Abstract

Condition assessment of building materials is critical when reassessing existing structures, since material ageing can result in performance loss, degradation of safety, and maintenance costs. For these reasons, the use of non destructive testing (NDT) has become more common to assess the condition of existing reinforced concrete structures.

Vincent Garnier, Martin Krause, Patrice Rivard, Felicita Pires and John Popovics have also contributed to this chapter.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Electrical Resistivity

- Concrete Structure

- Infrared Thermography

- Ultrasonic Pulse Velocity

- Strength Assessment

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Non-destructive assessment of concrete: objectives and key challenges

Condition assessment of building materials is critical when reassessing existing structures, since material ageing can result in performance loss, degradation of safety, and maintenance costs. For these reasons, the use of non destructive testing (NDT) has become more common to assess the condition of existing reinforced concrete structures. The first part of this book shows the range of NDT methods that are available, which show some sensitivity to concrete properties or defects. Their use has become more common to assess the condition of existing reinforced concrete structures. When detecting or suspecting of a possible pathology, e.g. after visual inspection, the usual approach with application of NDE is the following:

-

(a)

to identify first the roots of the problem,

-

(b)

to know if there is a possible evolution of damage and, if any, at what rate, and

-

(c)

finally to know what is the severity level of the problem, its location and extent.

Much research has been aimed to developing techniques and data processing. Some standards have been developed for individual techniques and reference texts have been produced on individual problems, like strength assessment (EN 13791 2007). Some authors have also tried to synthesize the capabilities of techniques with respect to a given problem (Bungey and Millar 1996, Uemoto 2000, IAEA 2002, Breysse and Abraham 2005) or to define the most promising paths for future developments (OECD 1998). The general agreement is that the quality of assessment is limited by various uncertainties caused by: the testing method, systematic interferences with the environment, random interference (due to intrinsic variability of materials), human factors, and data interpretation (Gehlen et al. 2006). The fact that concrete as a material is inherently variable also restricts the practical conclusions that can derive from NDT investigations. Thus, improved assessment can be achieved by reducing any of these sources of uncertainty/variability.

The lack of internationally acknowledged standards or guidelines is a significant limitation:

-

the choice of the most appropriate technique for a specific problem is not simple,

-

reference guidelines guaranteeing the relevance of the measurement protocol (preparation of the surface, number and mesh of measurement points…) are often lacking,

-

the interpretation of measurement results to assess the structural properties can be difficult.

Until now, efforts undertaken to improve techniques (e.g. developing innovative equipment or post processing of data, numerical simulations, benchmarking techniques on pilot sites, etc.) have mainly been done at a national level with many work groups or national research projects in Germany, Britain, France, USA, and Japan. But these efforts have not lead to conclusions or proposals which could be used by the various participants in the field: building managers, contractors, regulators, NDT practitioners and consulting engineers. Due to these increasing needs (validated NDT protocols, quality control and structural assessment of ageing structures) we must now integrate – at an international scale – the huge amount of information and knowledge that has already been produced. For this reason, RILEM created a Technical Committee working on these questions, whose results are presented in this book. The text of this introductory chapter will mainly focus on material condition assessment, but the reader is invited to consider that the same principles will remain valid for other problems, like geometrical assessment or defect detection.

ICRI guidelines have synthesized the more common uses of NDT (ICRI 2009). These guidelines cover the assessment of all information which seems useful for condition assessment of structural concrete prior to repair design and execution: in-situ concrete strength, location and extent of delaminations, location and extent of concrete cracking, severity, location and extent of fire and frost damage, location and extent of void honeycombing, thickness of concrete members, and presence and rate of corrosion activity. Among all of these issues, which will be addressed in the following chapters, three of them illustrate the complexity of concrete assessment:

