Abstract

Controlling pollution caused by hydrocarbon compounds, for example, crude oil pollution, in soils and waters by bioremediation has acquired considerable significance. Bioremediation is one technique that may be useful to remove spilled oil under certain geographic and climatic conditions. Researchers all around the world have developed different methodologies to reclaim the contaminated site according to the prevailing environmental conditions. A set of 125 patent/patent applications describing the use of oil-degrading microorganisms were analysed to find out the approach followed to achieve bioremediation. Patent documents revealed that the technique of bioremediation using microorganism follows two broad approaches, viz. fertilization and seeding. Fertilization is the bioremediation method of adding nutrients, such as nitrogen and phosphorus, to a contaminated environment to stimulate the growth of indigenous microorganisms, and seeding refers to the addition of naturally occurring or genetically engineered microorganisms to a spill site. Overall the success of a technique depends on the ability to establish appropriate conditions for the microorganisms in the contaminated environment. Another approach in a set of patents showed that growth may be enhanced by increasing the substrate bioavailability or by emulsification. United States of America is the leading country followed by China, Korea, Japan, and Russia in developing bioremediation technologies. Prominent companies working towards developing eco-friendly solutions include DuPont, Biosaint, Univ Nat Cheng Kung, Samsung Everland Inc., Technology Licensing Organization, Biorem AG, Petrozyme Technologies, Ocean University of China, and BioNutraTech.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

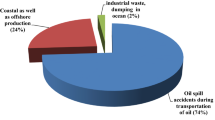

Introduction

Biodegradation refers to the natural process whereby microorganisms alter and break down organic molecules into other substances, such as fatty acids and carbon dioxide, and bioremediation is the act of adding materials to contaminated environments, such as oil spill sites. Amongst the other applications for which bioremediation is being considered or is currently in use are (1) treatment of nontoxic liquid and solid wastes (Liu et al. 2011), (2) treatment of toxic or hazardous wastes (Atlas and Hazen 2011), (3) treatment of contaminated groundwater, and (4) grease decomposition. Although recent marine oil spills and bioremediation efforts have called attention to the potential of bioremediation as an oil spill response technology, some of these other applications, in particular the treatment of hazardous waste, appear to have greater potential (Lin et al. 2011; Galindo et al. 2011; Chandran and Das 2011). Officials at approximately 135 hazardous waste sites, for example, are now either considering, planning, or operating full-scale bioremediation systems. A large number of refineries, tank farms, and transfer stations now employ in situ bioremediation methods to restore land contaminated by accidental spills of fuel oil or other hydrocarbons (Zhang et al. 2011). Much less progress has been made with respect to the practical problems of applying bioremediation technologies to marine oil spills, although advocates have suggested their use in the wake of several major spills.

The problems associated with using bioremediation technologies in marine environments are fundamentally different from those associated with land-based applications. Potential bioremediation approaches for marine oil spills fall into three major categories:

-

(a)

Stimulation of indigenous microorganisms through addition of nutrients (fertilization) (Chamkha et al. 2011; Mohite et al. 2011; Korotkevych et al. 2011)

-

(b)

Introduction of special assemblages of naturally occurring oil-degrading microorganisms (seeding)

-

(c)

Introduction of genetically engineered microorganisms (GEMs) with special oil-degrading properties

Stimulation of indigenous organisms by the addition of nutrients is the approach that has been tested most rigorously. This approach is viewed by many researchers as the most promising one for responding to most types of marine spills. Recent experiments suggest that rates of biodegradation in most marine environments are constrained by lack of nutrients rather than by the absence of oil-degrading microbes (Churchill et al. 1995). The introduction of microbes might be beneficial in areas where native organisms grow slowly or are unable to degrade a particular hydrocarbon. However, the effectiveness of this approach has not yet been demonstrated. The wide availability of naturally occurring microorganisms capable of degrading components of petroleum will likely deter consideration of GEMs for remediating marine oil spills. Degradation of hydrocarbons in the presence of synthetic surfactants is a delicate issue. Generally, the toxicity of surfactants increases with their hydrophobicity (Tiehm 1994). The use of surfactants of biological origin solves the toxicity problem.

Moreover, greater research and development needs, regulatory hurdles, and public perception problems will remain obstacles to the near-term use of GEMS even if they could prove useful for degrading some recalcitrant components of petroleum. Bioremediation technologies for beach cleanup have so far received the most attention (MacNaughton et al. 1999; Lloyd-Jones et al. 1999; Mesarch et al. 2000). Experiments conducted by United States Environmental Protection Agency (EPA), Exxon, and the State of Alaska on cobble beaches fouled by oil from the Exxon Valdez indicated that the addition of nutrients at least doubled the natural rate of biodegradation. The efficacy of commercial microbial products in remediating beaches is not yet known. Limited EPA field tests using two microbial products on heavily weathered oil in Alaska were inconclusive. Additional field experiments are required on other types of beaches that involve different oils and different climatic and marine conditions. The objective of this chapter is to analyse the current state of development of bioremediation technology through the patent documents filed in all the jurisdiction of this world. This chapter also describes some exemplary techniques used for the bioremediation of oil-contaminated sites and to clean up marine oil spills.

Methods

The scope of the study was to identify commercially viable patent families describing different bioremediation strategies to overcome pollution caused by oils. To shortlist the potentially relevant patent families in the field of bioremediation, search strings were made using the keywords based on the understanding developed for conducting a search for patents/published applications in the field of study.

Patents and published patent applications were extracted from Thomson Innovation patent database.

Results

Running search string S-1 in Thomson Innovation patent database yielded 390 patents and published applications. The patents and published applications obtained from Thomson Innovation patent database were reduced to ‘one member per patent family’. A unique set of 248 distinct patent families was obtained. A title-, abstract-, and claim-based screening was carried out to select certain technologies which were describing the use of microorganisms for bioremediation. One hundred and twenty five patent documents were short listed and analysed in more details.

