Abstract

It is well-known that the disposal of municipal solid waste (MSW) has become one of the challenges in landfill engineering. It is very important to consider mechanical processes that occur in settlement response of MSW with time. In the recent years, most of the researchers carried out different tests to understand the complex behavior of municipal solid waste and based on the observations and proposed different models for the analysis of stress-strain, time-dependent settlement response of MSW. However, in most of the cases, the variability of MSW is not considered. For the analysis of MSW settlement, it is very important to account for the variability of different parameters representing primary compression, mechanical creep, and effect of biodegradation. In this chapter, an approach is used to represent the complex behavior of municipal solid waste using response surface method constructed based on a newly developed constitutive model for MSW. The variability associated with parameters relating to primary compression, mechanical creep, and biodegradation are used to analyze MSW settlement using reliability analysis framework.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Landfilling is still the most common treatment and disposal technique for Municipal Solid Waste (MSW) worldwide. In every country, millions of tons of wastes are produced annually and it became one of the mammoth tasks to overcome it. Recently, MSW landfilling has significantly improved and has achieved a stage of highly engineered sanitary landfills in the most developed and developing countries. Evaluation of settlement is one of the critical components in landfill design. The contribution of engineered landfilling requires extensive knowledge of the different processes which occur simultaneously in MSW during settlement. The settlement in MSW is mainly attributed to (1) physical and mechanical processes that include the reorientation of particles, movement of the fine materials into larger voids, and collapse of void spaces; (2) chemical processes that include corrosion, combustion, and oxidation; (3) dissolution processes that consist of dissolving soluble substances by percolating liquids and then forming leachate; and (4) biological decomposition of organics with time depending on humidity and the amount of organics present in the waste.

Due to heterogeneity in the material of MSW, the analysis becomes more complicated because degradation process on MSW is time-dependent phenomena and continuously undergoes degradation with time. In the degradation process, two major mechanisms of biodegradation may occur: aerobic (in the presence of oxygen) and anaerobic (in the absence of oxygen) processes. The production of landfill biogas is a consequence of organic MSW biodegradation. This process is caused by the action of bacteria and other microorganisms that degrade the organic fraction of MSW in wet conditions. To capture this phenomenon in the prediction of settlement and stress-strain response of MSW, several researchers have proposed different models based on the different assumptions [1–3, 7, 8, 10, 12].

Marques et al. [10] presented a model to obtain the compression of MSW in terms of primary compression in response to applied load, secondary mechanical creep, and time-dependent biological decomposition. The model performance was assessed using data from the Bandeirantes landfill, which is a well-documented landfill located in Sao Paulo, Brazil, in which an instrumented test fill was constructed. Machado et al. [8] presented a constitutive model for MSW based on elastoplasticity considering that the MSW contains two component groups: the paste and the fibers. The effect of biodegradation is included in the model using a first-order decay model to simulate gas generation process through a mass-balance approach while the degradation of fibers is related to the decrease of fiber properties with time. The predictions of stress-strain response from the model and observations from the experiments were compared, and guidelines for the use of the model are suggested. Babu et al. [1, 3] proposed constitutive model based on the critical state soil mechanics concept. The model gives the prediction of stress-strain and pore water pressure response and the predicted results were compared with the experimental results. In addition, the model was used to calculate the time-settlement response of simple landfill case. The predicted settlements are compared with the results obtained from the model of Marques et al. [9, 10].

1.1 Settlement Predictive Model

Babu et al. [1] proposed a constitutive model which can be used to determine settlement of MSW landfills based on constitutive modeling approach. In this model, the elastic and plastic behavior as well as mechanical creep and biological decomposition is used to calculate the total volumetric strain of the MSW under loading as follows:

where \( {\text{d}}\varepsilon_{{_v}}^e \), \( {\text{d}}\varepsilon_{{_v}}^p \), \( {\text{d}}\varepsilon_{{_v}}^c \), and \( {\text{d}}\varepsilon_{{_v}}^b \) are the increments of volumetric strain due elastic, plastic, time-dependent mechanical creep, and biodegradation effects, respectively. The increment in elastic volumetric strain \( {\text{d}}\varepsilon_v^e \) can be written as:

And increment in plastic volumetric strain can be written as

The above formulations for increments in volumetric strain due to elastic and plastic are well established in critical state soil mechanics literature.