-

Stiffness and strength assessment. The knowledge of the elastic modulus or of the compressive strength of concrete is necessary to perform a structural evaluation, as they are prerequisites for any safety or reliability analysis. These parameters can be determined from tests on core samples, but cores offer information of the properties only at the point where the specimens have been taken. Thus it is difficult to obtain a representative view of the mechanical properties, since the material as well as the damage level can be spatially variable. NDT provides an interesting alternative since it enables wide coverage. The principal problem with NDE is correlating the values of the NDT measurements to the mechanical properties. Still, non-destructive techniques can be used to assess the structural condition, even if they only provide an indirect information (De Lorenzis et al. 2004). Rebound measurement and ultrasonic pulse velocity (UPV) are most suited NDT methods for this purpose (Malhotra 1981) and a recent European standard has given attention to this task (EN 13791 2007).

-

Water content (or moisture content) assessment. Monitoring moisture content is important for two reasons: a high value of water content can be the sign of poor quality concrete, and moisture content enables damage mechanisms even if concrete is of good quality originally. Many NDT methods are sensitive to both material parameter (e.g. Young’s modulus) and to moisture content. Due this double dependency, one cannot easily determine the cause for the measured variations in the NDT parameter. It has been shown that the question of damage detection and/or influence on deterioration process is similar in other building materials like timber or masonry (Breysse 2008). This problem has been named the “humidity paradox” (Shaw and Xu 1998).

-

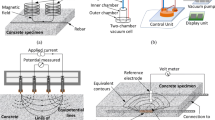

Corrosion assessment. This is an important problem since many reinforced concrete structures suffer severe damage due to corrosion of internal steel (due to chlorides in marine environment, deicing salts, or other causes). The cost of corrosion is estimated to be about 3 to 4 % of GNP in Western countries. The U.S. Federal Highway Administration (FHWA 2002) released a study in 2002 on the direct costs associated with metallic corrosion in nearly every U.S. industry sector. Results of the study show that the total annual estimated direct cost of corrosion in the U.S. is a staggering $276 billion—approximately 3.1% of the nation’s Gross Domestic Product (GDP). Corrosion attacks steel reinforcing bars and cables in pre-stressed structures, and material and structural assessment of such structures is critical when one wants to evaluate residual capacity, to design a reinforcing solution or to plan maintenance. The detection of defects like grout voids in tendon ducts, which favour corrosion, constitute another challenge. Some techniques have been standardized and make it possible to assess the material condition of corroding structures. However, many problems remain unresolved.

These three topics address the two domains of mechanical assessment and durability between which the boundary is not well defined: the mechanical properties of tomorrow are often dependent on the deterioration process of today. Different classes of concrete degradation can occur: either physico-mechanical (overloading, freeze and thaw, fire, restrained strains during shrinkage or temperature elevation, etc.) or physico-chemical (corrosion, alkali-aggregate reaction, sulfate attack, etc.). But regardless of the class of degradation, they result in distributed damage, which may take the form of a porosity increase or of a microcrack network, and local damage, which may take the form of delamination or macrocracks, which must be assessed (Breysse, 2010).

Three requirements should be satisfied for NDT assessment:

-

(a)

being able to detect defects or variation of properties, between two structures or within one structure,

-

(b)

being able to build a hierarchy (i.e. to rank on a scale) regarding a given property (e.g. mapping stiffness, plotting changes in dimensions…), between several areas in a given structure or between several structures,

-

(c)

being able to quantify these properties, e.g. comparing them to allowable thresholds or reference values (e.g. expected strength or planned dimension).

Of these three requirements, the last one is the most critical and also most difficult to satisfy. We propose that a well chosen combination of techniques can contribute to improved assessment of concrete structures.

In this chapter, we will first address the “traditional approaches” of NDT. In a second part, combinations of techniques will be analyzed from a formal point a view and illustrated by two practical examples. Finally, we will try to explain, relying on a single example, what can be the practical interest and the practical limits of such a combination. Throughout this book, many examples of combination of techniques will be presented. The reader is invited to keep in mind the opportunities and difficulties that will be discussed here when reading about combination of techniques for each specific application.

