Abstract

The success of any product depends on the quality of concepts developed, as per the customer requirements (CRs). It involves an information processing activity, where the information is formulated into a feasible concept. However, it is realized that during any design process, information about the problem is missing at the beginning of the design process. This work identifies that a consumable product may have a minimum of thirty-four design ingredients to define CRs precisely and represent domain information for the designers. The analytic hierarchy process (AHP) is applied to capture the intensity of the requirements by the acquired information. This work presents a systematic method of product design, driven by these thirty-four design ingredients. With product ingredients, a designer can pre-plan intended design space. The primary advantage of the proposed method is to target the required information correctly and quickly, for product design.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Product development is a process of creating new products to fulfill the customer requirements (CRs). On the basis of inputs gained from Wheelwright [1], Anderson [2], and Ulrich and Eppinger [3], this development process usually includes the design stage like: (i) identifying customer wants, (ii) setting target specifications, (iii) concept creation, (iv) concept selection, (v) concept examination, (vi) setting final specifications, (vii) project planning, (viii) economic analysis, (ix) benchmarking of competitive products, (x) modeling and (xi) prototyping. All the stage involves information processing activity, in which designers gather and organize information. The first and critical stage in the design process is the identification of CRs information because from this information whole design process is undertaken. Griffin [4] has discussed the richness of existing literature on CRs, yet inadequate consideration has been paid to how product management and experts are liable for defining the CRs.

Furthermore, it is still not explained clearly about the information desired for product design. Hence, as per the CRs in this work thirty-four design ingredients are presented for the desired information framework for design any product. Identifying customer needs very clearly and accordingly outlining product concepts is a critical step for successful product development. It is reported that designers invest about 60% of their time for the ‘right’ information [5], and this process is rated as the most baffling part of the design process. On the basis of the available, but limited information, the designer, generates concepts mainly with the help of design research, brainstorming, SCAMPER, concept fan, user narration, descriptive recombination, user creation, brain-writing, problem decomposition, cause and effect trees, etc. These techniques provide many solutions in the product design space. Selection of one concept among “n” number of concepts is a typical task, and the chances of a wrong selection are high. Further, as we have to select only one concept, thus the remaining (n − 1) concepts are responsible for the increase in turn-around time and resources committed. It is imperative that the smart idea is chosen, as it determines the course of the embodiment design stage. Hence, in brief, the objectives of this research can be stated as:

-

To identify the required information and accommodate CRs,

-

To capture the degree of importance of the CRs, and

-

To quickly target the right concept as per the weight of CRs

This work presents a new systematic method for capturing CRs information and accordingly development of conceptual phase of the product design, driven by thirty-four design ingredients. The analytic hierarchy process (AHP) has been utilized to capture the level of significance of CRs. The primary advantage of the proposed method is quick to target the right concept for optimum product configuration. As concept development and selection are the primary steps of a product design process, this work is limited to concept generation phase of product design.

2 Literature Review

Generating, gathering and sharing information, data and knowledge in design have been an underlying theme in the design research and practice for a long time [6]. Nowadays, both manufacturing and service sectors have embraced elaborate variety management and technique to capture the right information related to customer needs. As the design of any product start with CRs and accordingly designer generate product concepts to fulfill these needs. Hence, information related to CRs is very vital for successful product design. Therefore, review presented here is carried out under ‘CRs’ umbrella.

