Abstract

In this chapter the concept of thermal stresses in bars is introduced for the simple case of a perfectly clamped bar subjected to arbitrary temperature change. The problems and solutions related to thermal stresses in bars are: a perfectly clamped bar, a clamped bar with a small gap, a clamped circular frustum, a bar with variable cross-sectional area, two bars attached to each other, three bars fastened to each other, truss of three bars, and three bars hanging from a rigid plate.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

In this chapter the concept of thermal stresses in bars is introduced for the simple case of a perfectly clamped bar subjected to arbitrary temperature change. The problems and solutions related to thermal stresses in bars are: a perfectly clamped bar, a clamped bar with a small gap, a clamped circular frustum, a bar with variable cross-sectional area, two bars attached to each other, three bars fastened to each other, truss of three bars, and three bars hanging from a rigid plate.

1 Thermal Stresses in Bars

When the temperature of a circular bar of length \(l\) changes from an initial temperature\(T_{0}\) to its final temperature \(T_{1}\), the free thermal elongation\(\lambda _{T}\) of the bar is defined by

where \(\alpha \) is the coefficient of linear thermal expansion which is measured in one per one degree of the temperature 1/K, and \(\tau \) denotes the temperature change given by

The free thermal strain is given by

When an internal force and the temperature change act simultaneously in the bar, the normal strain is given by

where \(\epsilon _{s}\) denotes the strain produced by the internal force. The strain \(\epsilon _{s}\) produced by the internal force is proportional to the normal stress\(\sigma \)

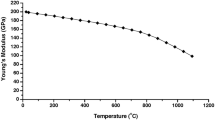

where \(E\) denotes Young’s modulus.

Hooke’s law with the temperature change is

When a perfectly clamped bar with length \(l\) and cross-sectional area \(A\), shown in Fig. 13.1, is subjected to the uniform temperature change\(\tau \), the thermal stress is

If the temperature change \(\tau (x)\) is a function of the position \(x\), the free thermal elongation\(\lambda _T\) of the bar of length \(l\) is

The thermal strain \(\epsilon _{T}\) is

The thermal stress in the perfectly clamped bar is

2 Problems and Solutions Related to Thermal Stresses in Bars

Problem 13.1.

If the temperature in a mild steel rail with length \(25\,\text{ m }\) is raised to \(50\,\text{ K }\), and the coefficient of linear thermal expansion for mild steel is \(11.2\times 10^{-6} \,\text{1/K }\), what elongation is produced in the rail?

Solution.

The elongation \(\lambda _T \) is from Eq. (13.1)

Problem 13.2.

The temperature of a bar of length \(1\,\text{ m }\) of mild steel is kept at \(300\,\text{ K }\). If the temperature at one end of the bar is raised to \(380\,\text{ K }\) and at the other end to \(480\,\text{ K }\), and the temperature distribution is linear along the bar, what elongation is produced in the bar? The coefficient of linear thermal expansion for mild steel is \(11.2\times 10^{-6}\,\text{1/K }\).

Solution.

The temperature rise \(\tau (x) = T_1 (x)-T_0 \) is

The free thermal elongation\(\lambda _T \)is

Problem 13.3.

A bar of mild steel at \(300\,\text{ K }\) is clamped between two walls. Calculate the thermal stress produced in the bar when the bar is heated to \(360\,\text{ K }\). The coefficient of linear thermal expansion and Young’s modulus are \(\alpha = 11.2 \times 10^6\) 1/K and \(E=206\) GPa, respectively.

Solution.

The thermal stress \(\sigma \) is from Eq. (13.7)

Problem 13.4.

In Problem 13.2, calculate the thermal stress produced in the bar if it is clamped between two walls. The coefficient of linear thermal expansion and Young’s modulus are \(\alpha = 11.2 \times 10^6\) 1/K and \(E=206\) GPa, respectively.

Solution.

As the summation of the free thermal elongation\(\lambda _T\) and the elongation \(\lambda _s \) due to the stress is zero, we get

Problem 13.5.

