Abstract

This paper emphasized on neural network-based approximation method to predict correct and optimize cycle time for productivity improvement of structural subassembly manufacturing system. Altogether 35 assorted independent variables were considered for the experimentation against cycle time of operation as a productivity measure. 600 experiments were conducted and data were collected over the span of 2 years, which is modeled using Artificial Neural network. Symbolic mathematical model is formulated to reveal black box nature of Neural Network. Scaled conjugate gradient and gradient descent methods are considered as optimization algorithms for ANN, both performs well with diversified topologies. Coefficient of correlation (R = 0.996) with the sum of square error in the range of (0.095–0.034) reflecting a better approximation of dependent variable.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Often it is of interest to study a system to understand the relations between its components or to predict how a system is responsive to changes. Sometimes it is possible to directly experiment with the system. However, this is not always possible, e.g., due to costs when a manufacturing system has to be stopped, changed, or extended. Often the system even does not yet exist. A model, defined as a representation of the system in order to investigate it, can solve this dilemma. Generally, it is sufficient to abstract the system with a view to analyze the issues under investigation. In terms of modeling and simulation, this abstract is named the simulation model. Simulation enables system analysis with time and space compression, provides a robust validation mechanism under realistic conditions and can reduce the risk of implementing new systems. Validation is achieved using a series of qualitative and quantitative experiments with changes of system variables and structures. The expanding capability of computing systems and the increasing demands of engineers and managers planning, implementing, and maintaining manufacturing systems have been pushing the boundaries of modeling and simulation based research. For many manufacturers, implementing a change in their operation can be risky, so simulation can be used as the test bed for evaluation of new manufacturing methods and strategies. Using engineering discipline, manufacturing systems can be measured through data collection, and processes analysis. Measurement efforts are the first step for better understanding of manufacturing systems. Where processes have been measured and data collected, simulation can be applied as a decision-making tool to enhance system understanding. When systems are not well defined or understood, it is difficult to build accurate models that are worthwhile. Manufacturing and material handling systems can be arbitrarily complex and difficult to understand. The number of possible combinations of input variables can be overwhelming when trying to perform experimentation. After manufacturing system data have been collected and verified, simulation can be used to represent almost any level of detail to provide an accurate representation of a real-world system. From a model of the system, the behavior of the system and its components can be better understood. It is important to note that optimizing on one measure of performance can adversely affect another measure of performance.

Case study of Structural subassembly production which is a batch processing manufacturing system from Sai Industries Pvt. Ltd. MIDC, Nagpur is considered in this paper. Despite some inherent variations which are inbuilt in manufacturing, it specifically comes under the category of deterministic in nature. Present investigation intended toward the formulation of generalized field data-based mathematical model for structural subassembly manufacturing. Decision regarding the disquiet about whether structural subassembly batch processing which is predominantly press working operation can be model using probabilistic or deterministic modeling approach thought out initially. The limitation of stochastic simulation about inability to consider human factor, workplace related factors and environmental factors during formulation of model clearly hints towards the second choice (Deterministic simulation). The approach suggested in the present investigation is to check out the effect of these parameters on performance measures such as production cycle time. Thus, pervasive attempt has been made in this paper to investigate the phenomenon of structural subassembly manufacturing by applying Artificial Neural network (ANN) technique.

Bergmann et al. [1] introduced a novel methodology for approximating dynamic behavior using artificial neural networks, rather than trying to determine exact representations. They suggested using neural networks in conjunction with traditional material flow simulation systems whenever a certain decision cannot be made in the model generation process due to insufficient knowledge about the behavior of the real system. Fowler and Rose [2], there is a need for the invasive use of modeling and simulation for decision support in current and future manufacturing systems, and several challenges need to be addressed by the simulation community to realize this vision. Hosseinpour and Hajihosseini [3] revealed the importance of simulation and according to them, implementing change can be a difficult task for any organization, big or small. For this purpose modeling of complex systems such as manufacturing systems is a strenuous task. Sabuncuoglu and Touhami [4] presented fundamentals of simulation metamodeling using neural networks for job shop manufacturing system. Cimino et al. [5] proposed a methodology for the effectual ergonomic design of workstations contained by industrial plants. The methodology based on multiple design parameters and multiple performance measures prop-up the design and the evaluation of workstations in terms of both ergonomics and work methods. Vainio et al. [6], used neural network for estimation of printed circuit board assembly time. In their study they trained multilayer neural networks to approximate the assembly times of two different types of assembly machines based on several parameter combinations. Abdelwahed et al. [7], presented a performance prediction approach for the product produced after multi-stages of manufacturing processes, as well as the assembly using ANN. Taghi et al. [8], presented designing of a multivariate multistage quality control system using artificial neural networks. Wang et al. [9] thoroughly presented an updated survey on Neural Network applications in intelligent manufacturing. Zain et al. [10], presented regression and ANN models for estimating minimum value of machining performance. Two modeling approaches, regression and Artificial Neural Network (ANN), were applied to predict the minimum Ra value. Dowler [11] in his theses on “Using Neural Networks with limited data to estimate manufacturing cost” concluded that, neural networks are an excellent option for cost estimation even when the amount of data available is limited. Researchers mentioned here have investigated the effect of various parameters such as environmental conditions, ergonomic and anthropometric consideration, and workstation design for various manufacturing scenarios. Unfortunately evidence is not sited regarding the generalized framework which consist of all parameters taken together and checking its effect on productivity. Scene is even more discern for structural subassembly manufacturing type of setups which are predominantly a press shop. In this paper attempt has been made to include other general parameters such as personal factors of operator and specification of the product to model batch manufacturing of structural subassemblies of tractors.

