Abstract

It is important to properly understand the light environment for improving plant production efficiency in a plant factory. Plant canopy structure affects the photosynthetic photon flux density (PPFD) distribution, thereby strongly affecting plant growth. Therefore, it is important to understand the canopy structure and control it in some cases for plant production. Indices for evaluating the canopy structure include extinction coefficient, leaf area index (LAI) or leaf area density (LAD) distribution, and leaf angle distribution. LAI is an important index not only for plant growth but also for evaluating the light environment of the canopy. Several indirect but nondestructive ways for LAI estimation have been proposed, including methods using plant canopy analyzer (PCA), hemispherical photography, terrestrial laser scanner (TLS), spectral reflectance, and image analysis. Moreover, the canopy surface has a PPFD distribution because of its variation in leaf inclination and orientation. A simple method for evaluating PPFD distribution on plant canopy surface using the reflection image of canopy was proposed and successfully constructed PPFD histograms of the canopy surface of several plant species under both natural and artificial lights.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Light environment, particularly photosynthetic photon flux density (PPFD; μmol m−2 s−1) distribution, critically affects biomass productivity. Therefore, it is very important to properly understand the distribution for improving plant production efficiency in a plant factory. As described in the previous chapter (Chap. 9), light is absorbed by leaves, and a vertical PPFD distribution is present within a plant canopy. Moreover, the canopy surface has a PPFD distribution because of its variation in leaf inclination and orientation. Determining PPFD on the leaf surface is essential for accurately evaluating plant photosynthetic status, particularly in methods using remotely acquired images (Ibaraki and Dutta Gupta 2014a).

In this chapter, methods for evaluating the PPFD distribution within and on the plant canopy will be introduced. Evaluation methods for plant canopy structure and leaf area, which are critical factors for determining the PPFD distribution in a canopy, will also be discussed.

2 Measurement of PPFD Distribution in a Plant Canopy

In plant production, “light intensity” on leaf surface is often evaluated as PPFD using a quantum sensor . Furthermore, “light intensity” on leaf surface can be measured as irradiance (W m−2), which is a measure of energy per unit area per unit time. PPFD is used for evaluating “light intensity” in plant production because it offers direct information on number of photons to be used for photosynthesis under the assumption that photons ranging from 400 to 700 nm can be equally used for photosynthesis. Although this assumption is not strictly true, it is acceptable for practical use. The relationship between irradiance and PPFD is constant under lighting conditions using the same light source, and they can be accordingly converted to each other. The metrics for expressing “light intensity” are described in detail in Chap. 25.

PPFD per se can be measured by several types of quantum sensor, including point-, line-, and globe-type sensors. However, determining the PPFD distribution on leaves that are located at the canopy surface is difficult even with these sensors because of dynamic variation in solar radiation and large variations in leaf angle and orientation in a plant canopy (Ibaraki et al. 2012b). For a plant factory using artificial lighting, dynamic variation in PPFD is unusual. In this case, spatial distribution can be potentially measured with a point sensor, although it is time-consuming and labor intensive. In addition, the size of the sensor may be too large to determine PPFD on a leaf for plant species with small leaves.

Line sensors can be used for estimating average PPFD over a given area. For example, a commercially available line quantum sensor (LI-COR, LI-191R) measures PPFD that is integrated over its 1-m length. It is used to measure sunlight under a plant canopy, where the light field is nonuniform, and is suitable for rapid and reproducible measurement of light within the canopy. This type of sensor is useful for determining the average PPFD in a horizontal layer as an input for calculating canopy photosynthesis.

The globe-type sensor is designed for measuring light from all directions. In a commercially available spherical quantum sensor (LI-COR, LI-193), photosynthetic photon flux fluence rate (PPFFR ; μmol m−2 s−1), which is the integral of photon flux radiance (μmol m−2 s−1 sr−1) at a point over all directions, is measured. The ideal PPFFR sensor has a spherical collecting surface and exhibits the properties of a cosine receiver at every point on its surface (William 2015). This type of sensor may be useful for evaluating “light intensity” in plant cultivation under combination of sideward and downward lighting, which is a possible occurrence in plant factories using artificial lights.

