of the dissolved salts on nano-fibers in PBS also increased. 15% (w/v) collagen was proper concentration to fabricate fine and stable nano-fibers. Porous structure was affected by the concentration of HA. 1% (w/v) HA contained matrices fabricated at 20 kV showed minimum sized pores.

FT-IR analysis was applied to characterize the deformation or degradation of collagenous structure by the variously applied voltage during electro spinning process. There were difference in intensity, but there was no shift of each collagen peaks. It showed that there was no structural difference by the voltage. 20 kV was ideal voltage to fabricate the matrix based on the results of FT-IR and FE-SEM. Because there was no difference in FT-IR peaks. At 20 kV, collected large amount of nano-fibers were observed by FE-SEM. According to the overall results, 15% (w/v) collagen and 20 kV was optimal to fabricate the collagen-HA nano-fibrous matrices.

In previous works, collagen-HA matrices were fabricated using 50 mM EDC solutions for 24 h [11, 12, 27]. But structural differences and concentration of collagen and HA could affect the EDC crosslinking time. Therefore, EDC crosslinking time was varied for 6, 12, 18, and 24 h without changing EDC concentration, and compared the FT-IR with FE-SEM results as time course. After EDC crosslinking, each matrix was washed by using ultrasonicator. Washing order was 20X PBS, 10X PBS, 5X PBS and DW to remove the salts derivate from the electro spinning solvents. Alteration of amide bond, ester bond, and carboxylate salt peak were investigated by FT-IR. Each peak appeared after crosslinking for 12 h. Particularly, these peaks’ intensity or appearance was diminished in 1% (w/v) HA added matrices. Therefore, 12 h was set as the proper time of EDC crosslinking. The morphological change was observed by FE-SEM, and nano-fibers were adhered each other. This was the same results of Dong et al. [28] in which 0.2 M EDC/N-hydroxysuccinimide(NHS) was used. Although EDC crosslinking was conducted for 24 h, there was no signs of adhesion of nano-fibers in 0.5% (w/v) HA contained matrices. These results could be interpreted as that crosslinking would be occurred by the adhesion between the adjacent nano-fibers. But it could reduce the pore sizes and also trigger a negative effect of the migration of materials through the pores.

Before seeding the cells on collagen-HA nanofibrous matrices, sterilization was done using 100 and 70% ethanol for 30 min respectively. After each step, ethanol was fully dried under clean bench, washed with 1X PBS and medium, and immersed in medium before use.

To find out the characteristics of cells after the short-term culture, hBM-MSCS were cultured for 4 days. Control was cultured on culture flasks to compare the cell attachment efficiency. Cell density was set as 5 × 103 cells/cm2. 6 h after cell seeding, hBM-MSCs were grown in the seeding spot with radially spreading by the permeation of medium in matrices in control groups. After observing the morphology, medium was added to the each matrix to fill it completely. Each matrix was transferred to new flask to calculate the efficiency of cell attachment 24 h after seeding. At the same time, cell seeded matrices were washed with 1X PBS to remove the dead or unattached cells. And the previous flasks were trypsinized to detach the cells from the surface of flasks, and the cells were calculated by hemocytometer. Cell attachment was highest at 0% (w/v) HA added matrices, and it decreased as increasing HA contents but increased again in 1% (w/v) HA contained matrix. Cellular distribution and morphological images were observed by a light microscope. And CCK8 analysis was also performed to verify the cell viability as time courses. After removing medium, matrices were washed with PBS and added new medium. CCK8 solution was added into each matrix, incubated for 2 h in CO2 incubator, and measured the optical density at 450 nm.

The cell viability of 0.75% (w/v) HA containing matrices demonstrated lower than the control, and that is assumed to be affected by the initial cell attachment efficacy. Meanwhile, cell viability of 1% (w/v) HA containing matrices revealed relatively low value whereas cell attachment was maintained. It would be the results of the higher HA content in the matrices, which could negatively affect cell proliferation at early stage that requires adaptation period to the high HA content. But in the short- term experiments, cell passage was 5 and cultured for only 4 days, and it would be difficult to define the influence of matrices on cells. Therefore, to assure the effect of matrices, experiments were conducted in long-term period, and behaviors of hBM-MSC, hESC and hiPSC on matrices were observed.

