Abstract

Recently, development of organic coagulants derived from microorganisms, animal, and plant tissues has been an area of interest of researchers. The present study conducts the performance of natural (M. oleifera seeds) coagulant for turbidity and organic constituent removal from textile wastewater. Impact of dose and pH on efficiency of M. oleifera in textile wastewater was also studied. M. oleifera seeds were extracted and used in powdered form, 2 g of M. oleifera powder mixed with 100 mL water. 95% degradation of textile wastewater sample was achieved when M. oleifera seeds (dose=16 mg/L, pH = 8) were used. Mechanism of M. oleifera coagulation consists of neutralization and adsorption of colloidal positive charge that attract negative charge impurities. Moringa seeds consist of proteins (cationic and dimeric) which help in neutralizing and absorbing colloidal charges in water containing suspended solids. These suspended impurities combine and form heavy clumps which results in easy settling of suspended particles. Natural coagulant produced less voluminous sludge and readily biodegradable that accounts for only 21–31% that of alum-treated counterpart. Seeds of M. oleifera (M. oleifera) yielded proteins which can act as effective coagulants in water and wastewater treatment. M. oleifera seeds have great turbidity and color removal potential. Use of M. oleifera seeds as a primary coagulant would decrease the cost of existing water treatment plants. It is eco-friendly method of purification of water, and consequently, it can be recommended for large-scale water treatment.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Treatment of textile industry effluent has been a major challenge for environmental engineers. Conventional treatment technologies include a combination of chemical, physical, and biological methods and operations to remove organic matter, solids, and nutrients from wastewater. Coagulation–flocculation has been a promising chemical treatment method to treat highly polluted wastewater [1]. However, use of chemicals as coagulants has been a point of concern for environmentalists. Recently, development of organic coagulants derived from microorganisms, animal, and plant tissues has been an area of interest of researchers. A multipurpose tree called as Moringa oleifera Lam (M. Oleifera) whose seed contains edible oil (40% weight). Seeds have proteins which act as primary coagulants in wastewater treatment [2]. The effective constituents of seeds of M. oleifera are cationic having pH 10 and molecular weight of 6–16 kDa. The by-product of seed pressing to extract oil from Moringa is a seed cake which can be utilized as a filter to obtain drinking water for living beings. Moringa seeds consist of proteins (cationic and dimeric) which help in neutralizing and absorbing colloidal charges in water containing suspended solids. These suspended impurities combine and form heavy clumps which results in easy settling of suspended particles.

Moringa seed cake eradicates the suspended solids from wastewater. Being nontoxic and sustainable as compared to other synthetic materials, it is one of the promising techniques to remove the pollutants from wastewater, particularly in Moringa-growing regions [3, 4]. Use of natural coagulant like

Arachis hypogaea (peanuts), M. oleifera, Vigna mungo (urad), Zea mays (corn), and Vigna unguiculata (cowpeas) is now being used for removal of heavy metal. The literature suggests that M. oleifera has high absorption capacity compared with other coagulant used. Moringa seeds give high removal efficiency [5, 6]. Copper (90%), cadmium (60%), lead (80%), and chrome and zinc (50%) were removed by the treatment of Moringa seeds. Moringa seeds can be used as coagulants primarily in a clarifier for the wastewater treatment especially in underdeveloped and developing countries as other coagulants have high operating costs for metal removal and are expensive.

It is observed that 64% COD removal from the effluent took place by using combination of M. oleifera with alum. This shows that M. oleifera can be replaced to commercial coagulant and reduce the use of commercial coagulant [7, 8]

The produced M. oleifera extracted by separation of various components from the seed as coagulant gave suspended solids removal of around 97% for the treatment of turbid water. M. oleifera used as coagulant alternative to alum which producing very high sludge compared to M. oleifera [9]. Jar test is generally used for defining optimum pH, optimum dose of M. oleifera and optimum temperature and optimum dose of alum. It has the capability to remove 40% organic constituents [10].

Various studies show that seeds are effective for removal of suspended particles. Moringa seed is not giving any toxic effect. It is eco-friendly.

In this study, the objective of treatment is the performance comparison on natural and commercial coagulant of turbidity and organic constituent removal from textile wastewater.

2 Materials and Methods

Standard methods for pH measurement and COD analysis were followed. The raw effluent was collected from textile industry located near Rajkot. An initial experiment carried out to determine characteristics of textile effluent for further examination. 100 ppm stock solution was prepared for the same standard curve was prepared for the same. 2% solution of alum was used as commercial coagulant, whereas M. oleifera seed solution was used as natural coagulant in jar test. Initial COD, pH, and turbidity of the effluent were found out to be 800,6.5, and 265 NTU, respectively, before treatment.

3 Result and Discussion

3.1 Treatment with Alum

-

(a)

Effect of alum dose:

Alum is used as commercial coagulant. 100 mL concentrated solution is mixed with 100 ml of water. Different alum doses like 0.10, 0.20, 0.30 mL are mixed to define optimum dose of alum. These coagulants are stirrer for 2 min at rapid speed and 30 min for slow speed. For floc settlement 30 min is providing. After that, absorption is measured by using spectrophotometer. 60% degradation found at 30 mg/L alum dose as shown in Fig. 1. Alum gets hydrolyzed to provide a number of products and cationic species that are neutralized by getting absorbed by negatively charged particles. This helps in destabilization of particles which results in flocculation. Result also indicates that if dosing is increased at some point decreasing occurs in removing capacity [10].

