Abstract

This chapter describes a knowledge-based system (KBS) for automatic design of bending dies. The system is developed using the production rule based approach of artificial intelligence (AI). The overall system is organized in 3 subsystems and 19 modules. System modules are coded in visual basic 6.0 language. The system is integrated with inventor CAD software. The proposed system automates all activities of design of bending die and finally gives outputs in form of drawings of die components and die assembly. It eliminates the dependency on domain experts for die design. The system is easy to operate and its knowledge base can be modified and/or updated on the advancement in technology in future.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Sheet metal parts are widely used in automobiles, electrical and electronic equipments, computer hardware, home and office furniture, kitchen utensils, and other similar products. Sheet metal operations are used to produce these parts. Sheet metal operations are performed using punch and die setup, commonly known as die or press tool, in a press machine. A die has a complex structure consisting of several components. Die block, punch(es), stripper plate, punch plate, back plate, die-set, etc., are some major components of a die. To manufacture good quality parts, die design is an important activity in tool design department of sheet metal industries.

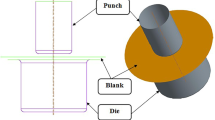

Bending shapes are obtained using bending process. Bending is one of the most common sheet metal forming processes. It is used to form the various shapes like L, U, V, and Z from sheet metal blanks. It improves the stiffness of blank by increasing its moment of inertia. Bending process has wide applications in electrical, electronic, automobile, aircraft, aerospace, pharmaceutical, refrigeration, and air-conditioning industries. Figure 1 shows a typical bending process. The downward movement of punch applies force on the blank which results in bending. Thereafter, the punch moves back in upward direction and the bent part is extracted from the die. The blank undergoes compressive stress on the concave side and tensile stress on convex side during bending operation. The inner radius of bent part depends on the radius of die opening.

Bending process is performed using a suitable type of bending die mounted in a press machine. Bending dies are generally classified into three types (Boljanovic 2004):

-

(i)

Wiping die,

-

(ii)

U-bending die, and

-

(iii)

V-bending die.

Wiping die is used to perform edge bending as shown in Fig. 1. U-bending die is used to produce U shaped bending parts. Similarly, V-bending die is used to form V-shaped bending parts. The sheet metal blank is bent between a V-shaped punch and die in V-bending die.

1.1 Design of Bending Dies

Die design is a highly specialized area and therefore usually performed by experienced and highly skilled die designers in sheet metal industries (Singh and Rao 1997; Kumar and Singh 2004, 2007; Lin and Hsu 2008; Narayanan 2010). In die design process, die designer needs to recognize design features of sheet metal part, check the features from manufacturability point of view, determine process planning parameters, select proper size of die components, and lastly prepare the drawings of die components and die assembly. Manual process of design of bending die is complex, time consuming, error prone, and skill-intensive (Cheok and Nee 1998a, b; Kumar and Singh 2011). Nowadays, some commercial softwares (AutoCAD, Inventor, CATIA, Pro-E, IDEA, Solid Edge, Unigraphics NX, CADCEUS, etc.) are being used in sheet metal industries for die design. These softwares assist the die designer in simple calculations, drafting, and storage and retrieval of data and drawings. But these systems are not capable to automate the die design process and need experienced persons to operate and interpret the results. Few software packages are developed specifically for the design of bending dies. For example, a dedicated tool “act/unfold” for unfolding of bending parts is developed by M/s Alma CAM of USA. The tool is unfolding software that uses table approach as well as neutral axis method. Since the tool is independently developed so integration approach is missing. M/s Autodesk’s Inventor software has a sheet metal modeling environment in which sheet metal bending parts can be modeled. M/s Dassualt System’s software CATIA has a tool named as generative sheet metal Design. The main features of the software are associative and dedicated sheet metal feature-based modeling, concurrent engineering between the unfolded or folded part representations, access to predeveloped standards tables, dedicated drawing capability including unfolded view and specific setting. The specialized CAD software “MetaBEND” is a product of M/s Metamation of United States. Key features of the CAD system are bend sequencing and collision checking optimized tool selection.