Long-term culture of hBM-MSCs was conducted same as short-term culture. In case of hESC and hiPSC, colonies are easily destroyed and damaged by ethanol or PBS. To completely remove ethanol, matrices were immersed in DMEM-hg medium for overnight. After washing with DMEM/F12, cells were seeded at the middle of the matrices which have been fully immersed in DMEM/F12. Since colony formation of hiPSC and hESC took more than 4 days on STO feeder layer, cells were checked under microscope 4 days after seeding. And to improve the colony formation, 4 ng/ml bFGF was added 48 h after seeding the cells on matrices. Culture media of hiPSC and hESC were changed every 5 days. Suspended cells were centrifuged and reseeded on each matrix during changing medium. To reduce the adaptation time, same volume of new and used medium was mixed. In the pilot study, hiPSC and hESC easily escaped from the matrices because the size of these cells was smaller than hBM-MSCs. To solve this problem, matrices were covered with sterilized cover glasses. Matrices were flipped every 6 days to find out the migration between cover glasses and matrices. Characteristics of every cell types were verified in period of 4, 10, 16, 22, and 28 days. bFGF was added into the hESC and hiPSC medium in contrary to the hBM-MSCs medium. In case of these cells, cell viability was measured whether the growth factor was added or not. Cells were seeded directly after thawing the cells from LN2. This method was used to maintain the cell condition without adapting the cells on flasks for further in vivo tests. The control group of hBM-MSCs were cultured on culture flask. Since hiPSC and hESC needed the feeder layer, feeder cells could affect the results of cell viability.

Colonies of hiPSC and hESC were grown under space between the matrix and glass cover by penetrating matrix, and over grown or differentiated cells were loosened and detached from the colony. Differentiated cells were flatly covered the surface and grew. Meanwhile, hBM-MSCs were grown within the matrices, and the over grown cells spread out from the matrix as increase in population as time courses.

In CCK8 analysis, cell viability of hBM-MSCs within 0.75% (w/v) HA containing matrices showed lowest values, likewise the short-term results. But values were increased as time courses. Therefore 0.75% (w/v) HA including matrices were proper for long-term culture, while the results of 1% (w/v) HA included matrix had the average values in comparison with the other matrices. This would be resulted from the difference of passage. FE-SEM results revealed there was no nano-structural deformation as time courses. But the 3D structures constructed by the concentration of matrices could affect the proliferation, and cell viability were different according to the matrices.

Microscopic images of hiPSC demonstrated maintenance of colony morphology in 0, 1% (w/v) HA containing matrices, while differentiation and spreading over the matrix was observed in 0.25, 0.75% (w/v) HA specimens. Particularly, large sized colony could found 10 days after seeding in 0.5% (w/v) HA contained matrices. And cells were grown coming out from the colony and spread as time courses. But these aspects did not appeared in the other matrices. Further confirmation is necessary to define whether it was affected by the initial size of colony, cell number or concentration of HA, and ihPSC viability in collagen matrix was not affected by additional growth factor

According to the CCK8 results, 0.25 and 0.5% (w/v) HA containing matrices were proper for long- term culture, as they revealed the highest value at 28 day. Whereas other types of matrix could be proper for short-term culture since the maximum value appeared at early and middle stage of culture. In case of hESC, colony spreads and differentiates in 0, 0.25, 0.5, and 0.75% (w/v) HA containing matrices, since oval shaped colonies were observed 4 days after seeding. In most matrices, spreading and differentiating oval shaped colony appeared earlier than hiPSC. CCK8 values on 10th day and 28th day increased as time courses disregarding additional growth factor was or not. In comparison of the results of day 10 with day 28, cells attached on the surface of cover glasses without directly attaching on matrices. This assumed to be resulted from the pressure of matrices weight. A loose or pressured biomechanical environment provided by matrix fibers assumed to influence cell viability. In consideration of 1.6 times larger amount of hiPSCs and hESCs than the general cell numbers are necessary to produce colony for STO cell line feeder layers, respectively, the CCK8 analysis resulted no significant cell proliferation in relation with viability. And the sizes of colonies and the numbers of hiPSC and hESC were difficult to quantify, and it was necessary to increase the initial cell numbers on matrix to subdue the effect of collagen-HA matrices which govern cell adaptable attachment. It is recommended to use cells dissociated from the cells cultured in matrix. Therefore, methods to uniformly distribute cells in matrix should be established.

