Abstract

Nuclear waste produced in light water-cooled reactors contains long half-life, high-level radioactive waste. Although this waste can be safely stored in underground repositories, the public remains anxious because they consider repository sites too close to their living space. Therefore, separation and transmutation of this radioactive waste is important. In this chapter, transuranic isotope separation and transmutation technologies using fast reactors are discussed, and a roadmap to achieve the realization of this process is proposed. This chapter introduces ways to maintain the use of nuclear power without producing additional waste because continued nuclear power is important to reduce carbon dioxide emissions.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Nuclear waste

- TRU separation and transmutation

- Fast reactor

- The Japanese Strategic Energy Plan

- Second reprocessing plant

1 Introduction

Uranium-238, a major component of uranium fuel for light water-cooled reactors (LWRs), is converted to heavier nuclides such as Pu (plutonium), Np (neptunium), Am (americium), and Cm (curium) by absorbing thermal neutrons in the reactor. The half-life of these nuclides is thousands to tens of thousands of years and they can be toxic to humans. This is called long half-life, high-level radioactive waste. These nuclides continue to be a serious concern with the use of nuclear energy.

As of 2014, the amount of spent LWR fuel reached 17,000 tons in Japan. The amount of long half-life, high-level radioactive waste of this spent fuel is 170 tons. If existing LWRs are used for the next 60 years, this waste will reach 496 tons [1].

If reliance on LWR is reduced, the emission of carbon dioxide will increase. Because there is no other reliable solution for generating power without emitting carbon dioxide, it is difficult to avoid using nuclear power. The problem of high-level radioactive waste must be resolved for newly built nuclear reactors.

In this chapter, several methods for separating the long half-life, high-level radioactive waste from spent LWR fuel are discussed, as well as the potential of transmutation using fast reactors , in which the nuclides are converted to other nuclides with a shorter half-life. Also discussed is a strategy introducing fast reactors, which are expected to resolve these problems.

2 Present Status

2.1 Current Strategy: Waste Disposal and Transmutation

Currently, several countries are looking into the possibility of using underground repositories for disposing of high-level radioactive waste. Although no countries are actually operating such repositories, there are a few that have selected sites. There are five other countries (including Japan) that have begun studying the geologic conditions of potential sites. In underground repositories, high-level radioactive waste is stored as vitrified waste and covered in steel. It has been shown theoretically that this can confine the waste for at least 70,000 years. After that, the waste may begin to leak, but based on analyses, the radioactive hazard to local residents through drinking water is less than individual exposure from natural radioactivity [2]. Despite this, the public remains anxious. Although the waste is stored underground, the public considers repository sites too close to their living space. Therefore, a few countries, including Japan and France, have stressed in their policy statements that separation and transmutation technology studies will be conducted.

In Japan, the Japanese Strategic Energy Plan [3] of 2014 states, “Specifically, development of technologies for decreasing the radiation dose remaining in radioactive waste over a long period of time and enhancing the safety of processing and disposal of radioactive waste, including nuclear transmutation technology using fast reactors and accelerators, will be promoted by utilizing global networks for cooperation.” Nuclear transmutation technology using fast reactors must be further developed.

2.2 Current Strategy: Ratio of Electricity Generated by Nuclear Plants

The Japanese Strategic Energy Plan states that reduced dependency on nuclear power in electricity generation is planned, “Dependency on nuclear power generation will be lowered to the extent possible by energy saving and introducing renewable energy as well as improving the efficiency of thermal power generation, etc.”

If carbon emission levels are maintained within the pledged range, it will be difficult to reduce dependence on nuclear power. However, producing more nuclear waste is not accepted by the public. Therefore, introducing fast reactors, which can solve the high-level radioactive waste problem, is important. In fast reactors, Pu, Np, Am, and Cm are converted to other nuclides with shorter half-life fission products at high probability through nuclear fission reaction.

Fuel for fast reactors is fabricated from the major nuclides of high-level radioactive waste from LWRs. Thus, introducing fast reactors is a win-win situation because it reduces this waste. Establishing a well-balanced ratio of electricity generated by nuclear plants is possible.