As per Nishino et al. [7] professional must explicitly observe customer behaviors using accessible information got through services. In spite of the fact that the customer purchase information is a major source to showcase customer attitude for service providers to establish customer desires; such information are inadequate for clarifying customer decision-making procedures including their inspirations, way of life, price opinions, or joy with products or services after usage. According to Chan and Wu [8], numerous methods are existing to collect CRs. They include focus group, personal interviews, listening and viewing, natural field communication, warranty data, feedback and criticisms, affinity diagram, cluster interpretation, etc. As of late, many traditional and trade-based decision making systems for product design have been revealed for making judgments on new product development, including CRs, consumer loyalty, product quality, product design, market demand and pricing [9,10,11,12,13]. Quality function deployment (QFD), which is a tool to convert customer requirement to engineering characteristics, is a long process, mostly analytical and fails to translate the relative importance of CRs into the relative importance of engineering characteristics uniformly [14]. An alternate approach that is widely used in both industry and academia for impressive analysis of CRs is Kano’s model, which identifies user requirement and expectation through a preference classification technique [15]. As per Lee and Huang [16], the conventional Kano’s model only considers crisp (the inverse to fuzzy) explanations, and thus, ignores the fact that CRs are vague and undefined due to their linguistic origins. The conventional Kano’s model not only has the drawback of ignoring the imprecision and uncertainty in CRs but also, it is a qualitative or subjective method based on discontinuous classification criteria. There are reports accessible in the literature on efforts to formulate a fuzzy extension of Kano’s model so as to manage the imprecision and vulnerability in CRs [17,18,19]. Nagamachi developed Kansei Engineering, as an ergonomics and consumer-oriented tool to translate customer perceptions and feelings into form ingredients [20, 21]. It has been effectively applied in the area of product design [22,23,24] to investigate the relationship between the feelings of the purchasers and the design components of products. Lin et al. [25] exhibited another method for converting users’ perception into product elements design, alongside a test investigation of cell phones. This robust design approach enhances quality observation by reducing the discrepancy between the actual customer feeling and the desired feeling, to decrease ambiguity produced by individualistic characteristics of the customers. A statistical technique conjoint analysis is regularly utilized in market research to determine how people value different attributes (requirements) [26]. Most of the design techniques concentrate on technical domains to determine customer needs. However, various challenges exist in CRs identification and collection. Identifying actual CRs involve understanding genuine issues and what products empower customers to do. Acquiring implicit and complex knowledge from customers is laborious, and organizational barriers make it significantly harder [27]. The literature indicates product design can be a challenging task due to information about the problem is missing at the beginning of the design process. Therefore, this work presents a systematic method for capturing CRs information along with design information that is driven by thirty-four design ingredients.

3 Proposed Method

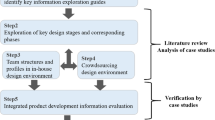

The thirty-four design ingredients are proposed on the basis of extensive study of the work done by previous researchers, Pahl and Beitz [28], Hubka and Eder [29], Pugh [30], Roozenburg and Eekels [31]. It is noted that a consumable product may have a minimum of thirty-four design ingredients, as shown in Table 1 column 2nd “Ingredients”. With the aid of proposed information framework thirty-four design ingredients, the necessary information required for the design process can be accumulated early during the design process. The purpose of introducing these ingredients is to capture the CRs in a lucid manner, as the requirement can be fragmented in terms of design ingredients. However, in literature, a few fuzzy models are proposed, if the information is fuzzy in nature. Among the various techniques available for information collection, this work uses interview technique to gather the required information about thirty-four design ingredients. The reason behind the choice of the interview is due to its cognitive approach and immediate availability of the required data for the desired application. In the reported work, random interviews were conducted among the university students and some other users due to the choice of the product (bed study table) to validate the method. After the first phase of the interview, which was generic in terms of thirty-four design ingredients of the product, later, the questions specifically addressed customer need identification. The analysis was directed by utilizing the subjective technique of reading the interviews many times to discover actual CRs information and noted in Table 1. All the significant CRs having an impact for the product design is accommodated. As it is not possible to fulfill all CRs, therefore, to address this issue, analytic hierarchy process (AHP) is utilized to decide the significance CRs [32].

4 Implementation and Validation

This section presents the implementation of the proposed method and develops an optimal product design concept for a test case. The motivation behind selecting bed table as a case study and presenting in this manuscript is due to its simple structure and easy functionality. Effectively capturing and analyzing customer requirement regarding bed table is a challenging task. To collect CRs information, the technique used in this work is an interview, with respect to thirty-four design ingredients. With the aid of proposed design ingredients, the necessary information required for any design process can be conveniently accumulated, as shown in Table 1. After analyzing the CRs (Table 1), it is observed that some requirements are very dynamic and can influence the customer as well as the design. All these important CRs having impact for the product design are following: foldable (CR1), shock loading (CR2), adjustable (CR3), easy to clean (CR4), aesthetics (CR5), ergonomics (CR6), vibration (CR7), safety (CR8), Cost (CR9). For the proposed case study (i.e. bed-table), a variety of requirements are mentioned by the customers and it is not-possible/beneficial for the manufacturer to satisfy the entire set of requirement with equal importance. Therefore, the next step determines the degree of importance of CRs through AHP.

For each CRs, pairwise comparisons are quantified by using a scale of 1–9 as per Saaty [32]. Pairwise comparisons are the well-recognized method of multi-criteria decision making [33, 34] and an effective way for eliciting qualitative data. The pairwise comparisons used in this study are shown in Table 2.

After normalizing the pairwise comparison values of Table 2, the summation of normalized values of each criterion provides the weight of CRs as shown in Table 3.

