Abstract

After the full power operation of the 10 MW High Temperature Gas-cooled Reactor-Test Module (HTR-10), two reactivity insertion tests were successfully conducted on this reactor by withdrawing a single control rod under 30% rated power. The reactor shutdown system was intentionally bypassed during such kind of tests, thus reflecting the anticipated transient without scram (ATWS) scenario. In the two tests, 1 and 5‰ ∆k/k positive reactivity were, respectively, introduced into the core by the control rod movement. In this study, post-test analyses are performed for the HTR-10 reactivity insertion ATWS tests using the THERMIX code. Both the analysis and the test results indicate that in the case of inadvertent control rod withdrawal the HTR-10 can be automatically shut down merely due to the negative reactivity feedback. The investigation of the reactor recriticality and the power oscillations in long term leads to a better understanding of the HTR-10 transients. For each test, the code reproduces the reactor power reasonably and accurately. Good agreement between the calculations and the tests proves the THERMIX simulation capability for the HTR-10 reactivity insertion ATWS tests.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

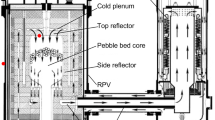

The 10 MW High Temperature Gas-cooled Reactor-Test Module (HTR-10) is a graphite-moderated and helium-cooled pebble-bed reactor located in the Institute of Nuclear and New Energy Technology (INET) of Tsinghua University. Figure 1 shows the primary system of the HTR-10 [1]. The reactor and the steam generator are installed in two separate steel pressure vessels and connected to each other by a horizontal hot gas duct pressure vessel. Under normal operation, all these steel pressure vessels are in touch with the cold helium coming from the helium circulator.

After the HTR-10 full power operation in 2003, two reactivity insertion tests were successfully conducted by withdrawing a single control rod under 3 MW power level. With the purpose of representing the anticipated transient without scram (ATWS) scenario, the reactor shutdown system was intentionally bypassed during such kind of tests. In the first test 1‰ ∆k/k positive reactivity was generated, while in the second one 5‰ ∆k/k positive reactivity was introduced [2].

In INET, the THERMIX code is one of the main tools for thermal hydraulics calculation and accident analysis of pebble-bed high-temperature reactors (HTRs). In this study, the two reactivity insertion ATWS tests are reanalysed using this code. Both the simulation and the test results reveal the built-in passive safety features of the HTR-10, i.e. during reactivity insertion ATWS condition, the reactor power at first increases because of the control rod withdrawal, but soon decreases rapidly to the decay heat level merely due to the negative reactivity feedback. In long term, the reactor meets recriticality and experiences several power oscillations before the final stabilization. Satisfactory agreement between the analysis results and the test data indicate the applicability and reasonability of the THERMIX code.

2 Test Conditions

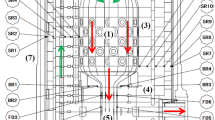

Before the initiation of a reactivity insertion ATWS test, it was confirmed that the HTR-10 was under normal operation of 3 MW (30% rated power). From the test procedure illustrated in Fig. 2, it can be seen that the reactor shutdown system was bypassed to represent the ATWS conditions, and each test was initiated by withdrawing a single control rod. The rod position during the two tests is presented in Fig. 3. The initial conditions of the two tests were very close. The helium inlet temperature was about 207 °C, and the outlet temperature was about 650 °C.

The HTR-10 shutdown system contains 10 control rods, which are symmetrically arranged in the side reflector. Through the reactivity worth measurement test [3], the worth curve of a single control rod was obtained, as shown in Fig. 4. The integral worth is about 14 × 10−3 ∆k/k, and the linear segment of the curve is from 600 to 1500 mm of the rod position. The control rod movement can change the reactor power directly via the reactivity insertion into the core.

3 Analysis Code

The THERMIX code is used for the reanalysis of the two reactivity insertion ATWS tests. It is a modular software package for steady-state thermal-hydraulic calculation as well as transient analysis of pebble-bed HTRs. The code mainly comprises modules for neutron kinetics calculation, solid heat conduction calculation in reactor, gas convection calculation in reactor and fluid flow calculation in primary circuit. Detailed description of these modules is given by Gao and Shi [4, 5]. For the HTR-10, main components (the pebble-bed core, the graphite reflectors, the carbon bricks and the reactor pressure vessel, etc.), flow passages (e.g. the reactor core, the cold helium channels, the cold and the hot helium plena) and different components in the primary circuit (including the hot gas duct, the steam generator, the helium circulator) can be modelled by the THERMIX code.

4 Analysis Results

According to the actual test conditions, the dynamic simulations of the two reactivity insertion ATWS tests are performed for 3 h using the THERMIX code.