2 Added-value of combining techniques: traditional approaches

2.1 Purpose for combining techniques

When addressing material condition, the expert can have different objectives. He can limit himself to a qualitative view, for instance by identifying spatial variations in the measured parameters, but he can be more ambitious and try to quantify these variations, for instance because he needs some input values for structural computations before repair or for reliability assessment. In this case, one needs a validated methodology such as to ensure the quality of estimates. Much research has been devoted to the development of techniques and data processing for improved assessment of building materials. Many case studies exist in which different techniques have been combined, but real added value can only be obtained if the issue of combination is correctly analyzed (Derobert et al. 2005). This added value can be defined in terms of (a) accuracy of estimation of properties, (b) relevance of physical explanations and diagnosis, (c) reduction in time to reach a given answer.

The combination of techniques can pursue various objectives, like confirming with a second technique what has been observed with a first one, zoning the area where a more sophisticated investigation will be performed in the following, decreasing the number of borings by identifying the areas where borings will be more informative.

We will refer now to to three possible types of combinations that will be illustrated by several examples (either in the laboratory or on site), all drawn from experiments performed in the frame a National Research Project (Balayssac 2008):

-

Type [A]: comparison of results obtained via two or more techniques, so as to confirm measurements and recorded variations,

-

Type [B]: comparison of results obtained via two or more techniques, so as to improve the interpretation of results. This improvement often needs some analysis (image analysis, statistical analysis), which enables one to go further than a simple visual confirmation,

-

Type [C]: use of a “quick” technique to have a first rough mapping, followed by a second “slow” technique in the areas selected in the first step.

The following sections show only a few examples, from limited experience. Tables 1.1 to 1.3 provide additional references of similar combinations.

2.2 Type [A] combination – confirmation of test results obtained with different techniques

The combination of three techniques (infrared thermography, electrical resistivity and capacitance) to assess the moisture content / damage state of material along a profile is described in detail in (Naar et al. 2005) and (Sirieix et al. 2007). In this case study, a precast concrete duct in which some damage (crack patterns) had been identified was inspected through several different techniques: capacimetry (measuring permittivity), infrared thermography and electrical resistivity. Radar and ultrasonic measurement were also tested but, for radar, the high density of rebars prevented any efficient processing of results, and reliable ultrasonic measurements were impossible with the device used due to the curvature of the surface. The longitudinal variations of the three measured properties along the duct profile show striking similarities (Figs. 1.1–1.3). In Fig. 1.1 the variation of a resonant frequency that is proportional to the material permittivity is shown. The variation of the electrical resistivity (Fig. 1.2) and the variation of the surface temperature, measured by infrared thermography (Fig. 1.3) show similar pattern. In all figures the black area indicates the part of the structure where the concrete had been repaired, because of extensive damage, which prevents any comparison. A dotted regression curve has also been added, which exhibits a parabolic shape for the three series of measurements.

The data scatter is indicated by error bars, which confirm that the magnitude of the longitudinal variation is much larger than the local variability/uncertainty. The similarities among the three NDT results illustrate their mutual confirmation. If a technique would have been used alone, a second technique (or a third one) would have reinforced the confidence in the assessment. This is a direct illustration of a Type [A] combination.

These similarities can be explained in terms of material moisture content and/or damage variation, since all three techniques are sensitive to these two causes. However, the measurements, even combined, do not provide any information about the reasons for these variations. Two opposite interpretations are suggested:

-

It is possible that the material damage varies along the abscissa, which is interpreted as an increase in porosity; this leads to lower frequencies, lower resistivities and lower temperatures in the mid part of the duct, due to higher moisture content in the saturated concrete,

-

It is also possible that the variations in the moisture content profile are caused by environmental conditions: the duct faces south-west on its left-end and north-east on its right-end, which favors a relative drying of the concrete cover near both ends. In this case, the longitudinal variations can be explained without any damage or cracking.

