Abstract

Zero running emission, sustainability and efficiency of Electric Vehicle (EV) make it appropriate option for future transportation. In-wheel propulsion system of electric vehicles has been one of the main research concentrations in past decades. Brushless DC (BLDC) motor is the most suitable in-wheel motor because of its high efficiency, torque/speed characteristics, high power to size ratio, high operating life and noiseless operation. In this chapter direct torque control (DTC) switching technique with digital pulse width modulation (PWM) speed controller of BLDC motor for drive train system of EV has been reported. Effectiveness of the proposed BLDC motor drive is investigated through simulation and experiment. Obtained results show effective control of torque and remarkable reduction of torque ripple amplitude compare to conventional reported switching techniques. Improvements of in-wheel motor’s torque controllability result to more efficient and safer electric vehicles.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Idea of using electricity instead of fossil fuels for propulsion system of vehicles is not new. Scientists and manufacturers have attempted to design or improve electric vehicles from long time ago. Rodert Anderson built the first electric carriage in 1839 and David Salomon developed an electric car with a light electric motor in 1870, however batteries were heavy at that time and performance was poor [1]. Nowadays hybrid vehicles are more popular than electric vehicles due to better mileage and absence of enough infrastructures for charging battery of electric vehicles. Using in-wheel technology, by wire technology and intelligent control systems instead of conventional hydraulic or pneumatic control systems result to an Intelligent Fully Electronically Controlled Vehicle (IFECV) [2]. Schematic diagram of four wheel drive train of an IFECV is shown in Fig. 1.

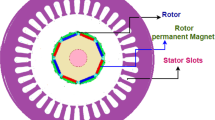

Improving performance of in-wheel motor and its controller can increase efficiency, controllability and safety of electric vehicles. Various electrical motors have been used by manufacturers in last decades. Brushed DC, induction, switched reluctance and BLDC motors have been compared and BLDC has been recommended for high performance electric vehicle [2]. High efficiency, high speed ranges and high dynamic response due to permanent magnet (low inertia) rotor are immediate advantages of BLDC motor over brushed DC and induction motors for electric vehicle application. BLDC motor is a type of DC motor which commutation is done electronically. Therefore it has more complex control algorithm compare to other motor types. Commutation is done by knowing exact position of permanent magnet rotor. Typically there are two algorithms for rotor position detection. One uses usually sensors (Hall Effect) and the other does not which is called sensorless. Hall Effect sensors are mounted inside motor in 120 electrical degrees to detect rotor position. Optical encoders are used for high resolution applications [3]. Back-EMF monitoring, flux linkage-based technique and free-wheeling diode conduction are some of sensorless control methods that can be used to commutate BLDC motor instead of using sensors [4]. Reducing complexity of motor construction, cost and maintenance are obvious advantages of sensorless control techniques but sensing back-EMF at low speeds, transient time and discontinuous response due to high commutation rates are its disadvantages.

Priceless researches and works have been discussed for developing different control algorithms of BLDC motor [4–8]. Sensorless control technique with a new flux linkage function has been reported for BLDC motors [4]. This method improves problem of sensorless control techniques at low speeds. A speed-independent position function named “\(\mathrm{G}(\theta )\)” has been defined with respect to mechanical angle of rotor. This technique is able to detect position of rotor at around 1.5 % of nominal speed. It is suitable for in-wheel application because we need to control the motor from stall position. Four-switch converter with the current controlled PWM control technique has been proposed for BLDC [5]. Difficulties in generating 120\(^\circ \) conducting current profiles in three phase winding of BLDC with four-switched converter and current distortion in two phase cause by back-EMF of silent phase are main problems of proposed technique. A new power supply, DSP-controlled PWM chopper and C-dump converter has been reported for BLDC motor drive [6]. A dual speed and current closed-loop control is used to keep ratio of voltage to frequency constant to have constant torque operation of motor. Forced commutation RC circuits and snubber circuits to control commutation and \({ dv}/dt_{ }\) rating on switches have been discussed. Simulation results show number of current spikes which cause increase on torque ripple of BLDC motor which is not suitable for in-wheel application. An adaptive fuzzy control scheme via parallel distributed compensation has been applied to control velocity of small BLDC motors [7]. Simulation results show stable velocity control of BLDC motor in case of any parameter perturbation. Although stability and smoothness of torque is essential in high performance EV’s, but it would be constructive for other applications like scooters and electric bikes. A digital controller of BLDC motor with two mode of operation, namely conduction angle control and current mode control has been introduced [8]. Torque is directly proportional to current in BLDC, thus current control results to torque control of motor. Speed ripple of BLDC is reduced via proposed digital controller up to maximum of 3.4 %. This method could be more suitable for EV application if torque ripple reduction also has been considered [9].

