Abstract

This paper researched a hot rolling product’s quality test expert system which was on the basics of radial basis function (RBF) neural network combined with quality-trace. Due to the insufficiency in the explanation facility of the conventional neural network expert system while it also could not afford the process of reasoning, this paper raises a new method which combined four RBF neural networks while it used Multiquadratic Functions as its kernel function. Besides, according to the characteristic of the products in Steel & Iron Industry, this paper takes combined neural network in the part of physical properties test. In order to solve the insufficiency in explanation facility of the conventional neural network expert system this system makes quality-trace after it judged the four results from the four neural networks.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In the torrent of economic development in the society, the development of Steel & Iron Industry experiences reformations on the technology again and again. At the same time, the conventional concept of the quality in Steel & Iron Industry has changed a lot. Quality assurance system (QAS) is now gradually becoming the target of enterprises’ work and the focus from the social attention. At present, the characteristic in the metallurgy industry has changed its direction. Now it requires strict quality specifications of the products. There are strict quality-traces and quality test in the whole productive process. And the enterprise must afford its clienteles with corresponding quality certificates. So, quality control takes the more important position in the Steel & Iron Industry. And the most pivotal technology to realize quality control is quality test. In this part we need to analyze the reason of the waste products accurately and trace back to the link which leads to the defects. Our final target is to control the quality to the best level. In order to make quality test accurate and intelligent, enterprises use expert system when they test the quality of products. However, in the conventional expert system there are bottleneck problem and low automaticity which restrict the function of it. So, the expert system which combines with neural networks brings quality test to a new stage which develops better.

2 RBF Neural Network in the Basis of Multiquadratic

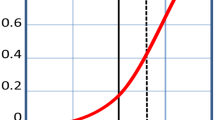

RBF neural network is a kind of effective feedforward network which has three layers and one of them is hidden layer. Its neurons basis function has a local performance which only produces effective nonzero response on the very small local scale. So it attains high speed in the process of study while it can avoid the default of falling into local optimum in the BP neural network [1–3]. RBF neural network can reflect nonlinear separable problems which exist in low-dimensional subspace to a high-dimensional subspace and makes it linearly separable. In the RBF neural network the neurons in the hidden layer makes the high-dimensional hidden unit space. At the same time, the transfer function in the hidden layer is a nonlinear function. This makes the nonlinear transformation from input space to the hidden unit space. In reference [4] the writer invented a superconducting power supply which makes uses of this characteristic of radial basis function neural networks. In the condition of enough neurons in the hidden layer the input data can be linear separable in the output mode of high-dimensional space. The network topology structure of RBF neural network is shown in the following picture.

This system uses a new RBF neural network which uses Multiquadratic as its kernel function and gradient descent as its training method to test the products. It uses gradient descent to optimize RBF neural network. The details of the training steps refer to reference [5]. The conventional methods all get used to make Gaussian function as its kernel function. But, Multiquadratic has its unique advantages such as highly symmetry, simple form, better smoothness, derivable at any degree and its rate of approach becomes faster near the training center. It can approach an input–output reflection with a higher precision. So, we use Multiquadratic as the activation function of hidden layer. Its main work is to calculate the output of hidden layer unit.

In the above formula, \( h_{j} \) is the output of the jth hidden layer unit. \( c_{j} = \left[ {c_{j1} ,c_{j2} , \ldots ,c_{jm} } \right] \) is the center of the jth basis function unit. It is also the centric vector. \( b = \left[ {b_{1} ,b_{2} , \ldots ,b_{n} } \right]^{T} \) is the expand constant or width of the basis function. The smaller the value is, the smaller the width of the basis functions is and the basis function is more selectable. \( b_{j} \) is a standardization constant whose value is bigger than zero. \( W = \left[ {w_{1} ,w{}_{2}, \ldots ,w_{n} } \right]^{T} \) is the weight vector of the network.