1.2 Knowledge-Based System

Knowledge-based system (KBS) is an important technique of artificial intelligence (AI) (Poole and Mackworth 2010). It is an intelligent computer program that uses knowledge and inference procedures to solve problems that are difficult enough to require significant human expertise for their solution (Feigenbaum 1981). As depicted in Fig. 2, a KBS has three main elements—knowledge base, inference mechanism, and user interface. The knowledge base contains domain knowledge, which may be expressed as any combination of IF-THEN rules, factual statements, frames, objects, procedures and cases. The inference mechanism allows manipulating the stored knowledge for solving problems. User interface is a platform of interaction between user and system. The use of KBS is proliferating in many domains, where their applications are proving to be critical in the process of decision support and problem solving. KBS has wide applications in engineering domain such as state transition analysis, production planning, advisory system, electronic power planning, automobile process planning, system development, knowledge verification/validation, knowledge base maintenance, scheduling strategy, communication system fault diagnosis, material processing design, resource utilization, probabilistic fault diagnosis, load scheduling, geoscience, sensor control, etc. (Kusiak 1990; Meziane et al. 2000; Liao 2005).

2 Literature Review

In the past sheet metal forming was heavily dependent on skills of workers. However, with increased production demands, this procedure was replaced by automated stamping, which today is one of the most widely used manufacturing process to plastically deform sheet metals into desired shapes. With the advancement in the area of CAD/CAM and artificial intelligence (AI), some researchers (Karima and Richardson 1987; Shpitalni and Saddan 1994; Cheok and Foong 1996; Huang et al. 1996; Singh and Sekhon 1998; Duflou et al. 1999; Cakir et al. 2005; Kim et al. 2006; Kumar and Singh 2011) started to exploit these techniques for the design of stamping dies.

Major published work related to the applications of CAD and KBS in the area of process planning of bending parts, and bending die design is discussed in this section.

2.1 Process Planning of Bending Parts

Worldwide researchers have applied research efforts to ease the complexity of process planning of sheet metal parts. For example, Hoffmann et al. (1992) developed a bending sequence generator and tool selection as part of a computerized process planning tool labeled as MANICAP. Shpitalni and Saddan (1994) proposed a technique for automatic determination of bending sequences in sheet metal parts. In this technique, the problem of automatic tool selection and bending sequence determination are formulated as a graph search problem. Vin et al. (1994) reported a bend sequencing approach which provides emphasis on the accuracy aspect. They used integrated approach of bend sequencing with other process planning parameters like planning and selection of tools, and blank size. Huang and Leu (1998) studied the effects of process variables in V-bending of steel sheet. Gupta et al. (1998) developed a process planning system for sheet metal parts for generation of possible bending sequences and manufacturing costs, selection of punches and dies, interference checking, gripper selection and robot motion plan, and near optimal plan development. Duflou et al. (1999) derived an algorithm for design verification and automatic process planning for bent sheet metal parts. Later they (Duflou et al. 2005) presented a tool selection methodology to be integrated in the automatic bend sequencing system. Shigeru and Koguchi (2002) proposed a method, which generates bending sequence for a sheet metal part handled by a robot. Rico et al. (2003) developed a system to obtain valid bending sequences automatically according to the possible tool–part collisions and tolerances. Sousa et al. (2006) presented an optimization method applied to the design of V and U-bending sheet metal processes. Mkaddem and Saidane (2007) examined springback in wiping die bending process using experimental approach and response surface methodology (RSM). Bozdemir and Golcu (2008) defined the springback angle with minimum error using the best reliable ANN training algorithm. Fu et al. (2010) optimized the process of multiple-step incremental air-bending forming of sheet metal by using genetic algorithm-back propagation neural network prediction and finite-element model simulation. Kontolatis and Vosniakos (2010) applied sheet metal bending processes in a multitude of mechanical parts. Thipprakmas and Phanitwong (2011) described process parameters of spring back in V-bending process using Taguchi technique. Lin (2012) proposed an approach of bending sequence for process planning of bending parts.