Most Frequently Used Microbial Groups

Analysis of the 125 patent documents revealed that more than 100 different genera of microorganisms have been claimed for oil degradation; major genera amongst these include (in decreasing order) Pseudomonas, Rhodococcus, Bacillus, Thauera, Acinetobacter, Shewanella, Stenotro-phomonas, Gordonia, Burkholderia, Alcaligenes, Pseudomonas, Marinobacter, Azotobacter, Comamonas, Marino-bacterium, Petrotoga, Microbulbifer, Alcanivorax, Yarrowia, Flavobacterium, and Moraxella (Table 16.1).

Representative Technologies

Complete analysis of the patent documents showed the following basis of achieving bioremediation of an oil-contaminated site:

-

1.

Use of an enriched steady-state microbial consortiums.

-

2.

Oil is broken down into microscopically small parts by way of some novel composition.

-

3.

Use of a chemical mixture which enhances the substrate bioavailability for micro-organism.

-

4.

Use of some particulate material for promoting growth of petroleum-degrading bacteria.

-

5.

Use of a nutrient microemulsion in spray form, useful as a biodegradation accelerator.

-

6.

Use of a nutrient mixture which has an emulsifying effect and would contain P- and N-yielding substances.

-

7.

Use of a combined approach by using microorganisms directly and by promoting growth of oil-degrading bacteria.

Strategy 1

Use of Anaerobic Microorganisms Contained in Capsules, Coated Pellets, or Pods Having Cores of Varying Densities: The first strategy disclosed by Leon Kirschner (1999) in his European patent EP1088109B1 describes the use of an anaerobic microorganism Vibrio desulfuricans for remediation of submerged petroleum products, which anaerobes result in an overall exponential increase in speed of remediation, and also adds versatility to the art of remediation as applied to the inadvertent release of petroleum products into an aqueous environment during transport or storage, or to an intentional release of oil products, which also requires remediation.

The use of such anaerobic microorganisms offers bioremediation to those petroleum products which sink below the surface of the water and often to the floor of the sea, where known application techniques for remediation do not reach submerged oil spills.

Preemption is achieved by incorporating within the petroleum products, before a spill occurs, remediating agents contained in capsules, coated pellets, or pods having cores of varying densities. Such agents are inert and inactive when encapsulated or within the coated pellets, but are activated when not in the encapsulated environment. These encapsulated or pelletized agents are preferably dispersed throughout a body of petroleum. The capsules or pellets may be installed into the petroleum at the wellhead or in a pipeline, in a cargo hold, at a refinery, or at any desired location during the processing and transport or storage of the petroleum product.

Preferably, these capsules or pellets are reclaimable when not activated and may be reused. Such reclamation may be accomplished through magnetic (utilizing either ferromagnetic, diamagnetic, or paramagnetic materials, or a combination of some or all of them) separation, centrifugation, filtration, electrostatic or ionic precipitation, vaporization, or heat or vacuum distillation or a combination of such techniques. The capsules or pellets may be constructed to permit ease of reclamation and reuse.

Capsules or pellets with a core containing microorganisms, surrounded by time dissolvable layers of nutrients and other enhancements, may be compounded using prior art skills and formulations. Such capsules, pellets, or pods of varying sizes and/or densities, so as to embody the present invention, may also be novelly compounded to include iron or other compound [within either the capsule, pellet, or pod core and/or their surrounding (encapsulating) material or coating (pellet)] so as to permit the capsules, pellets, or pods to be varied in density, preferably to approximate the density of the petroleum product in which they are placed, and to encourage their removal from a body of petroleum by the techniques described above, when desired. The capsule, pellet, or pod may also be sprayed with an aqueous soluble electrostatically charged material or marked with material having magnetic, electrostatic, or electroconductive properties. The core or encapsulating material or coating may also be either fabricated with gas bubbles or contain evacuated or gas-filled glass beads (bubbles or beads of varying sizes) so as to affect the density of the capsule or pellet. These capsules or pellets may also contain water or other aqueous solutions to be time released so as to activate release of microorganisms when oil transport (e.g. pipeline) occurs under arid (e.g. desert) conditions to aid remediation of a petroleum spill or discharge into a nonaqueous environment.

Preferably, such capsules, pellets, or pods contain microorganisms, both aerobes and anaerobes or either of them.

With reference to the accompanying drawings and particularly to Figs. 16.1 and 16.2, a microcapsule cell 10 of anaerobic and aerobic microorganism material having a microorganism nucleus (N) 11 is capable of degrading a hydrocarbon, which may comprise bacterium which degrades petrochemicals, such as organisms from the genus Vibrio, Micrococcus, Bacillus, Arthrobacter, Nocardia, Corynebacterium and also Vibrio desulfuricans, Arthrobacter spp., Bacillus subtilis, B. licheniformis, B. megaterium, B. cereus, B. polymyxa, Aspergillus simplex, A. oryzae, A. niger, Trichoderma reesei, Saccharomyces spp., Pseudomonas, Mycobacteria, Achromobacter, Geotrichum marinum, Thirumalachar sp. nov., or other hydrocarbon degradation bacterium. The nucleus 11 is preferably encapsulated by walls 12. The nucleus 11 may contain sufficient nutrients to sustain the microorganism; however, the walls 12 separate the nucleus from a source of bacterium nutrients (B) 13 which facilitate growth and are presented to the bacterium in the presence of an aqueous solution which penetrates or dissolves the wall 12. As illustrated in Fig. 16.2, these and similar cells 10 may be enclosed in envelopes 14 which have a time released coating 15, such as hydrophilic methacrylate or gelatin to regulate the time of contact with the environment once exposed to water, and these coatings may be of varying thickness or density, which not only varies the time of release but also varies the weight of the envelope.