3 Evaluation of Plant Canopy Structure

Plant canopy structure affects the PPFD distribution, thereby strongly affecting plant growth. Therefore, it is important to understand the canopy structure and control it in some cases for plant production. However, evaluating the canopy structure is not simple because of the complexity of the leaf spatial distribution patterns and their changes with growth. As described in Chap. 9, determining the extinction coefficient k provides information regarding the canopy structure. k can be estimated by measuring the vertical distribution of PPFD (by light interception measurements) and leaf area index (LAI). However, this approach, requiring the measurement of PPFD distribution, may not be reasonable if the main objective of evaluating the canopy structure is to characterize the PPFD distribution in the canopy. Instead, k can be estimated simply by Eq. 9.5 (in Chap. 9) under the assumption of vertical uniformity of k, requiring only photosynthetically active radiation (PAR) measurements above and below the canopy and estimation of canopy LAI.

Furthermore, the leaf angle distribution expresses the canopy structure. The leaf angle distribution can be determined by measuring the leaf angle one by one with a clinometer although this method requires time-consuming and labor intensive work and may be difficult to apply for some cases. In real canopies, leaves assume a range of orientations, with some (planophile ) canopies having predominantly horizontal leaves and others (erectophile ) having predominantly vertically oriented leaves; however, many other distributions are also found (Jones 1992). The ellipsoidal leaf angle density function (Campbell 1999) is often used as a close approximation of real plant canopies (Flerchinger and Yu 2007). The function expresses the probability density of leaf angle, namely, the fraction of leaf area per unit leaf inclination angle, based on the assumption that the angular distribution of leaves in a canopy is similar to the distribution of area on the surface of an ellipsoid (Wang et al. 2007). To compute the fraction of leaves between leaf inclination angles α 1 and α 2, leaf angle distribution function can be integrated from α 1 to α 2 (Wang et al. 2007). In the function, a single parameter, x (the ratio of the horizontal to the vertical semiaxis of the ellipsoid), is used for determining the shape of the distribution (Jones 1992). Examples of leaf angle distribution by the ellipsoidal leaf angle density function are shown in Fig. 10.1.

Examples of leaf inclination angle distribution determined by the ellipsoidal leaf angle density function. Calculations were made by the following equation for \( x=0.5,\;x=1,\kern0.5em \mathrm{and}\kern0.5em x=2 \). \( g\left(\alpha \right)=2{x}^3 \sin \alpha /\left(A{\left({ \cos}^2\alpha +{x}^2{ \sin}^2\alpha \right)}^2\right) \), where g(α) is a probability density of inclination angle α, x is the ratio of the horizontal semiaxis length to the vertical semiaxis length of an ellipsoid, and A is a parameter determined by x. See Campbell (1999) or Wang et al. (2007) in detail for calculation

Other important indices for evaluating the canopy structure are LAI and leaf area density (LAD) . Although LAI is a measure of the amount of leaves in the plant canopy, it provides information regarding the canopy structure. In contrast, LAD (m−1) is the total one-sided leaf surface area (m2) per unit volume (m3) in the canopy, and the integral of LAD up to the canopy height is LAI (Fig. 10.2). The vertical distribution of LAD is a direct measure of the canopy structure, and knowing it is helpful in analyzing the PPFD distribution. The vertical distribution patterns of LAD for crops may be roughly classified into several types: increasing toward the bottom, decreasing toward the bottom, increasing to the center and then decreasing, and being distributed uniformly.

Methods for estimating LAI or LAD will be introduced in Sect. 10.4.

4 LAI Estimation

4.1 Direct and Indirect Estimation

LAI is defined as the total projected leaf area (one side only) per unit area of ground and is an important index not only for plant growth but also for evaluating the light environment of the canopy, as described in Chap. 9. Here we should note the difference in units between LAI and LAD. The integral of LAD (m−1) up to the canopy height (m) is LAI (dimensionless), as previously described.

Normally LAI can be measured by destructive means, such as detaching all leaves within a unit area of ground and measuring their area with a leaf area meter or scanning them with an optical scanner. Similarly, LAD can be measured by sampling at every unit of the horizontal layer. This requirement for destructive sampling is a defect of LAI measurement, precluding time-course analysis. Therefore, it is desirable to develop nondestructive methods. For rough estimation, measuring the number of leaves and area of the representative leaf which is determined from length and width of the leaf measured with a ruler can be used. Several indirect but nondestructive ways have been proposed, including methods using plant canopy analyzer, hemispherical photography, terrestrial laser scanner, spectral reflectance, and image analysis.

