Abstract

Aluminium and its alloys have high demand in manufacturing and service industries due to their high specific strength. Addition of different metals like Cu, Mg, Ni, Cr, and Zn provides enhanced service life. In this work, commercially available 99 % pure aluminium was alloyed with copper powder of 10 μm particles size, which was melted by CO2 laser . Three different methods were used for uniform placing of 95 % copper powder and 5 % aluminium powder on the aluminium substrate. The result was examined by Vickers hardness test. SEM and FESEM were used for studying surface and subsurface defects. Defect free aluminium alloy with improved microstructure and enhanced mechanical properties was obtained.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Most applications in real world require specific surface properties of components with good corrosion resistance, wear resistance and hardness. However, it is not easy to get alloys with such properties since they are expensive due to the cost of producing those parts. Investigations have been carried out to improve the properties and to reduce the cost of components made of Aluminium alloys. An important and recent technology is the laser surface alloying, which is a cost-effective technique to improve the surface properties of materials using laser beam heat (Hecht 2011). In this technique, the structure and physical characteristics at the surface get changed. Laser surface alloying utilizes a high power density laser beam to melt the metal coatings (alloying elements) and the surface of substrate material. This melting takes place in a very short period of time while bulk material remains cold and acts as heat sink for self-quenching and fast solidification phenomenon.

Laser surface alloying is similar to laser surface melting except that in the former, alloying materials are added into the melt pool in order to impart its properties as per requirements. It is also similar to laser surface cladding, but laser surface alloying requires more energy compared to cladding. The surface alloying improves corrosion resistance, oxidation and solidification resistance, wear resistance, mechanical properties, electrical & electronic properties, thermal insulation and aesthetic appearance. By improving the surface, it reduces the frictional energy loss.

2 Significances of Surface Alloying

Failure of engineering components due to some reasons such as mechanical, chemical or electrochemical interaction with the surrounding environment initiates at the surface due to the high intensity of external stress and environmental attack. To develop the resistance of materials, laser surface alloying is one method to modify the surface properties of a material without affecting its bulk property. The intimate contact between the melt and the solid substrate causes a very fast heat extraction during solidification resulting in very high cooling rates of the order of 105–108 K/s. The high cooling rates to which this surface layer is subjected result in the formation of different microstructures from bulk metal leading to improved surface properties (Dubourg et al. 2002).

Adding alloying elements into the melted pool makes them inter diffuse into the substrate material. Soon the solidification begins from the liquid-solid interface towards the direction of substrate material. It has been reported that the structure of alloyed zone depends on many properties like the particle size of the alloying material, power of laser irradiation and duration of irradiation time. Alloying brings changes in surface composition and microstructure of a material to give it certain desired properties. The benefits of rapid solidification by laser power for surface modification are as follows: fine grain structure due to fast solidification (Kannatey-Asibu 2009), reduced micro segregation and extended solubility of alloying elements.

3 Significance of (CO2) Laser for Surface Alloying

Carbon dioxide laser is the most popular laser used in industrial material processing because of its high energy efficiency and high average optical power output. It uses N2 gas for facilitating the pumping and population inversion process by providing molecule collisions with CO2 gas.

In addition He gas is used for bringing the N2 gas to ground state by from the lower excited state. CO2 laser can be operated both in continuous and pulsed modes for material processing. In this work the continuous mode is used.

A CO2 laser has the following characteristics (Dahotre 1998):

-

Wave length of 10.6 µm. It is in the far infra-red spectrum thus not visible.

-

It can be operated in continuous wave (CW) mode where the output power is at constant level, or pulse mode where the laser output power can be pulsed.

-

The laser beam is well absorbed by organic materials and ceramics but poorly absorbed by metallic materials.

-

Mirrors rather than optical fibers are used for beam delivery since normal glass or silica in optical fibers is opaque to the CO2 laser beam.

4 Details of Experiments

In the present work, commercially pure Aluminium of 99 % purity was alloyed with copper powder of 10 μm particle size and melting was done by continuous CO2 laser power. During alloying 50 % overlap is provided between consequent beads. After cooling, re-melting was carried out at orthogonal direction to alloyed layers.

Sample dimension used was 110 mm × 50 mm × 6 mm. Table 1 shows substrate material composition tested by analytical technique used for the elemental analysis in energy-dispersive X-ray spectroscopy (EDX). Figure 1 shows the schematic diagram of alloying used for this experiment.