Working of the Technology: When a breach of the hold or vessel containing the oil product occurs, the leaking of oil product through the breach in the vessel carries with it the pods, which when subject to water, become activated. The enteric coating may be removed by the water or by time, and the microorganism will be induced to consume the escaped petroleum product, and such consumption may be enhanced by the nutrients packed with microorganisms, or these materials may be used primarily to keep the microorganisms hearty over time before they are activated by the presence of water. A Venturi-like effect carries the pods into the spill, dispersing the microorganism pods throughout the escaped oil product floating and submerged in contaminated water.

In summary, this invention teaches the following: first, a methodology of preemption through the introduction of remediating agents into the petroleum product before a spill occurs; second, time or controlled release remediating agents encapsulated or pelletized as products of varying densities to provide for relatively even dispersal throughout the petroleum product; third, remediating agents which may include magnetic or similar materials, or means permitting the removal of unused remediating agents from a body of petroleum product which has not been subjected to aqueous environment; fourth, including anaerobes for the metabolism of submerged petroleum products (which disperse throughout the petroleum bulk to exponentially increase the overall rate of bioremediation); and fifth, time release of aqueous components within the product to affect remediation of spills into nonaqueous environments.

Strategy 2

Combating Oil Slicks Floating on a Water Surface Using Natural Mineral Raw Materials Which Break Oil into Microscopically Small Parts: The second technology belongs to Swisstech Holding AG, Zug, CH. Swisstech Holding AG is a leading cleantech engineering group in onshore and offshore oil decontamination. The group is a worldwide pioneer in natural bioremediation products for oil-polluted substances. This group has offered highly efficient, economical, and ecological solutions. This group has filed a US patent application US20090120872A1 for this technology.

The inventor Kroh (2008), described a methodology for combating oil slicks floating on a water surface. The oil is broken down into microscopically small parts by way of the new composition. The new composition and the new method permit an in situ bioremediation. This strategy enables decomposition of the crude oil by accelerating the biological decomposition on location.

A composition according to the invention is a product that can be efficiently applied for the complete removal of spilled crude oil, also in port facilities or for tank ship accidents. The market-ready product is a dry, free-flowing mixture of solids, comprising a composition of natural mineral raw materials, naturally occurring as solids. These raw materials are obtained from primary or secondary deposits (quarries, stone pits, or other mineral deposits). They may also be recycled from certified non-contaminated natural mineral raw materials. Preferably the natural mineral raw materials are not thermally or chemically pretreated or treated.

The natural mineral raw materials, as a single compound, as mixtures, and in the final composition according to the invention, are chemically inert under natural surrounding conditions (on land, in the water, on ice). During long-time storage, transport, application, and also disposal, they are thus completely harmless for the people, animals, plants, and environment.

For the manufacture of the compositions according to the invention, the natural mineral raw materials are solely broken down, milled, and grinded to the necessary particle size, efficiently working from the invention. It results in a total particle surface of the compositions to which the polluting hydrocarbons, particularly crude oil, may adhesively attach in a quantitatively optimal manner (monomolecular level).

For combating an oil slick floating on a water surface, it is sufficient to scatter or blow the composition according to the invention over the oil slick. The composition according to the invention specifically has the advantageous and amazing characteristic that it spontaneously combines with the oil, and the sorbent without the formation of larger lumps sinks from the surface of the water to the bed of the water and settles there as a fine sediment. With the application of adequate quantities of the composition according to the invention, one may ascertain hardly any toxic hydrocarbons at all in the treated water within a few hours or days. Laboratory trials have even shown that one may even achieve drinking water quality.

The oil is broken down into microscopically small parts by way of the new composition according to the invention. The powder particles bind the oil particles by adsorption, by way of arranging themselves around the oil droplet. Due to the higher specific weight of the powder according to the invention which is preferably between 2.5 and 3.5, preferably about 3.0, the parts of the oil-powder complex completely sink to the bed of the respective water. The present invention utilizes the physical sorption, a special form of adsorption, with which the sorptive is bonded by way of physical forces and not the formation of chemical bonding to the sorbent. The physical forces acting here, as a rule, are not directed and have the advantage that the bondings are reversible. The sorptive may thus be released from the sorbent again, which encourages the microbial breakdown of the oil.

The sunk oil may also neither be separated from the composition according to the invention by way of violent turbulence and thus may no longer drift to the surface of the water.

Since the crude oil is adsorbed onto the particles of the composition, the effective surface which is available for attack by the microorganisms breaking down the oil is increased enormously. By way of this the breakdown of the oil is rendered possible and is accelerated enormously until a complete decomposition of the oil. The microscopically small droplets serve as a substrate for the profuse development of the microorganisms taking part in the breakdown. The oil is broken down without any residue within 3–4 months, depending on the geological region and the prevailing environmental conditions. The biodegradation or the remediation therefore preferably takes place in situ. The difficult and cost-intensive suctioning of the oil-binding agent mixtures from the surface of the water and the subsequent disposal, dumping, and reprocessing of this highly problematic waste, which as mentioned above often leads to the fact that no measures at all are taken for cleaning oil contaminations, are rendered superfluous by way of the inventive in situ decomposition of the toxic hydrocarbon compound.

Microorganisms which are suitable for the decomposition of crude oil or other hydrocarbon contamination are added to the composition and form an important constituent of the product in one advantageous embodiment. The microorganisms are formulated such that its storage capability and flowing ability are ensured. The formulation is preferably effected in the form of pellets or capsules. In particular, national or local regulations are to be observed and adhered to with the application of nonindigenous microorganisms. Since these may be admixed without any problem into the suitable flowable formulation, even on location, the microorganism constituent may be adapted to the regulations which apply to the respective location of application without significant effort. A new solution for the previously mentioned problem and the task, which is derived from it, is specified by the present invention as is characterized in the patent claims.