2 Problem Formulation and Design of Experiments

The specific objective of the present investigation is to developed mathematical model for structural subassembly manufacturing process using time honored artificial neural network (ANN). Investigation also provokes the aim of statistical and reliability analysis of any computational problem which can be numerically simulated, mainly the estimation of statistical parameters of response variable. Thus identification of number of influential variables and grouping them logically is essential for the present investigation. This can be achieved because of the ingrained difference in factors which impinge on the production process.

For example, all variable related to machine specification are grouped together. In order to accomplish the intention

The independent variables are grouped and identified as:

-

1.

Anthropometric data of an operator

-

2.

Personal factors of an operator

-

3.

Machine specifications

-

4.

Workplace parameters

-

5.

Specification of the product

-

6.

Environmental conditions

The Dependent variables can be distinguished as:

-

Production cycle time

The variable listing with specific symbol for respective groups are depicted in the Table 1a–c.

The quality of results obtained from field research depends on the data gathered in the field. Data collection method is gathering of information to address a research problem. Data that will be subjected to statistical analysis must be gathered in such a way that they can be quantified. For statistical analysis variables must be quantitatively measured. A formal data collection process is necessary as it ensures that data gathered are both defined and accurate and that subsequent decisions based on arguments embodied in the findings are valid. Formal data collection method using calibrated instruments is used for this investigation. Parameters which are constant have been recorded first and then other parameters were recorded. Altogether 600 experiments conducted over the span of 2 years for 35 independent variables and production cycle time as a dependent variable (Fig. 1).

3 Neural Network Modeling

The term neural network applies to a limply related family of models, characterized by a large parameter space and flexible structure, descending from studies of brain functioning. As the family grew, most of the new models were designed for nonbiological applications, though much of the associated terminology reflects its origin. Specific definitions of neural networks are as varied as the fields in which they are used. While no single definition properly covers the entire family of models, for now, considers the following description

“A neural network is a massively parallel distributed processor that has a natural propensity for storing experiential knowledge and making it available for use.” It resembles the brain in two respects:

-

Knowledge is acquired by the network through a learning process.

-

Interneuron connection strengths known as synaptic weights are used to store the knowledge.

By contrast, the definition above makes minimal demands on model structure and assumptions. Thus, a neural network can approximate a wide range of statistical models without requiring that one hypothesize in advance certain relationships between the dependent and independent variables. Instead, the form of the relationships is determined during the learning process. If a linear relationship between the dependent and independent variables is appropriate, the results of the neural network should closely approximate those of the linear regression model. If a nonlinear relationship is more appropriate, the neural network will automatically approximate the “correct” model structure.

The trade-off for this flexibility is that the synaptic weights of a neural network are not easily interpretable. Thus, if one is trying to explain an underlying process that produces the relationships between the dependent and independent variables, it would be better to use a more traditional statistical model. However, if model interpretability is not important, one can often obtain good model results more quickly using a neural network (Fig. 2).

3.1 Feedforward Neural Network

Although neural networks impose minimal demands on model structure and assumptions, it is useful to understand the general network architecture. The multilayer perceptron (MLP) or radial basis function (RBF) network is a function of predictors (also called inputs or independent variables) that minimize the prediction error of target variables (also called outputs).