A bar of mild steel at \(300\,\text{ K }\) is clamped between two walls in such a way that the initial stress is zero. Calculate the temperature when the thermal stress in the bar reaches the compressive strength\((\sigma _{BC} =400\,\text{ MPa })\). The coefficient of linear thermal expansion and Young’s modulus are \(\alpha = 11.2 \times 10^6\) 1/K and \(E=206\) GPa, respectively.

Solution.

The compressive thermal stress \(\sigma \) is given by Eq. (13.7). Therefore, the temperature rise \(\tau \) is

Then

Problem 13.6.

The temperature of a bar with a small gap\(e=1\) mm, shown in Fig. 13.2 is kept at \(300\,\text{ K }\). If the temperature at one end of the bar is raised to \(380\,\text{ K }\) and at the other end to \(480\,\text{ K }\), and the temperature distribution is linear along the bar, calculate the thermal stress. Where length of the bar is \(1\,\text{ m }\), and the coefficient of linear thermal expansion and Young’s modulus are \(\alpha = 11.2 \times 10^6\) 1/K and \(E=206\) GPa, respectively.

Solution.

The free thermal elongation is assumed to be longer than the gap. The summation of elongations due to the free thermal elongation and the elongation due to the stress is equal to the small gap \(e\)

Then, we get

The free thermal expansion is given by Eq. (13.12). Therefore,

Problem 13.7.

If a clamped circular frustum of mild steel with \(d_{0} =1\,\text{ cm }\), \(d_{1} =2\,\text{ cm }\), and \(l=2\,\text{ m }\) is subjected to the temperature change \(-50\,\text{ K }\), calculate the resulting thermal stress. The coefficient of linear thermal expansion and Young’s modulus are \(\alpha = 11.2 \times 10^6\) 1/K and \(E=206\) GPa, respectively.

Solution.

The free thermal elongation\(\lambda _T\) is

The cross-sectional area \(A_{x}\) at the position \(x\) is given by

Thus, the strain \(\epsilon _{x}\) of the frustum at \(x\) due to an internal force\(Q\) becomes

and the elongation \(\lambda _s\) of the frustum due to the internal force \(Q\) equals

As the frustum is perfectly constrained in the \(x\) direction, the combined elongation of the free thermal elongation\(\lambda _T\) and the elongation \(\lambda _s\) due to the internal force \(Q\) must be zero

From Eqs. (13.16), (13.19), and (13.20) the internal force \(Q\) is

Then, the thermal stress is

If \(d_{1}>d_{0}\), the maximum thermal stress \((\sigma _{x})_{\max }\) occurs at the minimum cross-sectional area and the minimum thermal stress \((\sigma _{x})_{\min }\) occurs at the maximum cross-sectional area

The thermal stress \(\sigma _{x}\) is calculated from Eq. (13.22)

The maximum and minimum thermal stresses are from Eq. (13.24)

Problem 13.8.

If the temperature of a clamped circular frustum of mild steel with \(d_{0} =1\,\text{ cm }\), \(d_{1} =2\,\text{ cm }\), and \(l=2\,\text{ m }\) changes linearly from \(0\,\text{ K }\) at one end to \(-50\,\text{ K }\) at the other end, calculate the resulting thermal stress. The coefficient of linear thermal expansion and Young’s modulus are \(\alpha = 11.2 \times 10^6\) 1/K and \(E=206\) GPa, respectively.

Solution.

The distribution of the temperature change \(\tau (x)\) is

The free thermal elongation\(\lambda _T \) is

The cross-sectional area \(A_{x}\) at the position \(x\) is given by

Thus, the strain \(\epsilon _{x}\) of the frustum at \(x\) due to an internal force \(Q\) becomes

and the elongation \(\lambda _s\) of the frustum due to the internal force \(Q\) equals

As the frustum is perfectly constrained in the \(x\) direction, the summation of elongation of the free thermal elongation \(\lambda _T\) and the elongation \(\lambda _s\) due to the internal force \(Q\) must be zero

From Eqs. (13.29) and (13.30) the internal force \(Q\) is

and the thermal stress is calculated to be

The maximum and minimum thermal stresses are

Problem 13.9.