The mechanical creep is a time-dependent phenomenon proposed by Gibson and Lo’s [6] model, in exponential function, is given by

where b is the coefficient of mechanical creep, \( \Delta p^{\prime} \) is the change in mean effective stress, c is the rate constant for mechanical creep, and \( t^{\prime} \) is the time since application of the stress increment. The biological degradation is a function of time and is related to the total amount of strain that can occur due to biological decomposition and the rate of degradation. The time-dependent biodegradation proposed by Park and Lee [12] is given by

where \( {{E}_{{dg}}} \) is the total amount of strain that can occur due to biological decomposition, d is the rate constant for biological decomposition, and \( t^{\prime\prime} \) is the time since placement of the waste in the landfill.

From Eq. (4), increment in volumetric strain due to creep is written as

From Eq. (5), increment in volumetric strain due to biodegradation effect is written as

In the present case, \( t^{\prime} \) time since application of the stress increment and \( t^{\prime\prime} \) time since placement of the waste in the landfill are considered equal to “t.”

Using Eqs. (2), (3), (6), and (7) and substituting in Eq. (1), total increment in strain is given by

Calculation procedure of settlement response of MSW using above equations is given in Babu et al. [2].

1.2 Variability of MSW Parameters

Settlement models of Marques et al. [10] and Babu et al. [1, 3] have parameters such as compressibility index, coefficient of mechanical creep (b), creep constant (c), biodegradation constant (\( {{E}_{{dg}}} \)) and rate of biodegradation (d). All these parameters are highly variable in nature due to heterogeneity of MSW. For any engineering design of landfill, these parameters are design parameters, and their variability plays vital role in design. Literature review indicates that the influence of all these parameters and their variations have significant effects on prediction of MSW settlement. Based on experimental and field observations, various researchers reported different range of values and percentage of coefficient of variations (COV). For example, Sowers [13] reported that the compression index (\( {{c}_c} \)) is related to the initial void ratio (\( {{e}_0} \)) and can vary between 0.15 \( {{e}_0} \) and 0.55 \( {{e}_0} \) and the value of secondary compression index (\( {{c}_a} \)) varied between 0.03 \( {{e}_0} \) and 0.09 \( {{e}_0} \). The upper limit corresponds to MSW containing large quantities of food waste and high decomposable materials. Results of Gabr and Valero [5] indicated \( {{c}_c} \) values varying from 0.4 to 0.9, and \( {{c}_a} \) values varying from 0.03 to 0.009 for the initial void ratios (\( {{e}_0} \)) in the range of approximately 1.0–3.0. Machado et al. [7] obtained the values of primary compression index which varied between 0.52 and 0.92. Marques et al. [10] reported \( {{c}_c} \) values varying from 0.073 to 1.32 with a coefficient of variation (COV) of 12.6%. The coefficient of mechanical creep (b) was reported in the range of 0.000292–0.000726 and COV of 17.7% and creep constant varying from 0.000969 to 0.00257 with COV of 26.9%. The time-dependent strain due to biodegradation is expressed by equation which uses \( {{E}_{{dg}}} \), the parameter related to total amount of strain that can occur due to biodegradation, and d is the rate constant for biological decomposition. Biodegradation constant depends upon the organic content present in MSW. Marques et al. [10] gave typical range of \( {{E}_{{dg}}} \) varying from 0.131 to 0.214 and COV of 12.7% and biodegradation rate constant d varying from 0.000677 to 0.00257 and COV of 42.3%. Foye and Zhao [4] used random field model to analyze differential settlement of existing landfills. They used \( {{c}_c} \) values 0.22 and 0.29 with COV of 36% and \( {{E}_{{dg}}} \) time-dependent strain due to biodegradation equal to 0.03724 and rate constant due to biodegradation (d) equal to 0.00007516. These variables are not certain; their values depend upon the variation conditions like site conditions, initial moisture content, and quantity of biodegradable material present in the existing MSW. Therefore, it is very important to perform settlement analysis of MSW with consideration of variability and their influence on reliability index or probability of failure. In order to simplify the settlement calculations, the above settlement evaluation procedure is used with reference to a typical landfill condition using response surface method (RSM).