2.2 Bending Die Design

Since its emergence in the 1950s, AI has provided several techniques that have been used in efforts to solve some complex and narrow domain industrial problems. The KBS/expert system (ES), neural networks (NN), fuzzy logic (FL), multi agents (MA), genetic algorithms (GA), and simulated annealing (SA) are important AI techniques. Among these techniques, KBS is one of the most promising developments (Ismail et al. 1995). The KBS approach is being used in sheet metal industries for manufacturability assessment, process planning, strip-layout design, die design, die material selection, etc., Karima and Richardson (1987) conceptualized application of KBS in sheet metal forming industry. The system supports in converting the knowledge acquired from relevant sources into facts, procedures, judgment and control. Karima (1989) proposed a hybrid system for process planning in sheet metal forming. System considers the overall process of stamping engineering from the micro and the macro perspectives. Shpitalni and Saddan (1994) presented an application “BEND” of the graph search method for the generation of bending sequences. Lin and Chang (1996) developed an expert system for the selection of sheet metal bending tool. Ong et al. (1997) reported to develop a fuzzy set system to determine the sequence of bending operations in press brake machines. Gupta et al. (1998) proposed a process planning system for sheet metal parts. They applied a greedy algorithm to determine the bending sequence. Duflou et al. (1999) suggested a penalty function method and the traveling salesman problem method to determine bending sequences in press brake machines. Cakir et al. (2005) proposed an expert system for die and mold making operations. System requires the input from the user for part geometry and material, tool condition, and operation type. Kim et al. (2006) developed a fuzzy set theory method for determining the sequence of bending operations. Farsi and Arezoo (2009) proposed a procedure for bend sequencing determination with Fuzzy sets. Kumar and Singh (2011) developed an intelligent progressive die design system named as “INTPDIE” using KBS approach. Naranje and Kumar (2014) proposed a KBS for automatic design of deep drawing dies. Nasr et al. (2014) reported an expert system for design of sheet metal blanking dies.

The reviewed literature reveals the growing interest of worldwide researchers and technocrats in the area of computer aided die design for sheet metal work. Commercial CAD softwares being used in sheet metal industries assist die designer to reduce the design time to some extent and hence increase productivity. But these are unable to fully automate the die design process. Further, die designer needs to use multiple software packages for various activities of die design process and faces problems pertaining to nonexistence of connectivity between these softwares. Also these systems are costly and hence unaffordable for small scale industries, especially in developing countries. Further well trained, competent and experienced persons are required to operate these softwares and interpret the results. Some researchers have applied efforts to develop KBSs for die design. But very less effort is applied to automate the design of bending dies. Further, the systems reported in the literature for bending dies are not able to accomplish all design tasks and not fully automatic. Also domain experts are required to operate and accomplish the die design process.

The present chapter describes a KBS developed for automatic design of bending dies.

3 Proposed KBS for Automatic Design of Bending Dies

As the design task of bending die involves various activities, therefore, the proposed system namely ASDBD ( Automatic System for Design of Bending Dies) has been organized into various subsystems and modules as depicted in Fig. 3. The subsystems and modules are briefly described as under (Panghal and Kumar 2013).

3.1 Subsystem PPBP

The subsystem namely PPBP (Process Planning of Bending Parts) is developed for process planning of sheet metal parts produced on bending die. System is structured in form of five modules as listed below.

-

(i)

Module SPRINGBA for determination of springback angle,

-

(ii)

Module BALOW for calculation of bend allowance,

-

(iii)

Module BSIZE for determination of blank size,

-

(iv)

Module BSEQ for determination of bending sequence, and

-

(v)

Module BFORCE for calculation of bend force.

(i) Module SPRINGBA

This module is developed for determination of springback angle. The Springback angle depends on sheet material, sheet thickness, and bend radius (Boljanovic 2004 ). It decreases with decrease in bend radius, sheet thickness, hardness of sheet material, and bend angle. There are certain parameters like punch radius, die radius, and clearance between punch and die which are used to control springback angle. Most of the die designers in sheet metal industries determine springback angle using their own thumb rules. After detailed discussion with domain experts, production rules are framed to develop KBS module for determining springback angle. The knowledge base of this module consists of more than 200 production rules coded in VB 6.0 language. A sample of production rules incorporated in the module is given in Table 1. The execution of this module is shown in Fig. 4. Module takes its inputs automatically from part data files PART.DAT and FE.DAT (generated during execution of computer aided system for feature extraction as discussed in Chap. 3). Finally it displays springback angle and stores this output in a data file namely SBA.DAT.

(ii) Module BALOW

Bend allowance is length of arc of neutral axis of a bend angle (Fig. 5). For a larger bend radius neutral axis is located approximately at the half of sheet thickness of bending part. The die designer needs to determine bend allowance for bending parts before designing the die (Boljanovic 2004). The general equation for the bend allowance (B.A.) at the neutral axis is given as:

where

-

φ = bend angle

-

R n = bend allowance radius at neutral axis (Fig. 4)

where

-

ξ = bend factor

-

R i = inner radius

Therefore, from Eqs. (1) and (2),

The value of bend factor (ξ) corresponding to R i /t ratio is given in Table 2 (Boljanovic 2004).

