Abstract

This chapter presents a brief overview of the concept of reliability applied to asphalt pavement design. It discusses how reliability can be estimated for a given pavement structure and how a pavement structure can be designed for a given reliability level. Reliability-based design principles for design of new asphalt pavement, as well as rehabilitation of existing pavement, have been presented.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Asphalt pavement design process involves design input as material properties, weather conditions, traffic characteristics, design period, etc. Each input is linked with a set of design parameters. For example, material property includes elastic modulus and Poisson’s ratio values of asphalt, granular, cemented, subgrade layers, etc. All these parameters show significant variability [6, 11, 18, 29, 31, 32]. It would be reasonable approach to account for such variability in the pavement design process. This is done by invoking the concepts of reliability in pavement design.

Reliability issues in pavement design have been studied as early as 1970s [5, 6, 15]. Some of the initial considerations included variation of a single parameter (e.g. the subgrade strength); [28] subsequently, variability of different parameters and different modes of failures are added to the analysis.

2 Concept of Reliability

Reliability is the probability of not having a failure. Failure does not happen if the number of repetitions of expected traffic (T) does not exceed the number of repetitions that the pavement can sustain (N). Since it is assumed that there are variabilities associated with the pavement design parameters, T and N can be represented in the form of probability distributions.

Figure 1 shows a schematic diagram with hypothetical distributions of T and N for any given pavement section. These distributions are shown to be nonintersecting in the present case. In case 1, the pavement would definitely fail, because the expected traffic is always greater than the allowable traffic, indicating the reliability value as 0%. Following similar logic, it can be said that the reliability of pavement for case 2 is 100%.

Reliability values of 0 and 100% (in other scale, the reliability values of 0 and 1), are two extreme cases, and generally, the reliability value of any given pavement lies somewhere in between. Such a case is represented in Fig. 2. Thus, reliability of a pavement (R) can be defined as:

Probability (number of repetitions a pavement can sustain is greater than number of traffic repetitions expected to occur on the pavement), that is

If a parameter ‘safety margin’ (S) is defined as \( S = T - N \), reliability can be defined as \( R = P(S < 0) \). If the probability density function (pdf) of S is given as f S (s), then R can be calculated as follows:

Reliability is sometimes expressed using ‘damage factor’, D, defined as \( D = \frac{T}{N} \). In that case, reliability can be defined as \( R = P(D < 1) \). If the pdf of D is known as f D (d), then R can be calculated as follows:

If the distributions of T and N are known, the reliability value (R) can obtained using either Eqs. (2) or (3) [4, 14, 17, 23]. Knowing the distributions of T and N sometimes becomes a complex task.

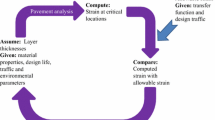

T is dependent on traffic volume, axle load, traffic growth rate, design period, etc. The design period is generally prespecified and therefore has a fixed value. N is dependent on material properties (e.g. elastic moduli and Poisson’s ratio values of the individual layers), layer thicknesses, loading configuration, performance equations, etc. The performance equation relates the critical stress/strain values to the life (in terms of traffic repetitions) of the pavement for a given mode of failure. These equations are generally developed empirically through calibration of pavement performance data. Figure 3 schematically shows various parameters that influence the distributions of T and N and, in turn, the reliability of pavement.

To estimate the pavement reliability, the distributions of these basic parameters (i.e. traffic volume, axle load, traffic growth rate, material properties, thicknesses, loading configuration, performance equation coefficients) are to be known first. Substantial literature is available which contains information on the variabilities of these parameters [4, 6, 11–13, 21, 29, 31–33]. Various analytical and numerical methods (e.g. point estimate method, first- or second-order reliability method, simulation method [3, 9, 35]) have been used [6, 14, 17] to obtain the parameter related to possible distribution of T and N, when the distribution of these basic parameters are assumed to be known.

2.1 Reliability for a Single or Multiple Mode of Failure

The structural failure of asphalt pavement may occur in various modes, for example, load fatigue, thermal fatigue, rutting, thermal shrinkage and top-down cracking. The calculation of overall reliability of the pavement would depend on how the failure is defined. One may define the failure of a pavement when (1) the pavement fails due to all the failure modes or (2) the pavement fails due to any one of the failure modes [18]. These can be conceptually thought as failure modes linked in parallel (refer Fig. 4a) or failure modes linked in series (refer Fig. 4b), respectively.