In view of the importance of Aluminium for automobile, aerospace and many other sectors, this chapter investigates the surface alloying of aluminium by copper. Three methods of alloying have been used. The mechanical properties and microstructures of surface alloyed samples have been compared. Table 1 shows the substrate material composition.

Three methods used for depositing the copper powder are as follows:

-

(a)

Stirring of metal powder with Fevicol and then painting it on substrate to achieve 0.5 mm coating for samples 12, 13, 14, 15.

-

(b)

First painting the substrate by Fevicol, then applying powder uniformly and finally compacting it to achieve total coating thickness of 1 mm for samples 4, 5, 6, and 9.

-

(c)

First painting the substrate by Fevicol, then applying powder and blowing out excess powder to achieve total coating thickness of 0.5 mm for samples 1, 2, 3, 7, 8, 10 and 11. Table 2 shows the process parameters in different experiments.

Table 2 Process parameters for surface alloying Al with Cu

5 Results and Discussions

5.1 Crystal Size and Lattice Strain

The crystal size and lattice strain developed due to thermal effect was examined for Sample 4 by XRD and the result is shown in Fig. 2. Strain was calculated from (Williamson and Hall 1953):

where β is the full width at half maximum, K is a constant, λ is the X-ray wave length of Cuk α radiation (λ = 1.5418 Å), D is the average crystal size and η is the lattice strain. The strain in the sample was 0.002 as observed in the inset of Fig. 2 and average size of crystallite is 152.06 nm. The crystal is cubic in structure as justified from the International Centre for Diffraction Data (ICDD)#: 02-1254, confirming the formation of Al4Cu9 phase.

5.2 Surface Roughness

Roughness plays an important role in determining how a real object will interact with its environment. Surfaces with roughness usually wear more quickly and have higher friction coefficients than smooth surfaces. The performance of a mechanical component highly depends on the condition of the surface finish, since irregularities in the surface may form nucleation sites for cracks or corrosion.

In the present work, the surfaces of the alloyed layers were tested without polishing the surface. Taylor Hobson make CCI Light, non-contact optical profilometer was used to check surface quality of alloyed samples. Figure 3a shows Sample 2, where the area of non-uniform coating resulted in void surface with larger peaks and valleys and Fig. 3b is Sample 9, with uniform deposited and alloyed surface with centre average roughness value (R a ) up to 1.9 µm.

5.3 Micro Hardness Analysis

Micro-hardness test was conducted on thickness side of the samples by Vickers hardness test using 500 gf and the results are plotted in Fig. 4. Maximum hardness achieved is 156 HV at laser power of 1.7 kW laser beam diameter of 5.39 mm and scanning speed of 500 mm/min. The re-melting was done in orthogonal direction to the alloyed direction at laser power of 1.6 kW and scanning speed of 800 mm/min. The re-melting was done after alloying improved hardness (Pinto et al. 2003). Samples 4 and 9, surface alloyed with 1 mm deposition thickness of alloying element, resulted in improved hardness compared to other samples.

5.4 Microstructure and Morphology Analysis

A pure metal normally solidifies at a constant temperature with the inter-face between the solid and liquid media being planar for an alloy. Figure 5a for sample 4 and Fig. 5b for sample 9 show the morphological result at the solidified regions analysed by scanning electron microscopy (SEM). It shows the Cu growth in Al4Cu9 inter metallic phase with a fine microstructure region (Dubourg et al. 2002). After initial cellular growth from the bottom of the molten pool, the solidifying area developed lateral instability favourable for forming homogeneous structure.

Figure 6a shows uniformity of Cu growth into white Al primary grains and dark eutectic well distributed forming inter-metallic of Al4Cu9 phase. Figure 6b shows the grain boundary crack that contain appreciable amounts of copper, when the cooling rate is insufficient to prevent precipitation on grain boundaries at higher temperature and hence is susceptible to stress corrosion cracking (SCC) and micro-crack initiation (van Otterloo et al. 1995).

