Abstract

Agricultural pests and disease control is one of the main aspect of the crop production especially in orchards. Agricultural sprayers currently used in the orchards are basically constant rate air-assisted sprayers, which uses heavy stream of air to carry fine droplets toward the target. As, orchard trees vary in their size and geometry, spraying with these sprayers often results in either over spraying or under spraying. The variation in size and shape of the orchard trees makes necessary to take into consideration these tree parameters while spraying to adjust spray output to avoid losses due to over spraying. To adjust the amount of pesticide to be sprayed as per the tree size, an electronic control system was developed. The tree parameters were obtained using a high-speed ultrasonic sensor; a microcontroller was developed to control the system and to process the developed algorithm and variation in spray volume to be sprayed was achieved with a proportional solenoid valve. The developed system was tested in the laboratory to test the homogeneity of the flow rate sprayed through nozzle.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In orchard production, protection of trees from pest and disease infestation is most important. In recent years, chemical control, i.e., foliar pesticide application has proved to be most effective pest and disease control method. To apply these pesticides, different equipment are used which uses high-pressure pump to pressurize liquid through nozzles to produce fine droplets. However, all these existing spraying equipment are constant rate applicators and spraying with these sprayers often results in over spraying. Unlike the field crops, orchard crops vary in their structure, size, and density. With the conventional sprayers, applicators are unable to manually adjust sprayer output to match the canopy size of the target trees, which results in wastage of pesticide. To control these losses, Morgon [12] stated the importance of taking into consideration the dimensions and other geometric parameters of the canopy to apply calculated amount of spray. This can be achieved using sensor technologies to identify trees and then apply precise amount of material needed for adequate pest and disease control.

Scientists have used ultrasonic sensors for canopy detection and characterization of plant canopy [7, 10, 15]. Using ultrasonic sensors, various researchers made efforts to develop an automatic spray control system with suitable proportional solenoid valve [1, 5, 8–11, 14]. Laser sensors were also found to be more suitable for detection of canopy occurrence, size and accordingly vary the spray output [2, 3, 13] but because of the low cost and simplicity, ultrasonic sensors have been extensively used.

The objective of this work was to develop an electronic control system using ultrasonic sensor to characterize the occurrence and width of canopy and then control the spray output to match the target tree structure.

2 Materials and Methods

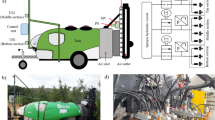

The basic principle of the system was to control the output of the nozzle according to canopy characteristics and to shut the nozzle off when there is no canopy. The developed system consisted of a pesticide tank, pump, pressure regulator, and nozzle assembly together with an ultrasonic sensor, a microcontroller and a proportional solenoid valve (Fig. 1). The developed system was based on the electronic method for canopy width measurement and the amount of spray liquid was modified accordingly through proportional solenoid valve in order to achieve a proportional spray distribution based on crop geometry [4, 6].

2.1 Canopy Sensing and Characterization

A high-speed ultrasonic sensor with IP65 water and dust proof rating (Model UC 2000-30GM-1U-V1, Pepperl+Fuchs Group, Germany) was used for canopy detection and characterization. The power to the sensor was provided by a custom designed microcontroller board by regulating 12 V (DC) supply. The sensor was programmed to detect the objects in the range of 200–1700 mm. For the selected range, sensor was giving electronic output signal between 0 and 10 V. Laboratory experiments were conducted to develop a relationship between measured distances and corresponding electronic output signal (Fig. 2). Following equation represents that relation.

where, d i is the measured distance and v i is the output electrical signal of the sensor.

2.2 Microcontroller and Algorithm Design

The control algorithm was based on the measurement of canopy width (d). Once that parameter was electronically determined, information about system travel speed (v) and canopy height covered by single nozzle section (h) was added. The algorithm was developed in order to calculate the spray volume to be sprayed per unit time (Q), which was expressed in liter per minute. The main objective of the algorithm was to modify the delivered nozzle flow rate based on the measurements of the canopy volume along the crop line. Following equation represents the relationship applied for this process.

where, Q is the real time flow rate of individual nozzle (l/min.); v is the sprayer/tractor travel speed (m/min.); h is the height of canopy section covered by nozzle (m) (determined by dividing total canopy height with number of nozzle sections on one side of sprayer); V i is the recommended application rate per unit tree volume (l/m3), and d is the depth of canopy (m).

