Abstract

The paper provides an overview of the structural optimization system development. The basis and also the primary idea for algorithm formulation was the bone remodelling phenomenon leading to the optimization of the trabecular net within the bone. The idea was completed with theorems concerning the surface constant strain energy principle to form the biomimetic optimization system. The paper describes the key element of the optimization procedure: our own mesh generator called Cosmoprojector. It also presents the concept of Finite Element mesh parallel generation as well as Finite Element Analysis in a parallel environment as a recent enhancement of the presented method. Finally, it presents some results of computations obtained with the use of biomimetic structural optimization.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Bone Remodeling Simulation

- Trabecular Bone Adaptation

- Strain Energy Density (SED)

- Structural Optimization Method

- Topology Optimization

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

The Wolff law, stated in the 19th century, says that bone is capable of adapting itself to mechanical stimulation. After carrying out many experiments, it is now clear that the number and organization of beams in trabecular bone tend to a mechanical optimum. There are many models of bone remodelling [2, 3, 7, 9] used for the adaptation simulations of bone, treated as a continuum material. The main idea behind that is to prepare a model for bone adaptation as a material of specific properties. These properties vary and depend on the load history. The progress in computer hardware technology and parallel computations now enable modelling of the bone adaptation process using the real topology of the trabecular bone with the use of a linear model of the trabecula [3, 7]. The latter one is justified by experimental investigations stating that on the trabecular level bone can be treated as a linear material. Such an approach can be considered as very useful, especially when the details of mechanical stimuli are discussed. The trabecular bone mechanical adaptation process is similar to all other structural optimization problems. In this context, the bone remodelling could be also the model of the structural optimization procedure.

The paper presents the main stages of the numerical implementation of this concept, from the idea of bone remodelling simulation to parallel structural optimization. Section 18.2 covers the basic assumptions of numerical simulation of the trabecular bone remodelling process. Section 18.3 recalls the theoretical background for treating the biological process as a pattern for the structural optimization. Section 18.4 presents the practical realisation of the structural optimization method based on the bone remodelling model. Section 18.5 describes the recent enhancement of the presented system—parallelisation of the Finite Element Method (FEM) mesh generation. Section 18.6 presents the numerical example summarizing the overview of the system.

2 Simulations of Trabecular Bone Adaptation to Mechanical Loading

The healthy bone trabecular tissue has a very sophisticated structure. The tissue forms a network of beams called trabeculae and this structure is capable of handling a wide range of loads. The length of the trabecula amounts to one or two hundred micrometers whereas its diameter is about 50 micrometers. This structure is continually rebuilt so that the whole bone tissue is replaced in the course of about three years and the process is called the trabecular bone adaptation or remodelling. The examined phenomenon is based on the balance between bone resorption and formation of the new tissue. Thus the trabecular bone is capable of repairing the fractures, by simply replacing part of its structure with the new one.

The phenomenon of trabecular bone adaptation has two important attributes. Firstly, the mechanical stimulation is needed to conserve the rebuilding balance. Secondly, the process of resorption and formation occurs on the trabecular bone surface only. The need of effective simulation of bone remodelling was the beginning of the presented optimization system [4].

The developed generic three-dimensional system for bone remodeling simulation employing the Finite Element Method (FEM) consists of the following three blocks: FEM preprocessing, FEM solution, and optimization and modification procedures. The system used in this study uses the algorithm of bone remodeling stimulated by mechanical loading, based on the strain energy density (SED) distribution. The beams of trabecular bone are assumed to be made of isotropic linear elastic material where the marrow space is treated as voids. In contrast to other approaches used so far, the system mimics the real bone geometry evolution where not only the volumetric FEM mesh but also the surface of the trabecular network is controlled during the simulation. Because the remodelling process occurs only on the surface of the trabecular bone, only the ‘surface’ layer of the structure is taken into consideration during the simulation process. In contrast to other voxel models, the approach adopted in this system does not relay on earlier voxel discretisations, but mimics the natural evolution of the bone tissue as the biological process of bone formation and resorption.

Adaptation to the mechanical stimulation results in adaptation of the surface position in the virtual space. The surface position adaptation is realized on the two-dimensional input images in the graphical form, by adding or removing pixels. Thus, both the consolidation and the separation of the tissue can be modeled easily. Figure 18.1 shows the remodeling simulation of the trabecular bone sample under compression with the use of the presented system [4].

