Abstract

Suspension design is always been a challenging task for automobile designers in view of multiple input parameters, complex objectives, and disturbances which are stochastic in nature. The conflicting nature of ride comfort (RC) and road holding (RH) compels a judicial compromise between these two. In the present work, full factorial design of experiment (DoE) has been used successfully for the purpose of multi-objective optimization of RC and RH with input variables spring stiffness (K), damping coefficient (C), sprung mass (M), and speed. For experiments with combination of various input variables, a quarter car test rig is developed with proper data acquisition system by NI-hardware and Laboratory Virtual Instrumentation Engineering Workbench (LabVIEW) to collect real-time data. A regression model of RC and RH with R 2 value 95.98 and 95.78 %, respectively, can be effectively used to evaluate optimal settings of various input parameters using response optimization with a high desirability value.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Quarter car test rig

- Ride comfort

- Road holding

- Design of experimentation

- LabVIEW

- DAQ system

- Response optimization method

1 Introduction

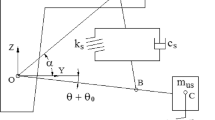

The suspension system separates vehicle body frame from road surface. Harmful effects of vehicle vibrations on human body are nausea, back pain, osteoarthritis, slipping of disk, etc. [1]. The suspension systems are designed firstly to meet the ride comfort (RC) which is measured by root mean square (RMS) value of sprung mass acceleration, a lower value which leads better RC and secondly, to satisfy, road holding (RH), which is measured by relative displacement between unsprung mass and road input, negative value of which leads to good RH [2]. It has been well established by other researchers in the field, that the ride characteristics of passenger vehicles can be characterized by considering a quarter car model of a vehicle [3]. This method is being widely used to investigate the performance of passive suspension system [4]. In this paper, optimization of RC and RH as per ISO 2631-1:1997 standard [5] is presented by the experimentation conducted on a quarter car test rig using the approach of design of experiments (DoE) response optimization method [6].

Laboratory Virtual Instrumentation Engineering Workbench (LabVIEW) is used to acquire data for RC and RH from quarter car test rig. IEPE accelerometers and proximity sensor are used to acquire readings for RC and RH, respectively [7, 8].

2 Data Acquisition Hardware and Sensors

In this study, multi-objective optimization of RC represents acceleration of sprung mass and RH represents relative displacement of road input and unsprung mass and rpm of CAM which represents the speed of vehicle approaching to road bump. Sensor selection was the most important step of a data acquisition system.

A high-sensitive 2-pin accelerometer of ICP® (IEPE) make (Model: 351B03) is used to measure the acceleration of sprung and unsprung mass.

A proximity sensor (GP2Y0A21YK0F) [9] is used to measure the distance, which is an integrated combination of position-sensitive detector (PSD), infrared-emitting diode (IRED), and signal processing circuit. The variety of the reflectivity of the object, the environmental temperature, and the operating duration do not influence easily the distance detection because of adoption of the triangulation method. This device gives output as voltage corresponding to the detection distance.

To measure the rpm, an IR trans-receiver is placed facing each other so that extension connected to motor shaft may cut the rays between transmitter and receiver. Frequency as well as rpm of the shaft can be calculated by a LabVIEW programming. The entire sensors are connected to NI-9234 a 4-channel, ±5 V, 24-Bit IEPE module. IEPE module is calibrated to all IEPE type of sensor, but proximity and IR sensor is non-IEPE-type sensor, which requires some scaling factors. Quarter car test rig with sensors and NI-9234 hardware is shown in Fig. 1.

3 LabVIEW Programming

LabVIEW is a platform and development environment for a visual programming language from National Instruments. LabVIEW coding is the most integral part of the data acquisition (DAQ) system. As LabVIEW is graphical coding language, it is easier to write code compared to other software. LabVIEW coding to acquire acceleration, displacement, and rpm is shown in Fig. 2, called ‘Block Diagram Panel.’ All the measured parameters can be displayed in a ‘front panel’ shown in Fig. 3. Time-domain acceleration data are also converted to frequency domain using a spectral measurement block.

NI-9234 hardware which is an integrated electronic piezoelectric (IEPE)-type module calibrated for ICP® IEPE-type accelerometers has been utilized for benefit. In this DAQ system, proximity sensor is also to be connected with NI-9234 by using external scaling factors mentioned in data sheet [9] as shown in Fig. 4.

Figure 5 represents a rpm measurement VI, where a frequency measurement block measures the frequency of interruption of the transmitting and receiving ray in the IR sensor which must be greater than 2 Hz (120 rpm) in real time, and for lower rpm measurement shows error. To tackle this problem, two extensions are attached on shaft so that measured rpm will be twice the actual rpm. A counter has been used to count the number of times the extension cuts the ray per second, and then, that value is converted in per minutes to measure rpm of the shaft.