In this study, recommended application rate (V i ) of 0.02741 l/m3 was selected by considering the tree row volume (TRV) of orchard crop and forward speed of 2.5 km/h (42 m/min) was considered. Depth (width) of canopy is calculated from canopy distance given by sensor (Eq. 3, Fig. 3) [6].

where, d is the depth of canopy (m); R is the tree row spacing (m); d c is the distance between sensor and tree (m), and d s is the distance between center of sprayer and sensor (m).

A custom designed microcontroller board (ATMEGA-328, ARDUINO) was fabricated to control the sensor and proportional solenoid valve. After the microcontroller was powered up, it triggered the sensor to begin acquiring the signals for canopy detection and width of canopy. The data acquisition system begins to receive information from the ultrasonic sensor. All data were then processed in the microcontroller, where signals acquired from the ultrasonic sensor were transformed first into width of canopy and then into intended flow rate, and finally into an electric control signal to be sent to the proportional solenoid valve. For each measured data, the system determines the distance from the sensor to the nearest tree foliage. According to Eq. 3, this value was transformed into crop width. All conversions were based on a defined orchard row-to-row spacing distance (R) and the assumption that the sprayer travelled along the centerline between rows [8]. Once the distance has been determined, the system transforms those values into the required flow rate according to Eq. 2 in order to apply the required amount of liquid in proportion to the orchard tree width variations.

The program flow chart for the microcontroller of the control system is shown in Fig. 4. The program started and stopped when the microcontroller power was turned on and off manually by the operator.

2.3 Proportional Solenoid Valve

To achieve the variation in flow rate as determined by the designed algorithm, the system was provided with a proportional solenoid valve. A normally closed proportional solenoid valve (model: Possiflow, ASCO Numatics, USA) with ¼″ size having maximum operating pressure of 8 bar was used. The valve was supplied with 24 V (DC) supply. The opening of the valve was controlled by the microcontroller by providing pulse width modulated control signal between 0 and 10 V according to size of the canopy. This pulse width modulation was achieved through external driver (L298, Motor and Solenoid Driver).

2.4 Testing of the Developed System in the Laboratory

To analyze the behavior of the selected proportional solenoid valve, the developed system was tested inside the laboratory conditions. During the test proportional solenoid valve was provided with known control signal between 0 and 10 V corresponding to the size of the canopy and delivered flow rate was measured. The test was performed to establish the relationship between given control signal and corresponding flow rate delivered by the valve. During the testing, pump was operated at 3 kg/cm2 pressure and it was kept constant throughout the supply system using suitable valves.

3 Results and Discussion

During the laboratory testing, per minute discharge of the valve was measured for provided control signal. Figure 5 shows the relationship between the flow rates delivered by the solenoid valve versus control signal provided. A cubic polynomial equation (Eq. 4) was developed which helps to determine the control signal to be sent to the solenoid valve to spray the determined flow rate. This equation is valid only within the selected range of parameters. The coefficient of determination for the developed equation was R 2 = 0.98.

where V is the control signal sent to the proportional solenoid valve (V) and q is the flow rate to be sprayed by an independent section (l/min).

4 Conclusions

An effort was made to develop an automatic control system to control the flow rate of the output nozzle according to the size of the tree to be sprayed. The system consisted of an ultrasonic sensor to automatically characterize the tree parameters. A suitable algorithm was developed to calculate the amount of flow rate (spray volume to be sprayed per unit time) needed to be sprayed through nozzle in accordance with the size of the tree in real time. The variation in flow rate was obtained with a proportional solenoid valve. To control the ultrasonic sensor and proportional solenoid valve, a customary microcontroller board was developed. The microcontroller processed the control algorithm after receiving signals from the sensor and subsequently controlled the proportional solenoid valve. The laboratory testing of the system produced relation between the signals to be sent to the valve to obtain required flow rate through nozzles.

