Abstract

Polythiophenes and, in particular, poly(3-alkylthiophenes) have attracted much interest as VOCs sensing materials due to their good environmental stability, easy processability and their particular sensing ability. In this work, the potentiality of a particular class of polythiophenes, the highly regioregular poly[3-(4-alkoxyphenyl)thiophenes], has been investigated as VOCs sensor. This class of polymers showed long term stability under room temperature operation, very high sensitivity towards hydrocarbons and low response time.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Conjugated polymers are intrinsically conductive materials which have been extensively investigated because of their electrical properties. The interest on conductive polymers arises from the suitability of these materials for applications in organic electronics, solar cells, batteries, supercapacitors, biological and chemical sensors [1–5].

Polythiophenes and, in particular, poly(3-alkylthiophenes) have attracted much interest in the sensor field as VOCs sensing materials due to their tunable properties of environmental stability, processability and sensing ability. The mechanism of interaction between an analyte and the polymer can be either physical or chemical: nucleophilic gases (H2, NH3, N2H4, H2S, etc.) interact chemically with the polymeric chain dedoping the polymers and decreasing the conductivity, while electrophilic (NOx, SO2, etc.) gases have an opposite effect. Other gases, including VOCs, interact via van der Waals forces with the polymer chain and, upon absorption onto the polymer film, a change in resistance, correlated with the concentration of analyte, can be observed [3]. These features have been mostly exploited in e-nose applications where sensitivities in the low ppm level, good repeatability, reversibility and stable room-temperature operation are required.

In this work, the potentiality of a particular class of polythiophenes, the highly regioregular poly[3-(4-alkoxyphenyl)thiophenes], has been investigated as VOCs sensor. These polymers show several advantages in terms of ease and cost of the synthetic pathway, regioregularity, order and planarity of the polymeric chain.

Moreover, the pronounced electron donor character of the alkoxyphenylic side-chain improves the stability of the doped state conferring a greater stability to the conducting state.

In particular, the potential of poly(3-(4-octyloxyphenyl)thiophene (PO) and of the copolymer poly(4-pentenoxyphenyl-stat-4-hexyloxyphenyl)thiophene as VOCs sensor has been probed; polymeric films have been deposited onto a chemiresistor transducers and exposed to toluene, acetone and alcohol vapours. The devices show good responses in terms of sensitivity and response time.

2 Results and Discussion

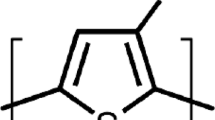

The poly[3-(4-octyloxyphenyl)thiophene] and the copolymer poly[4-pentenoxyphenyl-stat-4-hexyloxyphenyl)thiophene] (Fig. 5.1), hereafter indicated as PO and coP5P6 respectively, have been synthesized by an oxidative coupling polymerization reaction that leads to highly regioregular polymers (up to 80%). The polymers have been p-doped with chloroform solution of FeCl3 (2% with respect to polymer) [6].

Chemiresistor devices have been obtained by drop casting 20 ?l of a 10 mg/ml chloroform solution of polymers onto a 15 × 5 mm2 Al2O3 substrate with pre- printed gold interdigitated electrodes. The devices, biased at 0,5V DC, have been electrically characterized in a Gas Sensor Characterization System where VOCs vapours, such as toluene, acetone, ethanol and 1-butanol are introduced by means of a bubbler system in controlled amounts [7]. The gas mixture and concentration output were checked by a Thermo Antaris IGS FTIR gas analyzer.

The chemiresistors, exposed to different concentrations of those analytes, show good responses in terms of sensitivity and detection limits in the ppm region (see Fig. 5.2 and Table 5.1). PO has very fast response time – comparable or even lower than the filling time of the test chamber – towards all the selected analytes, with a higher sensitivity to acetone and toluene. The copolymer film shows an overall higher sensitivity but slower response time. In particular, coP5P6 has a very good response to toluene and 1-butanol, with a lowest detection limits as low as 0.2 ppm for toluene (value extrapolated by evaluation of the ratio between baseline noise and sensitivity). The exposure of coP5P6 to alcohol vapours shows a double effect on the measured current: soon after the inlet of the vapour the conductivity of the film increases but afterwards it seems to reduce with a slower kinetics. The same kind of kinetics can be also observed after the removal of the analyte. In summary, it can be noticed that toluene and 1-butanol are well detected by the copolymer sensing layer while PO shows better responses to more polar compounds, such as acetone and ethanol.