Atoms of Cu lower their free energy when they migrate to lattice defects such as grain boundaries, phase boundaries and dislocation. In Fig. 7a marked region ‘A’ shows un-melted region. A regular growth of binary Al4Cu9 eutectic morphology as a result of uniform and fast cooling time resulted in fine microstructure as shown in Fig. 7b at higher magnification. Segregation to grain boundaries affects the mobility of the boundary and has pronounced effects on re-crystallization, texture and grain growth.

5.5 Porosity Challenges in Alloying

Porosity is not a usual problem in surface alloying like in other processes such as welding. However, if proper care is not taken it may cause material failure during service life. Porosity is the presence of gas pores or pockets within the fusion zone in the form of discontinuity formed by gas entrapment during solidification phenomenon. It occurs when gases such as oxygen, nitrogen and hydrogen are absorbed from atmosphere or developed when chemical reactions takes place between substrate and alloying elements during melting and solidification phenomenon.

The sources of these gases may also arises from contaminated substrate material or wetting conditions. For example, present experiments show the existence of gas pores or pockets within the alloyed area for samples first painted by adhesive followed by the copper powder deposition. Figure 8a shows a photograph and Fig. 8b a SEM photo. The voids are formed due to gas entrapment during solidification which are likely to occur when the rate of solidification is fast and there is no adequate time for the evolved gas to escape.

The laser parameter for alloying are P = 1.8 kW, SOD = 30 mm and SS = 500 mm/min. Re-melting laser parameters are P = 1.5 kW and stand of distance SOD = 40 mm and scanning velocity SS = 400 mm/min.

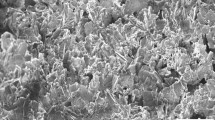

The quality of alloyed layers should be free of any cracks which may form under the subsurface layers due to some reasons. Powders of alloyed regions were tested by field emission scanning electron microscopy (FESEM) to check whether cracks and defects are formed at subsurface of alloyed regions. To check for it powders from alloyed layers were prepared and tested by the above mentioned machine for well alloyed layers selected. Figure 9 shows fractography results. No defects were observed.

5.6 Conclusions

Surface alloying of commercially pure Aluminium by 10 µm copper powder was carried out. The following are the main observations:

-

Uniformly deposited Cu powder by compacting method resulted in good surface alloyed layer with average surface roughness of 1.9 µm.

-

For laser alloying at 1.7 kW and scanning speed of 500 mm/min and re-melting at lower power of 1.6 kW in orthogonal direction to alloyed layer resulted in improved micro hardness from 60 to 156 HV.

-

Formation of fine microstructure with Al4Cu9 intermetallic phase developed due to fast solidification and uniform alloying of Cu powder on substrate material.

References

Dahotre, N. B. (Ed.). (1998). Lasers in surface engineering (Vol. 1). USA: ASM International.

Dubourg, L., Pelletier, H., Vaissiere, D., Hlawka, F., & Cornet, A. (2002). Mechanical characterization of laser surface alloyed aluminium–copper systems. Wear, 253(9), 1077–1085.

Hecht, J. (2011). Understanding lasers: An entry-level guide (Vol. 21). New York: Wiley.

Kannatey-Asibu, E, Jr. (2009). Principles of laser materials processing (Vol. 4). New York: Wiley.

Pinto, M. A., Cheung, N., Ierardi, M. C. F., & Garcia, A. (2003). Microstructural and hardness investigation of an aluminum–copper alloy processed by laser surface melting. Materials Characterization, 50(2), 249–253.

van Otterloo, J. L. D. M., Bagnoli, D., & De Hosson, J. T. M. (1995). Enhanced mechanical properties of laser treated Al-Cu alloys: A microstructural analysis. Acta Metallurgica et Materialia, 43(7), 2649–2656.

Williamson, G. K., & Hall, W. H. (1953). X-ray line broadening from filed aluminium and wolfram. Acta Metallurgica, 1(1), 22–31.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer India

About this chapter

Cite this chapter

Jiru, W.G., Sankar, M.R., Dixit, U.S. (2015). Surface Alloying of Aluminum with Copper Using CO2 Laser. In: Joshi, S., Dixit, U. (eds) Lasers Based Manufacturing. Topics in Mining, Metallurgy and Materials Engineering. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2352-8_7

Download citation

DOI: https://doi.org/10.1007/978-81-322-2352-8_7

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-2351-1

Online ISBN: 978-81-322-2352-8

eBook Packages: EngineeringEngineering (R0)