Abstract

Co-simulation using ADAMS and MATLAB is implemented for active vibration control of flexible beam with piezoelectric stack actuator. The virtual prototype of flexible beam with piezoelectric actuator is created in ADAMS, and the implement of prototype provides an approach for acquiring the information of dynamic and kinematic properties. When the properties analysis is finished, the controller based on FXLMS algorithm is established in MATLAB. The controller calculates the signals of acceleration which are measured from virtual prototype, then the force is generated to suppress the vibration of flexible beam. The results and analysis prove that active vibration control for flexible beam has a great suppression performance.

This work is supported by National Natural Science Foundation (NNSF) of China under Grant 51575328. Mechatronics Engineering Innovation Group project from Shanghai Education Commission and Shanghai Key Laboratory of Power Station Automation Technology.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Flexible body is widely used because of its flexibility. Especially in aerospace field, flexible structure is also essential, such as solar panels, satellite antenna, and the space manipulator, all of them tend to be flexible [1]. However, flexible structure also has shortcomings, there will be elastic vibration caused by external disturbance. The vibration affects the accuracy and stability of space instrument seriously, so it is important to suppress the vibration of flexible structure. In general, many flexible structures as research objects can be replaced by flexible beams [1]. In theory, the analysis process of flexible structure is complex because of its infinite dimension, so the flexible structure is usually modeled and analysis with the discretization [2]. ADAMS is implemented for kinematics and dynamics analysis of mechanical system. The virtual prototype created by ADAMS is significant in engineering. And co-simulation using ADAMS and MATLAB provides the theoretical basis for practical system. In these years there are some researches on co-simulation using ADAMS and MATLAB for flexible structure. Malcolm D.J. did research on modeling of blades as equivalent beams for aeroelastic analysis [3]. Boscariol P. did the research on design and implementation of a simulator for 3D flexible-link serial robots [4]. Brannan J.C. did research on modeling flexible-body Dynamics in Real-Time Robotic Systems used in Satellite Servicing Simulations [5]. On one hand, the virtual prototype breaks through the limitations of the use of the test equipment and avoids the possibility that the experimental method may cause damage to the equipment, on the other hand, it avoids the complex mechanical derivation process, the object parameters are only needed to consider. In this paper, the model of flexible beam with piezoelectric stack is created in ADAMS, the vibration controller based on FXLMS algorithm is established in MATLAB. The result of co-simulation shows that the vibration of flexible can be suppressed by active vibration control system, which consists of piezoelectric and controller based on FXLMS algorithm.

2 Design for Flexible Beam with Piezoelectric Stack Actuator

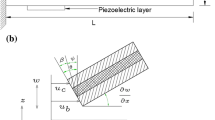

The structure model of flexible beam with system is shown in Fig. 1, including the ground base, one beam, and one piezoelectric stack actuator. The beam is fixed on base station. The piezoelectric stack actuator exerts force to control the vibration of beam, and the piezoelectric stack actuator is regarded as stiffness-damper for mechanical analysis. The piezoelectric stack actuator consists of a piezoelectric stack and a rubber block. And the piezoelectric stack is fixed above the rubber block. In this model, the vibration of Y direction will only be studied [6, 7].

The force and motion equation of piezoelectric actuator is expressed:

In these equation, \( F \) is control force, \( M \) is the mass which the force affect, \( m \) is the middle mass which connects the piezoelectric stack with rubber block, \( k_{c} \) is the piezoelectric stack stiffness coefficient, \( k_{r} \) is the rubber block stiffness coefficient, \( c_{c} \) is the active isolation’s damping coefficient, \( c_{r} \) is the rubber block damping coefficient, \( x_{m} \) is the displacement of the middle mass, \( x_{M} \) is the displacement of the object.

In generalized coordinate system, the motion equation of the flexible beam which is based on the analytical mechanics theory is expressed as:

\( L \) is Lagrange variable, \( B \) is energy loss function, \( \psi \) is constraint function, \( \lambda \) is Lagrange coefficient, \( Q \) is generalized coordinate is generalized force, \( T \) is kinetic energy, \( V \) is potential energy. According to the analysis of the system, there are some parameters should be designed:

- \( X { :} \) :

-

The length of the beam

- \( H { :} \) :

-

The width of the beam

- \( H { :} \) :

-

The thickness of the beam

- \( K_{\text{r}} { :} \) :

-

The stiffness coefficient of the rubber block

- \( C_{\text{r}} { :} \) :

-

The damping coefficient of the rubber block

- \( K_{a} { :} \) :

-

The stiffness coefficient of the piezoelectric stack

- \( C_{a} { :} \) :

-

The damping coefficient of the piezoelectric stack

- \( x_{1} { :} \) :

-

The location where the piezoelectric stack used to suppress vibration fixed on the beam

- \( x_{2} { :} \) :

-

The location where the piezoelectric stack used to produce vibration fixed on the beam.