These performances persist even after more than two weeks under ambient conditions; after this period the electrical conductivity of the PO devices is dramatically reduced because of the dedoping process originated from the environmental water humidity [8]. Noteworthy, in the same storage conditions coP5P6 films are stable for more than 1 month.

3 Conclusions

Poly[3-(4-alkoxyphenyl)thiophenes] based gas sensors show a good sensitivity towards VOCs combined with a low detection thresholds. In addition, these sensing layers show a good repeatability and reversibility. The two polymers tested, notwithstanding the similar chemical structures, have different sensitivity and response kinetics to the same analytes. In particular, PO sensing layers responds with higher sensitivity to polar compounds whereas coP5P6 exhibits more affinity to apolar analytes. On account of this the sensors based on these layers can be profitably implemented in solid state sensor arrays for VOCs detection.

References

Lange U, Roznyatovskaya NV, Mirsky VM (2008) Conducting polymers in chemical sensors and arrays. Anal Chim Acta 614:1–26

Zhan L, Song Z, Shan N, Zhang J, Tang J, Zhan H, Zhou Y, Li Z, Zhan C (2009) Poly(tetrahydrobenzodithiophene): high discharge specific capacity as cathode material for lithium batteries. J Power Sour 193:859–863

Guan H, Zhou P, Zeng S, Zhou X, Wang Y, He Z (2009) Detection of deletion mutations in DNA using water-soluble cationic fluorescent thiophene copolymer. Talanta 79:153–158U

Dua V, Surwade SP, Ammu S, Zhang X, Jain S, Manohar SK (2009) Chemical vapor detection using parent Polythiophene nanofibers. Macromolecules 42:5414–5415

Li B, Santhanam S, Schultz L, Jeffries M, Iovu MC, Sauvè G, Cooper J, Zhang R, Revelli JC, Kusne AG, Snyder JL, Kowalewski T, Weiss LE, McCullough RD, Fedder GK, Lambeth DN (2007) Inkjet printed chemical sensor array based on polythiophene conductive polymers. Sens Actuators B 123:651–660

Barra M, Biasucci M, Cassinese A, D’Angelo P, Barone AC, Carella A, Roviello A (2007) Direct current and alternating current electrical transport properties of regioregular poly[3-(4- alkoxyphenyl)-thiophenes]. J Appl Phys 102:093712

Quercia L, Cerullo F, La Ferrara V, Di Francia G, Baratto C, Faglia G (2000) Fabrication and characterization of a sensing device based on porous silicon. Phys Status Solidi A 182:473–477

Koizumi H, Dougauchi H, Ichikawa T (2005) Mechanism of dedoping processes of conducting poly(3-alkylthiophenes). J Phys Chem B 109:15288–15290

Acknowledgments

The authors gratefully acknowledge the Ministry of Universities and Research (MUR) for financial support as part of Public-Private Laboratory TRIPODE (Technologies and Research for the application of polymers in electronics devices).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2011 Springer Science+Business Media B.V.

About this paper

Cite this paper

Massera, E. et al. (2011). Poly[3-(4-Alkoxyphenyl)thiophenes] Based Chemical Sensors. In: Neri, G., Donato, N., d'Amico, A., Di Natale, C. (eds) Sensors and Microsystems. Lecture Notes in Electrical Engineering, vol 91. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-1324-6_5

Download citation

DOI: https://doi.org/10.1007/978-94-007-1324-6_5

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-1323-9

Online ISBN: 978-94-007-1324-6

eBook Packages: EngineeringEngineering (R0)