DTC technique is a sensorless control technique. It does not use any Hall Effect sensor for detecting rotor position. Output torque of an electric motor is directly proportional to output power of the motor. Therefore torque control is one of important factors in drive train of electric vehicle. Reduction of torque ripples cause to deliver smoother power to the wheel. Delivering as minimum as possible ripple free torque with desired value to the wheels in various conditions, essentially increase safety and efficiency of electric vehicle. Therefore DTC switching technique is a suitable choice for high performance electric vehicles [9].

In this chapter direct torque control switching technique and PWM speed controller of BLDC motor reported in [9] for drive train of electric vehicles are described in more details. Simulation and experimental results of proposed BLDC drive are presented and discussed.

2 Direct Torque Control of BLDC Using Three Phase Conduction Mode

Direct torque control (DTC) technique of induction motors has been proposed for the first time by Takahashi and Noguchi in 1986 [10] and Depenbrock in 1988 [11]. Recently, many researchers worked on DTC of BLDC motor for applications which need precise torque control [12–17]. DTC of BLDC for drive train of hybrid electric vehicle is presented [16]. Schematic diagram of DTC of BLDC motor is shown in Fig. 2.

Torque error, stator flux error and stator flux angle are regularly used to select proper voltage space vector for switching in DTC technique. Here flux linkage error is eliminated Because of variations of stator flux magnitude regarding changes in resistance, current and voltage and specifically sharp dips at every commutation [12]. BLDC operates in both constant torque region and constant power region. Back-EMF of motor is below DC voltage source of inverter in constant torque region (below base speed) and is increased more than DC voltage value above nominal speed. Stator inductance avoids abrupt increase of phase current and deteriorates output torque of motor. Therefore in this paper operation of BLDC motor is considered at constant torque region. Accurate estimation of flux linkage magnitude and torque is required for DTC of in-wheel motors. In some techniques, Current sensors have been used to determine flux linkage and estimate voltage from DC bus of inverter [14, 16, 17]. This method is too sensitive to voltage errors caused by dead-time effects of inverter switches, voltage drop of power electronic devices and fluctuation of DC link voltage [18]. In this chapter, both current and voltage sensors are used for accurate estimation of flux linkage magnitude and torque [15].

Precise estimation are mainly depends on accurate sensing of currents and voltages. Variations of stator resistance due to changes of temperature cause error in stator flux estimation. Pure analogue integrator also produces DC offset in signal. It is considered that BLDC motor is working in constant torque region below rated speed. Therefore there is no need of flux magnitude change during operation. Second algorithm proposed in [19] with limiting level of \(2K_L \pi /(3\sqrt{3})\) (\(K_L \) is flux linkage) is used to solve analogue integrator DC drift error.

Clarke transformation is used to convert the balanced three phase system (voltages and currents) to the \(\alpha \beta \)-axis references. Stator flux linkage magnitude, stator flux angle and electrical torque of motor can be estimated by [9],

where \(R\) is stator resistance, \(L\) is stator inductance, \(V_\upalpha \) is \(\upalpha \)-axis voltage vector, \(V_\beta \) is \(\upbeta \)-axis voltage vector, \(i_\alpha \) is \(\upalpha \)-axis current vector, \(i_\beta \) is \(\upbeta \)-axis current vector, \(\varphi _{S\alpha } \) is \(\upalpha \)-axis stator flux vector, \(\varphi _{S\beta } \) is \(\upbeta \)-axis stator flux vector, \(\varphi _{S\alpha } \) is stator flux magnitude, \(\theta _S\) is stator flux angle, \(e_\alpha \) is \(\upalpha \)-axis back-EMF, \(e_\beta \) is \(\upbeta \)-axis back-EMF, \(T_e \) is electric torque. After finding values of stator flux linkage in the stationary \(\upalpha \upbeta \)-axis by (1) and (2), flux linkage magnitude and angle are calculated from (5) and (6). By deriving rotor flux linkage from (3) and (4) torque of BLDC is evaluated by (9).

