Abstract

It is well known that one way to increase concrete toughness is the use of steel fibers, where increasing of material toughness is done with an aim to enhance structural ductility. However, in a former test series, reduced flexural ductility was observed in high strength concrete (HSC) beams with relatively low reinforcement ratios that included steel fibers. The motivation for the current study was to examine whether similar behavior of reduced flexural ductility occurs also in Fibrous Normal Strength Concrete (FNSC). For this purpose, a series of flexural tests of beam specimens was planned. The specimens were made of NSC, with and without fibers, with various reinforcement ratios. This paper shows preliminary results that indicate a similar phenomenon to the one observed in HSC. That is, reduced flexural ductility, which occurred in NSC specimens with a low reinforcement ratio and with steel fibers. Yet, ductility of the FNSC beams increased with increasing reinforcement ratio. A possible reason for these results, which involves localization of steel-concrete slip, is discussed.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

12.1 Introduction

One of the design aspects of flexural members is maintaining an adequate ductility at ultimate limit state. For example, design principles for Fiber Reinforced Concrete (FRC) in the draft of the New Model-Mode require that the ultimate and peak-load displacements would be (respectively) at least 20 and 5 times larger than the displacement at service load (fib 2010).

FRC is known to be a material with increased toughness compared to plain concrete (fib 2010). High strength concrete (HSC) is characterized by its high compressive strength but also by its relatively high brittleness (fib 2008). Therefore, addition of steel fibers to concrete is considered an efficient way to increase the material toughness and obtain high performance concrete (HPC).

Thus, the effects of applying steel fibers in HSC on the flexural behavior of beam specimens were examined in a series of tests (Dancygier and Savir 2006). Experimental observations from these tests showed that the displacement ductility of HSC beams with steel fibers and with moderate to high ratios of flexural reinforcement (higher than ∼0.5%) had increased displacement ductility compared to similar reinforced HSC specimens without fibers, as expected. However, these tests also showed that when steel fibers were used in beams with relatively low reinforcement ratios (0.3%) they had a significantly lower ductility, compared to similar beams without fibers (Dancygier and Savir 2006). The plain reinforced concrete (RC) specimens in these tests responded according to the classical RC behavior, with flexural cracks whose widths developed with an increasing deflection of the beam. The initial response of the fibrous specimens involved also the development of flexural cracks at spacing similar to that of the plain specimens. Yet conversely to the plain specimens, as the deflection increased, the width of only a single crack continued to develop whereas widths of the other cracks remained almost unchanged.

This local response of a crack, which widened more than the others, led to high strains of the longitudinal steel in its vicinity. Consequently, the steel at the location of this crack reached its rupture strain. This occurred at a relatively low deflection – about one third of the ultimate deflection of similar plain specimens, exhibiting lower displacement ductility.

The current study is aimed at examining whether it was the concrete high strength that caused the above result or was it because of another reason. That is, the current experiments were planned to test whether similar behavior would occur also in normal strength concrete (NSC) specimens. Initial results of these tests are described herein.

12.2 Experimental Program

Four-point loading tests were performed of beam specimens made of NSC. The beams had different reinforcement ratios, starting at 0.15%. Most specimens included steel fibers. Some of the beams that served as control specimens were also cast with plain concrete mixes.

12.3 Materials

Concrete mixes included Portland cement type CEM I-52.5N, dolomite coarse aggregates of 19 mm maximum size, and natural quartz sand (Table 12.1). Average compressive strengths from 100 mm cubes at 28 days are given in Table 12.2.

The fibrous mixes included hooked-end steel fibers that were given in a constant weight of 60 Kg/m3 of mixture (volume ratio of 0.75%). The fibers were 35-mm long and 0.55 mm in diameter with an aspect ratio of 64 and a minimum tensile strength of 1,000 MPa (manufacturer’s data).