If a bar with a small gap\(e\) between its free end and a rigid wall is subjected to the positive temperature change \(\tau (x)\), and the cross-sectional area of the bar is given by \(A(x)\), calculate the thermal stress produced in the bar.

Solution.

The small elongation\(d\lambda (x)\) of the small element \(dx\) is

The elongation \(\lambda \) of the bar with length \(l\) is

in which \(Q\) is an internal force. The free thermal elongation is assumed to be longer than the gap. The summation of elongation due to the free thermal elongation and elongation due to the stress is equal to the small gap \(e\)

Then, we get

Thermal stress is

The maximum and minimum thermal stresses are

Problem 13.10.

A hollow cylinder with a bar of the same length \(l\) and the same centerline, shown in Fig. 13.3 is subjected to different temperature changes\(\tau _{i}, (i=1, 2)\). The hollow cylinder and the bar are connected to two rigid plates. Calculate the thermal stresses produced in both the hollow cylinder and the bar, and the elongations.

Solution.

The elongations \(\lambda _{i}\) due to both the free thermal elongation and the thermal stress are

where \(A_{i}\), \(E_{i}\), and \(\alpha _{i}\) denote cross-sectional area, Young’s modulus, and the coefficient of linear thermal expansion of the \(i\)-th material, respectively. Since the final length of both the cylinder and the bar after deformation is the same, the following relation holds

The equilibrium of the internal forces is described by

Solving Eqs. (13.37) and (13.38) gives the stresses

Substitution of these stresses into Eq. (13.36) gives the elongations of the cylinder and the bar

Problem 13.11.

Two circular bars, one is mild steel of length \(50\) cm and diameter \(1\) cm, and the other is aluminum of length \(25\) cm and diameter \(2\) cm, are attached to each other in series, placed between rigid walls, and subjected to the temperature change \(\tau =T_1-T_0\), as shown in Fig. 13.4. Calculate the temperature rise needed for the thermal stresses in the bars to reach the compressive strength. The coefficient of linear thermal expansion, Young’s modulus and the compressive strength for mild steel are \(\alpha _{1} = 11.2 \times 10^6\) 1/K, \(E_{1} = 206\) GPa and \(400\) MPa, respectively. The coefficient of linear thermal expansion, Young’s modulus and the compressive strength for aluminum are \(\alpha _{2} = 23.1 \times 10^6\) 1/K, \(E_{2} = 72\) GPa and \(70\) MPa, respectively.

Solution.

The elongations of bar 1 and 2 are, respectively, given by

As two bars are placed between rigid walls, the combined elongation of the bars is zero. Thus,

From the equilibrium condition of internal forces, the internal force in bar 1 is equal to the internal force in bar 2

From Eqs. (13.40) and (13.41), the thermal stresses \(\sigma _{1}\) and \(\sigma _{2}\) are given as

Therefore, the necessary temperature rise for bar 1 is

Numerical calculation gives the temperature rise

On the other hand, the necessary temperature rise for bar 2 is given by

Therefore, the necessary temperature rise is

Then, comparison between Eqs. (13.44) and (13.46) gives the necessary temperature rise 81 K.

Problem 13.12.

A hollow cylinder with an inserted screw, shown in Fig. 13.5 is subjected to different temperature changes \(\tau _{i}, (i=1, 2)\). Calculate the thermal stresses produced in both the hollow cylinder and the screw.

Solution.

The elongations \(\lambda _{i}\) due to both the free thermal elongation and the thermal stress are

where \(A_{i}\), \(E_{i}\), and \(\alpha _{i}\) denote cross-sectional area, Young’s modulus, and the coefficient of linear thermal expansion of the \(i\)-th material, respectively. Since the final length of both the hollow cylinder and the screw after deformation is the same, the following relation holds

The equilibrium condition of the internal forces is described by

Solving Eqs. (13.48) and (13.49) gives the thermal stresses

Problem 13.13.