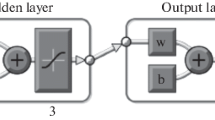

The structure depicted in Fig. 3 is known as feedforward architecture, because the connections in the network flow forward from the input layer to the output layer without any feedback loops. In the figure:

-

The input layer contains the predictors.

-

The hidden layer contains unobservable nodes, or units.

The value of each hidden unit is some function of the predictors; the exact form of the function depends in part upon the network type and in part upon user-controllable specifications.

-

The output layer contains the responses.

Each output unit is some function of the hidden units. Again, the exact form of the function depends in part on the network type and in part on user-controllable specifications.

3.2 Activation Function

A function used to transform the activation level of a unit (neuron) into an output signal. Typically, activation functions have a “squashing” effect. Neural Networks supports a wide range of activation functions. Only a few of these are used by default; the others are available for customization (Table 2).

The hyperbolic tangent function (tanh): a sigmoid curve, like the logistic function, except that output lies in the range (−1, +1), often performs better than the logistic function because of its symmetry. Ideal for customization of multilayer perceptron, particularly the hidden layers. Several researchers have indicated that single hidden layer architecture with an arbitrarily large quantity of hidden nodes in the layer, is capable of modeling any categorization mapping. In the present work number of architectures were tried and tested to find out the best one for the prediction of productivity.

4 ANN Modeling

An experimental means for determining an appropriate topology for solving a particular problem involves the training of a larger-than-necessary network and the subsequent removal of unnecessary weights and nodes during training. This approach, called pruning, requires advance knowledge of initial network size, but such upper bounds may not be difficult to estimate. An alternative means for determining appropriate network topology involves algorithms which start with a small network and build it larger; such algorithms are known as constructive algorithms.

4.1 ANN Model with Base Variable as Input and Cycle Time Output

Mathematical Model based on basic 35 independent variables and Cycle time of operation as dependent variable is formulated. Model is based on 600 experiments conducted over the span of two years and considering three bifurcation of entire period (Summer, Winter, Rainy season). Symbolic representation of ANN equation is formulated as follows:

where sum (Layer1cell0) = 0.24 * X 0.1 − 0.43 * X 0.2 − 0.307 * X 0.3 + 0.17 * X 0.4 + 0.1888 * X 0.5 − 0.4 * X 0.6 + 0.24 * X 0.7 + 0.4 * X 0.8 + 0.02 * X 0.9 − 0.074 * X 0.10 − 0.023 * X 0.11 + 0.15 * X 0.12 + 0.099 * X 0.13 + 0.02 * X 0.14 + 0.33 * X 0.15 − 0.421 * X 0.16 + 0.29 * X 0.17 − 0.009 * X 0.18 + 0.04 * X 0.19 + 0.077 * X 0.20 + 0.471 * X 0.21 − 0.146 * X 0.22 − 0.363 * X 0.23 − 0.417 * X 0.24 + 0.163 * X 0.25 − 0.237 * X 0.26 − 0.329 * X 0.27 + 0.389 * X 0.28 + 0.196 * X 0.29 + 0.18 * X 0.30 − 0.359 * X 0.31 + 0.04 * X 0.32 − 0.096 * X 0.33 − 0.0321 * X 0.34 − 0.228 * X 0,35 − 0.421

where sum (Layer1cell1) = 0.24 * X 0,1 − 0.43 * X 0.2 – 0.307 * X 0.3 + 0.17 * X 0.4 + 0.1888 * X 0.5 − 0.4 * X 0.6 + 0.24 * X 0.7 + 0.4 * X 0.8 + 0.02 * X 0.9 − 0.074 * X 0.10 − 0.023 * X 0.11 + 0.15 * X 0.12 + 0.099 * X 0.13 + 0.02 * X 0.14 + 0.33 * X 0.15 − 0.421 * X 0.16 + 0.29 * X 0.17 − 0.009 * X 0.18 + 0.04 * X 0.19 + 0.077 * X 0.20 + 0.471 * X 0.21 − 0.146 * X 0.22 − 0.363 * X 0.23 − 0.417 * X 0.24 + 0.163 * X 0.25 − 0.237 * X 0.26 − 0.329 * X 0.27 + 0.389 * X 0.28 + 0.196 * X 0.29 + 0.18 * X 0.30 − 0.359 * X 0.31 + 0.04 * X 0.32 − 0.096 * X 0.33 − 0.0321 * X 0.34 − 0.228 * X 0,35 − 0.433

5 Result and Discussion

Prediction of cycle time as a productivity measure of a small-scale manufacturing unit is considered to established relationship between dependent variable and 35 assorted independent variables.Mathematical Model is developed using fundamentals of Artificial Neural network-based function approximation. Former relationship between output and input was unknown till correct approximation by ANN model. Neural Network is of black box nature, an attempt has been made to showcase mathematical structure of ANN model by using hyperbolic tangential function as a transfer function. Random synapses were generated using training and optimization algorithm and weighted sum of synapses and scaled input data then further constricted through nonlinear transfer function (Table 3).