2.3 Current Status of Technology: Separation and Its Efficiency

Radioactive waste treatment covers a variety of technologies. Among them, the following two are important:

-

Technology to separate the long half-life, high-level radioactive waste from LWR spent fuel with 99.9 % efficiency

-

Technology to shorten the half-life by transmutation in fast reactors

With waste separation technology, it is important to prioritize the nuclides. The long half-life nuclides fall into two categories, fission products and the transuranic (TRU) isotope. TRU is composed of Pu, Np, Am, and Cm , which is produced with uranium-238 from the LWR fuel. Water-soluble fission products may leak from disposal sites after the degradation of vitrified waste, causing exposure to humans. However, the dose caused by radioactivity of leaked fission products is well below the exposure dose from natural radioactivity [2].

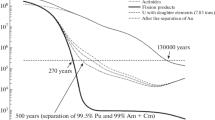

Several countries have focused on the transmutation of TRU because of its serious hazard to humans, although TRU stored in vitrified waste does not leak. TRU is a major concern, and its separation efficiency from spent LWR fuels is a high priority. A separation efficiency of 99.9 % and transmutation of separated TRU lead to a storage period of 300 years , much shorter than tens of thousands years [4]. The public may be willing to accept this period.

There are two methods to separate TRU from spent LWR fuels. One is pyro-reprocessing using an electrochemical process and the other is aqueous reprocessing , which is based on the principle of extraction of materials with a solvent. The high separation efficiency of 99.9 % has been achieved for Pu with the conventional aqueous method, and reprocessing plants using this method are already in commercial operation in several countries. R&D is still needed for the separation of Np, Am, and Cm, because of different chemical behaviors of Pu in an aqueous process. New solvents should be developed. According to recent French studies, 99.9 % separation efficiency has been achieved for Am and Cm using a newly developed solvent [5]. The pyroprocess can theoretically recover almost 100 % of TRU using electrodes in electric field vessels. Because TRU not recovered in the first treatment remains in the electric field vessel, a larger decontamination factor or collection rate can be ensured by repeating this treatment. This process has achieved a recovery rate of 99.5 % or higher through the treatment of 4,400 kg of spent fuel from fast experimental reactor EBR II in the United States [6].

In Japan, R&D is still in the experimental phase. Because it is not easy to conduct demonstration tests on the separation of TRU using actual spent LWR fuels in the country, it is preferable to participate in overseas studies and share information.

2.4 Current Status of Technology: Transmutation in Fast Reactors

There are three options for transmuting TRU using fast reactors. The first two concern only the use of fast reactors and the third the use of an accelerator and fast reactor. With the first two options, there is a choice of fast reactor cores, one with a breeding ratio of one or one with a ratio of zero. The third option uses an accelerator to accelerate heavy particles into a target. High-energy neutrons generated by spallation in the target maintain the high power level, while the reactor core is subcritical. This is called an accelerator-driven reactor system (ADS) .

Because ADS raises electricity generation costs as much as 25 % compared with present costs [6], it is not a high priority in this chapter. The fast reactor core with zero breeding ratio is not a high priority either, because it causes new safety issues [7]. Further, neither ADS nor such fast reactors can meet future electricity demands. They are suitable to transmute TRU but do not generate sufficient electricity.

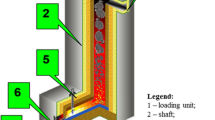

Upon examining the development of the fast reactors with breeding ratio of one or larger, we see that this technology is ready for commercial application. One such fast reactor is the sodium-cooled type, which has a particularly long history. Argonne National Laboratories in the United States built the first such reactor for experimentation, EBR I, which began generating electricity in 1946. EBR II has been successfully operated for a long time. Other experimental or prototype fast reactors have been safely operated in the world. In France, Super Phoenix with 1200 MWe electrical output reached critical condition in 1985. It was closed in 1997 because of political debates regarding the use of plutonium. Recently, China has expressed the desire to import Russian fast reactors in the near future. In 2014, the Russian fast reactor 800-MWe BN800 reached critical condition in June 2014. The 500-MWe Indian PFBR is scheduled to reach critical condition in 2015. Both Russian and Indian fast reactors are intended to produce electricity only, and transmutation of TRU is not within their scope. However, France aims to start operating ASTRID , a 600-MWe fast reactor in 2025. The main purpose is to reduce the amount of TRU generated from LWRs.