In the proposed system, a data base file for values of ‘ξ’ with respect to R i /t ratio is constructed to determine bend allowance. The execution of the module BALOW is shown in Fig. 6. The module recalls the data file FE.DAT (as discussed in Chap. 3) to read sheet thickness. Then the system searches the value of ξ corresponding to R i /t ratio in the data file. The intermediate values of ‘ξ’, which are not available in the database are determined by interpolation method. Finally, the system calculates bend allowance and displays it for the user. The value of bend allowance is stored automatically in a data file namely BALOW.DAT which is used further for determining blank size.

(iii) Module BSIZE

Blank size of a bending part depends on part shape (bend width, length of legs, bend angle, and bend radius) and bend allowance. A module namely BSIZE is developed for determination of blank size of part. Execution of the proposed module is depicted in Fig. 7. The module recalls data file FE.DAT, to read part detail. Bend allowance is taken from the data file BALOW.DAT generated during execution of previous module. Next, module unfolds all bends one by one using built-in API (application programming interface) namely ‘UNFOLD’ of Inventor software for determination of blank size. This API uses the matrix transformation approach for unfolding the bends. Finally module displays the three-dimensional (3-D) and two-dimensional (2-D) drawings of blank of bending part for the user. The 3-D drawing of blank is stored in a drawing file labeled as BSIZE.IPT.

(iv) Module BSEQ

For determination of bending sequence, a module namely BSEQ (Bending Sequence) is developed (Panghal et al. 2016). There are certain process variables like bend angle, position of a bend, angle with feed direction, etc., that play a vital role in deciding bend sequence. By considering these parameters, a procedure is developed to determine the bend sequence of a complex bending part. The steps to determine bend sequence are briefly described as under.

(a) Identification of base/mother plane

The base plane is most important plane in a bending part. All the bends are formed around it as it remains stationary during bending operation. Base plane is identified on the basis of following criteria:

-

It must be centrally located, i.e., base plane must be surrounded by maximum number of bends, and It must be the largest plane.

-

If more than one plane qualifies on the basis of above criteria, then selection of base plane is done on the basis of minimum distance between the centers of plane to the farthest bend axis among the qualifying planes.

To implement the above criteria, all planes of bending part are sorted area wise. The plane of highest area is awarded highest marks (i.e., 100 marks) and other planes are awarded marks as per their proportionate area with reference to the plane having highest marks. Thereafter, the planes are sorted as per number of surrounding planes. The plane with highest number of surrounded planes is awarded highest marks and other planes are awarded marks as per their proportionate number of surrounding planes. The plane having highest total marks (i.e., out of 200 marks) awarded as per the above two criteria is selected as base/mother plane. In case of tie of marks among the planes, then selection of base plane is done on the basis of minimum distance between the centers of plane to the farthest bend axis among the qualifying planes. The proposed procedure for identification of base plane is shown in Fig. 8.

(b) Categorization of Bends

Bends are required to be categorized in such a manner that they have highest probability of getting grouped together. Feed direction plays a vital role in categorization of bends. Bends can be categorized on the basis of bend axis position with reference to the feed direction, i.e., parallel, perpendicular, or inclined.

(c) Grouping of Bends

The bends from each category is required to be grouped together. The purpose of the grouping is to identify the bends which can be formed together. There are many variables on the basis of which bends can be grouped together. After detailed discussion with the domain experts and review of published literature, the following rules have been identified which have much impact on grouping of bends.

Rule1: Bends whose bend axis is coplanar and having the same direction (either up or down) can be grouped in the same group.

For example, in a typical bending part shown in Fig. 9 bends B1 and B2 are grouped in same group.

Rule 2: Bends that are equal number of bends away from the base plane and also have the same direction (either up or down) can be grouped in the same group.

For example, in a typical bending part as shown in Fig. 10, bends B1 and B2 should be grouped in the same group.

The above two rules are applied to all categories of bends individually. The procedure for grouping of bends is shown in Fig. 11.

(d) Prioritization of Bend Groups

There are number of variables that contribute in prioritization of groups. On reviewing published literature and detailed discussion with domain experts, the rules that are most significant in deciding the prioritization of groups are identified. All these rules do not have equal impact on deciding the sequence of groups. A significance factor for each rule is identified. The groups are awarded marks as per rules and further multiplied by individual significance factor. The total marks for individual groups are calculated. The groups are further sorted in descending order as per total marks obtained to decide the sequence of groups. The rules with their significance factor are tabulated in Table 3.

