Abstract

South Africa and Russia are the world’s leading platinum group elements (PGE) producers with over 80 % of the global PGE output. Studies performed in the Bushveld Igneous Complex in South Africa and on the Kola Peninsula in Russia show that PGE mining and production activities are important regional PGE sources. Elevated PGE concentrations have been found in snow, soil, road dust, grass, moss and humus collected near PGE mining and production sites. The occurrence of elevated PGE concentrations near mining sites raises concern over environmental effects and exposure of the local population. Studies on the occurrence of PGE in remote environments also suggest that emissions from PGE production activities contribute to the global biogeochemical cycle of the PGE. The loss of PGE during metal production could be as much as 5 % of the global supply and represents a substantial economic loss. Studies on the impact of PGE mining and production activities are few. Further research is needed to better assess the environmental impact of PGE emissions from mining and production activities.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Studies on the environmental relevance of the platinum group elements (PGE) have until now largely focused on urban and roadside environments where elevated PGE concentrations have been reported as a result of automobile catalyst emissions (Ravindra et al. 2004; Rauch and Morrison 2008). Although metal production activities are recognised to be an important source of metals into the environment (Nriagu and Pacyna 1988; Dudka and Adriano 1997), PGE emission from mining and production activities have only received little attention. Recent studies performed in remote environments indicate however that additional PGE sources contribute to the global biogeochemical cycles of these element and metal production activities have been suggested as a potential source of PGE into the environment (Barbante et al. 2001; Rauch et al. 2005; Moldovan et al. 2007; Rauch et al. 2010; Sen et al. 2013).

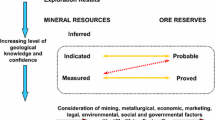

PGE are present at trace concentrations in the Earth’s upper continental crust (Peucker-Ehrenbrink and Jahn 2001) and economic recovery is only possible at a few sites where PGE concentrations are sufficiently high. PGE are mined from primary deposits where they are typically in igneous minerals and associate to other elements (e.g. Cu and Ni) in igneous rocks, and secondary deposits formed by erosion and relocation of PGE in pure metallic form. Primary deposits, such as the Bushveld Igneous Complex (BIC) in South Africa and the Norilsk/Talnakh complex in Russia, account for most of the PGE production. It is estimated that 179 tons Pt, 197 tons Pd and 22 tons Rh were produced in 2013, and South Africa and Russia accounted for 82 % of the global PGE production (Fig. 1). The remaining 18 % were mainly produced by Canada, the USA and Zimbabwe (Johnson-Matthey 2013).

PGE production estimates by country for 2013 (Data Johnson-Matthey 2013)

This chapter summarizes current knowledge on PGE emissions from PGE mining and production activities in South Africa and Russia, as well as their contribution to the global biogeochemical cycles of the PGE.

2 Impact of PGE Mining in South Africa

2.1 Mining Areas

South Africa is the world’s largest PGE producer with 72 % of Pt production, 37 % of Pd production and 80 % of Rh production in 2013 (Johnson-Matthey 2013). South Africa’s PGE resources are located in the Bushveld Igneous Complex (BIC) in the Northern part of the country (Fig. 2). The BIC is the world’s largest mafic-ultramafic intrusion with an area of 65,000 km2 and 75 % of the world’s Pt resources (Cawthorn 1999). Mining has until recently concentrated on the shallower Merinsky Reef in the western limb of the BIC because of higher grade, lower chromite content and easier access to mining sites. Increasing demand and decreasing reserves are now resulting in the exploitation of the deeper Upper Group 2 (UG2) chromitite layer and of the eastern limb of the BIC. In 2006 mining of UG2 was expected to represent as much as 60 % of the total ore processed in the BIC and 18 % of the production was expected to take place in the eastern limb (Johnson-Matthey 2003). Processing plants and smelters are operated in both the Western and Eastern Limbs of the BIC.

Map of the Bushveld Igneous Complex with the location of mines (M1–M6) in the Rauch and Fatoki (2013) study

2.2 Platinum Concentrations in the Vicinity of PGE Mines in the BIC

Elevated Pt and Pd concentrations in the BIC were first reported in the context of geochemical mapping. Concentrations exceeding 180 ng Pt g−1 and 99 ng Pd g−1 were found in soil in the BIC and mining operations were suggested as a possible Pt and Pd source (Wilhelm et al. 1997). Potential PGE emissions by mining activities in the BIC were however not investigated further.