12.3.1 Specimens

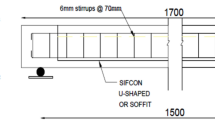

The beam specimens had 240 × 300 mm2 cross-sections with different tension reinforcement ratios (Table 12.2). The longitudinal reinforcement consisted of deformed rebars with yield and ultimate strengths that are given in Table 12.2. The length of the shear span was 0.85 m and the span was 3.2 m, leaving a 1.5 m length for the constant moment zone between the two loads (Fig. 12.1). Spacing of the ties was reduced within the shear span in order to ensure flexural response of the beams. Concrete cover (of the ties) was 15 mm.

12.3.2 Measurements

Measurements included the external load, mid-span displacement and strains along the beam length. Strains at the top part of the beam were measured directly by strain gages. Indirect strain measurements were obtained from pairs of Linear Variable Displacement Transducers (LVDT) that were attached on both sides of the beam at the level of the longitudinal tension steel (Fig. 12.1). Thus, top and bottom strains were recorded at seven locations along the beam. The curvature at these locations was calculated by applying the Euler-Bernoulli theory, as the linear vertical gradient of the measured longitudinal strains along the cross-section where they were measured (i.e., sum of the absolute values of the top and bottom strains divided by the vertical distance between measurement points).

12.3.3 Test Procedure

The tests were performed with a manually stroke-controlled loading, which led to mid-span displacement rates that ranged from 0.5 to 1.0 mm/min up to post-yield. Experiments of the fibrous specimens included 1–2 repetitions of each specimen type.

12.4 Results

All specimens reached failure in a flexural mode as expected. Failure was characterized by concrete crushing at the top fiber of the beams. However, in the NF-1-015 specimens, which included steel fibers and had a 0.15% reinforcement ratio, it was followed by rupture of the tension rebars (rupture of one of the rebars occurred also in one of the beams without fibers and 0.15% of tension reinforcement, but it was at a much larger beam deflection). Load-mid-span displacement curves of the beams that had a low reinforcement ratio of 0.15% show that while the plain concrete specimens (NF-0-015) reached a maximum deflection of 120–150 mm the maximum deflections of similar beams with fibers were only 30–50 mm (Fig. 12.2a). Addition of fibers in the beams with higher longitudinal reinforcement ratios led to increased ultimate displacements, as demonstrated in Fig. 12.2b.

Another similarity to the response that was observed in FHSC beams was the development of cracks, where only a single crack continued to widen with increasing deflection in the lightly reinforced beams that include fibers (as opposed to relatively uniform widening of the cracks within the constant moment zone in the similar plain RC beams).

Flexural capacities according to the measured maximum total load Pmax were similar in the beams with and without fibers. Yet it is interesting to note that with decreasing reinforcement ratio there was an increase in the fibrous-to-plain concrete capacity ratios: P max(with fibers)/P max(plain concrete) ratios were 1.13 and 1.05 for the specimens with 0.15% and 1.26% reinforcement ratios (respectively).

12.4.1 Curvature Distribution

Measurements of longitudinal strains at the top and near-bottom of the cross-sections at seven locations along the beam (refer to Fig. 12.1) were converted to curvatures at these locations. Figure 12.3 shows the curvature distribution between the two points of loading (within the constant moment zone) at various levels of mid-span displacement.

It can be seen that in both specimen types shown in Fig. 12.3 (ρ = 0.15% and ρ = 1.26%) and at a relatively low displacement of L/500 (L = span), curvature distribution in beams that included fibers and in beams made of plain RC was similar (compare solid and dashed lines in Fig. 12.3a). However, as the beam deflection increased there was a difference between the curvature distribution in the lightly reinforced specimens and the beams with a higher amount of longitudinal steel (compare ρ = 0.15% and ρ = 1.26% in Fig. 12.3b): While the distribution remained relatively uniform in the beams with ρ = 1.26% (with or without fibers) it had distinct peaks in the beams with ρ = 0.15% that included fibers (refer to the three dashed lines of three specimens in the left Fig. 12.3b). This observation was more pronounced at larger deflections (Fig. 12.3c). Comparison of the locations of the curvature peaks in the fibrous specimens with pictures taken during the tests showed that the peak location coincided with the location of the crack whose width was significantly larger than the others.

