Abstract

Precision measurement of AC power at conversion rates comparable to the driving frequency is a challenging task but is a desirable feature in applications involving regulation of power, loaded on a device. Practically, the application assumes significance, typically in developing a test-bench for characterization of a power generation system such as engine (DG set), or to measure and manage the power load in a specified pattern. A good analysis of demands and deliveries of power loads require capturing of transient responses, leading to a need for faster conversion rates in the measurement. Since the AC power measurement involves RMS integration, known to be inherently a slower process, the transient phenomena like a step loading tends to get smudged during measurement and often could lose its identity. It is known that typical conversion rates of commercially available power meters are about 0.5–1 Hz. In the approach presented here, a specifically developed analog circuitry, that is built using industrially common analog devices is shown to provide a high definition RMS integration of the AC power (with a typical conversion rate better than 35 Hz for a 50 Hz signal source) that is developed, tested and qualified for its functional integrity.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Analog circuitry

- Engine testing

- Higher conversion rates

- Power regulation

- Precision AC transient capture

- RMS measurement

13.1 Introduction

Quality of electrical power is an important factor for the life today, with the AC power being made as the widest from of energy distribution and consumption. To maintain a good quality of service, having backup power generation units and in the other upcoming trend of having distributed power generation, use of engines of appropriate size is becoming more practical. This leads to an important need for assessment and qualifying of the engines on their performance in meeting the power demands for varied applications in tandem with fuel efficiency. With medium to small engines, this performance testing is a lucid indicator of its economic viability and evaluating this critically for varying loads is not a commonly addressed problem. In addressing this aspect, precision of measurement of power under transient states of operation is necessary for evaluating the compliance of the system under test. Building a test rig that has ability to load the system in a designated pattern is another important factor to render such tests carried out. In designing such a facility, a common and most important link is the high quality measurement system. The commercially available true RMS meters generally have a limited functional scope as regards to their response times and are not quite adoptable for using them for generating a control signal and in analyzing the transients cost effectively. The approach presented imbibes a cost effective electronic circuitry that is designed, built and tested in an attempt to address the issues mentioned.

The device presented has been developed and tested with an intention for producing an affordable industry standard electronic unit (EU) and is expected to enhance the scope of measurement of AC power to applications that are currently limited as mentioned before. The design imbibes multi-functionality to the module allowing it to be used also as precision voltmeter and ammeter, each of which can be independently used.

In realizing the test facility discussed, that calls for a regulated or controlled power levels that effectively corrects for fluctuations in power inputs and on fluctuations in load the design needs a control with an error correcting system having feedback loop of power output. The EU designed provides options for using precision feedback control of voltage and thereby controlling the RMS power of the system. This serves to either to regulate the power to constant value or to control it precisely in a predefined pattern. This aspect of control could also be found useful in certain other applications such as establishing of constant fluid flow rate or in constant torque devices.

13.2 Approach

The design concept involves rendering a high speed and a strongly linearized conversion of analog AC signals that correspond to the applied current and voltage on the device drawing the power, into the true RMS of power with all the signals processed in analog condition. The analog design adopted in the present approach is an important aspect that eliminates the ‘conversion time’ involved in a digital processing. The design is focused on a reliable measurement of power and uses lower number of components. The unit is designed to respond faster, to be better than half of the cycle period of the source signal. Active filters are integrated to selectively and dynamically filter out the ripples resulting at the integrators. The ripple free output could be reliably used in the high quality measurements or in controlling of external devices for power regulation or for other sub-systems with pre-designated actions such as power loading panels.

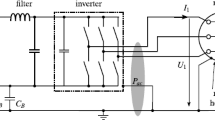

The operational schematics of the design features are shown Fig. 13.1. The input stages draw signals from a current transformer (CT) or from an alternate current sensor and another input from voltage transformer (PT) or an alternate sensor for it, to acquire separately the ‘current’ and ‘voltage’ of the monitored power device concurrently. The inputs are individually conditioned to suit subsequent processing.

The conditioned AC signals are rendered non–negative with a precision rectifier built out of active components and Schottky diodes [1, 2]. The output of this stage is fed to a two stage integrator taking care to see the integration is manage to be linear enough by selecting suitable range of charge pump. A bank of two analog low pass active filters of Butterworth design is introduced in cascade with a cut off frequency of 25 Hz (with the background that the source under measurement is at 50 Hz) that determines the adequateness of the response of the RMS conversions of the parameters—voltage and current. Two independent and identical processing streams consisting of these functional blocks of precision rectification, RMS Integration and low pass active ripple filtering constitute the analog linearized AC to DC converter for the current and voltages being measured. These parameters are multiplied in the analog state using AD632—a precision device from analog devices [3] that provides the quantity of power derived from the product of current and voltage signals. Provisions for adjustable gain and offset corrections are embedded at suitable points for end-use customization.