Hysteresis controller will generate square wave pulse with respect to torque error. Hysteresis controller output is ‘1’ if the actual value of torque produced by motor is more than reference torque value of controller and is ‘0’ if actual torque value is less than reference value. In this paper hysteresis band limits has been set 1, 0.1 and 0. 01 to show torque ripple reduction capability of controller. The maximum switching frequency for minimum value of hysteresis band limits is near 10 KHz.

Three phase conduction mode is used for switching of VSI of BLDC motor. Six none zero voltage vectors that have been used to switch VSI are \(V_1 (100),V_2 (110),V_3(010),V_4 (011),V_5 (001),V_6 (101)\). Voltage space vectors are chosen with respect to output of torque hysteresis controller and stator flux angle of motor [20]. Estimated stator flux angle of BLDC motor has been divided to six equal sectors. Sector one is starting from \(-30\) degrees to 30 degrees and so on to complete one full rotation of flux linkage. Switching table of inverter to choose space vectors in each sector is shown in Table 1.

3 Digital PWM Speed Controller of BLDC

Various algorithms have been used for speed control of BLDC motor. Hysteresis current control and pulse width modulation (PWM) control are the most widely used BLDC motor control techniques [21]. Speed of BLDC motor is directly proportional to its terminal voltages. A three phase voltage source is used to supply voltage to the BLDC motor. There are two methods to adjusting the average output voltage of VSI, the variable DC link inverter and PWM switching technique. In variable DC link technique, DC bus voltage of inverter is adjusted to get the desired speed of motor. In PWM technique, a duty cycle controlled high frequency signal is multiplied to either control switching signals of upper switch of each leg, or lower switch of each leg, or all six switches of VSI [3].

In the proposed drive of BLDC motor, PWM technique is employed for speed control. PWM technique reported by Sathyan et al. [21], two predetermined states of duty cycle values (high, DH, and low, DL, PWM duty cycles) have been chosen to control the speed of BLDC motor. In this chapter a proportional and integral (PI) controller is utilized to choose a duty cycle of high frequency signal with respect to speed error. Therefore, ideally one duty cycle is chosen by controller for any particular reference speed. However, practically the controller continuously changes duty cycle value in boundaries around ideal duty cycle instead of having two predefined values [22]. Regarding safety issue which is vital factor in electric vehicles, high frequency signal is added to all six switches of inverter [3].

4 Simulation Results and Discussion

The proposed direct torque controlled drive of BLDC motor for in-wheel application is simulated by MATLAB/SIMULINK. Specification and parameters of BLDC used in simulation model are listed in Table 2. Simulation results are compared with conventional Hall Effect switching method. It is shown that controller is able to estimate torque, flux linkage magnitude and angle of BLDC precisely. By applying various hysteresis band limits, electrical torque variation is controlled in desired limit.

Speed response and torque response of DTC of BLDC for 1500 rpm speed reference under 10 N.m torque load is shown in Fig. 3. Sampling time is 5 \(\upmu \)s and Hysteresis band limit is set to 0.01. Model is tested for different hysteresis bands and torque responses are shown in Fig. 4. Simulation results of Fig. 4 show that width of Hysteresis band limit effects amplitude of torque ripple of BLDC motor. Peak to peak amplitude of torque ripple is reduced up to four percent of reference torque (0.4 N.m) in simulation model of proposed DTC. It is 10 times lesser than conventional Hall Effect sensors control technique. Proposed BLDC drive has a better torque response compare to presented model in [16].

Although reducing hysteresis band limits result in smoother torque but increase switching frequency of VSI. Switching frequency directly affects switching loss of inverter and practically it may not possible to have high switching frequencies. Therefore hysteresis band limits cannot be less than a particular threshold practically.