Remodelling simulation of the trabecular bone sample under compression with the use of the presented system [4]

3 Remodelling as a Structural Optimization Process

The two attributes of trabecular bone remodelling, mechanosensitivity and surface adaptation, can be described from the point of view of mechanics. Bearing in mind the design with optimal stiffness [6, 10], one can conclude that for the stiffest design the strain energy density along the shape to be designed must be constant:

In the case of bone, the remodelling scenario described above, based on the phenomenological model, seems to realize the postulate of the constant value of the strain energy density. By balancing the SED value on the bone surface, the stiffness of the entire structure is ensured. In ideal conditions when the bone structure is only rebuilt, also the volume constraint is valid. In the real process, the bone volume undergoes continuous change. In this study the presented examples employ the scenario of bone remodelling which assumes changes of the bone volume in the successive iterations.

So, the fixed volume constraint, resulting from the minimum compliance discussion, is not a case in the bone remodelling. The optimization goal can also be formulated as a minimum volume problem with assumed fixed strain energy. The resulting condition concerning the strain energy density is the same as in the case of the minimum compliance, so the value of the strain energy density on the designed surface must be equal when the volume is minimal by the assumed value of the strain energy in the structure.

In the model of bone remodelling, there is a special value of strain energy density—the energy of homeostasis where the balance between resorption and formation of the bone tissue is perfect. Figure 18.2 shows the computation scheme with strain energy density as a remodelling criterion.

Now, after the discussion of the stiffest design issues, the numerical implementation of the bone remodelling can be treated as a par excellence structural optimization procedure.

A more detailed description of the assumptions and the arguments can be found in [5, 6, 10].

4 Structural Optimization Method Based on the Bone Remodelling Scheme

The developed numerical trabecular bone remodelling simulation environment was dedicated to and tested for biomechanical purposes. To compare the optimization procedure based on trabecular bone surface adaptation to the standard optimization method, a typical topology optimization method example, i.e. the bending cantilever beam, was chosen. To illustrate the special features of the proposed optimization technique, the domain was reduced to a minimum, and the fixed part of the structure was simply connected to the loaded part. As it was possible to add material during the simulation, the result shown in Fig. 18.3 is very similar to the three-dimensional solution given in the Topology Optimization book by Bendsøe and Sigmund [1, p. 25]. The result is similar, but starting from such domain, it is not possible to achieve the solution using the standard method of topology optimization. This feature, which facilitates adaptation of the structure conserving functional configurations, necessary in the case of biological structures, can also be valuable for mechanical structures (in space or civil engineering) [5].

Optimization results of the cantilever beam using the presented system, based on the trabecular bone surface adaptation—an empty domain [5]

5 Parallellisation of the Mesh Generation Procedure

Due to necessity of surface control and the specific rules of structural adaptation, the optimization procedure requires relatively big computational effort to produce an appropriate and accurate mesh. The development of the structural optimization method was thus focused on the use of a parallel computational environment to generate the structural mesh.

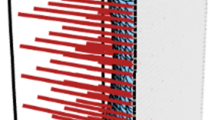

The presented method is based on structure evolution. Thus, a bottleneck of the optimization process is finite element mesh generation for each step of structural evolution. The finite element mesh generator, Cosmoprojector, was originally dedicated to mesh creation for biological entities. Since the visualization for the biological entities is based on the digital images, e.g., Computer Tomography, the input to the system is also based on the collection of the two-dimensional images. After some graphical operations the images of slices are directly used for the building of the three-dimensional finite element mesh. The two-dimensional image is first translated into the bitmap where ‘0’ represents void and ‘1’ the tissue. On the bitmap the initial step of discretisation is executed. The aim of this first step is to describe the areas with tissue (or just the material in the case of optimization issues). The discretisation procedure produces a two-dimensional network of tetragonal elements, according to the tissue image shape. The discretised two-dimensional image is projected to the subsequent one. If there are areas containing material on both images, the boxes are created. Each box is in turn translated into six tetrahedral volume elements. The information about nodes and elements is stored in a special database and translated into an ABAQUS finite element system input file. The system has to enable the surface control, so in the whole structure the elements on the structure are distinguished. The detailed scheme of the mesh generation procedure is shown in Fig. 18.4.

The strain energy density computations are carried out in a parallel environment, which is a condition to solve bigger problems. But the same question concerns mesh generation, especially if the mesh element’s number is of order 106.

To increase the capabilities of the optimization system the mesh generation tool was parallelised. The scheme of the parallel mesh generation procedure is shown in Fig. 18.5. In the natural way the mesh generation for the whole domain can be divided into independent tasks. The only change is the modification of input data necessary to define the overlapping areas. The aim of overlapping areas is to ensure that the slice-by-slice mesh creation procedure is independent of the number of processors used in the computation. The parallel finite element mesh generator was successfully tested up to 200 nodes and is able to create meshes of order of millions tetrahedral elements.

6 The Multiphisics Example—Biomimetic Structural Optimization Coupled with Aeroelastic Analysis

As an example of the biomimetic structural optimization method described here, the problem of internal wing structure design is presented. To design an aircraft structure, the coupled fluid-structure interactions (FSI) simulations are crucial. On the other hand, for the structural design optimization techniques have to be used.