The design uses standard analog devices such as op-amps and other passive devices allowing for an option for standardization of the EU built for this at the end-user level. The required design information on the components is available in corresponding data sheets of the devices concerned. The design of active filter used, is based on the earlier well-established and long standing research activities as reported in [4–7].

13.3 The EU Built and Tested

The EU was built to test the designed circuitry.

Figure 13.2 gives a schematic capture of the circuit designed and Fig. 13.3 give the view of the test bench model built. The test board is powered by an AC power pack and commercially available CT and PTs are used as the sourcing sensors as can be seen in the Fig. 13.3.

13.4 Salient Operating Features

The EU has functionally three distinguishable operations. Sequence of their occurence in the measurement process is as listed.

1. Capturing and conditioning of inputs from voltage and current sensors.

2. Integration of the conditioned signals with true RMS feature.

3. Analog processing for multiplication of the filtered RMS outputs from the above stage rendering it to be the measure of the power.

CTs and VTs (used in this testing) but could be changed to more The measurement of voltage and current, the components for the power measurement is drawn from signals from sensors like precision sensing devices like Hall sensors or resistive sensors for a more reliable and linear measurements.

The signals from the transformers are conditioned (gained and trimmed off with offsets, if any) in two independent channels allowing for finer corrections on the inputs. Care is taken to include a rectifier with low small signal error [8, 9] before passing the signal on to an integrator. The integrator section has two stage integration and the RC combinations used are to reduce the non-linearity during the integration. The integration stages are allowed to have significant ripple factor, inherently to retain a better dynamic response.

A cascaded two stage active low pass filters of third order Butterworth design [10, 11] is used in sequence to these integrators so as to have the signal passing through them get off with the ripples and still retain the dynamic response at their best. While it is known that integration of the ACs will impose a loss of dynamic response the aspects discussed above take adequate measures in limiting this loss to a practical lower limit, thereby enabling an achievable best dynamic response for the unit.

Low pass active filters are designed for a cut off center frequency of 25 Hz. This is center frequency is selected to see that the major frequency component of the ripples being at around 100 Hz (twice the line frequency due to the rectification) would be well be eliminated and still will be responsive enough to the input variations. In this consideration, the EU selectively responds to variation of power (the parameter measured) and not to the native AC components of the signal. It can be viewed that the design stands at an optimum point having a trade–off between the fastest transients captured over the allowable ripple factors in the output. The active filter provides a good enhancement in the achievable frequency with no loss of measurement accuracy. Fine tuning options are provided to render the usage of the EU offering wider range in measurement and in meeting larger requirements. This is to make the unit more field–worthy. Distinct sample points for a diagnostic data acquisition were used for characterizing and studying the performance of the EU.

13.5 Results and Discussions

The EU was tested for its compliance to the design and its performance has been validated with a set of field as well as simulated test conditions [12]. The diagnostic data at different stages of the circuit useful in evaluation and characterizations was captured. With the AC power signal running 50 Hz, a sampling interval of 1 ms was chosen to capture the transient responses at different test points with adequate time resolution. During the tests, a PC based data acquisition system with eight channels of acquisition at 12 bit resolution for the digital conversion was used.

The tests were conducted in two categories, one with simulated signals for the inputs so as to capture the response characteristics of the unit and to evaluate it for its compliance to the design features and the other set of tests in field condition (with the inputs received from CT and PT, as in Fig. 13.3) to validate its usability and reliability.

Simulated signals from a controllable analog function generator were used for the two AC input signals representing current and voltage components of the power being measured. This arrangement allowed for creating different test conditions and to get comprehensive performance characterization of the EU.

Figure 13.4 represents the capture of transient response of the integrator and active filters. It can be seen clearly that the ripple factors that have the dominating harmonics of the rectification peaks that runs at the double the native frequency of the signal are considerably high at a magnitude of about 5 % of the peak. This is filter off in the subsequent stage of active filters with virtually no loss of additional response, as one can infer from the figure. The response reaches to its asymptotic steady value for the step input in about 80 ms indicating that the large signal response to be easily crossing 10 Hz while the dynamic response for small signal variations would be about much higher than that.

The response seen in Fig. 13.5 shows the behavior of the true RMS capture during the AC integration. In the test carried out a simulated train of signal that switches between sine to triangular waves are given at the inputs (both current and voltage) and the transients are captured as seen in the figure. One can clearly observe that for the amplitudes of the shifted waves are set nearly being same the integrator output and the final dc output of the unit have shifted swiftly on the changeover indicating its good characteristics of having true RMS capture. It can also be seen that the change in the wave forms has resulted in a transient settlement in less than 1 ms indicating that small signal dynamic response is easily better than 50 Hz, the native frequency of the AC signals. This shows one of the important design features established.