The stator flux magnitude and flux angle of BLDC motor are shown in Fig. 5. It can be observed that the stator flux magnitude in constant torque region is oscillating around 0.22 Wb. The flux magnitude value is almost the same as limiting level of integration algorithm.

Stator flux linkage locus of BLDC for different load torques (5 N.m and 10 N.m) is shown in Fig. 6.

The flux linkage angle sectors are clearly visible in Figure. As it can be seen increasing of torque load cause increase of flux magnitude and more sharp changes are observed [12].

According to in-wheel motor requirements, robustness of motor and controller is critical in safety point of view. Behavior of BLDC motor for proposed DTC drive and conventional Hall Effect switching technique is compared under same mechanical shocks. Sudden fifty percent change of torque load (from 10 N.m to 15 N.m) is applied to BLDC model at 1500 rpm reference speed. Speed response and torque response of BLDC motor under torque load change are shown in Figs. 7 and 8, respectively.

Abrupt change of torque load is applied at time 0.4 second. As it can be seen in Fig. 7, the speed response of DTC technique is almost fifteen times faster than conventional switching technique under mechanical shock. Speed fluctuation of DTC is more than conventional switching technique, however its torque response is smoother. Figure 8 shows that dynamic torque response of DTC is much faster than Hall Effects witching technique.

5 Experimental Results

Effectiveness of proposed DTC switching technique and PWM speed controller for BLDC motor is investigated by experiment. Experimental setup of BLDC motor is shown in Fig. 9. A low voltage BLDC motor is tested as prototype. PIC18F4231 microcontroller on development board of microchip is programmed to implement proposed drive of BLDC motor. A three phase voltage source inverter with MOSFET switches is used to supply BLDC motor. The BLDC motor specification for experiment is given in Table 3.

Direct torque control switching technique of BLDC motor is tested for 0.1 N.m reference torque and 0.01 hysteresis band limits. Reference speed of PWM speed controller is set to 2000 RPM (below nominal speed of motor). Torque response of BLDC is shown in Fig. 10.

High frequency controlled PWM signal is applied to all six switches of inverter. The line voltage of phase ‘A’ of BLDC motor with respect to negative terminal of DC source of inverter is shown in Fig. 11. Experimental results of proposed drive are satisfactory and show correct performance of BLDC motor.

6 Conclusion

There is a growing attention to the electric vehicles in automotive industry due to control of emission of greenhouses gases in atmosphere. In-wheel technology is an advanced propulsion system in electric vehicles. BLDC motors are in interest of many manufacturers for in-wheel application. In this chapter, direct torque control switching technique of BLDC motor has been proposed as a suitable choice for drive train of electric vehicles. Simplified proposed DTC model of BLDC motor without flux observation for constant torque region has been simulated simultaneously with a digital PWM speed control technique. Proposed model has also been practically tested. The obtained results show that estimated torque calculated with state observer is very close approximation of actual output torque of motor. In this case, it has been possible to successfully control torque ripple amplitude by adjusting of Hysteresis band limit. In this model, torque ripple amplitude has reduced effectively. Hence, the developed DTC switching technique is capable of minimizing the pulsating torque of BLDC motor to deliver smoother power to the wheels. Consequently safety and efficiency of electric vehicle has been improved.

References

Bergsson K (2005) Hybrid vehicle history more than a century of evolution and refinement, http://www.hybrid-vehicle.org/hybrid-vehicle-history.html, Accessed 18 Sep 2012

Tashakori A, Ektesabi M, Hosseinzadeh N (2011) Characteristics of suitable drive train for electric vehicle. In: Proceedings of international conference on instrumentation, measurement, circuits and systems (ICIMCS 2011), vol 2. ASME, pp 51–57

Tashakori A, Ektesabi M (2012) Comparison of different PWM switching modes of BLDC motor as drive train of electric vehicles. (World Academy of Science) J Eng Technol 67:719–725

Tae-Hyung K, Ehsani M (2004) Sensorless control of the BLDC motors from near-zero to high speeds. IEEE Trans Power Electron ISSN 0885–8993, p1635

Lee BK, Ehsani M (2001) Advanced BLDC motor drive for low cost and high performance propulsion system in electric and hybrid vehicles, Texas A &M University, Dept. of Electrical Engineering, College Station, TX 77843–3128, USA