References

Balsari, P., Doruchowski, G., Marucco, P., Tamagnone, M., Van de Zonde, J., Wenneker, M.: A system adjusting the spray application to the target characteristics. Agricultural Engineering International: the CIGR E-journal, 10 Manuscript ALNARP 08 002 (2008).

Chen, Y., Zhu, H., Ozkan, H.E.: Development of a variable rate sprayer with laser scanning sensor to synchronize spray outputs to tree structures. Transactions of the ASABE, 55 (3), 773–781 (2012).

Chen, Y., Ozkan, H.E., Zhu, H., Derksen, R.C., Krause, C.R.: Spray deposition inside tree canopies from a newly developed variable-rate air-assisted sprayer. Transactions of the ASABE, 56 (6), 1263–1272 (2013).

Escola, A., Rossel-Polo, J.R., Planas, S., Gil, E., Pomer, J., Camp, F., Llorens, J., Solanelles, F.: Variable rate sprayer. Part 1 – Orchard prototype: Design, implementation and validation. Computers and Electronics in Agriculture, 95, 122–135 (2013).

Gil, E., Escola, A., Rosell, J.R., Planas, S., Val, L.: Variable rate application of plant protection products in vineyard using ultrasonic sensors. Crop Protection, 26 (8), 1287–1297 (2007).

Gil, E., Llorens, J., Llop, J., Fabregas, X., Escola, A., Rossel-Polo, J.R.: Variable rate sprayer. Part 2 – Vineyard prototype: Design, implementation and validation. Computers and Electronics in Agriculture, 95, 136–150 (2013).

Giles, D.K., Delwiche, M.J., Dodd, R.B.: Electronic measurement of tree canopy volume. Transactions of the ASAE, 31 (1), 264–272 (1988).

Giles, D.K., Delwiche, M.J., Dodd, R.B.: Sprayer control by sensing orchards crop characteristics: Orchard architecture and spray liquid saving. Journal of Agriculture Engineering Research, 43 (4), 271–289 (1989).

Jeon, H.Y., Zhu, H.: Development of variable rate sprayer for nursery liner applications. Transactions of the ASABE, 55 (1), 303–312 (2012).

Llorens, J., Gil, E., Llop, J., Escola, A.: Variable rate dosing in precision viniculture: Use of electronic device to improve application efficiency. Crop Protection, 29 (3), 239–248 (2010).

Molto, E., Martin, B., Gutierrez, A.: Pesticide loss reduction by automatic adoption of spraying on globular trees. Journal of Agricultural Engineering Research, 78 (1), 35–41 (2001).

Morgan, N.G.: Gallons per acre of sprayed area: an alternative standard term for the spraying of plantation crops. World Crops, 16, 64–65 (1964).

Osterman, A., Godesa, T., Hocevar, M., Sirok, B., Stopar, M.: Real-time positioning algorithm for variable-geometry air-assisted sprayer. Computers and Electronics in Agriculture, 98, 175–182 (2013).

Solanelles, F., Escola, A., Planas, S., Rosell, J., Camp, F., Gracia, F.: An electronic control system for pesticide application proportional to the canopy width of tree crops. Biosystems Engineering, 95 (4), 473–481 (2006).

Tumbo, S.D., Salyani, M., Whitney, J.D., Wheaton, T.A., Miller, W.M.: Investigation of laser and ultrasonic ranging sensors for measurements of citrus canopy volume. Applied Engineering in Agriculture, 18 (3), 367–372 (2002).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media Singapore

About this paper

Cite this paper

Sachin Wandkar, Bhatt, Y.C. (2016). Development of Electronic Control System to Automatically Adjust Spray Output. In: Satapathy, S., Bhatt, Y., Joshi, A., Mishra, D. (eds) Proceedings of the International Congress on Information and Communication Technology. Advances in Intelligent Systems and Computing, vol 438. Springer, Singapore. https://doi.org/10.1007/978-981-10-0767-5_34

Download citation

DOI: https://doi.org/10.1007/978-981-10-0767-5_34

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-0766-8

Online ISBN: 978-981-10-0767-5

eBook Packages: EngineeringEngineering (R0)