The above procedure is coded in VB 6.0 programing language. User can interact with the system through GUI. The system is parametric and automatic in nature. Execution of the proposed module is depicted in Fig. 12. The module reads 3-D drawing of blank from the file BSIZE.IPT generated during execution of BSIZE module. The module also recalls data file FE.DAT to take inputs such as sheet thickness, number of bends, bend angle, and bend direction. Thereafter, module sequentially performs the activities includes identification of base plane, bend categorisation, bend grouping, bend group prioritization, and finally displays the bending sequence through 3-D drawings of bending part. The output of the module in form of group sequence (along with detail of bends in each group) is stored in a data file namely BSEQ.DAT.

(v) Module BFORCE

Bending force depends on the strength of sheet material, size and thickness of bending part, and clearance between punch and die. Bending force is required to be calculated for different types of bends. A schematic diagram for bending force calculation is depicted in Fig. 13.

Schematic diagram for bending force calculation (Boljanovic 2004)

The formula used for force calculation is as follows:

where

- K :

-

bend Constant (values are listed in Table 4)

Table 4 Value of constant K (Boljanovic 2004) - S :

-

Ultimate tensile strength of material

- w :

-

Sheet metal width at bend

- t :

-

Sheet thickness

where

- r 1 :

-

punch corner radius

- c :

-

die clearance

- r 2 :

-

die corner radius

A module namely BFORCE is developed to calculate the bend force required to bend a part. The execution of this module is shown in Fig. 14. Module BFORCE reads essential input data from data files PART.DAT and FE.DAT. Then the module calculates the bend force and displays it for the user.

The Execution of subsystem PPBP is shown in Fig. 15. System initially takes input from PART.DAT file. Further, the required inputs related to design features of bending part are taken from another data file namely FE.DAT. The output of SPRINGBA module in the form of springback angle is stored in the data file namely SBA.DAT. The module namely BALOW is capable to determine bend allowance for all bend and the output of it is stored in the data file BA.DAT. The next module namely BSIZE is developed for determination of blank size of bend part. Bend allowance is taken from the data file BA.DAT generated during execution of previous module. The module recalls a built-in API (application programming interface) namely “UNFOLD” of Inventor software for determination of blank size. This API uses the matrix transformation approach for unfolding the bends. Finally module displays the three-dimensional (3-D) and two-dimensional (2-D) drawings of blank of bending part for the user. The outputs of the module stores in data file BSIZE.DAT. Next module namely BSEQ is used to determine the bend sequencing of bend part. The module reads 3-D drawing of blank from the file BSIZE.DAT generated during execution of BSIZE module. The module also recalls data file FE.DAT to take inputs such as sheet thickness, number of bends, bend angle, and bend direction. Thereafter module sequentially performs the activities including identification of base plane, bends categorization, bend grouping, bend group prioritization, and finally displays the bending sequence through 3-D drawings of bending part. The output of the module in form of group sequence (along with detail of bends in each group) is stored in a data file namely BSEQ.DAT. Finally, a module namely BFORCE is developed for determining the bend force. A module namely BFORCE developed to calculate the bend force required to bend a part. Module BFORCE reads essential input data from data files PART.DAT and BFE.DAT. The module calculates the bend force and displays it for the user.

3.2 Subsystem BDCOMP

A subsystem namely BDCOMP(Bending Die Components) is developed for selection of type and size of bending die components. It is structured in form of six KBS modules namely:

-

(i)

Module BDBLOCK for selection of die block,

-

(ii)

Module STPP for selection of stripper plate/pressure plate,

-

(iii)

Module PUNCH for selection of punch(es),

-

(iv)

Module PPBPLT for selection of punch plate and back plate,

-

(v)

Module DSET for selection of die-set, and

-

(vi)

Module FASTNR for selection of fasteners (bolts and dowels).

The knowledge base of proposed subsystem consists of more than 700 production rules coded in VB 6.0 language. A sample of production rules is given in Table 5. Execution of the system is shown in Fig. 16. For required inputs, the system reads data files PART.DAT and BSEQ.DAT generated during execution of process planning subsystem. Various modules of the system impart expert advices for selection of bending die components including die block, stripper plate/pressure plate, punch(es), punch plate, back plate, die-set, and fasteners. The module namely BDBLOCK imparts expert advice on the selection of die block. The outputs of modules are stored in different data files which can be recalled for automatic die modeling.