4 Design of Experiments

The aim of the present work was to achieve multi-objective optimization formulations for RC and RH by determining the effects of some main factors and their interactions by regression analysis. DoE methodology was used for gathering information by conducting experiments on quarter car test rig (Table 1).

Four variables such as stiffness (K), damping coefficient (C), sprung mass (M), and speed are used as input variables with two-level and twice-replicating experimental reading, which are listed in Table 2 as per 2k full factorial DoE matrix. The experiments are performed as per DoE matrix on the quarter car test rig, and values of various output parameters such as RC and RH are actually measured and stored in a computer using LabVIEW.

4.1 Regression Model

A MINITAB® software is used to fit the regression model with only significant terms. The ‘goodness of the fit’ of regression model in Eqs. (1) and (2) can be quantified from analysis of variance (ANOVA) by the R 2 value of RC 95.98 % and RH 95.78 %, which indicates the validity of model with input variables with 4.02 and 4.22 % variation due to error or by some noise factors, respectively. The high values of predicted R 2 as 89.70 and 89.21 % for RC and RH, respectively, ensures that models can be used for further analysis. The regression models with final significant estimated coefficients of RC and RH in uncoded units are as Eqs. (1) and (2).

5 Result and Discussion

Multiple response functions are estimated as polynomial functions of the factors in Eqs. (1) and (2) from regression analysis. The response variable is transformed to give a composite desirability value which is proportional to the priority given to the response variable. In this study, goals are set in Table 3 as per ISO 2631-1:1997 standard of RC with higher value of weightage and importance than RH.

The optimization plot in Fig. 6 shows the factor settings to get individual desirability [10] of both the RC and RH as 1.0. Therefore, the combined or composite desirability of these two variables is 1.0. To obtain this desirability, one would set the factor levels at values shown under global solution, i.e., K = 18,700 N/m and C = 435 N-s/m, M = 75 kg, and speed of CAM = 155 rpm.

6 Conclusion

In this study, a quarter car test rig is developed with proper DAQ system using LabVIEW. A regression model from this experimental results based on 2k full factorial has been developed with significant terms of coefficient. The ‘goodness of fit’ for RC and RH models is checked from quantitative measures of R 2 as equal to 95.98 and 95.78 % with the \( R_{\text{Pred}}^{2} \) equal to 89.70 and 89.21 %, respectively, being verified by the assumptions of random error by ANOVA. Such a model not only assists to estimate the magnitude and direction of the effects of change in the factors but also predicts the effects of their mutual interactions.

The model has assisted optimizing the RC and RH for factor setting of K = 18,700 N/m, C = 435 N s/m, M = 75 kg, and speed = 155 rpm. With optimized parameters, the predicted values of RC and RH come out to be equal to 0.5 m/s2 and −0.5 m, which is very much acceptable by ISO 2631-1:1997.

References

Kjellberg, A.: Psychological aspects of occupational vibration. Scand. J. Work Environ. Health 16(Suppl. 1), 39–43 (1990)

Dixon, J.C.: Suspension Geometry and Computation. Wiley, New York (2009)

Crolla, D.A.: Vehicle dynamics: theory into practice. Proc. Inst. Mech. Eng. Part D: J. Automobile Eng. 210, 83–94 (1996)

Sharp, R.S., Hassan, S.A.: Evaluation of passive automotive suspension systems with variable stiffness and damping parameters. Veh. Syst. Dyn. 15(6), 335–350 (1986)

ISO: 2631-1, 1997: Mechanical vibration and shock—evaluation of human exposure to whole-body vibration (1997)

Montgomery, D.C.: Design and Analysis of Experiments, 7th edn. Wiley, New Jersey (2009)

Paton, B.E.: Sensors, Transducers, and LabVIEW (Virtual Instrumentation Series), 1st edn. Prentice Hall PTR, New Jersey (1998)

Gupta, S., John, J.: Virtual Instrumentation Using LabVIEW. Tata McGraw Hill, New Delhi (2005)

Data sheet No: E4-A00201EN Date Dec.01.2006 ©SHARP Corporation (2006)

Designing Experiments Manual ©Minitab Inc. (2005)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer India

About this paper

Cite this paper

Mitra, A.C., Banerjee, N. (2015). A LabVIEW-Based Data Acquisition System in a Quarter Car Test Rig to Optimize Vehicle Suspension System. In: Mandal, D., Kar, R., Das, S., Panigrahi, B. (eds) Intelligent Computing and Applications. Advances in Intelligent Systems and Computing, vol 343. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2268-2_60

Download citation

DOI: https://doi.org/10.1007/978-81-322-2268-2_60

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-2267-5

Online ISBN: 978-81-322-2268-2

eBook Packages: EngineeringEngineering (R0)