1.3 Response Surface Method

RSM is a collection of statistical and mathematical techniques useful for developing, improving, and optimizing process. In the practical application of response surface methodology (RSM), it is necessary to develop an approximating model for the true response surface. A first-order (multilinear) response surface model is given by

Here, \( {{y}_i} \) is the observed settlement of MSW; the term “linear” is used because Eq. (9) is a linear function of the unknown parameters \( {{\beta }_1},{{\beta }_2},{{\beta }_3},{{\beta }_4} \), and \( {{\beta }_5} \) that are called the regression coefficients, and \( {{x}_1},{{x}_2},{{x}_3}, \cdots \cdots \cdots \cdots \cdots {{x}_n} \) are coded variables which are usually defined to be dimensionless with mean zero and same standard deviation. In the multiple linear regression model, natural variables \( \left( {b,c,d,{{E}_{{dg}}},\lambda } \right) \) are converted into coded variable by relationship

In the present study, RSM analysis is performed using single replicate 2n factorial design to fit first-order linear regression model, where n is the total number of input variables involved in the analysis and corresponding to these variables the number of sample point required is 2n. For example, in the present case five variables are considered; here, n is equal to 5 and number of sample points required is 32. These 32 sample points are generated using “+”and “−” notation to represent the high and low levels of each factor, the 32 runs in the 25 design in the tabular format shown in Table 1.

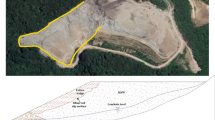

For the analysis, the maximum and minimum values are assigned based on the one-sigma, two-sigma, and three-sigma rule, i.e., \( \sigma \pm \mu \), \( \sigma \pm 2\mu \), and \( \sigma \pm 3\mu \), where \( \mu \) is the mean value and \( \sigma \) is the standard deviation of variables given in Table 2. In order to account the variability of different parameters in the settlement analysis of MSW, five major parameters are used under the loading conditions (from bottom to top) as shown in Fig. 1; the following variable parameters are used for the study. They are coefficient of time-dependent mechanical creep (b), time-dependent mechanical creep rate constant (c), rate of biodegradation (d), biodegradation constant (\( {{E}_{{dg}}} \)), and the slope of normally consolidate line (\( \lambda \)). In the literature, it was reported that they are highly variable in nature, and it is very important to account these variation during the prediction of MSW settlement.

One-sigma (standard deviation) rule considers about 68%, and two sigma (standard deviations) consider almost 95% of sample variation assuming normal distribution, whereas three sigma (standard deviations) account for 99.7% of the sample variations, assuming the normal distribution. Using one-, two-, and three-sigma rules, the sample points are generated, and corresponding settlements are calculated using proposed model by Babu et al. [1].

The method of least squares is typically used to estimate the regression coefficients in a multiple linear regression model for the simple case of landfill as shown in Fig. 1. Myers and Montgomery [11] gave the multilinear regression in the form of matrix.

where,

Using above method, regression coefficients are calculated, and least square fit with the regression coefficients in terms of natural variables corresponding to the different COVs is presented in Table 3. Settlements are obtained from first-order regression model and from Babu et al. [1]. It is always necessary to examine the fitted model to ensure that it provides an adequate approximation to the true system and verify that none of the least square regression assumptions are violated. To ensure the adequacy of the regression equations, coefficient of regression (\( {{R}^2} \) and \( R_{{adj}}^2 \)) is calculated. Table 4 presents regression coefficients for the different standard deviations and at different COV.

1.4 Reliability Index Formulation

The reliability index \( \beta \) for the independent variables in n-dimensional space is given as:

In the present study, using deterministic analysis, with mean values given in Table 2, an ultimate settlement of 9.3 m for 30 years is obtained using the proposed model as well as the response surface equations. To ascertain the probability of ultimate settlement reaching this value, the limit state function is defined as

2 Methodology

In order to evaluate the reliability index or probability of failure considering variability of different parameters in the calculation of MSW settlement, the settlement given by the model is converted into Eq. (9) to using the procedure described earlier. In this chapter, settlement is evaluated for the one, two, and three standard deviations. Using the mean and standard deviation given in Table 2 and with “+” and “−” or maximum or minimum, values are calculated for all the variables. Table 1 shows the generation of sample points for the one standard deviation considering the normal distribution. These values are used to evaluate performance function based on the multilinear regression analysis as discussed previously for one, two, and three standard deviations at all the percentages of COV. Table 3 present the performance functions for the one, two, and three standard deviation at different percentages (10, 14, 18, and 20%) of COV. The performance functions are in the form of multilinear equations that include all the contributing variables used for the prediction of MSW settlement in the form of natural variables \( \left( {b,c,d,{{E}_{{dg}}},\lambda } \right) \). Equations (12) and (13) are used to calculate mean and standard deviation of the approximated limit state function. Knowing approximated mean (\( {{\mu }_g} \)) and standard deviation (\( {{\sigma }_g} \)), reliability index is calculated using relation given in Eq. (14). Table 5 presents the summary of variation of reliability index values for the one, two, and three standard deviations at different COV. It is observed from Table 5 that the reliability index is inversely proportional to the COV of design variables decreases with increase in percentageof COVs of the design variables and also with increase in standard deviations.