4.2 Methods Using Gap Fraction

As a nondestructive method for measuring plant leaf area, a plant canopy analyzer was developed and is commercially available (LI-COR, LAI-2200). The device estimates LAI from measurements of light made above and below the canopy and uses them to determine canopy light interception at five angles (Fig. 10.3). These data are used to compute leaf area index, mean tilt angle, and canopy gap fraction.

Canopy gap fraction is defined as the probability of a ray of light passing through the canopy without encountering leaves or other plant elements (Danson et al. 2007). Canopy directional gap fraction indicates the probability that a beam will not be intercepted by canopy elements in a given direction (Danson et al. 2007). It is an important index for analyzing a forest canopy, which is related to canopy LAI, and can be measured by hemispherical photography or laser scanners. Methods of deriving LAI from gap fraction measurements are reviewed by Weiss et al. (2004).

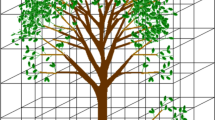

For estimation of a gap fraction using hemispherical photography, the images are taken with a circular fish-eye lens from below the canopy looking upward (Fig. 10.4). Gap fractions are computed from such an image by determining the fraction of exposed background within rings or bands about the center of the image (Anderson 1964). Whereas hemispherical photography provides a two-dimensional record of the canopy structure, terrestrial laser scanners (TLS) have the potential to provide a 3-D record of canopy structure (Danson et al. 2007). TLS uses range-finding measurement techniques, which measure the distance to objects by emitting a series of laser pulses, to determine the 3-D positions of the objects within the scanner field of view (Danson et al. 2007) (Fig. 10.5). Gap fraction can be estimated from records of return to a laser “shot” in a given direction. In addition, laser scanning may be used for the direct estimation of vertical LAD distribution. Hosoi and Omasa (2009) proposed a method for estimating vertical LAD profiles using 3-D portable lidar (light detection and ranging), which is referred to as the voxel-based canopy profiling method. The method successfully estimated the LAD profile of an individual tree of Camellia sasanqua (Hosoi and Omasa 2009).

4.3 The Use of Spectral Reflectance

With respect to the use of spectral reflectance, methods using vegetation index or reflectance in specific wavelength regions have been proposed. As plant leaves absorb red light and reflect near-infrared (NIR) light, canopies with more leaves demonstrate low reflectance in the red region and high reflectance for NIR. Using this principle, we can estimate LAI from the measurement of reflectance in red and NIR regions. Normalized difference vegetation index (NDVI), which has been widely used for evaluating plant cover in remote sensing, is sometimes used for estimating LAI. NDVI can be derived as follows:

where R NIR is the reflectance of NIR (e.g., 730–1100 nm) and R Red is the reflectance in the red region (e.g., 620–690 nm). These methods using spectral reflectance are based on an empirical relationship, i.e., the regression model for estimation of LAI should be determined in advance, and the model parameters depend on the canopy type (plant species and growth stage).

As an alternative approach, a method using a ratio of PAR and NIR irradiance within the canopy is also proposed. The LAI sensor (Environmental Measurement Japan, MIJ-15LAI, Japan) estimates LAI of a target canopy, being set within the canopy (on the ground), using the predetermined relationship between the ratio of irradiance at PAR (400–700 nm) and at IR (700–1000 nm) within the canopy and LAI.

4.4 Image Analysis

Image analysis using digital cameras potentially permits the acquisition of size information of objects (Ibaraki and Dutta Gupta 2014b). Normally, a projected area can be nondestructively measured from an image. If a linear relationship between a projected area and actual leaf area is observed, LAI can be estimated simply by image analysis. Liu and Pattey (2010) reported the effectiveness of digital photography for LAI estimation of agricultural crops using a rectilinear lens at the top of the canopy. Campillo et al. (2010) also developed a nondestructive method for estimating LAI in vegetable crops using digital images that were acquired from above the crop canopy.

5 Estimation of PPFD Distribution on Plant Canopy Surface

5.1 Importance of Understanding Light Distribution on the Canopy Surface

Recently, nondestructive methods for evaluating photosynthetic properties of plants using images remotely acquired have been used for environmental control on the basis of the understanding of plant status in plant production. In such methods, proper understanding of the irradiance/photon flux density distribution on the target surface of the canopy is essential (Ibaraki and Dutta Gupta 2014a). For example, parameters that are derived from chlorophyll fluorescence measurement, such as PSII quantum yield, strongly depend on PPFD on leaves and would be meaningless without PPFD information. Moreover, irradiance on leaves affects leaf temperature and may be a limiting factor for evaluating plant stress by leaf temperature measurement. Thus, it is essential to evaluate the irradiance/photon flux density distribution on the canopy surface for analyzing the distribution of photosynthetic properties on the canopy surface using such image-based methods. In addition, the light distribution on the surface may be critical for considering plant productivity (canopy photosynthesis) in some types of canopy, in which leaves are concentrated in the upper layer or leaf layer is difficult to define because of its low height.