If the failure probability for the ith mode is represented as F i , then the overall reliability (R o) can be calculated as follows:

If the pavement is thought to be failed when it fails due to all the failure modes (refer Fig. 4a), then

If the pavement is thought to be failed when it fails due to either of the failure modes (refer Fig. 4b), then

One may even further consider the failure modes as mixed combinations of parallel and series connections, and accordingly, different expressions for the overall reliability (R o) can be obtained. It is difficult to know the mutual dependency between the individual failure modes; the calculation of R o, therefore, becomes quite simple when the failure modes are assumed to be mutually independent.

3 Estimation of Reliability

It is a difficult task to derive a closed-form analytical solution for estimating the critical stress/strain parameters (refer Fig. 3) of a multilayered asphalt pavement structure. Thus, Monte Carlo simulation method has been quite popularly [4, 13, 32, 33] used to estimate the reliability of a given pavement section. Simulation studies show that T generally follows a normal distribution, whereas the fatigue or rutting life of a given pavement generally follows a log-normal distribution [5, 18, 33]. Sensitivity studies have been conducted by various researches [3, 6, 13, 18, 30, 32] to study the effect of various parameters on reliability, and it is generally observed that the thicknesses and stiffness moduli of pavement layers significantly affect the fatigue and rutting reliabilities [3, 18, 32].

4 Design of Pavement for a Given Reliability

The effect of thickness on reliability for low-temperature shrinkage cracking and reliability of thermal cracking is generally not very significant [24, 26]. The design reliability levels of these failure modes can be achieved by adjusting at the asphalt mix design stage. Thus, the asphalt pavement thickness design becomes primarily governed by the fatigue and rutting considerations. Reliability-based design of new asphalt pavement and rehabilitation of existing asphalt pavement are discussed in the following.

4.1 Design of New Pavement

Design of a pavement for a given reliability level is an iterative process. For a given traffic data, the distribution of T is fixed, and the distribution of N value changes once the trial thickness values are changed. The iteration is continued until the reliability levels (of the fatigue and rutting failure modes, since these are strongly affected by thickness) satisfy the respective design reliability levels. Similar concept is used in the AASHTO [1] guidelines, where difference between the expected traffic and allowable traffic is adjusted to achieve a reliability level. However, the recent NCHRP guidelines [20] suggest use of reliability in terms of a system of pavements (i.e. the probability that a pavement section survives out of a number of pavement sections under similar conditions) for design purpose. In this approach, empirical equations are developed from performance data (of a number of pavement sections) to predict individual pavement distresses.

Figure 5 presents a schematic pavement design chart. The asphalt pavement is assumed to be made up of three basic layers, asphalt layer, unbound granular layer and the soil subgrade. Thus, the thicknesses of the asphalt layer (h 1) and the granular layer (h 2) are the two variables to be designed. From Fig. 5, it can be seen that for a given value, h 2, the reliability level increases as h 1 increases. Similarly, for a given value of h 1, the reliability value is higher if larger h 2 is used. Different sets of curves can be obtained for various failure modes (say, fatigue and rutting). Thus, from this design chart, for given reliability levels of fatigue and rutting failure modes, one can choose suitable values of h 1 and h 2.

As seen from Fig. 5, for a given pavement design problem, a number of alternative design solutions are possible – all of them may satisfy the reliability requirements, but their costs may differ [25]. The final design solution would be the one whose cost, C (total construction cost including the cost of materials), is the least. Thus, a reliability-based pavement design problem can be formulated as an optimization scheme as follows:

Minimize C

Subject to:

where j is the number of design layers, i is the number of modes for failure, R i (h j ) is the reliability of ith failure mode which is a dependent on the thickness of all the design layers (h j ) and R i d is the design reliability (i.e. target reliability) level for the ith failure mode.