Elevated Pt concentrations have been reported near selected mines (M1–M6 in Fig. 2) in the BIC (Rauch and Fatoki 2013). Platinum concentrations in topsoil ranged from 9.9 ± 0.7 ng g−1 near an underground shaft to 653 ± 40 ng g−1 near a PGE smelter (Fig. 2). In comparison, Pt concentrations in the BIC were 4–250 times larger than Pt concentrations at a background site. The observed variation in Pt concentrations is attributed to the type of activity in the direct vicinity of the sampling point and indicate that smelters are more important Pt sources than mining from underground shafts or ore processing (Fig. 3).

Pt concentrations in top soil collected at a background site, near PGE mines (M1–M6) and in villages located near mine M4 (Data Rauch and Fatoki 2013)

Pt was found to be enriched in fine particles (<125 µm) near the smelter, whereas a more even particle size distribution was found at the processing plant (Rauch and Fatoki 2013). Ore processing essentially consists of milling and separation by flotation, and may therefore only result in the emission coarse particles. In contrast, smelting involves high temperature processes that may result in the formation of finer particles.

Elevated Pt concentrations were also found in grass collected at mine M4 and in nearby towns with the highest concentration (256 ± 122 ng g−1) measured near the smelter at mine M4. Exposure experiments in the lab showed that uptake from contaminated soil is relatively limited and the occurrence of PGE in grass is therefore attributed to deposition of Pt-containing aerosols.

2.3 Platinum Concentrations in South African Road Dust

Road dust was collected in four South African cities to assess the relative importance of automobile catalysts and PGE production activities (Rauch and Fatoki 2010). Average Pt concentrations in road dust ranged from 4 ng g−1 in Cape Town to 223 ng g−1 in Rustenburg (Fig. 4) with a minimum concentration of 2 ng g−1 along highway N2 in Cape Town and a maximum concentration of 391 ng g−1 at Mandela Street in Rustenburg. The results show that automobile catalysts are a minor source of Pt into the South African environment with relatively low concentrations at high traffic sites in Cape Town and Port Elizabeth. Rustenburg is located in the Western Bushveld and elevated Pt concentrations are associated with PGE mining and production activities. Elevated Pt concentrations in Pretoria relative to Cape Town and Port Elizabeth indicate that Pt emitted in the BIC is dispersed at regional scale. Pretoria is located 150 km East of Rustenburg.

Average Pt concentration in road dust collected in South African cities (Data Rauch and Fatoki 2010)

3 Impact of PGE Mining in Russia

3.1 Mining Areas

PGE production in Russia dates back to the early nineteenth century when alluvial deposits were discovered in the Ural Region. Today, Russia is the world’s second largest PGE producer and the largest Pd producer with 14 % of Pt production, 41 % of Pd production and 12 % of Rh production (Johnson-Matthey 2013). PGE production activities are located at 5 sites across the country (Fig. 5).

Map of Russia with PGE mining districts (adapted from Johnson-Matthey 2004)

The Norilsk/Talnakh site on the Taimyr Peninsula in Northern Siberia accounts for most of Russia’s PGE production. PGE at Norilsk/Talnakh occur in large sheets of PGE-containing copper-nickel ores associated with a sequence of igneous intrusions. PGE occur in massive sulphide ores, copper-rich ores and disseminated ores and are produced along with copper and nickel. While the Norilsk/Talnakh deposit is larger than the Bushveld Igneous Complex, PGE grades vary widely. Lower grade nickel-copper ores with PGE by-products are produced on the Kola Peninsula. Concentrating and smelting operations are performed at both the Norilsk/Talnakh and the Kola Peninsula sites (Johnson-Matthey 2004; Reimann and Niskavaara 2006).

Platinum is also produced from Koryak and Kondyor, two alluvial deposits in the far Eastern regions of Russia. Alluvial platinum deposits in the Urals are still being mined, but account for a small fraction of Russian PGE production (Johnson-Matthey 2004).

3.2 Platinum Concentrations in the Vicinity of PGE Mines on the Kola Peninsula

The Norilsk/Talnakh area and the Kola Peninsula are heavily polluted by metal production industries (Blacksmith Institute 2013; Zhulidov et al. 2011; Reimann et al. 1998). Studies on PGE contamination in Russia have only focused on the Kola Peninsula; there is no published information on the contamination levels at the Norilsk/Talnakh site, despite higher production levels.