There are two adjustable parameters in the whole network when we use Multiquadratic as the basis function. They are the center of the function, and the width and the weight of output unit. To RBF neural network the conventional method to ensure the parameters usually is K-means cluster. In reference [6] the writer used RBF neural network to check the defect of slab. He used K-means cluster to confirm the center and width. However, although the K-means cluster can confirm the expand constant according to the distance during every center there are two shortcomings about it: The first is when it confirm the center of data it only uses the input data of the samples but not together with the output data of the samples or the error. The second one is this method cannot conform the numbers of cluster. Gradient descent takes the direction of negative gradient as the direction of descending. It is a kind of minimization arithmetic. And it overcomes the shortcomings in the K-means cluster. It realizes unrestraint optimization with the fastest rate of convergence [7–10].

In Fig. 1 the structure of RBF neural network the input vector \( X = [x_{1} ,x_{2} , \cdots ,x_{\text{m}} ] \) with its number of the input unit is m. \( H = [h_{1} ,h_{2} , \cdots ,h_{{_{\text{n}} }} ]^{T} \) is the radial basis function vector. In it \( h_{j} \) is the kernel function and we use Multiquadratic as its kernel function, as it is shown in formula (1). The output of RBF neural network is a linear combination of the output of hidden layer unit. It is:

From formulas (1) and (2) we could see the parameters we need to confirm in RBF neural network are weight vector W, centric vector \( c_{j} \), the width B and the number of hidden layer units m.

To the number of hidden layer units there is no specific theory at the moment. We confirm it by experiences at the most cases. To the width B, centric vector \( c_{j} \) and weight vector W we use gradient descent which is on the basis of Delta learning rule to confirm them.

Suppose \( y(k) \) is the practical output at the kth moment and the performance index function of the RBF neural network is:

We use gradient descent to adjust W, B, and \( c_{j} \):

Therefore,

Therefore,

Therefore,

Therefore, \( \alpha \) is the momentum factor, \( \eta \) is the learning rate, and the value of \( \alpha \) and \( \eta \) is between 0 and 1.

3 The Hot Rolling Products Quality Test Expert System Using Radial Basis Function (RBF) Neural Network

The RBF neural network can change the nonlinear information in one space into the linear information in another space with the effect of mapping. And in the hot rolling products quality test system the parameters of hot rolling products quality are highly nonlinearly so we need to use the neural network to generate the results which can be understand and accept by the users.

At present the newest method of quality test is to take use of expert system. In conventional expert system the part of knowledge acquisition is accomplished by labour. Workers summarize the knowledge and experiences and then analyze and trim them. However, by the use of expert system which combines with neural network we do not need labour anymore in disposing those knowledge. What we need to do is only to input the previous examples and parameters into the new system and then train the neural network. After we finish training the neural network the prepared network will dispose these parameters and output the results which are accurately similar with the answers of experts. So it can replace the labour in dealing with some nonlinear problems with a more effective and accurate method [5, 11–13].

The main job of this system is to investigate the relationship between the defects of products and parameters in operations and inspect the quality of the products. And store the parameters of every inspection into the data base of expert system. Then dispose those data in the RBF neural network and sent the results to the transfer layer. After all the steps there will be a final results brought out on the transfer layer (UI).

The hot rolling products quality test expert system mainly detects the chemical properties, physical properties, dimensional accuracy and the quality of surface of the products. It produces the results after the processing of RBF neural network and determines whether the product is an acceptable product or a waste product. The process of quality test is very complex. This system need to input and check dozens of parameters. There are 38 parameters in the part of chemical properties(C) including C, Mn, S, Pi, Si, Ni, Alt, Als, Cu, Ca/Als, etc.; And nine parameters in the part of physical prosperities(P) including yield strength, strength of extension, percentage elongation after fracture, blow-test (under the condition of 20, 0, –20, –40 °C), bending test and etc.; And 9 parameters in the part of dimensional accuracy(D) including the width of edge, the thickness of edge, the arc radius of inside, etc.; And 41 parameters in the part of the surface of the products including silted, edge crack, lapped, indentation, pitting surface, etc.