12.5 Discussion

It is noted that a longer part of a beam, along which the curvature is larger than the yield curvature, denotes larger plastic hinge length and thereby enhanced beam ductility. The distribution of the curvature within the constant moment zone (i.e., between the loading points) is expected to have peaks at the cracked cross-sections. Yet, in case of a fairly uniform pattern of cracks of similar widths the distribution of these peaks as well as their size is likely to be relatively uniform. At increased deflections, curvature values near or at the maximum moment zone are likely to be high and it is therefore expected that a more uniform distribution of these curvature values would indicate longer plastic hinge and increased structural ductility. Thus, the relatively non-uniform distribution of the curvature within the constant moment zone, at large deflections of the beams with low reinforcement ratio and with fibers (ρ = 0.15%, Fig. 12.3c) conforms to their reduced ductility, as displayed in Fig. 12.2a.

A more quantitative measure of the uniformity of the curvature distribution is the ratio between the standard deviation of the curvature values and their average (Stdv/Avg, i.e., the coefficient of variation) within the constant moment zone (a perfectly uniform distribution would result in a ratio of zero). This ratio is shown in Fig. 12.4 at three levels of the mid-span displacement. Figure 12.4 shows that as the reinforcement ratio increased the Stdv/Avg ratio decreased as well, indicating a more uniformly distributed curvature. These ratios were clearly higher in the specimens that included fibers at relatively low reinforcement ratios and at mid-span deflection of L/75 (∼43 mm) (ρ = 0.15%, Fig. 12.4c). This result reflects in a quantitative manner the localization of cracking and curvature in lightly reinforced beams with steel fibers.

Another measure of the ductility is the mid-span deflection at maximum load. Figure 12.5 shows mid-span displacements (normalized with respect to the span) that were measured at maximum load in the current tests and in a previous series of tests of HSC beams without fibers and with steel fibers (FHSC), which also included control NSC specimens (Dancygier and Savir 2006). It can be seen in Fig. 12.5 that the plain specimens showed the expected trend of increasing peak-load deflection with decreasing reinforcement ratio (Fig. 12.5a). However, in lightly reinforced beams the specimens that included fibers had a different trend, where the peak-load deflection decreased with decreasing reinforcement ratios that were lower than about 0.75% (Fig. 12.5b).

Normalized mid-span displacements measured at maximum load in (a) plain and (b) fibrous beam specimens (in current tests and in tests reported by Dancygier and Savir 2006)

The current results together with those of a previous series of tests of HSC and FHSC specimens (Dancygier and Savir 2006) show that when fibers are added to concrete in a lightly reinforced concrete beam its response is different than that of RC beam without fibers. Cracking pattern at early stages of loading is similar in both types of beams (Fig. 12.3a). However, while in plain RC beams the widths of cracks under the same moment develop in a relatively uniform manner, in fibrous RC beams the response is localized to one of the cracks, which keeps widening more than the other cracks. This leads to a reduced length of the “plastic” behavior (or length of the plastic hinge), and to localization of the strains in the longitudinal reinforcement.

It may be thought that this phenomenon is a result of the effect of fibers on bond strength. However, a study, which consisted on a series of pullout tests of NSC, FNSC, HSC and FHSC specimens with deformed bars of different diameters, showed that there was no clear difference in bond strength when fibers were added (Dancygier et al. 2010). Moreover, it was shown that fibers had a more pronounced effect on bond in HSC than in NSC, while the above result was similar in both types of concrete. Yet, it is interesting to note that unlike bond strength, slip was reported to be higher in the fibrous specimens at peak and at post-peak pullout load (Dancygier et al. 2010).