However, electro spun 15% (w/v) collagen containing 0.5% (w/v) HA porous nano-fibrous matrices provided favorable environment for cell hBM-MSC, hiPSC and hESC attachment and proliferation with maintaining cell viability. But proper cell amount, proliferation rate, differentiation and viability shall be established for each stem cell type.

References

Suh, H., Chung, E., & Jae Hyung, K. (2013). Global safety guidance for the cell-based implants. Tissue Science & Engineering, 4.

Suh, H. (1998). Fundamental concepts for the tissue engineering. Biomaterials Research, 2, 1–7.

Langer, R., & Vacanti, J. P. (1993). Tissue engineering. Science, 260, 920–926.

Langer, R., & Tirrell, D. A. (2004). Designing materials for biology and medicine. Nature, 428, 487–492.

Murphy, S. V., & Atala, A. (2013). Organ engineering—combining stem cells, biomaterials, and bioreactors to produce bioengineered organs for transplantation. BioEssays, 35, 163–172.

Naderi, H., Matin, M. M., Bahrami, A. R. (2011). Review article: Critical issues in tissue engineering: Biomaterials, cell sources, angiogenesis, and drug delivery systems. Journal of Biomaterials Applications. https://doi.org/10.1177/0885328211408946.

Matthews, J. A., Wnek, G. E., Simpson, D. G., & Bowlin, G. L. (2002). Electrospinning of collagen nanofibers. Biomacromolecules, 3, 232–238.

Hsu, F. Y., Hung, Y. S., Liou, H. M., & Shen, C. H. (2010). Electrospun hyaluronate-collagen nanofibrous matrix and the effects of varying the concentration of hyaluronate on the characteristics of foreskin fibroblast cells. Acta Biomaterialia, 6, 2140–2147.

Sell, S. A., Wolfe, P. S., Garg, K., McCool, J. M., Rodriguez, I. A., & Bowlin, G. L. (2010). The use of natural polymers in tissue engineering: A focus on electrospun extracellular matrix analogues. Polymers, 2, 522.

Suh, H., & Lee, J. E. (2002). Behavior of fibroblasts on a porous hyaluronic acid incorporated collagen matrix. Yonsei Medical Journal, 43, 193–202.

Park, S. N., Lee, H. J., Lee, K. H., & Suh, H. (2003). Biological characterization of EDC-crosslinked collagen- hyaluronic acid matrix in dermal tissue restoration. Biomaterials, 24, 1631–1641.

Park, S. N., Park, J. C., Kim, H. O., Song, M. J., & Suh, H. (2002). Characterization of porous collagen/hyaluronic acid scaffold modified by 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide cross-linking. Biomaterials, 23, 1205–1212.

Lee, J. M., Edwards, H. H. L., Pereira, C. A., Samii, S. I. Crosslinking of tissue-derived biomaterials in 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide (EDC). Journal of Materials Science: Materials in Medicine, 7, 531–541.

Fischer, R. L., McCoy, M. G., & Grant, S. A. (2012). Electrospinning collagen and hyaluronic acid nanofiber meshes. Journal of Materials Science Materials in Medicine, 23, 1645–1654.

Kim, T. G., Chung, H. J., & Park, T. G. (2008). Macroporous and nanofibrous hyaluronic acid/collagen hybrid scaffold fabricated by concurrent electrospinning and deposition/leaching of salt particles. Acta Biomaterialia, 4, 1611–1619.