At present, most methods which the enterprise uses to detect the quality of products is to detect the chemical properties, physical properties, dimensional accuracy, and the quality of surface of the products separately. This leads to low confluent level in every performance index of the products. However, the chemical properties,physical properties,dimensional accuracy, and the quality of surface of the products are related to each other. For example, the reasons which results in the low tensile strength are maybe because there appears inclusion, shrinkage cavity or air bubble in steel. It cannot be welded together very well so as to fissure in the steel. Superficial fissure may cause edge crack or corner crack. Or maybe because of the serious segregation in the chemical composition in steel. When the purity of carbon and other alloying element is too high there maybe difficulty in rolling while it also results in low elongation. It is also easy to result in fissures which make tensile strength low. Besides, the high heating temperature or the long heating time may also results in low tensile strength. So, we can see there is connotative relevance in every parameters of section steel. And chemical properties are almost relevant to physical prosperities directionally. It is the content level of chemical element can influence the parameters of physical properties directly. So we take use of the relativity of chemical–physical prosperities of products to forecast the physical properties of the products after the process of the neural network to the chemical parameters. This method simplifies the link of instrument detection to physical prosperities and saves amount of manpower and material while it saves the testing cost. When testing the physical properties of section steel we take combined neural network. There are four neural network layers in the whole structure. In the first neural network input part of the first layer input the chemical properties parameters and after the processing in the hidden layer the first neural network output part output the predicted physical properties parameters which form the input part of the second neural network part. After the processing of the hidden layer of the second neural network part the final testing results of physical properties will be outputted in the output part of the second neural network part. The following three neural network layers test the chemical properties parameters, dimensional accuracy parameters and the surface of the products. The structure of the combined neural network is showed in the following figure. In Fig. 2, at the input part of the first neural network layer, \( x_{c1} \) to \( x_{c38} \) are chemical properties parameters. At the end of the first neural network part which is also the input part of the second neural network part \( y_{c1} (x_{p1} ) \) to \( y_{c9} (x_{p9} ) \) are physical properties parameters. In the following there neural network layers the \( x_{c1} \) to \( x_{c38} \) are chemical properties parameters, \( x_{D1} \) to \( x_{D9} \) are dimensional accuracy parameters, \( x_{s1} \) to \( x_{s41} \) are about the parameters of the surface of the products. For the test of the surface of the products the mainly method are human check. There are not different degrees of the defect of the surface, so if there exist any defect the input value is 1 or else 0. To the test of chemical properties, dimensional accuracy and the surface of the products we adopt the common neural network.

After the conversion of all the hidden layers there are four results generated: \( y_{c} ,y_{p} ,y_{d} ,y_{s} \). The four results are all digital outputs. Later they would be adjusted in the results testing layer. The final output of the whole neural network part is Y, which is composed by two parts: qualified and disqualified. If the product is disqualified there is a further checking about it. Then the system would give out the reasons of disqualification. Then it transfers the digital outputs to the practical outputs and the final results shown on the UI are two possible results: qualified and disqualified (with its reasons).

In this system the data base software is Oracle11g. There two kinds of data in the data base which are input data and feedback data. The input data serve for the knowledge acquisition part of the expert system while the feedback datas are the result data outputted from the inference engine after the processing of the RBF neural network. The feedback data also includes the weight and other coefficients of the neural network. They are all stored in the data base to form a knowledge base.

The whole system included a secondary database server, a three-stage database server, an industrial personal computer (IPC) which is used to exhibit the data in the proscenium. This system adopted the browser/server (B/S) model. And it is developed by ASP.NET. The programming language is C#. The operating system on the server is Windows Server 2008. The Web server is IIS7 while the operating system we used Windows Server 2008. The database management system we used Oracle11g.

The data from product quality test has the following characteristics: the data size is large (generally speaking the data is from the latterly 5–10 years), the types of the parameter are not sole (in this system there are four types), the result is complex (if the result is not qualified there are many different cases to the rejected product), it does not need to update the data. According to the characteristics of the data from product quality test the whole structure of the expert system is shown in Fig. 3. The knowledge base is supported by the Oracle database. It organized and managed the knowledge base under the database management mechanism. The RBF neural network is used in knowledge acquisition and inference machine part. The data is transferred and disposed according to the direction of arrow. At last the UI and the database share the output result.

The reasoning process of the expert system is a process of parallel computing. There are five steps about it: I. Input the parameters from the input layer of RBF neural network. II. The data are transferred to the input end of the hidden layer by a specific transmission mode. III. After the training of Multiquadratic in the hidden layer the data which are processed are output in the output end of the hidden layer. IV. Linearize the data and output the results \( y_{c} ,y_{p} ,y_{d} ,y_{s} \). V. Transfer the result to the UI and the data base at the same time after the process of judging layer.