Going further in the interpretation would require a more detailed analysis of the parameters influencing each property measured; this will be discussed in § 3.1. This is the reason why recent efforts have been undertaken, in an extensive research project, to better understand (and quantify) how NDT parameters are sensitive to various possible influencing factors (Balayssac 2008). This issue is a central one, and will be addressed in detailed fashion in this book.

This type [A] of combination has also been carried out in another case study. The specimens, made of various types of concrete in the 25 MPa-120 MPa 28-day compressive strength range, had been subjected to marine attack (in the tidal domain in La Rochelle harbor) for several years. The specimens were investigated and ranked by various non-destructive techniques. Figure 1.4 illustrates how the electrical resistivity varied with the concrete mix. For each type of concrete, the corresponding rectangle marks the average value of resistivity plus/minus one standard deviation.

The very high sensitivity of resistivity to concrete strength is confirmed here. It enables to rank strengths for similar concretes (normal concrete, or concrete with fly ash addition or silica fume addition) kept in comparable environments. Figure 1.4 also confirms that various types of concrete cannot be directly compared.

The resistivity of M30CV (compressive strength 30 MPa with fly ash additions) is higher than that of M50 (normal concrete, compressive strength 50 MPa). Measurements performed by (Wolsiefer 1991) had yet shown the higher resistivity of concrete with silica fume addition, this increase being more important for low w/c ratios. The ranking of specimens based on electrical resistivity measurements (Lataste et al. 2005) was confirmed with radar measurements and capacimetry. However, as observed in the first case study, this confirmation (Type [A] combination) tells nothing about the physical explanation. The physics involved in each non-destructive technique is sensitive to many microstructural parameters (porosity and connectivity, properties of the particles…) as well as to parameters depending on environmental conditions (moisture content, chloride content…). Thus, the variation of a single physical property (radar attenuation, electrical resistivity, capacity…) can have various alternative explanations. For instance, the variation in electrical resistivity could be due to a variation in porosity (which changes greatly between different mixes), moisture content (which changes with time due to the tidal effects) or chloride content. The magnitude of influence of these possible causes must be assessed before interpretation.

Several influences control the NDT response: here the material strength cannot be deduced from the measurement of the resistivity alone, since the relation between strength and resistivity depends on the concrete mix. This question will also be addressed in this book: since many NDT parameters are sensitive to individual influences, it is difficult to formulate “universal laws” which, after inversion, provide direct access to the property that is sought. For this reason, the combination of NDT measurements can be fruitful. Table 1.1 gives some additional references where the authors have used a “Type A” approach when combining non-destructive techniques.

2.3 Type [B] combination – improvement of test result interpretation obtained with different techniques

This type of combination is illustrated in the case of an abutment wall of a French bridge near Lilles, Nord (Fig. 1.5).

The inspected area, below the deck, is subject to alkali-aggregate reaction (AAR), and some cracking patterns can be seen on the concrete surface. The structure can only be investigated from one side. The same profile, approximately 12 m long, was inspected using radar and electrical resistivity measurements. The visible damaged area was localized between 9.8 m and 12.4 m.

Both techniques are potentially sensitive to AAR, since damaged areas have higher moisture content. A higher value of moisture content increases the attenuation of the direct wave amplitude (radar) and decreases the resistivity. Thus the AAR assessment is only indirect, since the two techniques take advantage of moisture content sensitivity.

Figures 1.6 and 1.7 show the results obtained along the profile with a measurement step equal to 20 cm (each point is the average value of three neighboring measurements. The electrical resistivity is obtained using a 5-cm-square device. The repetition of measurements reduces the effects of noise measurements, as will be seen in §3.2. For both curves, the longitudinal profiles indicate a slow variation (decrease of radar amplitude, decrease of resistivity for electrical measurements) and a drop at the right end, more contrasted for radar. The two NDT also show a very different sensitivity: since resistivity is divided by a factor 6 between the left end and the right end, the decrease of the amplitude of the radar wave is only about 20 %. The question of sensitivity is a key issue, when performing NDT investigation, since one has to choose techniques that are the most sensitive as possible to the parameters that are sought. This issue will be addressed into more details throughout this book.