Working of the Technology: So much agent according to the invention in the composition mentioned above was scattered onto the oil, floating essentially on the surface of the saltwater (a part of the oil however was also distributed in the water in the form of small droplets) that the complete oil layer floating on the water surface was covered with a roughly uniformly thin layer of the agent according to the invention.

Already a few seconds after scattering an agent according to the invention with 40% silica sand (grain size 0.2–0.3 mm), 40% granite meal, 15% meal of siliceous limestone, and 5% CaCO3, the agent bonded to the oil, disappeared from the surface of the water, and as a result slowly fell to the bottom of the test vessel as a fine sediment. The water became rapidly clearer, and oil could no longer be ascertained in the water optically as well as by smell, already after about 1 day. The oil was completely bonded in the sediment.

Strategy 3

Substrate Bioavailability Enhancing Solution: The third strategy for bioremediation has been developed by Kaiser and Collins (1995) and is protected by a US patent (US5561059A). The technology is about a chemical mixture which enhances the substrate bioavailability.

The invention describes a liquid substrate bioavailability enhancing solution that cofunctions as an emulsifier and cleaner for oil-contaminated surfaces and subsurfaces and as an enhancing nutritional liquid carrier for specially selected naturally occurring microbes to be added and indigenous organisms. The added specially selected microbes multiply in the host liquid. After application to oil-contaminated surfaces or subsurfaces as the liquid emulsifies the contaminants, the microbes efficiently begin the digestion of the microscopic particles produced thereby.

The method developed by Conard and Collins is comprised of two separate parts: the microbe enhancing emulsifier and cleaner and the selected naturally occurring microbes. The liquid part of the invention is an aqueous mixture of nonionic and anionic surfactants and other chemicals.

The method claimed by Conard and Collins has the following exclusive features:

-

Provides environmental workers with a substrate bioavailability enhancing emulsifier and cleaner for control of hydrocarbon contamination

-

Provides an efficient substrate bioavailability enhancing oil emulsifier and cleaner-carrier for the practical delivery of selected bioremediating microbes

-

Provides substrate bioavailability enhancing emulsifier-cleaner that, when applied to oil-contaminated surface or substrate, is not detrimental to the indigenous microbial population

-

Provides a liquid carrier that acts as a life-enhancing medium for the selected naturally occurring microbes that are added prior to application to an oil-contaminated surface or substrate biocatalyst

-

Provides a liquid carrier that acts as a life-enhancing medium for the indigenous microbes that are present prior to application to an oil-contaminated surface or substrate

-

Provides a carrier liquid whose components can also act as a food source for the naturally occurring microbes prior to application to an oil-contaminated surface of substrate

-

Provides a carrier that stimulates the dormant naturally occurring microbes when added and provides for their rapid multiplication through the presence of an atomically bonded stable nonoxidizing oxygen biocatalyst added prior to application to the contaminates

-

Provides a substrate bioavailability enhancing chemical mixture that may be diluted with water, thus providing an economical method for delivery to, and application upon, contaminated areas

-

Provides a carrier for microbes that is not harmful to the intact normal human skin so that it can be safely handled by the applicators

-

Provides a method of practical bioremediation by using emulsifiers that efficiently portion food for the microbes

-

Provides a method of hydrocarbon cleanup that does not require transportation and relocation of the contaminants which contributes to further pollution of the environment

-

Provides a carrier whose active components do not react with each other

These and other attributes of the invention are realized by combining into an aqueous base, emulsifiers, surfactants, and other ingredients such as the emulsifier nonylphenol ethoxylate, a surfactant such as linear alkyl aryl sodium sulfonate, a sequestering agent such as ethylenedinitrilotetraacetic acid – tetrasodium salt – an emulsifying solvent such as dipropylene glycol monomethyl ether, a pH control agent such as sodium silicate, and an atomically bonded oxygen source as part of the water component which serves as a nonoxidizing oxygen biocatalyst.

Working of the Technology: Selected live naturally occurring microbes are added to the liquid emulsifier at the job site prior to use. The microbes may be anaerobic microbes, aerobic microbes, or facultative microbes which are added under anaerobic or aerobic conditions. The microbes may be dormant live naturally occurring microbes packaged in powder form.

The liquid substrate bioavailability enhancing emulsifier of the present invention, when the dormant dry powder microbes are added, acts as a host liquid for the microbes and with the action of the biocatalyst causes the microbes to be activated and nourished to activate their reproduction cycle.

The combination of ingredients stimulates a very rapid arousal of the microbes from their dormant state, activating their rapid division so that when the liquid mixture is applied, the microbes are vigorous and reproducing exponentially.

The substrate bioavailability enhancing chemical mixture is applied to oil-contaminated surfaces, and upon contact with the hydrocarbons, the mixture of ingredients rapidly emulsifies the oil contaminates into tiny droplets. Just as milk fat (oil) is in a near colloid state in milk and thus does not easily rise to the surface as cream, the emulsifiers decrease the size of the contaminating oil and hold it in suspension because of the tiny droplet sizes. This exposes tremendous surface area to the activated oil-consuming microbes which can then efficiently begin bioremediation. Microbes can most efficiently biodegrade their food substrate if it is available in sizes smaller than themselves.

The encapsulation of the microscopic particles of oil in the resultant colloid state gives the microbes the important oil/water interface that is necessary, along with supplemental oxygen, for their efficient oil-digesting activities.