4 Analysis of Test Results

At present, the qualified rate of the section steel product is up to 96.27 %. This experiment extracts 200 samples of the section steel product to test the expert system. Thereinto, we extract four sets of data from the unqualified products and 1 set of data from the qualified product as the followings. In order to inspect the generalization ability of the neural network the five sets of data are not included in the training samples. Table 1, 2, 3, 4 takes the chemical prosperities parameters, physical properties parameters, dimensional accuracy parameters and the surface of the products parameters of i-beam as the representative of the four sets of input data. Table 5 is about the results and analysis after the comprehensive judgment about the chemical constituents, physical properties parameters, dimensional accuracy and the surface of the products. Suppose the weight of chemical properties is \( W_{ci} \), the weight of physical prosperities is \( W_{pi} \), the weight of dimensional accuracy parameters is \( W_{di} \), the weight of the surface quality parameters is \( W_{si} \). So, the final outputs of the four neural network are \( y_{c} = \sum\nolimits_{i = 1}^{38} {W_{ci} h_{ci} } \), \( y_{p} = \sum\nolimits_{i = 1}^{9} {W_{pi} h_{pi} } \), \( y_{d} = \sum\nolimits_{i = 1}^{9} {W_{di} h_{di} } \), \( y_{s} = \sum\nolimits_{i = 1}^{41} {W_{si} h_{si} } \). The \( W_{ci} ,W_{pi} ,W_{di} ,W_{si} \) and \( h_{ci} ,h_{pi} ,h_{di} ,h_{si} \) are confirmed by the formulas of gradient-decent at the beginning of the paper. The brand of the products is Q295 with A level.

This system detects the products from four aspects and gives out the reasons of disqualification. This is good for the following quality-trace and analyzing the results detailedly. Compare with the traditional way, it saves 60 % of the time.

5 Quality-Trace on Basis of RBF Neural Network Expert System

At present neural network expert system can solve the “bottleneck” problem in the conventional expert system very well. However, the black box problems in the explanation mechanic of the neural network expert system have not been solved up to now [14–17]. Although the system can provide a result which is close to the idea from experts infinitely, it cannot provide the further explanation to the result. It also cannot provide the whole reasoning process. In order to overcome the shortcoming of neural network expert system this system raised a new idea on the module settings. This system set a quality analysis module and a quality trace module which is based on the essential data real time data acquisition module and the neural network expert system quality test module. After the quality test all the data and the result from the expert system would be recorded in the database. Due to the large test data and result this system set a quality analysis module which was suit for the characteristic of the steel industry. It combined the data and the specific actual situation to analyze deeply. And summarize the internal relations of the parameters and the law of the production achievement. Then made a conclusion under these information and made quality trace with right direction. This paper raises a method that combines neural network expert system and quality-trace. According to the result from the neural network expert system it makes quality-trace to the unqualified products. The part of quality-trace reappears the reasoning process in the conventional expert system while it also makes up the drawback of the explanation mechanic in the neural network expert system on the one hand. On the other hand it can trace to the process which induces the problem and can help the workers to know the responsible part.

The production of hot rolled steel is belonged to the type of process industry. The productive process from the primal raw material to the final product is continuous. So the information to the productive process is also continuous. And the technological parameters to every process are so many. At the same time the production environment is complex so there are many factors can influence the quality of the final products. And it is also important that the products are formed from a kind of raw material which is changed in chemical properties and physical properties in many processes and is finally turned into many kinds of products. So the quality problem in the productive process would influence many down-stream products. So when it traces the quality of the hot rolled steel product it needs to trace to the raw material widdershins according to the production technology process of the products [18, 19].

There must be reliable trace- basis when realize the process of quality trace. If an enterprise wants to realize quality trace it must establish an impeccable and effective quality management mechanism to record the identification of product well. An identification of product is the only sign during the whole manufacturing process. It includes the product ID, batch number, sequence number, date, etc. At the same time it must establish a search mechanism about these information accurately and fastly. According to the characteristic of the steel industry the identifier records the raw material batch number, batch number, procedure parameter, etc. When there happens any quality problem the workers can review the information during the whole life cycle according to the identifier.