Although there are still some safety issues to be resolved with sodium-cooled fast reactors, solutions may have been found. These issues are fragility of thin-walled structures against earthquakes, difficulty of visual inspection inside sodium, rapid accident progression because of positive coolant reactivity feedback upon mismatch between power and flow rate or gas entrainment into the core, pressure buildup caused by sodium water reactions in steam generators, and potential explosions caused by re-criticality during severe accidents. Several countries have conducted studies to overcome these difficulties, and solutions to improve safety are being developed [4].

Reduced construction costs are required before commercialization is possible. Simplified structures and components are being adapted to recent fast reactors, reducing cost.

In Japan, prototype reactor Monju has been inoperative for a long time because of political reasons, and the government has requested to move toward a restart. This will take some time, so international cooperation is a necessary step toward commercialization of fast reactors in Japan.

3 Technology Roadmap

3.1 Technological Goals and Solutions

As of 2014, the amount of spent LWR fuel was 17,000 tons, with 170 tons TRU. Based on discussions to develop the Japanese Strategic Energy Plan, existing LWRs were assumed to operate until 2069 if the life extension of LWRs is approved by the regulatory authority. The amount of spent LWR fuel would reach 49,600 tons, with 496 tons TRU.

3.1.1 Separation of Np, Am, and Cm from Highly Radioactive Liquid Waste

The Japanese reprocessing plant Rokkasho can reprocess spent LWR fuels with an annual capacity of 800 tons. The plant is planned to be in operation for 40 years, beginning in 2014 or 2015. Because this plant is only designed to separate Pu, other TRU such as Np, Am, and Cm are left in highly radioactive liquid waste. To separate Np, Am, and Cm, an additional chemical process is needed downstream of the main process at the plant. In this process, Np, Am, and Cu can be separated from the highly radioactive liquid waste with 99.9 % efficiency. Development of this technology is a high priority.

3.1.2 Separation of TRU in a Second Reprocessing Plant

The Rokkasho plant will be closed in 2054 after operating for 40 years. Because LWRs can operate until 2069, 49,600 tons of LWR spent fuel will accumulate, so 20,000 tons of that fuel will remain un-reprocessed by Rokkasho. Because all TRU in the spent fuels is required to be separated and transmuted, a second new reprocessing plant is necessary to reprocess the remaining spent fuel. More comprehensive technology is needed for that plant, including technology for treating mixed oxide fuel, MOX fuel, which is richer in Pu than conventional LWR fuel. In addition, to reduce reprocessing costs, a single process is necessary to separate all TRU with 99.9 % efficiency. Establishing this technology for the second reprocessing plant is also a priority.

3.1.3 Transmutation of TRU Using Commercially Developed Fast Reactors

Introducing safe and economical fast reactors is essential to transmute TRU separated from both the Rokkasho and second reprocessing plants. Safer fast reactors are being designed to comply with current safety guidelines in several countries. These guidelines focus on the enhancement of inherent safety features of reactor cores, steam generators, and seismic resistance. Several countries have developed post-Fukushima guidelines that require greater robustness and resilience against natural hazards and terrorist attacks. New safety features in recent fast reactors can meet these guidelines. To introduce more economical fast reactors, a reduction in the quantity of necessary material can be achieved using more simplified structures and components. Recent reactor designs in France and India are using these simplified design features. The Japanese reactor Monju will be used for studying efficient transmutation methods. It is important to participate in overseas projects to build demonstration reactors and in basic studies using Monju. Thus, developing safe and cost-effective commercial fast reactors should be a high priority. If commercial fast reactors are successfully introduced beginning in 2030, it will be possible to complete the transmutation of 496 tons TRU by 2069, providing 25 GWe using fast reactors [1]. This is half the power currently generated by existing Japanese LWRs. The TRU is converted to fission products by nuclear fission reaction with shorter lifetime.

Transmuting TRU and power generation using fast reactors is the goal of the Japanese roadmap in this chapter.

3.2 Steps Toward the Goal

The following steps are recommended to reach the goal:

-

Start separating TRU from highly radioactive liquid waste in the Rokkasho plant in 2020.