3 Build the Model of Flexible Model with Piezoelectric Stack Actuator

ADAMS provides a module for flexible body creation. There are two kinds of approach for modeling flexible body in ADAMS. One is discretization, and the other is extension. The geometry model is divided into multiple rigid elements, and the mechanical properties of each element will be defined. Both of them create the modal neutral file. Extension method is implemented to create the flexible beam in this model.

According to the analysis above, the geometry model consists of three parts is built. In this step, the flexible beam is created with extension method. At first, flexible beam endpoints and attachments are defined. The endpoint determines the stretch path for flexible beam. Then Cross section is drawn based on the center line. At this point, the geometry shape of the flexible beam is determined. Next, the properties of the element units can be setup. In this way, the element shape is hexahedra. This method can better represents the elasticity of the beam. Then the attachments are chosen to establish the constraints between beam and other parts. After that, the properties of these attachments should be determined. At last, aluminum is chosen as the material of beam. Meanwhile, the number of modes used to calculate should be determined [10].

When the modeling of flexible beam is finished, the other parts are created, and the connection between the flexible beam and other parts is established with attachments. The holder is fixed on ground with fixed joint, then the beam is fixed on holder, and the piezoelectric stack actuator is fixed on beam. Then attachments exist between beam and holder, and they also exist between beam and piezoelectric stack actuator. The piezoelectric is modeling as a translational spring-damper [8, 9] (Table 1).

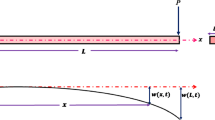

After all of operations have been finished, the computer started the calculation process of a flexible beam. It shows that the flexible beam with meshes in Fig. 2.

Explanation of annotations:

-

1:

The flexible beam

-

2:

The piezoelectric stack actuator

-

3:

The holder.

4 Establish the Co-simulation Module

In mechanical system dynamics and kinematics analysis, ADAMS possesses powerful functions, but it is not good at control system design. Simulink possesses powerful function of control simulation, although mechanics module in MATLAB is able to establish mechanical systems, in terms of programming for dynamics and kinematics analysis, the work is complex. Co-simulation combines their advantages effectively, and it establishes a connection between ADAMS and MATLAB. The coupled data relation is defined as state variable before the softwares begin to work. ADAMS/Controls provides the interface for data interaction. State variables are divided into two categories: input signal and output signal. Input signals presents the state variables which come from MATLAB controller, they will affect the system in ADAMS, and output signals presents the state variables which calculated by ADAMS, they will work as the input of controller. In Table 2, four variables from system in ADAMS are designed for the controller. Source force is used to produce the vibration, and control force is used to suppress the vibration. The accelerations work as reference signal and error signal for controller. The reference signal is measured near the disturbance signal, and the error signal is measured near the end of flexible beam.

At last, run interaction file produced by ADAMS/controls, and use the command to open the interaction module in Simulink. In this way, the variables in ADAMS are verified same as the variables in MATLAB.

5 Controller Based on FXLMS Algorithm

The principle of active vibration control is following the original signal to generate the action signal for vibration suppression. FXLMS algorithm is shown in Fig. 3.

FXLMS algorithm relies on the reference signal to produce the desired signal which is used to control vibration [11]. FXLMS algorithm constantly adjusts the weight of filter until the error is eliminated to convergence. LMS algorithm is usually used as an update algorithm of weight, its objective function is the square of instantaneous error:

In this equation, \( y(n) \) is the vibration of object, \( d(n) \) is the desirable signal.

The gradient descent method is proposed to minimize the objective, the update function of weight is that:

In this equation, \( \mu \) is the step size, \( x(n) \) is the reference signal. \( W(n) \) is the weight of filter.

In order that the convergence of the algorithm is not destroyed, it is usually necessary to estimate the secondary path of the system. \( S(z) \) is estimation of secondary path.

6 Results and Analysis of Co-simulation

The connection module of co-simulation is imported into SIMULINK to establish the controller. In Fig. 4, the acceleration, which is error signal, is input to the controller. After the controller has processed date, the force signal is output from interface y. The voltage signal drives the piezoelectric stack to suppress vibration of flexible beam until the error signal tend to converge.