By means of the records of all the information during the whole life cycle the system accumulates product data and quality test data continually through the expert knowledge database. So as to realize tracking back management of the product quality automatically and effectively.

In order to solve the problem of the neural network that cannot afford reasoning process we made some trace-rules especially to the expert system:

-

1.

Input the identification of product you can inquire the corresponding slab number, steel type number, semi-finished numbers, material group numbers, executive standard number, heating furnace number and the mill number, roll number, continuous casting number during the productive process and other information in the pivotal link.

-

2.

Input the identification of product you can inquire the test results in the quality test neural network expert system and all the parameters in the quality test about chemical properties, physical properties, dimensional accuracy and the surface of the products. The unqualified item would be colored red. At the same time you can inquire the detailed overweight data.

-

3.

Input the productive time and the information as mill number, furnace number, etc. you can inquire product batch at the same time which passed the corresponding equipment.

-

4.

Input the process name and time you can inquire the corresponding classes and teams information so as to search the department information, role information, user information, job number and name.

In the process of quality-trace the informations are divided into two types. They are lateral tracing and lengthways tracing.

-

(1)

Lateral tracing

When there appears any problem in the products the quality-trace system can trace to the heating process, steel rolling process or sizing operation according to the informations of the code on the product. And the quality-trace information link can be crosswise expanded on the basis of the associated content from all the information. It traces strictly according to the reversed order of production technology process. Then it locks the specific link which causes the quality problems. After separately confirmation to the four neural networks it finds out the problematical parameters and review to the parameters of the other products which is also belonged to the same brammennummer. The specific steps are shown in Fig. 4.

-

(2)

Lengthways tracing

When there occurs any quality problem and after it has locked the problematical link by the lateral tracing we need to develop the lengthways tracing about the problematical link. That is the case-by-case. First, we need to make sure about the batch of the problematical products according to the reason which resulted in the defect. Then trace the storage informations and the informations of the production department of the same batch. The aim is to lock the scope of the problematical products. Then analyze the reason which leads to the defect in detail so as to improve the method of quality control and improve the quality of products.

The process of tracing is a kind of reversed order to the process flow of the production. It is from the finished product number to the semifinished product number, intermediate blank number, raw materials number, furnace time number, and slab number.

The quality trace to the steel products can be divided into 4 parts according to the productive technology: chemical properties tracing, physical properties tracing, dimensional accuracy tracing, the surface of the products tracing. The objective of quality trace is not only to find out the negligence of the craft and to improve the process, but also to trace back the products of the same batch. Then checkout these products again to ensure the products of the same batch are safe.

In the chemical properties tracing part, the fault is not resulted from the hot rolling productive process. There are two sources to the slabs: home-grown and outsourcing. To the outsourcing slabs, the workers can trace the manufacturers according to the order number and some other informations. To the home-grown slabs, the workers can trace the craft process to the steel-making part. And trace the process in accordance with the “tree- rule.” We see every process of every product as a panel point. The production sequence is from up to down while the trace sequence is from down to up, as is shown in Fig. 5. At the same time trace back the product from the same batch.

When trace to the slab number do the lateral tracing and find out all the slabs which are the same batch. Then sample randomly from the same batch and recheck the quality. If the result is eligible, only downgrading the former subquality product. If the result is disqualification, dispose the slabs from the same batch unitively.

In the physical properties tracing part, we trace the heating link, rolling link, cooling link and dephosphorization link according to the craft process. If there is any defect on the physical properties, trace the product from the same batch and recheck the quality. Lock the bottleneck link according to the inquiring to every parameter. And trace the other products which experienced the same equipment and the same process. Sample and recheck the products to ensure their quality.

In the dimensional accuracy tracing part, trace the cut to length cold saw cutting part. In the surface of the products tracing part, we need to consider the chemical properties. The defect of the surface of the products is mainly because of the chemical properties problem. If there is any defect on the surface of the products, trace directly to the slab. Inquire if the slab is home-grown or outsourcing to lock the problem part.