Glowacki, J., & Mizuno, S. (2008). Collagen scaffolds for tissue engineering. Biopolymers, 89, 338–344.

Parenteau-Bareil, R., Gauvin, R., & Berthod, F. (2010). Collagen-based biomaterials for tissue engineering applications. Materials, 3, 1863.

Furthmayr, H., & Timpl, R. (1976). Immunochemistry of collagens and procollagens. International Review Connective Tissue Research, 7, 61–99.

Her, G. J., Wu, H. C., Chen, M. H., Chen, M. Y., Chang, S. C., & Wang, T. W. (2013). Control of three-dimensional substrate stiffness to manipulate mesenchymal stem cell fate toward neuronal or glial lineages. Acta Biomaterialia, 9, 5170–5180.

Murphy, C. M., Matsiko, A., Haugh, M. G., Gleeson, J. P., & O’Brien, F. J. (2012). Mesenchymal stem cell fate is regulated by the composition and mechanical properties of collagen-glycosaminoglycan scaffolds. Journal of the Mechanical Behavior of Biomedical Materials, 11, 53–62.

Hortensius, R. A., & Harley, B. A. (2013). The use of bioinspired alterations in the glycosaminoglycan content of collagen-GAG scaffolds to regulate cell activity. Biomaterials, 34, 7645–7652.

Knudson, C. B. (2003). Hyaluronan and CD44: Strategic players for cell-matrix interactions during chondrogenesis and matrix assembly. Birth Defects Res C Embryo Today, 69, 174–196.

Wang, X., Ding, B., & Li, B. (2013). Biomimetic electrospun nanofibrous structures for tissue engineering. Materials Today, 16, 229–241.

Gupta, K. C., Haider, A., Y, Choi, & I, Kang. (2014). Nanofibrous scaffolds in biomedical applications. Biomaterials Research, 18, 1–11.

Lu, T., Li, Y., & Chen, T. (2013). Techniques for fabrication and construction of three-dimensional scaffolds for tissue engineering. International Journal of Nanomedicine, 8, 337–350.

Shih, Y. R. V., Chen, C. N., Tsai, S. W., Wang, Y. J., & Lee, O. K. (2006). Growth of mesenchymal stem cells on electrospun type I collagen nanofibers. Stem Cells, 24, 2391–2397.

Park, S. N., Kim, J. H., Kim, I., Seol, A., & Suh, H. (2006). Electrospun nanofibrous matrices for the engineering of cultured skin substitute. Biomaterials Research, 10, 7.

Dong, B., Arnoult, O., Smith, M. E., & Wnek, G. E. (2009). Electrospinning of collagen nanofiber scaffolds from benign solvents. Macromolecular Rapid Communications, 30, 539–542.

Suh, H., Suh, S., & Min, B. (1994). Anti-infection treatment of a transcutaneous device by a collagen- rifampicine composite. ASAIO Journal, 40, M406–M411.

Wang, X., Um, I. C., Fang, D., Okamoto, A., Hsiao, B. S., & Chu, B. (2005). Formation of water-resistant hyaluronic acid nanofibers by blowing-assisted electro-spinning and non-toxic post treatments. Polymer, 46, 4853–4867.

Bhardwaj, N., & Kundu, S. C. (2010). Electrospinning: A fascinating fiber fabrication technique. Biotechnology Advances, 28, 325–347.

Barnes, C. P., Sell, S. A., Boland, E. D., Simpson, D. G., & Bowlin, G. L. (2007). Nanofiber technology: Designing the next generation of tissue engineering scaffolds. Advanced Drug Delivery Reviews, 59, 1413–1433.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Chung, E., Yoon, G., (Matthew) Suh, H. (2018). A Collagen-Hyaluronic Acid Matrix for Stem Cell Culture. In: Artmann, G., Artmann, A., Zhubanova, A., Digel, I. (eds) Biological, Physical and Technical Basics of Cell Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-10-7904-7_4

Download citation

DOI: https://doi.org/10.1007/978-981-10-7904-7_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-7903-0

Online ISBN: 978-981-10-7904-7

eBook Packages: EngineeringEngineering (R0)