Strategy 4

Nutrient Material for Promoting Growth of Petroleum-Degrading Bacteria: The fourth strategy was devised by Felix and Hruza (1998) who are working for a US-based company named BioNutraTech, Inc. This company manufactures and distributes micro-encapsulated bio-nutrients that stimulate microbial activity for advanced commercial, industrial, and environmental bioremediation. Their proprietary products provide essential nutrients that stimulate and sustain the accelerated growth of highly desirable types of naturally occurring microbes that are already present in targeted wastes. The technology developed by BioNutraTech was first disclosed publically through a patent application WO-1999046210A1.

The method disclosed by Felix and Hruza uses a particulate material for promoting growth of petroleum-degrading bacteria. Each particle of the nutrient material comprises a core of water-soluble, microbial available nutrients selected from the group consisting of nitrogen in the form of ammonium or urea compounds, phosphorous in the form of microbial available phosphate compounds, iron in the form of microbial available iron compounds, and oxygen in the form of various hydrogen peroxide compounds. The coating formulation of this invention uses a mixture of saturated and unsaturated fatty acids to form a coating material which is readily biodegradable, has physical properties making it efficient for encapsulating microbial nutrients, increases the oil phase partitioning of the composite, and reduces the cost of manufacture. More particularly, the encapsulation for the core of nutrients is formed of an oleophilic and biodegradable coating comprising oleic acid and a carboxylic acid selected from the group consisting of stearic acid, palmitic acid, and mixtures thereof. The preferred ratio of oleic acid to the selected carboxylic acid is between about 70:30 and about 30:70 by weight.

The invention also provides a process of manufacturing the coated nutrient material (Fig. 16.3), which comprises mixing microbial nutrients together as dry ingredients and grinding them into a powder sufficient to pass through a number 40 sieves. A coating mixture is prepared from commercial grade stearic acid and oleic acid at a preferred ratio of 40:60 by weight.

The coating mixture is melted by heating to 100°C and resolidified to form a homogeneous composite and remelted at 100°C. Upon cooling to 65°C, the coating is blended into the nutrients at a ratio of 90% nutrients to 10% coating by weight.

Working of the Technology: Biodegradation potential was assessed by treatment of artificially weathered crude oil treated with an oleophilic nutrient mixture without an oxygen-releasing compound. An identical untreated control was maintained for comparison. The oil was then treated with 0.30 g of a nutrient mixture composed of 0.256 g (NH4)2SO4, 0.011 g of KH2PO4, and 0.003 g of FeSO4⋅7H2O, coated with a mixture of 0.018 g oleic acid and 0.012 g of stearic acid. The reaction vessel was continuously aerated with bubblers at a rate of 250 mm of air per minute. After 48 h, a follow-up application was made using only one-half the amount of nutrient mixture as in the original application. Percent difference in reduction of oil between the treated and untreated oil was measured after each time period.

Strategy 5

Enriched Steady-State Microbial Consortiums for Microbial Enhanced Oil Recovery and In Situ Biore-mediation: The fifth strategy for bioremediation comes from a team of scientists working for a US-based company DuPont. The technology disclosed by Hendrickson et al. (2010) of DuPont through a patent application number WO2010096537A1 uses enriched steady-state microbial consortiums for microbial enhanced oil recovery, and in situ bioremediation of hydrocarbon-contaminated sites, under anaerobic denitrifying conditions, is disclosed. The consortium is identified by obtaining environmental samples comprising indigenous microbial populations exposed to crude oil and enriching the said populations per enrichment protocol. The enrichment protocol employs a chemostat bioreactor to provide a steady-state population. The steady-state population may be characterized by using phylogenetic DNA sequence analysis techniques, which include 16S rDNA profiling and/or DGGE fingerprint profiling as described herein. The steady-state population is further characterized as an enriched consortium comprising microbial constituents having relevant functionalities for improving oil recovery or in situ bioremediation of hydrocarbon-contaminated environmental sites. The steady-state enriched consortium may grow in situ, under reservoir conditions, using one or more electron acceptors and the reservoir’s crude oil as the carbon source for microbial enhancement of oil recovery or in situ bioremediation of hydrocarbon-contaminated environmental sites. The steady-state consortium may be used with other microorganisms to enhance oil recovery in reservoirs or wells or in situ bioremediation of hydrocarbon-contaminated environmental sites with analogous reservoir conditions of the selected/targeted wells.

The method described for in situ bioremediation of hydrocarbon-contaminated environmental sites comprises an isolated consortium of microbial species, comprising one Thauera strain and two other strains selected from the group consisting of Azoarcus sp. Pseudomonas sp. Azotobacter sp. Bacteroides sp. Clostridium sp. Anaerovorax sp. Finegoldia sp. Spirochetes sp. Deferribacter sp. Flexistipes sp. Chloroflexi sp. and Ochrobactrum sp. (Fig. 16.4).

Working of the Technology: Enrichment of a microbial consortium on targeted oil as the carbon source under denitrifying anaerobic condition is carried out. Parent enrichment cultures and a screening protocol were developed to identify microbes capable of growth under anoxic conditions on either crude oil or its components or samples from a hydrocarbon-contaminated site as the sole source of carbon. These soil suspensions were used as an inoculum into 60-mL serum vials that contained 2:1 v/v of the minimal salts medium (20 mL) and the autoclaved crude oil (10 mL).