The next phase is to generate concepts for the bed table in line with the requirements of the design element as shown in Table 1. Careful consideration of CRs weight, and accordingly proposing the concept would yield higher profit and competitive advantage to the company. For the proposed case, the primary objective function or maximum weight among the expectations of the customer is of “foldable” (weight of importance: 0.18278618). Therefore, this was considered as the most important technical requirement that needs to be improved first. One probable solution to address this is to use the hinge. The second most important factor was found to be “adjustable” (weight of importance: 0.14786853), which after lengthy discussions, was addressed by providing adjustable legs through adjustable leg screws or crutch. Accordingly, the weigh customer expectations (Table 3) are addressed.

Based on the identified ingredients, it is advised that the designer should generate and select the best idea to satisfy the product ingredients having high weight first. For example, for the bed table, the priority are foldable, adjustable, vibration, safety, ergonomics, shock loading, cost, aesthetics and easy to clean. If required the evolved concepts may be refined. This may involve the designer solving an unworkable part of the solution. Once the design concept meets all of the functions or product ingredients, the concept is ready for product architecture phase. It would be easy to evolve effective, manufacturable and feasible concepts.

5 Results and Discussion

The proposed method provides a systematic way to capture customer requirement and, to convert requirement into concept on the basis of sound technical knowledge and information. Figure 1 shows working prototype for the user study and demonstrates the product usage. This method transforms the design process from a creative activity to a systematic decision-making process and helps in evolving the most optimal concept design. Analysis of design ingredients (as shown in Table 1) allows the designers to be efficient and yet comprehensive in determining proper design choices as per the customer requirement. With the aid of customer requirements weight, maximum customer expectations are addressed in the proposed concept.

6 Conclusions

Identifying, understanding and meeting the customer expectations correctly are very important for product development. Precise and effective considerations of customer expectations, and accordingly improving products and services yield higher profits and competitive advantages to the companies. For the success of any product, the evolved concepts should aspire to meet maximum customer needs. This work reports a new systematic framework to capture customer requirements to generate concepts within optimal design space. The proposed thirty-four design ingredients define customer requirements precisely and represent domain information for the designers. However, the success of the method greatly depends on the implementation, which in turn depends on the customer inputs and the designer experience. If the conditions are fulfilled, the proposed method becomes a powerful tool for the designer, which provides a strong support in the process of new product design as per the customer expectation.

References

Wheelwright, S.C., Clark, K.B.: Revolutionizing Product Development: Quantum Leaps in Speed, Efficiency, and Quality. Simon and Schuster (1992)

Anderson, D.M., Pine, J.: Agile Product Development for Mass Customization: How to Develop and Deliver Products for Mass Customization, Niche Markets, JIT, Build-to-Order, and Flexible Manufacturing. McGraw-Hill, New York. http://ecsocman.hse.ru/text/19156922/ (1996)

Ulrich, K.T.: Product Design and Development. Tata McGraw-Hill (2003)

Griffin, A.: Obtaining customer needs for product development. PDMA Handb. New Prod. Dev. 153–166 (1996)

Ye, X., Liu, H., Chen, L., Chen, Z., Pan, X., Zhang, S.: Reverse innovative design—an integrated product design methodology. Comput. Aided Des. 40(7), 812–827 (2008)

McMahon, C.: Design informatics: supporting engineering design processes with information technology. J. Indian Inst. Sci. 365–378 (2016)

Nishino, N., Takenaka, T., Koshiba, H., Kodama, K.: Customer preference based optimization in selecting product/service variety. CIRP Ann. Manufact. Technol. 63(1), 421–424 (2014)

Chan, L.K., Wu, M.L.: Quality function deployment: a literature review. Eur. J. Oper. Res. 143(3), 463–497 (2002)

Alexouda, G.: A user-friendly marketing decision support system for the product line design using evolutionary algorithms. Decis. Support Syst. 38(4), 495–509 (2005)

Harding, J.A., Popplewell, K., Fung, R.Y., Omar, A.R.: An intelligent information framework relating customer requirements and product characteristics. Comput. Ind. 44(1), 51–65 (2001)

Herrmann, A., Huber, F., Braunstein, C.: Market-driven product and service design: bridging the gap between customer needs, quality management, and customer satisfaction. Int. J. Prod. Econ. 66(1), 77–96 (2000)

Khoo, L.P., Chen, C.H., Yan, W.: An investigation on a prototype customer-oriented information system for product concept development. Comput. Ind. 49(2), 157–174 (2002)

Xu, L., Li, Z., Li, S., Tang, F.: A decision support system for product design in concurrent engineering. Decis. Support Syst. 42(4), 2029–2042 (2007)