In order to make the experimental results more intuitive, the error signal without control force will be compared with the error signal which is suppressed by FXLMS controller. At first, the signal which only contains the disturbance signal is input to make vibration on the flexible beam in this simulation. The frequency of the disturbance signal is 99 Hz, and the amplitude of the signal is 0.1 N. The amplitude of acceleration error signal produce by disturbance force is approximately 15 mm/s2. In Fig. 5, the controller is set to start working after 1 s, and it tends to outputs a stable signal to drive the piezoelectric stack. The result of co-simulation is shown in Fig. 6, the error signal with FXLMS algorithm is compared with error signal without FXLMS algorithm. Obviously, when the controller starts working, the error signal converges quickly, and it attenuates to zero in 0.15 s.

Figure 6 is related to Fig. 5. In Fig. 6 it shows the variation of the control force. In practice, the force is produced by stack actuator, and the force is changed by FXLMS controller. The control force changes according to the error signal, and it tends to stabilization when the error signal convergence.

In this paper, active vibration control of flexible beam with piezoelectric stack actuator is investigated. The virtual prototype is the method which is useful in engineer analysis. In this way, the virtual prototype of flexible beam vibration system with piezoelectric stack actuator is designed in ADAMS, and the stack actuator can be analyzed as the stiffness-damping system which outputs the driving force, meanwhile, the vibration is suppressed by piezoelectric stack actuator effectively. It illustrates that co-simulation using ADAMS and MATLAB for active vibration control of flexible beam is feasible. In the other word, the virtual prototype of flexible beam system can be implemented in active vibration control. In addition, the parameter of prototype can be modified for different experiment.

7 Conclusion

Co-simulation using ADAMS and MATLAB is implemented for active vibration control of flexible beam with piezoelectric stack actuator. The simulation result shows that the active vibration algorithm has a good effect on the vibration of the flexible beam. The technology of virtual prototype provides an effective mean for the verification of different experimental methods, at the same time, it provides the theoretical basis for verification of engineering applications. Of course, the optimization design of virtual prototype is also a meaningful research content. In the future, the vibration control of flexible structure and mechanical multi-rigid body structure will be further studied.

References

Li, L.: Study on active vibration control of flexible beam using piezoelectric actuators. Zhejiang University (2008)

Chen, R.J.: A dynamic model of large flexible multi-body spacecraft structure and simulation platform for control. National University of Defense Technology (2002)

Malcolm, D., Laird, D.: Modeling of blades as equivalent beams for aeroelastic analysis. In: ASME Wind Energy Symposium, pp. 293–303 (2011)

Boscariol, P., Gasparetto, A., Giovagnoni, M., Moosavi, A.K., Vidoni, R.: Design and implementation of a simulator for 3D flexible-link serial robots. In: Biennial Conference on Engineering Systems Design and Analysis, ASME 2012, vol. 3, pp. 155–164 (2012)

Brannan, J.C., Carignan, C.: Modeling flexible-body dynamics in real-time robotic systems used in satellite servicing simulations. In: AIAA Modeling and Simulation Technologies, AIAA 2013-5157 (2013)

Pu, A.T., Harrison, A.S., Robertson, J.M., et al.: Vibration control of beams by beam-type dynamic vibration absorbers. J. Eng. Mech. 118(2), 248–258 (1992)

Samani, F.S., Pellicano, F., Masoumi, A.: Performances of dynamic vibration absorbers for beams subjected to moving loads. Nonlinear Dyn. 73(72), 1065–1079 (2013)

Kim, S.H., Choi, S.B., Hong, S.R., et al.: Vibration control of a flexible structure using a hybrid mount. Int. J. Mech. Sci. 46(1), 143–157 (2004)

Li, P., Fu, J., Wang, Y., et al.: Dynamic model and parameters identification of piezoelectric stack actuators. In: The 26th Chinese Control and Decision Conference, pp. 1918–1923. IEEE (2014)

Xing, J.W.: ADAMS_Flex and AutoFlex Training Tutorial. Science Press, Beijing (2006)

Kuo, S.M., Morgan, D.R.: Active noise control: a tutorial review. Proc. IEEE 87(6), 943–973 (1999)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Liu, H., Fang, Y., Bai, B., Zhu, X. (2017). Co-simulation Using ADAMS and MATLAB for Active Vibration Control of Flexible Beam with Piezoelectric Stack Actuator. In: Fei, M., Ma, S., Li, X., Sun, X., Jia, L., Su, Z. (eds) Advanced Computational Methods in Life System Modeling and Simulation. ICSEE LSMS 2017 2017. Communications in Computer and Information Science, vol 761. Springer, Singapore. https://doi.org/10.1007/978-981-10-6370-1_31

Download citation

DOI: https://doi.org/10.1007/978-981-10-6370-1_31

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-6369-5

Online ISBN: 978-981-10-6370-1

eBook Packages: Computer ScienceComputer Science (R0)