A copper tube is fastened by a mild steel bolt, as shown in Fig. 13.6. The length of the tube is \(50\) cm, and the cross-sectional areas of the bolt and the tube are \(A_s=1\) cm\({}^{2}\) and \(A_c=2\) cm\({}^{2}\), respectively. Calculate the thermal stresses produced if the system is subjected to the temperature change of \(80\,\text{ K }\). The coefficient of linear thermal expansion and Young’s modulus for mild steel are \(\alpha _s = 11.2 \times 10^6\) 1/K and \(E_s = 206\) GPa, respectively. The coefficient of linear thermal expansion and Young’s modulus for copper are \(\alpha _c = 16.5 \times 10^6\) 1/K and \(E_c = 120\) GPa, respectively.

Solution.

Since the final length of both the copper tube and the mild steel bolt after deformation is the same, the following relation holds

The equilibrium condition of the internal forces is described by

Solving Eqs. (13.50) and (13.51) gives the stresses

The numerical results are

Problem 13.14.

In the foregoing problem, calculate the maximum tolerable temperature rise such that stresses in the system do not exceed the compressive or the tensile strength. The tensile strengths of the steel and the copper are \(\sigma _{st}=400\) MPa and \(\sigma _{ct}=300\) MPa, respectively. We assume the compressive strength has the same magnitude as the tensile strength. The safety factor (defined by the ratio of yield stress or the tensile strength and the tolerable stress) is \(f=3\).

Solution.

The stresses due to the temperature change \(\tau \) are given by Eq. (13.52), namely

The tolerable stress of a mild steel bolt is

The maximum tolerable temperature rise\(\tau \) of the mild steel bolt is given by

Tolerable stress of the copper tube is

The maximum tolerable temperature rise\(\tau \) of the copper tube is given by

Therefore, from Eqs. (13.55) and (13.57), the maximum tolerable temperature rise is 227 K.

Problem 13.15.

A bar of mild steel of cross-sectional area\(A_s\) is placed between two parallel bars of copper of cross-sectional area \(A_c\), shown in Fig. 13.7. When the three bars of same length \(l\) are bonded together and are subjected to a temperature change of \(\tau _s\) in the bar of mild steel and \(\tau _c\) in the bar of copper, calculate the thermal stresses produced in each bar.

Solution.

The final lengths of middle steel and two copper bars are same

While the equilibrium condition of internal forces gives

From Eqs. (13.58) and (13.59) we get

Problem 13.16.

Calculate the thermal stresses produced in the bars of the truss shown in Fig. 13.8, if the temperature changes of the bars are \(\tau _{i}\).

Solution.

The relation between the elongation of bar 1 and bar 2 is

Therefore,

The relation between the length of bar 1 and bar 2 gives

Substitution of Eq. (13.62) into (13.61) reduces to

Then

The equilibrium of internal forces requires

Solution of Eqs. (13.64) and (13.65) gives

Problem 13.17.

Calculate the thermal stresses produced in the bars which hang from a rigid plate shown in Fig. 13.9, if the temperature changes of the bars are \(\tau _{i}\). The weight of the rigid plate may be neglected.

Solution.

The elongations of each bar are

The equilibrium condition of the internal forces in each bar requires

The equilibrium of the moments at the point A is

The relation between the elongation of each bar is

Solution of Eqs. (13.67), (13.68) and (13.69) gives

in which

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2013 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Eslami, R., Hetnarski, R.B., Ignaczak, J., Noda, N., Sumi, N., Tanigawa, Y. (2013). Thermal Stresses in Bars. In: Theory of Elasticity and Thermal Stresses. Solid Mechanics and Its Applications, vol 197. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-6356-2_13

Download citation

DOI: https://doi.org/10.1007/978-94-007-6356-2_13

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-6355-5

Online ISBN: 978-94-007-6356-2

eBook Packages: EngineeringEngineering (R0)