Figure 1.8 illustrates the relations between the two measurements. Despite what appears as “noise” (the variations seen in the resistivity values between 2 and 8 m in the 200-400 ohm.m range are not correlated with any “structured” variation visible on radar measurements), two sets of points can be clearly distinguished:

-

the first set corresponds to large values for both the radar amplitude (>11 800) and the resistivity (> 400 ohm.m),

-

the second set corresponds to low values for both the radar amplitude (<10 800) and the resistivity (< 150 ohm.m).

It is important to note that these sets are not randomly spatially distributed. The first set is located at the left end of the profile (facing south) and the second at the right end of the profile.

The similarity of shapes between the two profiles is a good argument to justify the combination of techniques. It helps the interpretation since one can focus first on the information that can be given by both techniques. (In a second step, it could be interesting to analyze whether some physical basis can explain the variations in the resistivity profile which were considered as “noise” in the first step.) The physical interpretation then stands on a more reliable basis:

-

the variations at the left end can be interpreted as corresponding to drier material, probably due to environmental conditions (this end faces South),

-

the variations at the right end can be interpreted as corresponding to the area where the alkali-aggregate reaction develops, as confirmed by visual inspection.

Another study (Rivard et al. 2005), performed on Bell’s Corner experimental site (Ottawa region, Canada) was devoted to the comparison provided by impact-echo, passive infrared thermography, electrical resistivity and radar measurements for assessing the alkali-aggregate reaction on concrete blocks of various mixes. It has shown that radar measurements (especially the magnitude of the direct wave) are the most promising method, when electrical resistivity is also sensitive to other factors, which makes data interpretation difficult.

In any case, the diagnosis of alkali-aggregate reaction is not direct, since it is only done through the variations in water content, which can be directly assessed by a simple visual inspection. In the case described here, NDT measurements provide, however, a more accurate estimation of the extent of the area affected by the chemical reaction. Another contribution is that they make it possible to quantify the material properties, opening the way towards the definition of critical values, which could be used for other structures, or for areas where the damage is not visible, but where NDT measurements would indicate values approaching critical values.

Table 1.2 provides some additional references in which the authors have used a Type [B] approach when combining non-destructive techniques. The combination used by (Romanescu et al. 2009) is usually referred to as the Sonreb method, which consists in combining ultrasonic velocity and rebound number for better assessing concrete strength. This question will be addressed into more detail in Chapter 3, devoted to strength assessment of concrete. Despite the high number of NDT used, the interpretation always remain a matter of expertise, since these techniques can show “clear similarities” on one instance and “significant differences” in another (Gucunski et al. 2010).

2.4 Type [C] combination – application of different techniques for “quick” localization of defected areas followed by detailed inspection with “slow” but more accurate measurements

Some techniques have the particular advantage of enabling a quick overview of the structure, because they use a quickly moving set of sensors or because they are wide-field. This is the case, for instance, of infrared thermography, which can be used to monitor a large scene with an optical sensor that can be located at a certain distance from the surface under investigation (Sirieix and Defer, 2005).

It is thus fruitful to use this technique in a first step and to investigate the areas where some interesting patterns are identified in greater detail (with a technique requiring more time or heavier equipment). The Empalot bridge case study, near Toulouse, provided us with such an opportunity. Figure 1.9 shows the infrared and visible pictures of one slab on the lower face of the deck. The two pictures were taken at the same time. The surface temperature range is [13.5 – 14.5] °C. The whitish areas indicate lower temperatures. Three of those areas can be seen on the infrared picture:

-

the first one, on the left side of the red contour (which corresponds to an area where surface concrete has fallen) is the lower face of a transversal beam, which is not at the same distance from the camera as the deck surface,

-

the two others, on the right side of the red contour do not correspond to any visible defect.

