Abstract

The experimental performance of a parabolic solar dish collector is investigated in this paper. The collector is located at Karunya University, Coimbatore (Longitude 76° 59′ and Latitude 11° 00′) Tamil Nadu. The diameter of the collector is 1180 mm with the depth of 310 mm. The diameter of the absorber which is made up of copper is about 75 mm and height is 200 mm for a concentration ratio of 10. The performance of the collector is evaluated without and with nanoparticles, under various operating conditions. It is observed that, without nanoparticles, the temperature of the water in the storage tank increased from 35 to 85 °C. When aluminium oxide nanoparticles (0.01% volume concentration) are used, the temperature increased up to 90 °C. The efficiency of the collector is found to be higher by about 10% when nanoparticles are used.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

As natural resources are decreasing day by day we need some sources of energy as substitute which are energy efficient, pollution free and economical. Solar energy is one of these. Solar energy can be used for heating purpose at micro and macro level. When solar energy is used in heat generation systems like solar dish type collectors, the efficiency of the systems can further be increased by using nanofluids for heat transfer and optical absorption. Higher optical efficiency and thermal efficiency can be obtained by the parabolic solar dish collectors. A parabolic-shaped dish concentrator that reflects solar radiation onto a receiver is mounted at the focal point of the parabolic dish system. The heat collected by the receiver can be used by a heat engine mounted on the receiver that moves with the dish structure, such as Stirling and Brayton cycle engines. The shape of the parabola needs to be relatively precise and concentrator needs to focus the sunlight on the receiver in order for the parabolic concentrator to be most effective. The utilization of solar energy by converting it to heat is the principal concern of the solar thermal technology. Solar energy is collected and concentrated so that higher temperatures can be obtained in the concentrating type of solar collector. The surface temperature of the sun is the limit. The solar radiant energy can be more efficiently harnessed by the Nanofluid-based solar collector compared to conventional solar collectors. Relevant application of Nanofluids have recently found in industrial applications, applications requiring quick and effective heat transfer such as, cooling of microchips, microscopic fluidic applications, etc.

2 Literature Survey

The use of reflectors [1] to concentrate sunlight on the absorber of a solar collector, reduces the absorber size, which in turn reduces heat losses and dramatically increases efficiency at high temperatures. The cost of reflectors is significantly less per unit area than collectors, which is yet an added advantage.

Basic types of concentrating collectors are as follows:

-

1.

Parabolic trough

-

2.

Parabolic dish

-

3.

Stationary concentrating collectors

Li and Dubinsky [2] have worked on a new approach to design a concentrating dish using flexible petals. In solar collectors, parabolic dish concentrator mirrors are very important parts as these are used to concentrate the sun rays to the focal point of the parabola and they should be relatively precise and are expensive to fabricate and also to transport. Wua et al. [3] proposed a solar thermal power system of parabolic dish/AMTEC. They worked on a combined system in which a parabolic dish solar collector was combined through a coupling heat exchanger with an alkali metal thermal to electric converter (AMTEC). Its overall performance of thermoelectric conversion was evaluated. Reddy and Veershetty [4] have come up with the viability analysis of solar parabolic dish collector for Indian conditions. Among the concentrating solar power systems, the parabolic solar dish collector is one of the most efficient energy conversion technologies. Sustainable energy generation can be achieved by the design and implementation of solar parabolic dish power plants. Reddy and Sendhil Kumar [5] numerically studied the combined laminar natural convection and surface radiation heat transfer of parabolic solar dish collector in a modified cavity receiver.

Arulkumaran and Christraj [6] presented experimental platform where steam is generated by non-tracking paraboloid solar dish collector. The design, development and performance characteristics were done in this experiment. Sagade and Shinde [7] evaluated the performance of the solar parabolic dish collector for industrial purpose. From Indian point of view there is a huge possibility for low cost solar water heating systems. The needs of the industrial sector can be fulfilled by this system. El Ouederni et al. [8] explains about the experimental study they had done on parabolic solar collector. The obtained results describe correctly the awaited physical phenomenon. Taylor et al. [9] presented the applicability of nanofluids for various type of solar collectors. The introduction of nanoparticles to conventional working fluids (i.e. nanofluids) can enhance heat transfer and solar collection. The paper explains about a notional design of this type of nanofluid receiver. Sayantan Mukherjee and Somjit Paria [10] presented a brief review to provide an update about the preparation and stabilization methods of nanofluids.