4.2 Design for Rehabilitation

A newly constructed pavement undergoes deterioration with the passage of time. This deterioration is due to traffic and environmental factors. An appropriate structural design prevents a pavement to undergo premature failure, but the pavement would finally fail after the expiry of its design life. The pavement performance is however stochastic in nature [10, 16, 27, 34], and the purpose of using reliability approach is to take into account this stochasticity in the design process.

A pavement, before it undergoes complete failure, needs to be rehabilitated. Determining the optimal rehabilitation timing and the extent of rehabilitation to be applied is an optimization problem. A number of formulations for estimation of optimal rehabilitation timing are available in literature [2, 19, 22]. The scope of these formulations include minimization of total cost of construction and rehabilitation as well as the cost incurred by the road users, over the entire life cycle of the pavement.

The reliability of a pavement structure discussed above indicates the reliability value at the end of the design period, when all the expected traffic repetitions have taken place. The reliability value of a newly constructed pavement is therefore higher than the value for which it is designed, and it gradually decreases as the cumulative traffic repetitions increase [7]. Once the reliability value reaches a prespecified threshold value, a rehabilitation (say, an overlay) may be needed, which would further shift the allowable traffic (i.e. improve the pavement capacity). This is shown schematically in Fig. 6. A suitable optimization formulation would be able to estimate the optimal rehabilitation timing so that reliability value does not fall below the threshold level and at the same time the total cost is minimized [8]. This forms the basis of reliability-based rehabilitation design scheme.

5 Summary

Significant level of variabilities present in the pavement design parameters necessitates use of reliability-based approach in pavement design. This chapter has discussed the reliability principles in use for the design of asphalt pavements.

References

AASHTO (1993) Guide for design of pavement structure. American Association of State Highway and Transportation Officials (AASHTO), Washington, DC

Abaza KA, Abu-Eisheh SA (2003) An optimum design approach for flexible pavements. Int J Pavement Eng 4(1):1–11

Chou YT (1990) Reliability design procedures for flexible pavements. J Trans Eng 116(5):602–614

Chua KH, Kiureghian AD, Monismith CL (1992) Stochastic model for pavement design. J Trans Eng 118(6):769–786

Darter MI, McCullough BF, Brown JL (1972) Reliability concepts applied to the Texas flexible pavement system. Highw Res Rec HRB 407:146–161

Darter MI, Hudson WR, Brown JL (1973) Statistical variation of flexible pavement properties and their consideration in design. Proc Assoc Asphalt Paving Technol 42:589–615

Despande VP, Damnjanvic ID, Gardoni P (2010) Modeling pavement fragility. J Trans Eng 136(6):592–596

Despande VP, Damnjanvic ID, Gardoni P (2010b) Reliability-based optimization models for scheduling pavement rehabilitation. Comput-Aided Civ Infrastruct Eng 25:227–237

Harr ME (1987) Reliability based design in civil engineering. McGraw-Hill Book Company, New York

Hong HP, Wang SS (2003) Stochastic modeling of pavement performance. Int J Pavement Eng 4(4):235–243

Jiang YJ, Selezneva O, Mladenovic G, Aref S, Darter MI (2003) Estimation of pavement layer thickness variability for reliability-based design. Trans Res Rec 1849:156–165, TRB, National Research Council, Washington, DC

Kim HB, Lee SH (2002) Reliability-based design model applied to mechanistic empirical pavement design. KSCE J Civ Eng 6(3):263–272

Kim HB, Buch N (2003) Reliability-based pavement design model accounting for inherent variability of design parameters. TRB 82nd annual meeting, CD-ROM, Washington, DC

Kulkarni RB (1994) Rational approach in applying reliability theory to pavement structural design. Trans Res Rec 1449:13–17, TRB, National Research Council, Washington, DC

Lamer AC, Moavenzadeh F (1971) Reliability of highway pavements. Highw Res Rec HRB 362:1–8

Li N, Haas R, Xie W (1996) Reliability-based processing of Markov chains for modeling pavement network deterioration. Trans Res Board 1524:203–213

Lytton RL, Zollinger D (1993) Modelling reliability in pavement. TRB 72nd annual meeting, Washington, DC

Maji A, Das A (2008) Reliability considerations of bituminous pavement design by mechanistic-empirical approach. Int J Pavement Eng 9(1):19–31