3.3 Subsystem AUTOBDMOD

A subsystem labeled as AUTOBDMOD (Automatic Bending Die Modeling) is developed for automatic modeling of die components and die assembly of bending die. This system works in conjunction with KBS modules developed for selection of die components of bending die. The outputs of various modules of subsystem BDCOMP are stored in different data files. These data files are recalled automatically for die modeling. The users need not to enter any input to the system. For development of the proposed subsystem, Visual Basic (VB 6.0) program is written to invoke commands of Inventor software such as EXTRUDE, DRAFT, CHAMFER, etc., for 3-D modeling of die components and die assembly. To generate 2-D drawings, a computer code in VB 6.0 language is written to open 3-D files into drawing view of Inventor software. The developed computer code also ensures the proper scaling and automatic dimensioning of 2-D drawings. Graphic user interface (GUI) of the proposed system is developed using VB 6.0 and is interfaced with Inventor software. The subsystem AUTOBDMOD is structured into eight modules namely:

-

(i)

Module DBMOD for modeling of die block,

-

(ii)

Module STPPMOD for modeling of stripper plate and pressure plate,

-

(iii)

Module PUNCHMOD for modeling of punch(es),

-

(iv)

Module PPMOD for modeling of punch plate,

-

(v)

Module BPMOD for modeling of back plate,

-

(vi)

Module DSMOD for modeling of die-set,

-

(vii)

Module DBAMOD for modeling of die bottom assembly, and

-

(viii)

Module DTAMOD for modeling of die top assembly.

Execution of the proposed subsystem AUTOBDMOD is shown in Fig. 17. The first module namely BDMOD is developed for automatic modeling of die block of bending die. This module takes required inputs from data files DBLOCK.DAT and FASTNR.DAT generated during the execution of KBS modules developed respectively for selection of die block and fasteners. Finally, the module generates 2-D and 3-D drawings of die block in the drawing editor of Inventor software. 3-D drawing is saved automatically as a global block namely GDBMOD. The next module labeled as STPPMOD is constructed for automatic modeling of stripper plate/pressure plate. Inputs in form of size of stripper plate/pressure plate and fasteners are read automatically from the data files namely STPP.DAT and FASTNR.DAT generated during execution of previously developed KBS modules of subsystem BDCOMP. Finally, the module generates 2-D and 3-D drawings of stripper plate/pressure plate. The output in form of 3-D drawing is stored automatically in a global block namely GSTPPMOD. The module namely PUNCHMOD is developed for automatic modeling of punch(es) of bending die. The module takes input automatically from data file PUNCH.DAT. The module generates 2-D and 3-D drawing of punch(s). The 3-D drawing is saved automatically as global block namely GPUNCHMOD. The module labeled as PPMOD is developed to generate drawings of punch plate of bending die. The module takes inputs in the form of size of punch plate from the data file PPBLT.DAT and number and size of fasteners from the data file FASTNR.DAT. Output in form of 3-D drawing of punch plate is saved as a global block namely GPPMOD. The module namely BPMOD takes required inputs from data files PPBLT.DAT and FASTNR.DAT. Finally it generates 3-D and 2-D drawings of back plate. The 3-D drawing of back plate is automatically saved as a global block namely GBPMOD. The module DSMOD is constructed for modeling of die-set of bending die. The module takes required input from data file DSET.DAT and FASTNR.DAT. The 3-D drawing of die-set is automatically saved as global block namely GDSETMOD. The modules labeled as DBAMOD and DTAMOD are developed, respectively for automatic modeling of bottom die assembly and top die assembly of bending die. Bottom die assembly consists of die holder plate of die-set, die block, and pressure plate (in case of U-die only). Top die assembly is a unit of punch holder plate of die-set, back plate, punch plate, punch(es) and stripper plate. The proposed modules compute reference point on die-set for inserting global blocks of respective die components to generate 3-D drawings of bottom die assembly and top die assembly. The 2-D drawings are generated automatically from 3-D files.