6 Conclusion

This paper expounded a hot rolling products quality test expert system which combined the RBF neural network and quality-trace. It tested the quality of the products in four aspects which were chemical properties, physical properties, dimensional accuracy and the surface of the products. It made the final results by the comprehensive judgment and gave a kind of rough analysis about the result. Then it made all-around quality-trace. On one hand the trace result can explain the result from the expert system on the other hand it can find out the responsible process during the course of manufacture. This system can explain the detailed reasons about the result so it mends the shortcoming of explain facility in the conventional neural network expert system. And it also offers the theory basis for the later improved work about the whole system. In addition, because of the powerful ability in data processing of RBF neural network it can also be incorporated into the detection control and fault diagnosis of chemical energy storage device such as rechargeable batteries, super capacitor. etc. However, how to make this theory helpful in the daily detective work is which we need to research further.

References

Galushkin AI (2010) Neural networks theory. Springer, Germany

Wen-yu LV, Wei-ming LI, Wei-hong LI (2012) Research on the Optimization selection of thin coal seam mining method based on ANNES. China Min Mag 32(4):132–138

Park H-S, Pedrycz W, Chung Y-D, Oh S-K (2012) Modeling of the charging characteristic of linear-type superconducting power supply using granular-based radial basis function neural networks. Expert Syst Appl 39(1):1021–1039

Shi Z (2009) Neural network. Higher Education Press, China

Du Z (2010) Application study of RBF in crack testing of steel. Harbin University of Science and Technology, China

Liang ZHOU, Kai-junIntrusion WU (2010) Detection system based on combination of expert system and BP neural network. Microcomput. Inf 18(5):456–461

Hanafizadeh P, Ravasan AZ, Khaki HR (2010) An expert system for perfume selection using artificial neural network. Expert Syst Appl 37(12): 8879–8887

Niu X, Zhao X (2012) The study of fault diagnosis the high-voltage circuit breaker based on neural network and expert system. Procedia Eng 29(11): 3286–3291

Rosa ES, Salgado RM, Ohishi T, Mastelari N (2010) Performance comparison of artificial neural networks and expert systems applied to flow pattern identification in vertical ascendant gas–liquid flows. Int J Multiph Flow 36(9):738–754

Du L-J, Zhang S-F, Yan E-L (2010) A Study on diagnostic expert system of electronic engine based on fuzzy neural network. J Agric Univ Hebei 5(8):156–162

Xu-jin LIU, Jian-ping LI, Chang-long DU, Zheng-wei HU (2011) Coal-mining Machine Fault Diagnosis Expert System Simulation Based on Fuzzy Neural Network. Coal Mine Mach 4(8):98–105

Li J, Han S-J, Chang Y-Q, Nie S-Y (2011) Application of artificial intelligence in sea cucumber cultivate expert system. J Comput Appl S1(3):188–192

Zhang X-H, Zhen T, Bao H (2010) Research and application of measurement and control expert system for grain storage based on neural network. J Henan Univ Technol (Nat Sci Edition) 3(6):228–234

Molina JM, Isasi P, Berlanga A, Sanchis A (2000) Hydroelectric power plant management relying on neural networks and expert system integration. Eng Appl Artif Intell 13(3):357–369

Ao Z (2010) Artificial intelligence and expert system. China Machine Press, China

Hai Z-H, Tian M-Q (2010) Research of expert system of fault diagnosis for asynchronous motor based on neural network. Industry and Mine Automation 4(7):557–562

Chen X (2010) Research on order tracking and product quality tracing system for discrete manufacturing. Zhejiang University, China

Li W (2011) The study of the tracing management system design about the white spirit products. Beijing University of Posts and Telecommunications, China

Ohshima M, Tanigaki M (2000) Quality control of polymer production processes. J Process Control 10(2): 135–148

Acknowledgments

[1] AQSIQ Nonprofit Industry SPecialized Research Funding Projects (201310003)

[2] AQSIQ Science and Technology Plan Projects (2014QK186)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Yao, L., Hailiang, Z., Jingtao, G., Xin, S., Xigang, W. (2016). Quality Test and Track System Based on Neural Network. In: Liang, Q., Mu, J., Wang, W., Zhang, B. (eds) Proceedings of the 2015 International Conference on Communications, Signal Processing, and Systems. Lecture Notes in Electrical Engineering, vol 386. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-49831-6_103

Download citation

DOI: https://doi.org/10.1007/978-3-662-49831-6_103

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-49829-3

Online ISBN: 978-3-662-49831-6

eBook Packages: EngineeringEngineering (R0)