The parent POG1 consortium cultures were examined for their ability to release oil from sand in a visual oil release assay using the microsand column described above. Inocula from early parallel enrichment cultures of the second-generation parent POG1 consortium and one third-generation culture (EH40:1) with high nitrate concentration (−1,600 ppm) were tested in this assay. All enrichment cultures were grown anaerobically in the SL10 minimal salts medium using ACO oil as the carbon source and nitrate as the electron acceptor until turbidity was observed. A 4.0 mL aliquot of each inoculum was added to the 13-mm glass tubes either directly or diluted 1:2 with the minimal salts medium. The microsand columns were placed in each glass tube, immersed in the medium/cell inoculum with the tapered neck of the Pasteur pipettes pointing up. The outer vials were sealed in the anaerobic Coy chamber and allowed to incubate at ambient temperatures for the next several weeks. Each column was periodically checked for oil release. Cultures that enhanced release of oil over background (sterile medium) were presumed to have altered the interaction of the oil with the sand surface. Oil released from the sand was visualized by the released oil collecting in the tapered neck of the Pasteur pipettes or forming droplets on the surface of the sand layer. Oil release was observed for some of the POG1 parent enrichment cultures as rapidly as only 3 h after inoculation.

Strategy 6

Microemulsion as a Biodegradation Accelerator: The sixth technology is assigned to Elf Aquitaine and is protected as US patent US6190646B1. Elf Aquitaine was a French oil company which merged with Total Fina to form Total Fina Elf. The new company changed its name to Total in 2003. The technology is about a nutrient microemulsion in spray form, useful as a biodegradation accelerator. This technology was invented by Tellier et al. (1999).

The invention describes a microemulsion which is useful as a biodegradation accelerator which is nontoxic, which is stable at temperatures from −10 to +50°C, and which has fluidity at +5°C which is sufficient for use in the applications desired.

This microemulsion, which is useful as a biodegradation accelerator, contains at least one nitrogenous compound such as amino acids, proteins, urea, and its derivatives from 10 to 35% by weight of a phosphorus surfactant compound of the alkyl or alkenyl phosphoric ester type, the ester being a monoalkyl- and/or dialkyl- or monoalkenyl- and/or dialkenylphosphoric ester from 3 to 20% by weight of at least one cosurfactant, a compound selected from the group consisting of vegetable oils, animal oils and fatty acids, and a plasticizer, said emulsion having a viscosity at 5°C less than or equal to 200 mPa sec and stable at a temperature of −10 to +50°C.

In the present invention, it is the combined effect of the surfactants derived from the above specific phosphoric esters, with a cosurfactant or a mixture of cosurfactants, which assures the stability of the microemulsion down to a very low temperature, at least −10°C, and allows the product to be used without difficulty in any cold environment.

Working of the Technology: There is an accelerator effect on the biodegradability of microemulsions of the invention, with regard to hydrocarbons with a radiorespirometry pilot. The measurement is conducted with the aid of a laboratory apparatus called a radiorespirometer. It enables continuous observation of the digestion of radioactive hydrocarbons while evaluating the abiotic losses on each culture which avoids incubating with sterile cultures.

Hundred milliliters of a reaction medium is formulated from synthetic seawater, bacterial flora, and phenanthrene labelled with 14C, biodegradable with difficulty, at 100 mg/L, in culture flasks or 250-mL Erlenmeyer flasks equipped with two lateral Torion (joints), with one being connected to the inlet for oxygen, and the other being connected to a trap for hydrocarbons formed by ORBO-43 columns sold by Supelco. The flow of oxygen for aeration is adjusted to 5 mL/min, and the medium is agitated with a back-and-forth agitator at 80 oscillations per minute. These reactors, thus agitated, are placed in the dark to incubate at 20°C for 1 month. Evaporated hydrocarbons are absorbed on the hydrocarbon traps. The flow of air entrains CO2 labelled with 14C derived from digestion of the phenanthrene into a CO2 trap formed by a solution of 4N sodium hydroxide.

During this incubation for 1 month, in order to measure the kinetics of digestion, samples are taken every 2 or 3 days, depending on the results obtained. Three aliquot samples of 0.5 mL of the solution of 4 N sodium hydroxide are placed for measurement in 10 mL of Hionic-Fluor cocktail from Packard.

The bacterial flora used to test the effectiveness of the microemulsions, or rather of the surfactant/cosurfactant pair, is a complex natural flora of marine origin. Before starting the tests, this flora is reactivated by being kept at 80°C on rich medium Marine Agar 2216 from Difco for 8 h. Then it is precultured on synthetic seawater of the Instant Ocean type at 33 g/L and enriched with 50 mg/L of light crude Arab oil for 2 days in the presence of nitrogenous and phosphorous nutrients, ammonium chloride, and potassium hydrogen phosphate, in concentrations such that the ratios C/N/P are equal to 106/16/1.

The labelled phenanthrene used is 9–14C, Sigma product 31,528-1. The tests are carried out in nine reactors placed in series, all containing the same reaction medium formed from synthetic seawater, labelled phenanthrene at 100 g/L, activated bacterial flora at 10% v/v, and a neutral pH buffer, TRIS at 6 g/L, these concentrations being reported as the reaction medium. Various microemulsions of the invention and of the prior art are introduced into 8 of these reactors. The concentrations of the microemulsions in the reaction media at the beginning of the trials are 10 mg/L.

A better digestion of the phenanthrene is noted in the presence of microemulsions × 16 and × 20. For certain other formulations of the invention, a certain latent period is observed before digestion is produced.

Strategy 7

Nutrient Concentrate for Accelerated Growth of Hydrocarbon-Consuming Microorganisms: The seventh representative technology invented by Holtwiesche, Bettina; Weiss, Albrecht; and Boehme, Adelheid, is assigned to Henkel and is protected by a US patent number US5635392A. Founded in 1876, Henkel holds globally leading market positions both in the consumer and industrial businesses. Headquartered in Düsseldorf, Germany, it has about 48,000 employees worldwide. The present invention provides a nutrient mixture which has an emulsifying effect and would contain P- and N-yielding substances, but would be made up of very few pure C-compounds.

This nutrient mixture leaves very few residues behind in the soil sample to be treated. The described nutrient mixture would prefer the pollutant-degrading microorganisms to other microorganisms.