4 Validation of System ASDBD

The developed system ASDBD has been tested successfully for different sheet metal parts taken from stamping industries. A sample run of the system for one sheet metal part (Fig. 18) of stamping industry namely M/s Kochar Agro Industries Pvt. Ltd. Faridabad, India is depicted in Figs. 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39, 40, 41, 42, 43, 44, 45, 46, 47, 48, 49, 50, 51, 52, 53, 54, 55, 56, 57, 58 and 59. The recommendations obtained by the system were found very similar to those actually used in the sheet metal industries for the example part. In sheet metal industries, experienced die designers use various commercial CAD softwares for drafting of die components. These softwares are not only costly (cost of a single software is more than 4 Lakhs Indian Rupees) but also not capable to automate die design process. Highly experienced persons are required to accomplish all tasks of die design. The developed system executes the tedious task of design of bending die in less than an hour and gives final outputs in form of drawings of die components and die assembly which can be used directly for die manufacturing. Even a novice can perform the die design using this system. Therefore, it eliminates dependency on domain experts. The system is implemented on a PC having Inventor software (Cost is approximately 3 Lakhs Indian Rupees). Therefore, its low cost of implementation makes it affordable even for small scale industries.

5 Conclusions

The developed system automates all major activities of design of bending dies including process planning, selection of type and size of die components, and modeling of die components and die assembly. The system takes most of the required inputs directly from the output data files generated during execution of CAD system of automatic feature extraction and KBS of manufacturability assessment as discussed in Chap. 3. Thereafter, the system modules select various process parameters like bend allowance, part blank size, bend sequencing, and bend force. Next, the system selects the type and size of various die components including die block, stripper plate/pressure plate, punch(es), punch plate, back plate, die-set, and fasteners. Finally, the system generates 2-D and 3-D drawings of all major die components, and bottom and top die assembly of bending die. These drawings can be directly used for die manufacturing. The developed system has been tested successfully on various types of sheet metal parts taken from stamping industries. The system is integrated and parametric in nature.

References

Boljanovic V (2004) Sheet metal forming processes and die design. Industrial Press Inc., New York

Bozdemir M, Golcu M (2008) Artificial neural network analysis of springback in V bending. J Applied Science 8(17):3038–3043

Cakir MC, Irfan O, Cavdar K (2005) An expert system approach for die and mold making operations. Robot Comput Integr Manuf 21(2):175–183

Cheok BT, Nee AYC (1998a) Configuration of progressive dies. Artif Intell Eng Des Anal Manuf 12:405–418

Cheok BT, Nee AYC (1998b) Trends and developments in the automation of design and manufacture of tools for metal stampings. J Mate Process Technol 75:240–252

Cheok BT, Foong KY (1996) An intelligent planning aid for the design of progressive dies’. Proc Inst Mech Eng, Part B: J Eng Manuf 210:25–35

Duflou J, Kruth, JP, Oudheusden DV (1999) Algorithms for the design verification and automatic process planning for bent sheet metal parts. CIRP Annals Manuf Technol 48(1):405–408

Duflou JR, Nguyen THM, Kruth JP, Cattrysse D (2005) Automated tool selection for computer-aided process planning in sheet metal bending. CIRP Annals Manuf Technol 54:451–454

Farsi MA, Arezoo B (2009) Development of a new method to determine bending sequence in progressive dies. Int J Adv Manuf Technol 43:52–60

Feigenbaum E (1981) Handbook of artificial intelligence. Heuris Tech Press, W. Kaufman Inc, California

Fu Z, Moa J, Chen L, Chen W (2010) Using genetic algorithm-back propagation neural network prediction and finite-element model simulation to optimize the process of multiple-step incremental air-bending forming of sheet metal’. Mater Des 31:267–277

Gupta SK, Bourne DA, Kim KH, Krishnan SS (1998) Automated process planning for sheet metal bending operations. J Manuf Syst 17:338–360

Hoffmann M, Geifiler U, Geiger M (1992) Computer-aided generation of bending sequences for die-bending machines’. J Mater Process Technol 30:1–12

Huang K, Ismail HS, Hon KKB (1996) Automated design of progressive dies. Proc Inst Mech Eng Part B: J Eng Manuf 210:367–376

Huang YM, Leu DK (1998) Effects of process variables on V-die bending process of steel sheet. Int J Mech Sci 40(1):631–650

Ismail HS, Hon KKB and Huang K (1995) An intelligent object oriented approach to the design and assembly of press tools. Ann CIRP 44(1):91–96

Karima M (1989) On the micro and macro perspectives of stamping engineering. J Mater Shaping Technol 7(4):213–227

Karima M, Richardson J (1987) A knowledge based system framework for computer-aided technology in metal forming. J Mech Working Technol 15(3):253–273

Kim JH, Kim C, Chang YC (2006) Development of a process sequence determination technique by fuzzy set theory for an electric product with piercing and bending operation. Int J Adv Manuf Technol 31:450–464