The Fig. 13.6 shows a history of estimated errors. Expectedly the errors near zero inputs for a rectifier is higher since zero crossing ideally cannot be captured. However, with the use of improved precision rectifier [13] this error is reduced to manageable low and the range of measurement is enhanced. The estimate of error is made by providing same simulated signals for both voltage and current and the error is estimated as the difference between the calculated RMS–square of the input signals and the output. One can see that the error band comes down to less than 5 % when the inputs cross 10 % of the peak measurable range and much less than less than 1 % in the other zones. Taking off the stray noises in the plot, one can see that the unit provides a good response that goes with a nominal error band of 0.1–0.5 % and is expected to be good in the industrial standards for such measurements.

The analysis of the behavior shown up in the test indicates clearly that all the design features are realized and system is functioning satisfactorily. Subsequent these simulated tests, field tests made with an electrical loading panel have shown a good consistency and performance.

13.6 Concluding Remarks

Though AC power measurement is not a new concept and many alternatives for this measurement are available, fast responding devices with good precision for such measurements are not seen commonly. More distinctly analog based approaches for such measurements are not in practice. However, for a cost effective delivery of the criteria considered, analog designs can provide a good alternative as compared to the digital approaches. In the present effort, this line of thinking is pursued and a distinctly convincible alternative is arrived at.

It may be useful to note that this development was a result of a need felt for providing a power regulation of the test load for an engine at the laboratory for a critical transient measurement and the device built on this concept was successfully used for in controlling with the analog feedback derived from this device. Another quick reference for a good usage comes out in its high usability in managing excellently the load sharing of an engine in a set of synchronized engines. In this context, the concept presented is considered to have addressed the technology gap wherein normally available power measurement devices do not capture the transients well and are seldom useable for good control logic.

The design concept presented is built, tested and found to have met the design criteria and the analysis and characterization presents show the benefits of the design concept clearly that stand out as an alternative to relatively highly expensive digital devices that match to this class of performance. In the background of the benefits the design concept presented could offer, it is considered to be of a good contribution in the area of power monitoring and regulation.

References

Data sheet for small signal Schottky diode (1N 5711), STMicroelectronics August 1999 Ed1A. http://www.st.com/

Data sheet for LM136-2.5/LM236-2.5/LM336-2.5 V, National Semiconductor Corporation DS005715, 2005. http://www.national.com/

Data sheet for AD 632 (internally trimmed precision IC multiplier)—Analog Devices Inc., 1997. http://www.analog.com

Bin Md Idros MF, Hassan SFbA (2009) A design of Butterworth low pass filter’s layout basideal filter approximation on the ideal filter approximation (published conference proceedings style). In: IEEE symposium on industrial electronics & applications (ISIEA) 2009, Kuala Lumpur, Malaysia

Vural RA, Yildirim T (2010) Component value selection for analog active filter using particle swarm optimization (published conference proceedings style). In: The 2nd international conference on computer and automation engineering (ICCAE) 2010, Singapore

Miao H, Liu X, Tan B, Shen J, Wang Y (2010) A universal active filter design method (published conference proceedings style). In: 2010 international conference on information networking and automation (ICINA), Kunming, China

Tow J (1969) A step-by-step active-filter design (periodical style—accepted for publication). Spectrum, IEEE, December 1969, pp 64–68

Djukic’ S, Veskovic’ M, Vulovic (2010) An improved precision full—wave rectifier for low-level signal (published conference proceedings style). 2010 9th international symposium on electronics and telecommunications (ISETC), Timisoara, Romania

Antoniou A (1979) Design of precision rectifiers with operational amplifiers. In: Proceedings of the Institution of Electrical Engineers IEEE, vol 121, No. 10. October 1979 (published conference proceedings style), pp 1041–1044

John Bishop, Bruce Trump and R. Mark Stitt (2012) FilterProTM MFB and Sallen-key low-pass filter design program (application report). SBFA001A-November 2001, Texas Instruments. http://www.ti.com/

Bruce C, Hruelsman LP (2012) Handbook of operational amplifier active RC network (application report). SB0A093A—October 2001, Texas Instruments. http://www.ti.com/

Kulkarni AP, Rajan NKS (2012) A precision high speed AC power monitoring device for power regulation and control, lecture notes in engineering and computer science. In: Proceedings of the world congress on engineering and computer science 2011, WCECS 2011, 19–21 October 2011, San Francisco, pp 748–752

Rod Elliot (ESP) (2010) Precision rectifiers (application report). AN-001, 18/12/2010. (http://sound.westhost.com/

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Kulkarni, A.P., Rajan, N.K.S. (2013). Development of Precision High Speed AC Power Monitoring Device for Power Regulation and Control. In: Kim, H., Ao, SI., Rieger, B. (eds) IAENG Transactions on Engineering Technologies. Lecture Notes in Electrical Engineering, vol 170. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-4786-9_13

Download citation

DOI: https://doi.org/10.1007/978-94-007-4786-9_13

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-4785-2

Online ISBN: 978-94-007-4786-9

eBook Packages: EngineeringEngineering (R0)