This invention relates to a nutrient concentrate for stimulation and as a growth aid for the accelerated growth of hydrocarbon-consuming microorganisms for their use in the biological degradation of organic components, containing water-soluble and/or oil-soluble compounds of Phosphorus (P) and Nitrogen (N) present in admixture with other water-soluble and/or oil-soluble organic mixture components which are at least partly endowed with nutrient character for the growth of the microorganisms, characterized in that it is in the form of a liquid water-based preparation and contains one or more esters of phosphoric acid as emulsifier and P-source and, if desired, one or more water-soluble or water-dispersible N-sources.

The present invention also relates to the use of the nutrient mixtures in combination with concentrates of microorganisms which are capable of degrading hydrocarbon compounds and which are preferably of natural origin. Important applications include the remediation of soils, freshwater, and/or saltwater through the elimination of pollution based on hydrocarbon compounds and also the treatment of working equipment, pipes, and large vessels, including tankers and the like, using the nutrient mixtures according to the invention.

In one particular embodiment, the invention relates to the use of the nutrient mixtures, more particularly in combination with microorganism concentrates capable of degrading hydrocarbon compounds, for the elimination of oil-wetted cuttings from geological land-supported or offshore drilling, for example, from the development of geological occurrences.

In the context of the invention, particular significance is attributed to the phosphoric acid esters used. These compounds act on the one hand as a P-source and on the other hand as emulsifiers. Although the way in which they act is not fully understood, it may be assumed that the compounds collect at the interface between the hydrophobic pollutant and the water present in the soil sample and, on the one hand, develop an emulsifying effect and, on the other hand, keep the phosphorus source available in the immediate vicinity of the pollutant so that it is useful in particular to those microorganisms which are capable of degrading the pollutants. Preferred phosphoric acid esters are those which can be taken up by microorganisms. Accordingly, amongst the compounds which meet this requirement, particular significance is attributed to the phospholipids. Phospholipids are amphiphilic substances which are obtained from vegetable or animal cells. Preferred phospholipids are the glycerophospholipids which, normally, are also known as lecithin. The sphingophospholipids are less preferred. Known compounds which may be used in accordance with the invention are the diacyl phospholipids, phosphatidylcholines, phosphatidylethanolamines, phosphatidylinositols, phosphatidylserines, phosphatidylglycerols, phosphatidylglycerol phosphates, diphosphatidylglycerol, N-acyl-phosphatidylethanolamine, and phosphatidic acid. Preferred compounds are the monoacyl phospholipids, lysophosphatidylcholines, lysophosphatidyl ethanolamines, lysophosphatidyl inositols, lysophosphatidyl serines, lysophosphatidyl glycerols, lysophosphatidyl glycerophosphates, lysodiphosphatidyl glycerols, lyso-N-acylphosphatidylethanolamines, and lysophosphatidic acid. By virtue of their accessibility, the expert will mainly use commercially available phosphatidyl glycerides which are marketed as vegetable or animal lecithins and cephalins. These preparations are generally obtained from oils, such as wheat germ oil or cottonseed oil or soybean oil. According to this strategy, preference is attributed to the enzymatically hydrolyzed glycerophospholipids (enzymatically hydrolyzed lecithin), which are more hydrophilic in character through the elimination of a fatty acid residue. The only exceptions are those products which have lost their phosphoric acid component as a result of the enzymatic hydrolysis.

In addition to or instead of the phospholipids mentioned above, partial esters of phosphoric acid with fatty alcohols, more particularly corresponding partial esters with linear fatty alcohols, may also be used as the P-source of the nutrient concentrates according to the invention. Esters of relatively short-chain fatty alcohols, for example, C6–10 fatty alcohols, are particularly suitable. However, alkyl phosphates with relatively long-chain fatty alcohols, that is, C12–24 fatty alcohols, may also be used. Fatty alcohol ether phosphates are also suitable. These are phosphoric acid partial esters of ethoxylated fatty alcohols, the fatty alcohols containing 8–24 carbon atoms and being ethoxylated with 1–10 mol and preferably 4–6 mol of ethylene oxide per mole of fatty alcohol.

The phosphoric acid esters mentioned are used in the nutrient concentrates according to the invention in quantities of 10–40% by weight and preferably in quantities of 20–30% by weight.

In addition, the nutrient concentrates according to the invention contain an N-source in the form of inorganically and/or organically bound nitrogen. N-sources which only contain organically bound nitrogen are preferred because the use of inorganically bound nitrogen can result in salinization of the soil.

Working of the Technology: A nutrient concentrate was prepared from glycerophospholipid (enzymatically hydrolyzed lecithin, trade name: Lipotin® NE, a product of Lucas Meyer) 20% by weight, urea 20% by weight, alkyl polyglycoside (C chain length: C.sub.8 to C.sub.16, D.P.: approx. 1.4) 2% by weight, and water ad 100% by weight. Substrate: 2kg of sand polluted with 7,000 ppm of crude oil. Incubation temperature: 16°C; observation period: 42 days; treatment interval: 0.4 g nutrient concentrate/kg sand every 10 days; pollutant analysis method: DIN 38409H18. The pollutant analysis method according to DIN 38409H18 comprises determining the specific spectral absorption of hydrocarbon mixtures by infrared spectroscopy in an organic solvent extract. The number of ‘degradation specialists’, that is, the microorganisms capable of degrading the contamination, was determined by initially determining the total number of growing microorganisms or microorganisms capable of growth and then determining the number of degradation specialists from the result obtained by transferring the cultures to a nutrient plate containing hexadecane as sole C-source. It was undoubtedly proved that the nutrient concentrate activates the degradation potential of marine flora.