Van De Poel, I.: Methodological problems in QFD and directions for future development. Res. Eng. Design 18(1), 21–36 (2007)

Kano, N., Seraku, N., Takahashi, F., Tsuji, S.: Attractive quality and must-be quality. J. Jpn. Soc. Qual. Control 147–156 (1984)

Lee, Y.-C., Huang, S.-Y.A.: New fuzzy concept approach for Kano’s model. Expert Syst. Appl. 36(3, Part 1), 4479–4484 (2009)

Hemati, M., Ghorbanian, F.: A hybrid Kano-fuzzy AHP method for measuring customer satisfaction: a case study of transportation system. Manag. Sci. Lett. 1(3), 263–270 (2011)

Chen, C.C., Lin, Y.C.: Integration of Kano model into TOPSIS method for effective product assessment. Appl. Mech. Mater. 475–479 (2012)

Lim, J.H., Min, D.K., Kim, K.J.: Fuzzy KANO model: fuzzy set-based classification of customer requirements. J. Korean Soc. Qual. Manage. 31(3), 98–113 (2003)

Nagamachi, M., Ito, K., Tsuji, T.: Image technology based on knowledge engineering and its application to design consultation. In Proceedings of the 10th Congress of International Ergonomics Association (1988, December)

Nagamachi, M.: Kansei engineering: a new ergonomic consumer-oriented technology for product development. Int. J. Ind. Ergon. 15(1), 3–11 (1995)

Liang, R.Y., Chen, D.X., Wang, T.Y., Zhang, X., Wu, K.F., Lin, F.X., Li, Y.C.: The research on the application of kansei engineering in the product design. Adv. Mater. Res. 690, 3453–3456 (2013)

McLoone, H., Jacobson, M., Goonetilleke, R.S., Kleiss, J., Liu, Y., Schütte, S.: Product design and emotion: frameworks, methods, and case studies. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, vol. 56, no. 1, pp. 1940–1941 (2012)

Chowdhury, A., Reddy, S.M., Chakrabarti, D., Karmakar, S.: Cognitive theories of product emotion and their applications in emotional product design. In ICoRD’15, vol. 1, pp. 329–340. Springer, Berlin (2015)

Lin, Y.C., Lai, H.H., Yeh, C.H.: Consumer-oriented product form design based on fuzzy logic: a case study of mobile phones. Int. J. Ind. Ergon. 37(6), 531–543 (2007)

Wang, Y., Tseng, M.M.: Incorporating probabilistic model of customers’ preferences in concurrent engineering. CIRP Ann. Manuf. Technol. 57(1), 137–140 (2008)

Un, C.A., Cuervo-Cazurra, A., Asakawa, K.: R&D collaborations and product innovation. J. Prod. Innov. Manage 27(5), 673–689 (2010)

Pahl, G., Beitz, W., Feldhusen, J., Grote, K.H.: Engineering Design: A Systematic Approach, vol. 157. Springer, Berlin (2007)

Hubka, V., Eder, W.E.: Theory of Technical Systems: A Total Concept Theory for Engineering Design, p. 291. Springer, Berlin (1988)

Pugh, S.: Total Design: Integrated Methods for Successful Product Engineering, pp. 44–45. Addison-Wesley, Wokingham (1991)

Roozenburg, N.F., Eekels, J.: Product Design: Fundamentals and Methods, vol. 2. Wiley, Chichester (1995)

Saaty, T.L.: The Analytic Hierarchy Process. McGraw-Hill, New York (1980)

Yannou, B., Coatanea, E.: Easy and flexible specifications and product evaluations by expert and customer comparisons with existing products. In: International Conference on Engineering Design: ICED’07, Paris 28–31 Aug 2007

Petiot, J.-F., Yannou, B.: Measuring consumer perceptions for a better comprehension, specification and assessment of product semantics. Int. J. Ind. Ergon. 33(6), 507–525 (2004)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Kumar, P., Tandon, P. (2017). Improvised Concept Development Process in Design Through Product Ingredients. In: Chakrabarti, A., Chakrabarti, D. (eds) Research into Design for Communities, Volume 2. ICoRD 2017. Smart Innovation, Systems and Technologies, vol 66. Springer, Singapore. https://doi.org/10.1007/978-981-10-3521-0_39

Download citation

DOI: https://doi.org/10.1007/978-981-10-3521-0_39

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-3520-3

Online ISBN: 978-981-10-3521-0

eBook Packages: EngineeringEngineering (R0)