The reactor power transients during the two tests are, respectively, shown in Figs. 5 and 6, from which similar phenomena can be observed. After the initiation of such tests, the reactor power increases very fast due to the positive reactivity insertion caused by the control rod withdrawal. At 20 s in the first test and at 12 s in the second test, the signal of “power growth rate is too high” comes to trigger the reactor protection system. Although the control rods cannot be inserted into their guide channels, the helium circulator is stopped and the blower baffle is closed, and therefore, the reactor core loses forced cooling. The power ascension and the core heat-up make the fuel temperature rise rapidly. Due to a considerable negative reactivity feedback, the reactor is shut down. Accordingly, the reactor power decreases sharply to residual heat level after a peak value. In the first test, the calculated peak power is 5146 kW occurring at 30 s, while the test result reaches 5037 kW at 23 s. In the second test, the peak power is about 7240 kW at 30 s, and the calculation result agrees well with the test result.

As shown in Fig. 7, the average fuel temperature after the reactor shutdown still increases because the instantaneous reactor power is still larger than the heat dissipated from the core. This makes the total reactivity in the core continuously drop, as presented in Fig. 8. Along with the core cooldown, the fuel temperature begins to decrease, and thus, the total reactivity begins to increase from its minimum. According to the code results, the reactor becomes recritical at 2815 s in the first test and at 2250 s in the second test since the total reactivity reaches zero at these time points. Because of the recriticality, the fuel temperature rises once again after its downtrend is stopped. Hence, the total reactivity declines again after experiencing a maximum. Soon, the reactor becomes subcritical once more after the total reactivity descends to zero.

In long term, the reactor power, the fuel temperature and the total reactivity oscillate several times due to the interaction of these three parameters. In the two tests, the measured reactor power stabilizes at about 180 kW. As regards the long-term behaviour, the phenomena of reactor recriticality, power fluctuations and final stabilization are well reproduced by the THERMIX code. In the first test, the calculated first peak power after the recriticality approaches 1070 kW at 3920 s, while the measured value is 853 kW that occurs at 4240 s. In the second test, the calculation result approaches 1152 kW at 3245 s, while the test one is 845 kW that occurs at 3400 s.

The safety limit for the maximum fuel temperature is 1620 °C. During the two tests, this value is never exceeded, as illustrated in Fig. 9.

5 Conclusions

In this study, two reactivity insertion ATWS tests are reanalysed using the THERMIX code. The investigation results lead to the following conclusions.

-

(1)

Following the initiation of such tests, the reactor power rises rapidly due to the positive reactivity insertion and then decreases because of the negative reactivity feedback. The short-term peak power is sensitive to the amount and the rate of the external reactivity.

-

(2)

As a result of bypassing the shutdown system, the reactor meets criticality again because of the positive reactivity produced by the core cooling.

-

(3)

In the two tests, the reactor power finally maintains a stable level after some oscillations. The heat generated by the core can be rejected by the passive cavity cooling without any problems.

-

(4)

The maximum fuel temperature, which is the most important safety-related parameter, is always far below the safety limit of 1620 °C.

-

(5)

For each test, THERMIX can reproduce good results for the power transient. It is concluded that this code is a useful tool for reanalysing these two tests.

References

Z. Wu, D. Lin and D. Zhong, “The design features of the HTR-10”, Nuclear Engineering and Design, Vol. 218, No. 1–3, pp. 25–32, 2002.

S. Hu, R. WANG, and Z. Gao, “Safety Demonstration Tests on HTR-10”, 2nd International Topical Meeting on High Temperature Reactor Technology, Beijing, China, 2004.

Q. Su, R. Wang, S. Hu, et al. Commissioning procedures of the 10 MW high temperature gas-cooled reactor-test module. Nuclear Engineering and Design, 2002, 218(1–3): 241–247.

Z. Gao and L. Shi, “Thermal hydraulic calculation of the HTR-10 for the initial and equilibrium core”, Nuclear Engineering and Design, Vol. 218, No. 1–3, pp. 51–64, 2002.

Z. Gao, L. Shi. Thermal hydraulic transient analysis of the HTR-10. Nuclear Engineering and Design, 2002, 218(1–3): 65–80.

Acknowledgments

This work has been supported by the Chinese National S&T Major Project (Grant No. ZX069).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Science+Business Media Singapore

About this paper

Cite this paper

Gou, F., Chen, F., Dong, Y. (2017). Power Transients of the HTR-10 During Reactivity Insertion ATWS Tests. In: Jiang, H. (eds) Proceedings of The 20th Pacific Basin Nuclear Conference. PBNC 2016. Springer, Singapore. https://doi.org/10.1007/978-981-10-2314-9_18

Download citation

DOI: https://doi.org/10.1007/978-981-10-2314-9_18

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-2313-2

Online ISBN: 978-981-10-2314-9

eBook Packages: EnergyEnergy (R0)