3 Results and Discussion

Using RSM, multilinear equations are developed and these equations are considered as performance functions for the calculation of reliability index using Eqs. (12), (13), and (14) for MSW settlement. It is noted that the reliability index of MSW settlement is inversely related to the coefficient of variation of design variable parameters. The results clearly depict that with increase in percentages of COV, reliability index decreases and probability of failure increases. For example, in case of 10% COV reliability index is calculated 9.71, whereas for the 20% COV this reliability index reduced to 2.42, which is reduction in 75% for one standard deviation. Similar results are observed for other cases. This indicates that probability of failure or reliability index is highly dependent upon COV of variable parameters. It is well-known that the MSW composition is highly heterogenous in nature which leads to higher percentages of COV, and hence, the chance of failure is very high. On the other hand, reliability index of MSW is highly dependent on sampling variations. It is observed that reliability index for 10% COV is 9.71 for one standard deviation, 2.42 for two standard deviations and 0.8078 for the three standard deviations. From one standard deviation to two standard deviation 75% reduction and for three standard deviations approximately 91% reduction in reliability index was observed. These results clearly point out the significance of sampling in the landfilling design for longer time periods.

4 Conclusions

The objective of this chapter is to demonstrate the influence of variability in the estimation of MSW settlement. Settlement is calculated based on the response surface method for the five design variables. Sample points are generated using “+” and “−” method for the one, two, and three standard deviations. Using these sample points, multilinear equations are developed for the estimation of MSW settlement. Based on these equations, reliability index is calculated for all percentages of COV. The results indicate that reliability index is highly dependent upon variability of the design variables and sample variations.

References

Babu Sivakumar GL, Reddy KR, Chouksey SK (2010) Constitutive model for municipal solid waste incorporating mechanical creep and biodegradation-induced compression. Waste Manage J 30(1):11–22

Babu Sivakumar GL, Reddy KR, Chouksey SK (2011) Parametric study of parametric study of MSW landfill settlement model. Waste Manage J 31(1):1222–1231

Babu Sivakumar GL, Reddy KR, Chouksey SK, Kulkarni H (2010) Prediction of long-term municipal solid waste landfill settlement using constitutive model. Pract Period Hazard Toxic Radioact Waste Manage ASCE 14(2):139–150

Foye KC, Zhao X (2011) Design criteria for the differential settlement of landfill foundations modeled using random fields. GeoRisk ASCE, Atlanta, GA, 26–28 June

Gabr MA, Valero SN (1995) Geotechnical properties of solid waste. ASTM Geotech Test J 18(2):241–251

Gibson RE, Lo KY (1961) A theory of soils exhibiting secondary compression. Acta Polytech Scand C-10:1–15

Machado SL, Carvalho MF, Vilar OM (2002) Constitutive model for municipal solid waste. J Geotech Geoenviron Eng ASCE 128(11):942–951

Machado SL, Vilar OM, Carvalho MF (2008) Constitutive model for long – term municipal solid waste mechanical behavior. Comput Geotech 35:775–790

Marques ACM (2001) Compaction and compressibility of municipal solid waste. Ph.D. thesis, Sao Paulo University, Sao Carlos, Brazil

Marques ACM, Filz GM, Vilar OM (2003) Composite compressibility model for municipal solid waste. J Geotech Geoenviron Eng 129(4):372–378

Myers RH, Montgomery DC (2002) Response surface methodology, process and product optimization using designed experiments, 2nd edn. Wiley, New York

Park HI, Lee SR (1997) Long-term settlement behavior of landfills with refuse decomposition. J Resour Manage Technol 24(4):159–165

Sowers F (1973) Settlement of waste disposal fills. In: Proceedings of 3rd international conference on soil mechanics and foundation engineering, vol 2, Moscow, pp 207–210

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer India

About this paper

Cite this paper

Chouksey, S.K., Babu, G.L.S. (2013). Reliability Analysis of Municipal Solid Waste Settlement. In: Chakraborty, S., Bhattacharya, G. (eds) Proceedings of the International Symposium on Engineering under Uncertainty: Safety Assessment and Management (ISEUSAM - 2012). Springer, India. https://doi.org/10.1007/978-81-322-0757-3_12

Download citation

DOI: https://doi.org/10.1007/978-81-322-0757-3_12

Published:

Publisher Name: Springer, India

Print ISBN: 978-81-322-0756-6

Online ISBN: 978-81-322-0757-3

eBook Packages: EngineeringEngineering (R0)