2.1 Inferences from the Review of Literature

From the literature review, it is inferred that no work has been done in order to estimate the characteristics of a parabolic dish collector with nanofluid. An attempt has been made to conduct performance evaluation of dish type solar collector with nanofluid of different volumetric concentrations for various operating conditions.

3 Experimental Studies

3.1 Experimental Set Up

The schematic representation of the experimental set up and its photographic view are shown in Figs. 1 and 2, respectively. The concentrator consists of a dish type frame and a stand. The material used for frame is Aluminium. The stand is made up of mild steel bars and bushes arc provided for proper seating of bearings. Reflectors are one of the important components that are of greater importance for a parabolic dish concentrator. The reflector used in the experimental set up is Aluminium foil which is cheap, durable, long life can cut using latest techniques to required shape and size.

The absorber tube has a diameter of 75 mm and a height of 200 mm. Copper is used because of its high thermal conductivity. The cylinder is placed at the focal point of the concentrator, which has an inlet and an outlet which consists of two thermocouples of K-type for reading the temperature of the water at two different points and a third one is provided for measuring the temperature of the fluid in the tank. The focal length of the collector is 298 mm.

3.2 Experimental Procedure

The absorber is fixed in the focal point of the concentrating collector. Fluid (Water/nanofluid) from the storage tank is allowed to flow through the absorber tube. For all the fluids a constant mass flow rate of 0.058 kg/s and the average radiation of 560 W/m2 was considered. The following observations are taken for every half-an-hour: (1) Solar insolation. (2) Ambient temperature. (3) Water inlet temperature. (4) Safer outlet temperature. Mechanical tracking mechanism is used so as to tilt the concentrator according to the sun’s movement to trap the radiations. The experiment is performed in a setup which has an Aluminium sheet as reflector. A copper absorber cylinder is used. Observations are taken first without Nanofluid that means with water as working fluid and then it is taken with nanofluid of volumetric concentration 0.01 and 0.02% one after another.

3.3 Nanofluid Preparation Process

The first step for experimental studies of nanofluid is the preparation of nanofluid. The two primary methods of nanofluid preparation are single-step and two-step process. In two-step preparation process base fluids are mixed with commercially available nanopowders. These nanopowders are obtained by different physical, chemical and mechanical routes such as grinding, milling and sol–gel and vapour phase methods. This is the mostly used method.

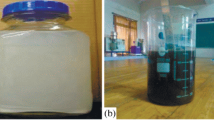

The device used to stir the nanopowders with host fluids is the ultrasonic vibrator as shown in Figs. 3 and 4. Frequent use of ultra-sonication or stirring is required to reduce particle agglomeration. Two-step method can be used to produce alumina nanofluids. Two-step process is the most suitable process to prepare nanofluids which contains oxide nanoparticles other than those containing metallic nanoparticles. The major inherently related issue to this operation is stability because these powders easily agglomerate due to the strong van der Walls forces among nanoparticles.

4 Results and Discussion

The variation of outlet temperature with respect to time is shown in Fig. 5. It shows that there is a considerable amount of increase in the absorber tube outlet temperature when nanofluid (Alumina-water) is taken as working fluid. Since nanofluid is introduced there is an increase in temperature of about 5–6 °C for 0.01% volume concentration.

From the above graph, it is inferred that when volume concentration increases outlet temperature also increases with respect to time. Since the amount of nanoparticles in the nanofluid increased which leads to increase in the thermal conductivity of nanofluid results in higher outlet temperature when compared to water. The variation of tank temperature with respect to time is shown in Fig. 6 which indicates that there is a considerable amount of increase in the tank temperature when nanofluid is used instead of using water as working fluid. Since nanofluid is introduced there is an increase in temperature of 6 °C for 0.01% volume concentration. The useful heat gain difference with respect to time is shown in Fig. 7. It shows that there is a temperature difference due to nanofluid of 0.01% volume concentration.

From the graph, it is clear that when volume concentration increases useful heat gain also increases with respect to time. Since the amount of nanoparticles in the nanofluid increased which increases the thermal conductivity of nanofluid and therefore, considerable amount of increase in heat gain is obtained. The transmittance of the absorber material affects the thermal efficiency of the system.