-

(b)

Effect of pH:

After optimizing of alum dose, this dose is used to define optimum pH of textile effluent. This fixed dose is mixed with 50:50 solution of textile effluent and water at different pH. At 8 pH, 65% maximum degradation found as shown in Fig. 2. 25% COD can be removed with the help of alum. Maximum degradation can be achieved at natural pH, and pH 8 is nearer to natural pH. At natural pH, degradation found maximum. Result also shows that degradation slightly decreases when increasing pH above 9. At 6–7 pH, result is quite similar [11].

4 Treatment with M. oleifera

4.1 Effect of Moringa oleifera Seed

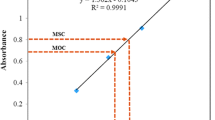

M. oleifera is used as natural coagulant. A 2% M. oleifera dosage is used to perform in jar test apparatus. In jar test, four beakers are used. 100 mL concentrated solution is mixed with 100 ml of water. Different M. oleifera doses like 0.10, 0.20, 0.30 mL are mixed to define optimum dose of M. oleifera. These coagulants are stirrer for 2 min at rapid speed and 30 min for slow speed. For floc settlement 30 min is providing. After that, absorption is measured by using spectrophotometer [2]. 95% degradation found at 16 mg/L dose of M. oleifera as shown in Fig. 3.

4.2 Effect of pH

After optimizing of M. oleifera, this dose is used to define optimum pH of textile effluent. This fixed dose is mixed with 50:50 solution of textile effluent and water at different pH. At 10 pH, 97% maximum degradation found as shown in Fig. 4. 75% COD can be removed with the help of M. oleifera. Optimum pH lies between 7 and 10, but at 10 pH, floc formation is high compared to other pH. At 10 pH, highest removal efficiency can be achieved [12].

5 Conclusion

The present study shows that alum is used as commercial coagulant and M. oleifera is used as natural coagulant to treat the textile wastewater. Result shows that at 10 pH, 16 mg/L optimization dose of M. oleifera is used to achieve 95% degradation. Use of M. oleifera would decrease the cost of treatment of wastewater. The M. oleifera seeds have immense suspended solids and color removal capacity. They reduce COD of textile wastewaters to a great extent. It is a nontoxic and eco-friendly way of treatment of wastewater, and consequently, it is being recommended for large-scale water treatment. So that M. oleifera is an alternative coagulant of water treatment plant.

References

Muyibi, S. A., & Evison, L. M. (1995). Optimizing physical parameters affecting coagulation of turbid water with Moringa oleifera seeds. Water Research, 29, 2689–2695.

Edzwald, J., James, K., & Dempsey, B. (1989). Coagulation as an integrated water treatment processes. Water Works Association, 81, 72–78.

Okuda, T., Naes, A. U., Nishijima, W., & Okada, M. (2001). Coagulation mechanism of salt solution extracted active component in Moringa oleifera seeds. Water Research, 35, 830–834.

Gottsch, E. (1992). Purification of turbid surface water by plants in Ethiopia. Moringa stenopetala, Walia, 14, 23–28.

Jahn, S. A. A. (1988). Using Moringa seeds as coagulants in developing countries. American Water Works Association.

APHA. (1995). Standards methods for the examination of water and waste water. American public Health Association, American water works Association and water pollution control Federation, 19th end, Washington, D.C.

Kawamura, S. (1991). Effectiveness of natural poly electrolytes in water treatment. Journal of the American Water Works Association, 83(10), 88–91.

Santos, A. F. S., Argolo, A. C. C., Coelho, L. C. B. B., & Paiva, P. M. G. (2005). Detection of water soluble lectin and antioxidant component from moringa oleifera seeds. Water Research, 39(6), 975–980.

Muyibi, S. A., & Alfugara, A. M. S. (2003). Treatment of surface water with Moringa oleifera seed extract and alum—a comparative study using pilot scale water treatment plant. International Journal of Environmental Studies, 60, 617–626.

Ndabigengesere, A., & Narasiah, K. S. (1998). Use of Moringa oleifera seed as a primary coagulant in wastewater treatment. Environmental Technology, 19, 789.

Folkard, G. K., & Sutherland, J. P. (2002). Development of a naturally derived coagulant for water and wastewater treatment. Water Science and Technology Water Supply.

Ghebremichael, K. A., Gunaratna, K. R., Henriksson, H., Brumer, H., & Dalhammar, G. (2005). A simple purification and activity assay of the coagulant protein from Moringa oleifera seed. Water Research, 39, 2338–2344.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Agarwal, V., Dixit, D., Bhatt, M.J. (2019). Use of Moringa oleifera Seeds as a Primary Coagulant in Textile Wastewater Treatment. In: Ghosh, S. (eds) Waste Management and Resource Efficiency. Springer, Singapore. https://doi.org/10.1007/978-981-10-7290-1_102

Download citation

DOI: https://doi.org/10.1007/978-981-10-7290-1_102

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-7289-5

Online ISBN: 978-981-10-7290-1

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)