Yuguang et al. (2009) tested reinforced concrete bars in uniaxial tension and analyzed their response. Some of the specimens in their study included steel fibers. They noted that “with increasing fiber content, localization is more likely to occur in one crack” and they associated this conclusion to the scatter in fiber content along the specimen.

Hence, for a given fiber volume there is a scatter of residual tensile strengths at the cracked cross-sections. This scatter is likely to be more significant as the amount of tension reinforcement decreases. For example, it would be most significant in fibrous concrete without steel rebars and almost insignificant in the presence of relatively high reinforcement ratios. The effect that this scatter may have on the slip of the tension steel at a particular crack could eventually cause larger strains of the rebars and, thereby, their premature rupture, as observed in the current tests.

12.6 Conclusions

Four-point loading tests were performed of beam specimens made of NSC, with and without steel fibers and with different reinforcement ratios, starting at 0.15%. In addition to the load and mid-span displacement, curvature distribution along the beam was evaluated according to measurements of longitudinal strains and displacements at seven cross-sections.

The tests were aimed to examine whether a phenomenon of reduced structural ductility, which was observed in lightly reinforced fibrous beams in a former series of tests of HSC, would repeat in NSC beams.

Reduced flexural ductility was observed in the current test specimens with low reinforcement ratios that included steel fibers. This result was characterized by relatively low maximum deflections accompanied by rupture of the tension rebars in the beams with fibers and low reinforcement ratio. Maximum displacements of these fibrous beam specimens were about one third of maximum displacements of the corresponding beam specimens with the same low amount of reinforcement but without fibers. Reduced structural ductility was also indicated by the relatively non-uniform curvature distribution within the constant moment zone, at large beam deflections, as compared to the curvature distribution in similar beam specimens, which did not include fibers. Ductility of fibrous RC beams increased though with increasing reinforcement ratios.

A possible reason for these results may be localization of slip of the tension rebars in the presence of fibers. Application of fibers leads to scatter in residual tensile strength at the cracks (more than in plain concrete). The effect of this scatter is likely to be stronger in the presence of low amounts of reinforcement (and vice versa). Hence, at low (e.g., minimum) reinforcement ratios, it would lead to locally larger strains of the reinforcing steel, which can be as large as its rupture strain.

These results may raise a question to whether larger amounts of minimum reinforcement ratios should be specified in FRC beams. This question is not based on the common concern for minimum moment capacity at cracking. It is raised in order to ensure their adequate ductility.

References

Dancygier AN, Savir Z (2006) Flexural behavior of HSFRC with low reinforcement ratios. Eng Struct 28(11):1503–1512

Dancygier AN, Katz A, Wexler U (2010) Bond between deformed reinforcement and normal and high strength concrete with and without fibers. Mater Struct 43(6):839–856

fib (2008) Constitutive modelling of high strength/high performance concrete, fib Bulletin 42. Federation internationale du beton, Lausanne

fib (2010) Model code 2010, First complete draft, vol 1, fib Bulletin 55. Federation internationale du beton, Lausanne

fib (2010) Model code 2010, First complete draft, vol 2, fib Bulletin 56. Federation internationale du beton, Lausanne

Yuguang Y, Walraven JC, den Uijl JA (2009) Combined effect of fibers and steel rebars in high performance concrete. HERON 54(2/3):205–224

Acknowledgments

This study was partially supported by the Israeli Ministry of Construction and Housing.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 Springer Science+Business Media B.V.

About this paper

Cite this paper

Dancygier, A.N., Berkover, E. (2012). Effect of Steel Fibers on the Flexural Ductility of Lightly Reinforced Concrete Beams. In: Fardis, M. (eds) Innovative Materials and Techniques in Concrete Construction. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-1997-2_12

Download citation

DOI: https://doi.org/10.1007/978-94-007-1997-2_12

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-1996-5

Online ISBN: 978-94-007-1997-2

eBook Packages: EngineeringEngineering (R0)