The measured and estimated parameters of uncertainities are given in Table 1.

The variation of collection efficiency with respect to time is shown in Fig. 8 which shows that there is a considerable amount of increase in collection efficiency when nanofluid is applied instead of water as working fluid. Since nanofluid is introduced there is an increase collection efficiency of about 2–3% for 0–0.02% volume concentration. It is inferred from the experimental studies that when volume concentration increases collection efficiency also increases with respect to time. Since the amount of nanoparticles in the nanofluid increased which increases the thermal conductivity of nanofluid and so considerable amount of increase in collection efficiency is obtained. The amount of solar energy that is concentrated on the receiver of the collector and before the heat is transferred to the liquid that flows along the receiver. Solar energy is drawn by the nanoparticles and transferred to the liquid. The thermal conductivity of nanofluid is better than that of water. Therefore, use of nanofluid gives better collection efficiency.

5 Conclusion

An experimental investigation on the of a parabolic dish type solar collector with nanofluid is done in this study. System’s performance has been compared with and without nanoparticles (aluminium oxide). It is observed that, for a volume concentration of 0.01%, the tank temperature reached a maximum of 90 °C with collection efficiency of 32.08%. When the volume concentration is increased to 0.02% a maximum collection efficiency of 32.8% as compared to the 30.07% achieved without nanofluid, has been obtained. It is inferred from Figs. 5, 6, 7 and 8 that when the nanoparticle is introduced with 0.01% concentration, the output parameters such as temperature, useful heat gain and collection efficiency of the system increases compared to that of water. However, when the volume concentration of nanoparticle is increased from 0.01 to 0.02%, the output parameters do not increase due to good stability exhibited by nanoparticles at 0.01% optimum concentration.

References

L. Crespo, Z. Dobrotkova, C. Philibert, C. Richter, Concentrating Solar Power. International Renewable Energy Agency, pp. 1–48 (2012)

L. Li, S. Dubowsky, A new design approach for solar concentrating parabolic dish based on optimized flexible petals. Mech. Mach. Theory, 1536–1548 (2011)

S.-Y. Wua, L. Xiao, Y. Cao, Y.-R. Li, A parabolic dish/AMTEC solar thermal power system and its performance evaluation. Appl. Energy 452–462 (2010)

K.S. Reddy, G. Veershetty, Viability analysis of solar parabolic dish stand-alone power plant for Indian conditions. Appl. Energy, 908–922 (2013)

K.S. Reddy, N. Sendhil Kumar, Combined laminar natural convection and surface radiation heat transfer in a modified cavity receiver of solar parabolic dish. Int. J. Therm. Sci., 1647–1657 (2008)

M. Arulkumaran, W. Christraj, Experimental analysis of non tracking solar parabolic dish concentrating system for steam generation. Eng. J. 1–6 (2012)

A. Sagade, N. Shinde, Performance evaluation of parabolic dish type solar collector for industrial heating application. Int. J. Energy Technol. Policy, 80–93 (2012)

A.R. El Ouederni, M. Ben Salah, F. Askri, M. Ben Nasrallah, F. Aloui, Experimental study of solar concentrator. Revue des Energies Renouvelables, 395–404 (2009)

R.A. Taylor, P.E. Phelan, Applicability of nanofluids in high flux solar collectors. J. Renew. Sustain. Energy, 1–8 (2010)

S. Mukherjee, S. Paria, Preparation and stability of nanofluids—a review. IOSR J. Mech. Civil Eng., 63–69 (2013)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Pakhare, J.N., Pandey, H., Selvam, M., Jawahar, C.P. (2018). Experimental Performance Evaluation of a Parabolic Solar Dish Collector with Nanofluid. In: Chandra, L., Dixit, A. (eds) Concentrated Solar Thermal Energy Technologies. Springer Proceedings in Energy. Springer, Singapore. https://doi.org/10.1007/978-981-10-4576-9_11

Download citation

DOI: https://doi.org/10.1007/978-981-10-4576-9_11

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-4575-2

Online ISBN: 978-981-10-4576-9

eBook Packages: EnergyEnergy (R0)