There are many examples of using optimization techniques to design the structural elements of an aircraft [8]. In the recent years, especially the topology optimization method has been introduced to the designing processes. A good industrial example is the structure of the Airbus A380 wing. The structural elements of the wing were designed in two designing steps. First, the optimal material distribution was defined using the topology optimization—the SIMP method. Then, after extraction of geometry from the topology optimization results, the model for size and shape optimizations was derived. The size and shape optimizations were the next step in the wing designing process. Splitting the topology and then the size and shape optimizations is necessary because of completely different optimization methods used in each case. The biomimetic approach described here allows comprising the optimizations of size, shape, and topology. Also the varying loads during the aeroelastic analysis due to assumptions adapted directly from the trabecular bone remodelling phenomenon do not interfere with the optimization process.

Figure 18.6 depicts the algorithm for coupling aeroelastic analysis with structural optimization. The approach presented here is based on the assumption that different codes will be used separately for each part of the simulation field. The starting domain was an empty domain in the internal area of the airfoil. The outer shape of the wing retains its form during the whole simulation process. The optimization procedure starts by computing the aerodynamic load resulting from the CFD computations. Then, the pressure distribution on the outer wing surface is interpolated on the structural mesh and the optimization loop is performed. The results of coupled aeroelastic analysis and biomimetic optimization for the whole internal wing structure is shown in Fig. 18.7.

7 Conclusions

The idea of bone remodelling simulation was the foundation of the studies which resulted in the creation of the numerical system capable of mimicking a real biological phenomenon. This system was a numerical base for the structural optimization method based directly on the principle of constant strain energy density on the surface. The biomimetic structural optimization method has some unique properties. The domain independence, functional configurations during the process of optimization, and a possible solution of multiple load problems are special features which provide new possibilities in the area of structural optimization. Thus, using the approach presented above it is possible to comprise optimizations of size, shape, and topology with no need to define parameters. The presented method is able to produce results similar to the standard method of topology optimization and can be useful in mechanical design, especially when functional structures are needed during the optimization process, broadening the spectrum of possible applications. Due to parallelisation of both the structural analysis of strain energy density distribution and volume mesh generation, the presented method can be useful in real industrial problems. The initial concept of the optimization system was dedicated to the bone remodelling purposes. Over time, the concept has evolved, and today it can be a useful tool for mechanical design.

References

Bendsøe MP, Sigmund O (2003) Topology optimisation. Theory, methods and applications. Springer, Berlin

Huiskes R, Ruimerman R, van Lenthe GH, Janssen JD (2000) Effects of mechanical forces on maintenance and adaptation of form in trabecular bone. Nature 405:704–706

Niebur GL, Feldstein MJ, Yuen JC, Chen TJ, Keaveny TM (2000) High-resolution finite element models with tissue strength asymmetry accurately predict failure of trabecular bone. J Biomech 33(12):1575–1583

Nowak M (2006) A generic 3-dimensional system to mimic trabecular bone surface adaptation. Comput Methods Biomech Biomed Eng 9(5):313–317

Nowak M (2006) Structural optimization system based on trabecular bone surface adaptation. Struct Multidiscip Optim 32(3):241–249

Pedersen P (2003) Optimal designs—structures and materials—problems and tools. Technical University of Denmark. Draft, ISBN 87-90416-06-6

Ruimerman R, Van Rietbergen B, Hilbers P, Huiskes R (2003) A 3-dimensional computer model to simulate trabecular bone metabolism. Biorheology 40(1–3):315–320

Schramm U, Zhou M (2006) Recent developments in the commercial implementation of topology optimization. In: IUTAM symposium on topological design optimization of structures, machines and materials. Springer, Berlin, pp 239–248

Tsubota K, Adachi T, Tomita Y (2002) Functional adaptation of cancellous bone in human proximal femur predicted by trabecular surface remodeling simulation toward uniform stress state. J Biomech 35(12):1541–1551

Wasiutynski Z (1960) On the congruency of the forming according to the minimum potential energy with that according to equal strength. Bull Acad Pol Sci, Ser Sci Tech 8(6):259–268

Acknowledgements

This work was partially supported by the Polish Ministry of Science and Higher Education under the grant no. N N518 328835.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Nowak, M. (2013). From the Idea of Bone Remodelling Simulation to Parallel Structural Optimization. In: Repin, S., Tiihonen, T., Tuovinen, T. (eds) Numerical Methods for Differential Equations, Optimization, and Technological Problems. Computational Methods in Applied Sciences, vol 27. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-5288-7_18

Download citation

DOI: https://doi.org/10.1007/978-94-007-5288-7_18

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-5287-0

Online ISBN: 978-94-007-5288-7

eBook Packages: EngineeringEngineering (R0)