Because the reflection image of a leaf includes information regarding light irradiating the leaf, it has the potential to be used for the simple estimation of irradiance/photon flux density. Ibaraki et al. (2012a, b) developed a simple method for evaluating PPFD distribution on plant canopy surface using the relationship between PPFD on the leaf surface and pixel value in the reflection image. In this section, the method is introduced with applications.

5.2 Reflection Image-Based Estimation Method of PPFD on Canopy Surface

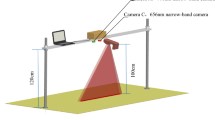

Reflection images of plant canopies were acquired with a monochrome 14-bit CCD camera (Bitran, BU-41L, Japan), digital camera (Canon, SX130, Japan), or Android tablet (Sony, Tablet-S, Japan) through a blue–green band-pass filter (Suruga, S76-BG28 or S76-BG7, Japan). The filter had a peak wavelength of approximately 450–500 nm and was used for improving the correlation between PPFD on the leaf surface and pixel value , which is a digital value assigned to each pixel to express brightness or color, in the reflection image. To minimize the effect of specular reflection, images were acquired from several directions. Cameras were horizontally moved at a fixed distance from the plant material and at a fixed angle of depression to acquire images from different directions (Fig. 10.6). In this method, the linearity of output (pixel value in an image) and input (PPFD entering the camera) should be confirmed for each camera before imaging. In other words, if possible, the gamma value should be set to 1.0, and if it cannot be changed, it is determined in advance and used for gamma correction in analyses (Ibaraki and Dutta Gupta 2014a). An example of gamma correction is shown in Fig. 10.7.

Ibaraki et al. (2012b) compared actual PPFD with a pixel value in the reflection images for several plant canopies. Linear relationships between these values were observed in both outdoor (under natural sunlight) and indoor (under artificial light) conditions for several plant species. However, they indicated that the slope and intercept of the linear regression model between the PPFD and pixel values depended on the canopy type (plant species), and thus, a regression model should be fitted for each measurement.

On the basis of these results, a simple method was proposed to estimate the PPFD distribution on a plant canopy surface in a greenhouse (Ibaraki et al. 2012b). In this method, the actual PPFD was measured with a quantum sensor at one point on the canopy surface and was used for constructing a linear regression model for calculating PPFD from the pixel value at any point in the reflection image. A small quantum sensor was placed adjacent to a leaf on which PPFD appeared to be high in the target canopy. After imaging, slope a in the linear regression model (y = ax) was calculated as the ratio of measured PPFD versus pixel value at the measurement point in the image. PPFD at any point on the leaf was estimated using the linear regression model.

Figure 10.8 shows the concept of the estimation method. The circles in the figure denote the values of the points at which PPFD was measured with the PPFD sensor, and the lines represent the regression models for estimating PPFD. On both clear and cloudy days, the method could roughly estimate PPFD on the leaves of a rose canopy in a greenhouse (Ibaraki et al. 2012b). This method, in which a regression model is fitted for each image on the basis of actual measurement at one point, can minimize the effects of canopy type (plant species) and/or light spectral distribution (Ibaraki and Dutta Gupta 2014a).

A concept of estimation of PPFD distribution on canopy surface. Examples for a rose canopy in the greenhouse on fine (closed circle) and cloudy days (closed squire) (Reproduced from Ibaraki et al. 2012b). The slope a in the linear model (y = ax) was determined as a ratio of measured PPFD (open circle) to pixel value at a measuring point in the image and used for estimation of PPFD at other points

5.3 Applications

Ibaraki et al. (2012a) successfully constructed a PPFD histogram of the canopy surface of tomato plants in a greenhouse from reflection images that were acquired between rows. The histogram of pixel values after gamma correction was converted into a PPFD histogram using a linear model on the basis of the relationship between the observed PPFD and pixel value at one point in each image. They demonstrated that the pattern of PPFD histograms on the tomato canopy surface changed over time during the day.