Topologies with 35-10-1, 35-20-1, 35-35-1 with sigmoidal transfer function in input and output layer appears to be best choice to predict cycle time. Sigmoidal transfer function performs well with both optimization algorithms. Coefficient of correlation in all three cases is closed to 0.996 which is an excellent indication for prediction of correct cycle time after ANN simulation. This ANN simulation will surely helpful for small-scale industries to approximate productivity measures via simulation process instead of cumbersome and exhaustive execution of experiments. It is practically nonviable for small industries to spend time in years to collect and measure huge data based on various influential variables. ANN simulation is rather a better perspective for researchers and small-scale industries for prediction of productivity-related parameters.

Sum of square error and relative error as basic statistical measure to check performance of ANN model is well within stipulated range for the best performing topologies. As relative error does not deviate during training and prediction phase indicating stability and reflected that network is not overtrain.

6 Conclusion

Convincing results are yielded through ANN Model simulation in this investigation. Relationship between 35 independent variables and one dependent variable is captured correctly by ANN. Though ANN modeling is of black box nature and understanding of model is complicated for general Understanding. Enigmatic nature of this hardheaded relationship is tough; but the precision of ANN model must be honored. Prediction of cycle time as a productivity measure using neural network acts as a useful guideline for small-scale industries working on similar line. The paper also elaborates comparative analysis between adoption of two training algorithms and two activation functions. Further, it is also observed that number of hidden nodes in hidden layer also have significant impact on output parameters.

References

Bergmann, S., Stelzer, S., Strassburger, S.: On the use of artificial neural net works in simulation-based manufacturing control. J. Simul. 8(1), 76–90 (2014)

Fowler, J.W.: Rose, O.: Grand challenges in modeling and simulation of complex manufacturing systems. Simulation 80(9), 469–476 (2004)

Hosseinpour, F., Hajihosseini, H.: Importance of Simulation in Manufacturing. World Academy of Science, Engineering and Technology, vol. 51 (2009)

Sabuncuoglu, I., Touhami, S.: Simulation metamodelling with neural networks: an experimental investigation. Int. J. Prod. Res. 40(11), 2483–2505 (2002)

Cimino, A., Longo, F., Mirabelli, G.: A multimeasure-based methodology for the ergonomic effective design of manufacturing system workstations. Int. J. Ind. Ergon. 39, 447–455(2009)

Vainio, F., Maier, M., Knuutila, T., Alhoniemi, E., Johnsson, M., Nevalainen, O.S.: Estimating printed circuit board assembly times using neural networks. Int. J. Prod. Res. 48(8), 2201–2218 (2010)

Abdelwahed, M.S., El-Baz, M.A., El-Midany, T.T.: A Proposed Performance Prediction Approach for Manufacturing Processes Using ANNs. World Academy of Science, Engineering and Technology, vol. 61 (2012)

Taghi, S., Niaki, A., Davoodi, M.: Designing a multivariate–multistage quality control system using artificial neural networks. Int. J. Prod. Res. (2009)

Wang, J., et al.: Applications in Intelligent Manufacturing: An Updated Survey. Computational Intelligence in Manufacturing Handbook. CRC Press LLC (2001)

Zain, A.M., Harona, H., Qasem, S.N., Sharif, S.: Regression and ANN models for estimating minimum value of machining performance. Appl. Math. Model. 36, 1477–1492 (2012)

Dowler, J.D. Using Neural networks with limited data to estimate manufacturing cost. Ph.D. thesis, Ohio University (2008)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Giri, J.P., Giri, P.J., Chadge, R. (2018). Neural Network-Based Prediction of Productivity Parameters. In: Pant, M., Ray, K., Sharma, T., Rawat, S., Bandyopadhyay, A. (eds) Soft Computing: Theories and Applications. Advances in Intelligent Systems and Computing, vol 583. Springer, Singapore. https://doi.org/10.1007/978-981-10-5687-1_8

Download citation

DOI: https://doi.org/10.1007/978-981-10-5687-1_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-5686-4

Online ISBN: 978-981-10-5687-1

eBook Packages: EngineeringEngineering (R0)