Kontolatis N, Vosniakos GC (2010) Optimisation of press-brake bending operations in 3-D space. J Intell Manuf

Kumar S, Singh R (2004) A low cost knowledge base system framework for progressive die design. J Mater Process Technol 153–154:958–964

Kumar S, Singh R (2007) An intelligent system for automatic modelling of progressive die. J Mater Process Technol 194:176–183

Kumar S, Singh R (2011) An automated design system for progressive die. Expert Syst Appl 38:4482–4489

Kusiak A (1990) Intelligent manufacturing system. Englewood cliffs, N.J. Prentice-Hall

Liao SH (2005) Expert system methodologies and applications—a decade review from 1995 to 2004. Expert Syst Appl 28:93–103

Lin Alan C (2012) Sequence planning for bending operations in progressive dies. Int J Production Research 50(24):7493–7521

Lin ZC, Chang DY (1996) The selection system for sheet bending tooling. Int J Adv Manuf Technol 11:127–135

Lin BT, Hsu SH (2008) Automated design system for drawing die. Expert Syst Appl 34:1586–1598

Meziane F, Vadera S, Kobbacy K, Proudlove N (2000) Intelligent systems in manufacturing: current developments and future prospects. Integr Manuf Syst 11:218–238

Mkaddem A, Saidane D (2007) Experimental approach and RSM procedure on the examination of spring back in wiping-die bending processes. J Mater Process Technol 189:325–333

Narayanan G (2010) Expert system applications in sheet metal forming. In: Vizureanu P (ed) Expert Systems, In Tech, Croatia, pp 91–116

Naranje V, Kumar S (2014) Knowledge based system for automated design of deep drawing die for axisymmetric parts. Expert Syst Appl 41:1419–1431

Nasr ESA, Hussein HMA, Ragab EA, Kamrani AK (2014) Feature-based approach to an integrated CAD/CAPP system in sheet metal blanking dies. Int J Rapid Prototyping 4:90–118

Ong SK, Vin LJD, Nee AYC, Kals HJJ (1997) Fuzzy set theory applied to bend sequencing for sheet metal bending. J Mater Process Technol 69:29–36

Panghal D, Kumar S (2013) A low cost knowledge based system framework for design of bending die. Key Eng Mater 549:284–291

Panghal D, Kashid S, Kumar S, Hussein HMA (2016) An automatic system for deciding bend sequence of bending parts. Adv Mater Proc Technol. doi:10.1080/2374068X.2015.1116232

Poole D, Mackworth A (2010) Artificial intelligence—foundations of computational agent. Cambridge University Press, UK

Rico JC, Gonzalez JM, Mateos S, Cuesta E, Valino G (2003) Automatic determination of bending sequences for sheet metal parts with parallel bends. Int J Production Research 41:3272–3299

Shigeru A, Koguchi A (2002) Optimized bending sequences of sheet metal bending by robot. Robot Comput Integr Manuf 18:29–39

Shpitalni I, Saddan D (1994) Automatic Determination of Bending Sequence in Sheet Metal Products. Annals of the ClRP 43(1):23–26

Singh WM, Rao KP (1997) Knowledge-based process layout system for axisymmetrical deep drawing using decision tables. Comput Ind Eng 32:299–319

Singh R, Sekhon GS (1998) An expert system for optimal selection of a press for a sheet metal operation. J Mater Process Technol 86:131–138

Sousa LC, Castro CF, Antonio CAC (2006) Optimal design of V and U bending processes using genetic algorithms. J Mater ProcessTechnol 172:35–41

Thipprakmas S, Phanitwong W (2011) Process parameter design of spring-back and spring-go in V-bending process using Taguchi technique. Mater Des 32(8–9):4430–4436

Vin LJ, Jde Vries, Streppel AH, Klaassen EJW, Kals HJJ (1994) The generation of bending sequences in a CAPP system for sheet-metal components. J Mater Process Technol 41:331–339

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Panghal, D., Kumar, S., Hussein, H.M.A. (2017). Knowledge-Based System for Automatic Design of Bending Dies. In: Kumar, S., Hussein, H. (eds) AI Applications in Sheet Metal Forming. Topics in Mining, Metallurgy and Materials Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-10-2251-7_10

Download citation

DOI: https://doi.org/10.1007/978-981-10-2251-7_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-2250-0

Online ISBN: 978-981-10-2251-7

eBook Packages: EngineeringEngineering (R0)