Luo FL, Yeo HG (2000) Advanced PM brushless DC motor control and system for electric vehicles. In: Proceedings of IEEE industry applications conference 2000, vol 2. Singapore, pp 1336–1343

Choi J, Park C, Rhyu S, Sung H (2004) Development and control of BLDC Motor using fuzzy models. In: Proceedings of IEEE conference on robotics, automation and mechatronics 2004, vol 2. Singapore, pp 1180–1185

Rodriguez F, Emadi A (Oct. 2007) A novel digital control technique for brushless dc motor drives. IEEE Trans on Industrial Electronics 54:2365–2373

Tashakori A, Ektesabi M (2012) Direct torque controlled drive train for electric vehicle. In : Proceeding of the world congress on engineering, WCE 2012. Lecturer notes in engineering and computer science, London, UK, 4–6 July 2012, pp 948–952

Takahashi I, Noguchi T (1986) A new quick-response and high-efficiency control strategies of an induction motor. IEEE Trans Ind Appl 22(5):820–827

Depenbrock M (Oct. 1988) Direct self-control of inverter-fed induction machine. IEEE Trans on Power Electronics 3(4):420–429

Ozturk SB, Toliyat HA (2007) Direct torque control of brushless dc motor with non-sinusoidal back-EMF. In: Proceedings of IEEE international conference on electric machines & drives, vol 1. IEMDC, pp 165–171

Oz turk SB, Toliyat HA (2008) Sensorless direct torque and indirect flux control of brushless dc motor with non-sinusoidal back-EMF. In: proceedings of 34th annual conference of IEEE on industrial electronics IECON 2008, pp 1373–1378

Yang J, Hu Y, Huang W, Chu J, Gao J (2009) Direct torque control of Brushless DC motor without flux linkage observation. In: proceedings of IEEE 6th international power electronics and motion control conference IPEMC 2009, pp 1934–1937

Wei-Sheng Y, Hai L, Hong L, Wei Y (2009) Sensorless direct torque controlled drive of brushless DC motor based on fuzzy logic. In: Proceedings of 4th IEEE conference on industrial electronics and applications ICIEA 2009, pp 3411–3416

Gupta A, Taehyung K, Taesik P, Cheol L (2009) Intelligent direct torque control of brushless dc motors for hybrid electric vehicles. In: Proceedings of IEEE conference on vehicle power and propulsion VPPC, pp 116–120

Ozturk SB, Toliyat HA (April 2011) Direct torque and indirect flux control of brushless dc motor. IEEE/ASME Trans Mechatron 16:351–360

Vas P (1998) Sensorless vector and direct torque control, Oxford University Press, 1998

Hu J, Wu B (1998) New integration algorithms for estimating motor flux over a wide speed range. IEEE Trans Power Electrons 13(5):969–977

Zhong L, Rahman MF, Hu WY, Lim KW (1997) Analysis of direct torque control in permanent magnet synchronous motor drives. IEEE Trans Power Electron 12(3):528–536

Sathyan A, Milivojevic N, Lee Y, Krishnamurthy M, Emadi A (2009) An FPGA-based novel digital PWM control scheme for BLDC motor drives, IEEE Trans Ind Electron 56(8): 3040–3049

Tashakori A, Ektesabi M (2012) Stability analysis of sensorless BLDC motor drive using digital PWM technique for electric vehicles. In: Proceedings of 38th annual conference of IEEE on industrial electronics, (IECON 2012) (accepted), Montreal, Canada, 25–28 Oct 2012

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Tashakori Abkenar, A., Motamed Ektesabi, M. (2013). Direct Torque Control of In-Wheel BLDC Motor Used in Electric Vehicle. In: Yang, GC., Ao, Sl., Gelman, L. (eds) IAENG Transactions on Engineering Technologies. Lecture Notes in Electrical Engineering, vol 229. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-6190-2_21

Download citation

DOI: https://doi.org/10.1007/978-94-007-6190-2_21

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-6189-6

Online ISBN: 978-94-007-6190-2

eBook Packages: EngineeringEngineering (R0)