-

Start introducing commercial fast reactors in 2030.

-

Start building the second reprocessing plant in 2050.

-

Completion of TRU transmutation using fast reactors by 2070.

It is important to establish the technology for separating Np, Am, and Cm from the highly radioactive liquid waste in the Rokkasho plant. Several methods can be applied, and development of this technology is necessary in Japan.

International cooperation is needed to introduce commercial fast reactors in Japan. Demonstration fast reactors have been built in Russia and India, and France is aiming to operate a demonstration reactor in 2020. In Japan, experimental studies on TRU transmutation using Monju are of first priority. In addition, international cooperation with the above countries is necessary for introducing commercial fast reactors by 2030, without building a demonstration reactor in Japan.

Before constructing the second reprocessing plant, it is important to select a reprocessing method. Because two methods (aqueous or pyro) can be used in the plant, a comparison of construction costs between the two methods is critical to the selection. This selection should be made by 2040 to launch the plant by 2050.

3.3 Problems and Risks

Most of the public do not support a restart of existing LWRs because of the unresolved problem of nuclear waste. Repository sites have not been determined and the technology of TRU separation and transmutation has not been fully developed. Therefore, it is unlikely that the public would accept the roadmap described in this chapter.

There is a technological risk in introducing commercial fast reactors without building a demonstration reactor. Despite operational experiences with Monju and shared information of demonstration reactors overseas, a careful approach is needed for design, fabrication, and building of the first commercial reactor.

4 Benefit and Future Vision

According to the roadmap, increased emissions of carbon dioxide caused by reduced dependence on nuclear power generation from LWRs can be controlled. Dependence on existing LWRs is assumed to decrease and become zero by 2070, according to the rule that old plants must cease operation upon reaching their 40-year lifespan. Recently built plants can operate for 60 years. New LWR plants (except already planned ones) cannot be built after 2014.

If fast reactors are not introduced beginning in 2030, 110 million tons of carbon dioxide will be released by 2050, but this can be reduced by 57 million tons with the use of fast reactors. Power generated by LWRs is shown by the blue broken line in Fig. 1, and the power is 23 GWe in 2050. Another 13 GWe will be generated using fast reactors by 2050, assuming a required TRU of 19.5 ton/GWe for one fast reactor core and recycling facility.

By 2070, dependence on LWRs could be zero, and a power generation of 25 GWe could be achieved using fast reactors instead. In addition, long-life, high-level waste produced by LWRs could be completely eliminated. Figure 1 shows these benefits.

After 2070, power supply using fast reactors with higher breeding ratio could meet future electricity demands without producing long half-life, high-level radioactive waste (Fig. 2).

References

The CANON Institute for Global Studies (2015) Survey of world trend of technologies of separation and transmutation for long half-life high-level radioactive waste (in Japanese). CIGS, Tokyo, Japan

ANDRA (2005) Dossier 2005 Argile, Tome- Évaluation de sûreté du stockage géologiqu, ANDRA and JAEA(1999) JNC TN1400-99-020 (in Japanese)

Agency for Natural Resources and Energy (2014) The strategic energy plan. METI, Japan

CEA (2012) Report on sustainable radioactive waste management vol 1–vol 5. CEA, France

Rostaing C et al (2013) Overview of the French R&D program for the development of minor actinides separation processes, Int. Conf. on Fast Reactors and Related Fuel Cycles, Paris

Till CE, Chang YI (2011) Plentiful energy the story of the IFR. ANL, U.S.

Hoffman et al (2006) Preliminary core design studies for advanced burner reactor over a wide range of conversion ratio. ANL AFCI, U.S.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Japan

About this chapter

Cite this chapter

Handa, N. (2016). Nuclear Waste and Power Generation. In: Kato, Y., Koyama, M., Fukushima, Y., Nakagaki, T. (eds) Energy Technology Roadmaps of Japan. Springer, Tokyo. https://doi.org/10.1007/978-4-431-55951-1_16

Download citation

DOI: https://doi.org/10.1007/978-4-431-55951-1_16

Published:

Publisher Name: Springer, Tokyo

Print ISBN: 978-4-431-55949-8

Online ISBN: 978-4-431-55951-1

eBook Packages: EnergyEnergy (R0)