Since delamination was suspected on this 60-year-old bridge, these areas (and the full deck surface) were thoroughly investigated (with radar, electrical measurements, sonic waves and capacimetry), and delamination was confirmed. Thermography gave information on the existence and extent of the affected area from a distance, when all other techniques required heavy equipment (truck and platform) to reach the concrete surface with the measurement devices. The potential interest of such a combination is to provide information quickly, which helps the expert defining and planning detailed investigations. The interest of the second technique will be to provide quantitative information on material properties, since it is not straightforward to derive them from surface temperature measurements.

Naturally, the information gathered with the quick technique can also be processed to help the diagnosis. For instance, the variations in the temperature differences throughout the day between the delaminated area and the “good” surrounding concrete can be processed so as to give an estimation of the delamination depth. The potential interest of infrared thermography and the increasing capacity of numerical data processing algorithms explains the recent advances in this topic (Maierhofer et al. 2002, Valluzzi et al. 2009). If the surface is of easy access, it remains simpler to use sonic techniques that will provide the same type of information.

Another promising type [C] coupling possibility has been recently used (Dilek 2006), which combined stress wave measurements and dynamic elastic Young’s modulus on thin disks from cores. Even if one of these two techniques cannot be considered as NDT, the interest is that the combination of NDT (stress-waves) and another technique provides very useful information for assessing near-surface gradients in fire or frost damaged concrete. In this case, NDT is used both for locating where coring is more relevant and for calibrating the results in terms of layering. Table 1.3 provides additional references in which the authors have used a Type [C] approach when combining non-destructive techniques. The recent work from (Arndt et al. 2010), even if limited to laboratory measurements, opens the way towards a more efficient long-term monitoring of corrosion, combining embedded sensors, quick techniques (like active infrared thermography) and slower techniques.

3 Conclusions

In the next Chapter, the common (and less common) non-destructive techniques will be presented. Each technique will be discussed in terms of the physics involved, which are the usual/possible use, which are the constraints and limits, etc. In this introductory chapter, we have shown how several different techniques can be combined to improve the assessment. We have defined three types of combination, according to their purpose. In most cases, this combination remains informal, which means that the understanding of the real added value of combining a second (or a third) NDT method simply does not exist. Thus, it is difficult to derive, from these individual experiences, any general conclusions that could be useful in other cases. It is only recently that this issue has been formally addressed by research (Balayssac 2008).

The chapters 3 to 7 will be devoted to five different practical questions engineers are faced with: strength assessment, voids detection in tendon ducts, damage and delamination detection, corrosion in cables, and geometry assessment. For each problem, we will explain which information NDT can provide, either used individually, or in combination. The text will be based on current engineering practice, but it will also present some innovative work. The issue of the combination of several NDT measurements will be specifically addressed. It is expected that the reader will find there new ideas and information about how better use NDT.

However we will see that, even in these situations, combination of NDT remains often informal. It is the reason why we will formalize this issue in Chapter 8. Our aim is that the reader becomes progressively more familiar with these central issues of variability (of the material), quality and sensitivity (of the NDT measurement) and complementary techniques. If so, he will be able to design and perform more efficient NDT investigation programmes, so as to get a more reliable view on the concrete structure.

References

Alt D., Meggers D. (1996) Determination of bridge deck subsurface anomalies using infrared thermography and ground penetrating radar, Kansas DOT, Report FHWA-KS-96-2, 18 p.

Arndt R.W., Jalinoos F., Cui J., Huston D. (2010) Periodic NDE for bridge maintenance, Structural Faults and Repair, Edimburgh, june 2010.

Balayssac J.P. (2008) SENSO: a French project for the evaluation of concrete structures by combining non-destructive methods, Sacomatis, RILEM conf., 1-2/9/2008, Varenna, It.

Breysse D. (2008) Condition assessment of concrete, masonry and timber structures and the role of water: how far the problem is similar ?, SACoMaTiS Int. RILEM Conf., 1-2 sept. 2008, Varenna, Como lake, Italy.