Top Assignees and Countries in the Domain of Bioremediation

Figure 16.5 shows that US-based company DuPont is the most aggressive company working towards developing microorganism-based technologies for bioremediation of oil-contaminated sites followed by Biosaint; Univ Nat Cheng Kung; Samsung Everland Inc.; Technology Licensing Organization, Japan; Biorem AG; Petrozyme Technologies, Canada; Ocean University of China; and BioNutraTech.

The USA is on the top of all the countries in patenting activity (Fig. 16.6). US-based companies E.I. du Pont de Nemours and Company, Wilmington; BioNutraTech Inc., USA, and Savannah River Nuclear Solutions LLC are actively working in this direction. In China the universities are very actively working in development of bioremediation technologies, prominent amongst these are Ocean University of China, Dalian University of Technology, and Peking University, Beijing, and in companies, PetroChina Co. Ltd. is very active. Korea is an East Asian country that is very active after China; main companies in Korea are Biosaint Co. Ltd., Samsung Everland Inc., and Korea Research Institute of Bioscience & Biotechnology. In Japan, Taisei Corp., Tosoh Corp., and Fukushima University are the top inventing companies.

References

Atlas RM, Hazen TC (2011) Oil biodegradation and bioremediation: a tale of the two worst spills in U.S. history. Environ Sci Technol 45:6709–6715

Chamkha M, Mnif S, Trabelsi Y, Sayadi S (2011) Isolation and characterization of Klebsiella oxytoca strain degrading crude oil from a Tunisian off-shore oil field. J Basic Microbiol 51(6):580–589

Chandran P, Das N (2011) Degradation of diesel oil by immobilized Candida tropicalis and biofilm formed on gravels. Biodegradation 22:1181–1189

Churchill PR, Dudley RJ, Churchill SA (1995) Surfactant enhanced bioremediation. Waste Manag 15:371–377

Felix E, Hruza SL (1998) Method and composition for enhanced bioremediation: WO1999046210A1, Bionutratech Inc., US

Galindo H, Revah S, Cervantes FJ, Arriaga S (2011) Effect of surfactant and oil additions in the biodegradation of hexane and toluene vapours in batch tests. Environ Technol 32:167–173

Hendrickson ER, Luckring AK, Keeler SJ, Perry MP, Choban ER (2010) A steady state anaerobic denitrifying consortium for application in In-Situ bioremediation of hydrocarbon-contaminated sites and enhanced oil recovery, Publication number: WO2010096537A1, E. I. Du Pont De Nemours And Company, Wilmington

Kaiser CE, Collins JR (1995) Substrate bioavailability enhancing chemical mixture for use in bioremediation, Publication number: US5561059A

Kirschner L (1999) Product and method for pre-emptive potential in remediation of oil spills, Publication number: EP1088109B1

Korotkevych O, Josefiova J, Praveckova M, Cajthaml T, Stavelova M, Brennerova MV (2011) Functional adaptation of microbial communities from jet fuel-contaminated soil under bioremediation treatment: simulation of pollutant rebound. FEMS Microbiol Ecol 78:137–149

Kroh W (2008) Composition and bioremediation method for water polluted by hydrocarbons, Publication number: US20090120872A1, Swisstech Holding Ag, Zug, Ch

Lin TC, Pan PT, Young CC, Chang JS, Chang TC, Cheng SS (2011) Evaluation of the optimal strategy for ex situ bioremediation of diesel oil-contaminated soil. Environ Sci Pollut Res Int 18:1487–1496

Liu X, Wang Z, Zhang X, Wang J, Xu G, Cao Z, Zhong C, Su P (2011) Degradation of diesel-originated pollutants in wetlands by Scirpus triqueter and microorganisms. Ecotoxicol Environ Saf 74:1967–1972

Lloyd-Jones G, Laurie AD, Hunter DWF, Fraser R (1999) Analysis of catabolic genes for naphthalene and phenanthrene degradation in contaminated New Zealand soils. FEMS Microbiol Ecol 29:69–79

MacNaughton SJ, Stephen JR, Venosa AD, Davis GA, Chang Y-J, White DC (1999) Microbial population changes during bioremediation of an experimental oil spill. Appl Environ Microbiol 65:3566–3574

Mesarch MB, Nakatsu CH, Nies L (2000) Development of catechol 2,3-dioxygenase-specific primers for monitoring bioremediation by competitive quantitative PCR. Appl Environ Microbiol 66:678–683

Mohite BV, Pawar SP, Morankar A (2011) Isolation, selection and biodegradation profile of phenol degrading bacteria from oil contaminated soil. Bull Environ Contam Toxicol 87:143–146

Tellier J, Basseres A, Brochette P, Espert A (1999) Nutrient microemulsion in spray form, useful as a biodegradation accelerator, Publication number: US6190646B1, ELF Aquitaine, Courbevoie, FR

Tiehm A (1994) Degradation of polycyclic aromatic hydrocarbons in the presence of synthetic surfactants. Appl Environ Microbiol 60:258–263

Zhang W, Li J, Huang G, Song W, Huang Y (2011) An experimental study on the bio-surfactant-assisted remediation of crude oil and salt contaminated soils. J Environ Sci Heal A Toxic Hazard Substrate Environ Eng 46:306–313

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer India

About this chapter

Cite this chapter

Kapoor, R.K., Gupta, R., Singh, A. (2013). Patenting Trends in Bioremediation Technologies for Oil-Contaminated Sites. In: Kuhad, R., Singh, A. (eds) Biotechnology for Environmental Management and Resource Recovery. Springer, India. https://doi.org/10.1007/978-81-322-0876-1_16

Download citation

DOI: https://doi.org/10.1007/978-81-322-0876-1_16

Published:

Publisher Name: Springer, India

Print ISBN: 978-81-322-0875-4

Online ISBN: 978-81-322-0876-1

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)