Mamlouk MS, Zaniewski JP, He W (2000) Analysis and design optimization of flexible pavement. J Trans Eng 126(2):161–167

Mechanistic-Empirical Design of New & Rehabilitated Pavement Structures, Appendix B: Design reliability (2003) Final document, NCHRP project 1-37A, National Research Council, Washington, DC, 2003. http://www.trb.org/mepdg/guide.htm. Accessed Aug 2010

Noureldin SA, Sharaf E, Arafah A, Al-Sugair F (1994) Estimation of standard deviation of predicted performance of flexible pavements using AASHTO model. Trans Res Rec 1449:46–56, Transportation Research Record, TRB, National Research Council, Washington, DC

Ouyang Y, Madanat S (2004) Optimal scheduling of rehabilitation activities for multiple pavement facilities: exact and approximate solutions. Trans Res A Policy Pract 38:347–365

Rajbongshi P, Das A (2008) Estimation of structural reliability of asphalt pavement for mixed axle loading conditions. In: Proceedings of the 6th International Conference of Roads and Airfield Pavement Technology (ICPT), Sapporo, Japan, pp 35–42

Rajbongshi P, Das A (2008) Thermal fatigue considerations in asphalt pavement design. Int J Pavement Res Technol 1(4):129–134

Rajbongshi P, Das A (2008) Optimal asphalt pavement design considering cost and reliability. J Trans Eng 134(6):255–261

Rajbongshi P, Das A (2009) Estimation of temperature stress and low-temperature crack spacing in asphalt pavements. J Trans Eng 135(10):745–752

Sanchez-Silva M, Arroyo O, Junca M, Caro S, Caicedo B (2005) Reliability based design optimization of asphalt pavements. Int J Pavement Eng 6(4):281–294

Shell International Petroleum Company Limited (1978) Shell pavement design manual – asphalt pavements and overlays for road traffic, Shell International Petroleum Company Limited, London

Stubstad RN, Tayabji SD, Lukanen EO (2002) LTPP data analysis: variation in pavement design inputs. Final report, NCHRP web document 48, TRB, National Research Council, Washington, DC. http://gulliver.trb.org/publications/nchrp/nchrp_w48.pdf. Accessed Aug 2010

Tarefder RA, Saha N, Stormont JC (2010) Evaluation of subgrade strength and pavement designs for reliability. J Trans Eng 136(4):379–391

Timm DH, Briggison B, Newcomb DE (1998) Variability of mechanistic-empirical flexible pavement design parameters. In: Proceedings of the 5th international conference on the bearing capacity of roads and airfields, vol 1, pp 629–638

Timm DH, Newcomb DE, Briggison B, Galambos TV (1999) Incorporation of reliability into the Minnesota mechanistic-empirical pavement design method. Final report, submitted to Minnesota Department of Transportation, Department of Civil Engineering, Minnesota University, Minneapolis

Timm DH, Newcomb DE, Galambos TV (2000) Incorporation of reliability into mechanistic-empirical pavement design. Trans Res Rec 1730:73–80, TRB, National Research Council, Washington, DC

Wang KCP, Zaniewski J, Way G (1994) Probabilistic behavior of pavements. J Trans Eng 120(3):358–375

Zhang Z, Damnjanović I (2006) Applying method of moments to model reliability of pavements infrastructure. J Trans Eng 132(5):416–424

Acknowledgement

The author wishes to thank Mr. Sudhir N. Varma, former master’s student, Department of Civil Engineering, IIT Kanpur, for helping in drawing some of the schematic diagrams presented in this chapter.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer India

About this paper

Cite this paper

Das, A. (2013). Reliability Considerations in Asphalt Pavement Design. In: Chakraborty, S., Bhattacharya, G. (eds) Proceedings of the International Symposium on Engineering under Uncertainty: Safety Assessment and Management (ISEUSAM - 2012). Springer, India. https://doi.org/10.1007/978-81-322-0757-3_19

Download citation

DOI: https://doi.org/10.1007/978-81-322-0757-3_19

Published:

Publisher Name: Springer, India

Print ISBN: 978-81-322-0756-6

Online ISBN: 978-81-322-0757-3

eBook Packages: EngineeringEngineering (R0)