Breysse D. (2010) Overview of deterioration processes, in Non-Destructive Evaluation of Reinforced Concrete Structures, ed. C. Maierhofer, H.W. Reinhardt, Bertram publ.

Breysse D., Abraham O. (2005) Guide méthodologique de l’évaluation non-destructive des ouvrages en béton armé, Presses ENPC, Paris, 550 pages.

Bungey J.H., Millard S.G. (1996) Testing of concrete in structures, Blackie Acd. and Prof., 3rd edition, 286 p.

De Bold R., Giannopoulos A., Forde M.C., Pareemamun K. (2010) Interpretation of NDT of thick concrete, Structural Faults and Repair, Edimburgh, june 2010.

De Lorenzis L., Nanni A. (2004) Int. workshop on preservation of historical structures with FRP composites, Final Report, NSF.

Dérobert X., Garnier V., François D., Lataste J.F., Laurens S. (2005) Complémentarité des méthodes d’END, in Guide méthodologique de l’évaluation non destructive des ouvrages en béton armé, ed. Breysse D., Abraham O., Presses ENPC, Paris, 550 pages.

Dilek U. (2006) Dynamic elastic Young’s modulus of concrete disks in validation of stress wave based non-destructive testing technique results, 85th TRB Annual meeting, 22-26 jan. 2006.

EN 13791 (2007) Assessment of in-situ compressive strength in structures and precast concrete, CEN, Brussels, 28 p.

FHWA (2002) Corrosion Costs and Preventive Strategies in the United States, Report from CC Technologies Laboratories, Inc. (Dublin, Ohio), for FHWA and NACE.

Gardei A., Mittag K., Wiggenhauser H., Ripke B., Jovanovic M. (2003) Inspection of concrete-embedded tracks process development for the quality assurance of concrete-embedded tracks using non-destructive testing methods, NDT-CE, conf., Berlin.

Gehlen C., Dauberschmidt C., Nürnberger U. (2006) Condition control of existing structures by performance testing, Otto-Graf-Journal, 17, 19-44.

Gucunski N., Romero F., Kruschwitz S., Feldmann R. (2010) Comparative study of bridge deck deterioration detection and characterization by multiple NDE methods, Structural Faults and Repair, Edimburgh, june 2010.

IAEA (2002) Guidebook on non-destructive testing of concrete structures, Training course series 17, International Atomic Energy Agency.

ICRI (2009) Nondestructive evaluation (NDE) methods for condition assessment, repair, and performance monitoring of concrete structures, ICRI Guideline.

Klysz G., Balayssac J.P., Derobert X., Aubagnac C. (2003) Evaluation of cover concrete by coupling some non-destructive etchniques – Contribution of in-situ measurements, NDT-CE conf., Berlin.

Lataste J.F., Abraham O., Breysse D., Sirieix C (2003) Sensitivity to crack parameters of two non-destructive techniques: electrical resistivity and acoustic methods, NDT-CE conf., Berlin.

Lataste J.F., Breysse D., Sirieix C., Naar S.. (2005) Electrical resistivity measurements on various concretes submitted to marine atmosphere, ICCRC conf., Moscow, 5-9/09/2005.

Maierhofer C., Bink A., Röllig M., Wiggenhauser H. (2002) Transient thermography for structural investigation of concrete and composites in the near surface region, Infrared Physics and Technology, 43, 271-278.

Maierhofer C., Krause M., Wiggenhauser H. (1998) Non-destructive investigation of sluices using radar and ultrasonic impulse echo, NDT&E Int., 31, 6, 421-427.

Malhotra, V.M. (1981) Rebound, penetration resistance and pulse velocity tests for testing in place, The Aberdeen Group.

Maser K.R., Holland T.J., Roberts R., Popovics J. (2003) Technology for quality insurance of new pavement thickness, NDT-CE conf. Berlin.