An Android application for easy, real-time estimation of the PPFD distribution on a plant canopy surface has also been developed (Miyoshi et al. 2016). The application was designed to semiautomatically analyze PPFD distribution on the canopy from a reflection image that was acquired by a tablet (Fig. 10.9). An image preview frame was captured and used for analysis. Plant canopy areas were extracted from the image using a combination of the threshold values of “luminance” and “g” [“G”⁄“(R + G + B)”], which users could input with Android SeekBars. When histogram data from three different directional images were stored, these data were averaged and analyzed. Figure 10.10 shows an example of PPFD distribution on a lettuce canopy under artificial light.

A screenshot of the Android tablet-based system (Miyoshi et al. 2016), when being applied to lettuce cultivated under artificial lighting. The PPFD histogram is shown in upper right

Examples of PPFD distribution (PPFD histogram) on the surface of lettuce canopies estimated with the Android tablet-based system (Miyoshi et al. 2016) under white fluorescent lamps. The distribution pattern changed with days after sowing (DAS). On 32 DAS, the frequencies in low PPFD increased possibly due to overlapping leaves

References

Anderson MC (1964) Studies of the woodland light climate. 1. The photographic computation of light conditions. J Ecol 52:27–41

Campbell GS (1999) Derivation of an angle density function for canopies with ellipsoidal leaf angle distributions. Agric For Meteorol 49:173–176

Campillo C, Garcia MI, Daza C et al (2010) Study of non-destructive method for estimating the leaf area index in vegetation crops using digital images. HortScience 45:1459–1463

Danson FM, Hetherington D, Morsdorf F et al (2007) Forest Canopy gap fraction from terrestrial laser scanning. IEEE Geol Remote Sens Lett 4:157–160

Flerchinger GN, Yu Q (2007) Simplified expressions for radiation scattering in canopies with ellipsoidal leaf angle distributions. Agric For Meteorol 144:230–235

Hosoi F, Omasa K (2009) Estimating vertical leaf area density profiles of tree canopies using three-dimensional portable lidar imaging. In: Bretar F et al (eds) Laser scanning. Vol. XXXVIII, Part 3/W8. IAPRS, Paris, pp 152–157

Ibaraki Y, Dutta Gupta S (2014a) PRI imaging and image-based estimation of light intensity distribution on plant canopy surface. In: Dutta Gupta S, Ibaraki Y (eds) Plant image analysis. CRC Press, Boca Raton, pp 229–244

Ibaraki Y, Dutta Gupta S (2014b) Image analysis for plants: basic procedures and techniques. In: Dutta Gupta S, Ibaraki Y (eds) Plant image analysis. CRC Press, Boca Raton, pp 25–40

Ibaraki Y, Kishida T, Shigemoto C (2012a) Image-based estimation of PPFD distribution on the canopy surface in a greenhouse. Acta Hortic 956:577–582

Ibaraki Y, Yano Y, Okuhara H et al (2012b) Estimation of light intensity distribution on a canopy surface from reflection images. Environ Control Biol 50:117–126

Jones HG (1992) Plants and microclimate: a quantitative approach to environmental plant physiology. Cambridge University Press, London

Liu J, Pattey E (2010) Retrieval of leaf area index from top-of-canopy digital photography over agricultural crops. Agric For Meteorol 150:1485–1490

Miyoshi T, Ibaraki Y, Sago Y (2016) Development of an android-tablet-based system for analyzing light intensity distribution on a plant canopy surface. Comput Electron Agric 122:211–217

Wang WM, Li ZL, Sub HB (2007) Comparison of leaf angle distribution functions: effects on extinction coefficient and fraction of sunlit foliage. Agric For Meteorol 143:106–122

Weiss M, Baret F, Smith GJ et al (2004) Review of methods for in situ leaf area index (LAI) determination: part II. Estimation of LAI, errors and sampling. Agric For Meteorol 121:37–53

William WB (2015) Principle of radiation measurement. LI-COR Biosciences. https://www.licor.com/env/pdf/light/Rad_Meas.pdf. Accessed 20 Dec 2015

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Ibaraki, Y. (2016). Evaluation of Spatial Light Environment and Plant Canopy Structure. In: Kozai, T., Fujiwara, K., Runkle, E. (eds) LED Lighting for Urban Agriculture. Springer, Singapore. https://doi.org/10.1007/978-981-10-1848-0_10

Download citation

DOI: https://doi.org/10.1007/978-981-10-1848-0_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-1846-6

Online ISBN: 978-981-10-1848-0

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)