Naar S., Sirieix C., Breysse D., Dérobert X. (2005) Assessment of water saturation rate in a reinforced concrete structures: non-destructive testing of Tarbes’ precast duct, ICCRC conf., Moscow, 5-9/09/2005.

OECD Nuclear Energy Agency (1998) Development priorities for Non-Destructive examination of concrete structures in nuclear plant, Nuclear Safety, NEA/CSNI/R(98) 6, 25-39.

Parthasarathy S., Murthy S.G.N., Sangoju B., Wiggenhauser H., Ravisankar K., Iyer. N.G., Lakshmanan N. (2009) Application of radar and ultrasonic pulse echo for testing concrete structures, NDTCE’09, Nantes, 30 june-3 july 2009.

Pina Santos C., Matias L., Magalhaes A.C., Veiga M.R. (2003) Application of thermography and ultrasounds for wall anomalies diagnosis. A laboratory research study, NDT-CE conf., Berlin.

Rivard P., Naar S., Sbartai M.Z., Fournier B. (2005) Couplage de méthodes non destructives pour l’évaluation de l’endommagement du béton, 12th Conf. on Recherche Québécoise sur les Ouvrages d’Art, 10-11/05/2005, Univ. Laval, Quebec.

Romanescu C., Ionescu C., Scinteie R. (2009) The Romanian road administration experience in the field of NDT for bridges, NDTCE’09, Nantes, 30 june-3 july 2009.

Scott M., Rezaizadeh A., Delahaza A., Santos C., Moore M., Graybeale B., Washer G. (2003) A comparison of nondestructive evaluation methods for bridge deck assessment, NDT&E Int., 36, 4, 245-255.

Shaw P., Xu A. (1998) Assessment of the deterioration of concrete in nuclear power plants – causes, effects and investigative methods, NDTnet, 3, 2.

Sirieix C., Defer D. (2005) Méthodes thermiques, in : D. Breysse, O. Abraham (Eds), Guide méthodologique de l’évaluation non destructive des ouvrages en béton armé, Presses ENPC, Paris, 550 pages.

Sirieix C., Lataste J.F., Breysse D., Naar S., Dérobert X. (2007) Comparison of nondestructive testing: Infrared thermography, electrical resistivity and capacity methods for assessing a reinforced concrete structure, J. Building Appraisal, 3, 1, 77-88.

Uemoto T. (2000) Maintenance of concrete structure and applications of non-destructive inspection in Japan, in Proc. of Non-Destructive testing in Civil Engineering, Elsevier, 1-11.

Valluzzi M.R., Grinzato E., Pellegrino C., Modena C. (2009) IR thermography for interface analysis of FRP laminates externally bonded to RC beams, Mat. Str. 42, 25-34.

Weise F., Pirskawetz S., Meng B. (2008), Application of innovative testing methods for the quasi non-destructive assessment of the material condition in hydraulic engineering structures, Sacomatis conf., Varenna, 1-2/9/2008.

Wolsiefer J.T. (1991) Silica fume concrete: a solution to steel reinforcement corrosion in concrete, Proc. 2nd Canmet/ACI Int. Conf. On durability of concrete, pp. 527-553, ACI, Farmington Hills, MI.

Yong Hao Z., Kee Ee Ng. (2003) Evaluation of concrete structures by advances nondestructive test methods – impact echo, impulse response test and radar survey, NDT-CE conf., Berlin.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 RILEM

About this chapter

Cite this chapter

Breysse, D. (2012). Non destructive assessment of concrete structures: usual combinations of techniques. In: Breysse, D. (eds) Non-Destructive Assessment of Concrete Structures: Reliability and Limits of Single and Combined Techniques. RILEM State of the Art Reports, vol 1. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-2736-6_1

Download citation

DOI: https://doi.org/10.1007/978-94-007-2736-6_1

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-2735-9

Online ISBN: 978-94-007-2736-6

eBook Packages: EngineeringEngineering (R0)