Elevated PGE concentrations have been reported in O-horizon soil near the Ni refinery in Monchegorsk, the Ni smelter in Nikel and the Cu–Ni ore roasting plant in Zapolyarnij (Niskavaara et al. 2004; Reimann and Niskavaara 2006). The highest concentrations (218 ng Pt g−1, 656 ng Pd g−1) were found near the Monchegorsk refinery, which processes PGE-rich ores from the Norilsk/Talnakh deposits, whereas local Pechenga ores with lower PGE contents are process in Nickel and Zapolyarnij (Reimann and Niskavaara 2006). Average concentrations of 49.6 ng Pt g−1, 187.6 ng Pd g−1 and 1.4 ng Rh g−1 have been reported in topsoil near the Monchegorsk plant (Boyd et al. 1997). In comparison, median concentrations of 0.62 ng Pt g−1 and 0.45 ng Pd g−1 have been reported in O-horizon soil in the European Artic (Finland, Norway, Russia) (Reimann and Niskavaara 2006). PGE concentrations in snow were found to be in the range <1–650 ng Pt l−1, <1–2770 ng Pd l−1, <0.5–19 ng Rh l−1 near the Monchegorsk, Nikel and Zapolyarnij plants). The highest concentrations were found at the Monchegorsk plant (Gregurek et al. 1999).

The PGE concentration pattern in soil and snow is similar to that of processed ores, suggesting that PGE are emitted in the form of ore dust. The PGE concentration pattern in soil reflects that of Talnakh ores processed at the Monchegorsk plant, whereas concentration pattern in snow suggest that both Norilsk and Pechenga (Kola Peninsula) ores contribute to elevated PGE concentrations on the Kola Peninsula. PGE concentration patterns in soil and snow samples also indicate that there is no preferential leaching or redistribution of emitted PGE (Boyd et al. 1997; Gregurek et al. 1999).

4 Implication of PGE Emissions by Mining and Production Activities

4.1 Environmental Impact and Human Exposure

The occurrence of elevated PGE concentrations has no proven environmental impact, possibly due to limited data on chronic effect. Although the occurrence of PGE in grass (Rauch and Fatoki 2013) and moss (Reimann and Niskavaara 2006) near PGE production sites is likely due to atmospheric deposition, it is known that PGE emitted by automobile catalysts can be bioaccumulated (Moldovan et al. 2001; Ek et al. 2004; Haus et al. 2007). Data on the occurrence of PGE in biota near PGE production sites is lacking. In addition, PGE mining and production activities are important point sources of SO2 and heavy metals (Blacksmith Institute 2013; Zhulidov et al. 2011; Reimann et al. 1998; Boyd et al. 2009). Severe environmental degradation has been observed around the Russian PGE production sites (Zhulidov et al. 2011) and Norilsk is considered to be one of the most contaminated places on Earth (Blacksmith Institute 2013).

Some of the main PGE mining and production sites are located in the direct vicinity of human settlements. Rustemburg (ca. 550,000 inhabitants in the Local Municipality), Norilsk (ca. 175,000 inhabitants) and Monchegorsk (ca. 45,000 inhabitant) are located within a few km of mines, smelter and refineries (Fig. 6). PGE emissions and occurrence of elevated PGE concentrations in the environment raise concern over exposure of the local population. Elevated Pt concentrations were found in soil and grass in two towns located within a few kilometres from mine M4 in the BIC (Rauch and Fatoki 2013). Platinum concentrations in soil in Town A (1 km North of the smelter) and Town B (3 km SW of the smelter) were 73 ± 61 and 109 ± 48 ng g−1 in 2008, respectively. The mining companies are also the main employers in these cities, resulting in a combination of both environmental and occupational exposures for many inhabitants. Potential toxic effects at high concentrations include sensitization, mutagenic effects and increased tumor incidence.

4.2 Global Impact of PGE Emissions from Mining

Increasing PGE concentrations in remote environments have been attributed to anthropogenic PGE emissions (Barbante et al. 2001; Rauch et al. 2005; Moldovan et al. 2007; Rauch et al. 2010; Sen et al. 2013). Atmospheric back trajectories indicate that PGE in Central Greenland and in the French Pyrenees partly originate from mining districts in Russia (Rauch et al. 2005; Moldovan et al. 2007). PGE ratios further suggest that anthropogenic PGE deposition in Greenland is the result of emissions from both automobile catalysts and PGE production activities (Rauch et al. 2005). However, studies at the PGE mining and production sites on the Kola Peninsula show that PGE concentrations decrease with increasing distance from the production sites and the prevailing wind direction (Gregurek et al. 1998, 1999). Background Pt and Pd concentrations are reached within 200 km from smelters (Reimann and Niskavaara 2006). Differences may be explained by a stronger influence of the geogenic background in the samples collected in the Kola Peninsula.

4.3 Economic Loss and Recovery

PGE emission by mining and production activities corresponds to a loss of resources. It is estimated that 2.2 tons Pd (1.1 % of global production) and 0.8 tons Pt (0.5 % of global production) were emitted yearly by the Monchegorsk smelter in the mid 1990s (Reimann and Niskavaara 2006). Emission rates at the Monchegorsk smelter indicate that global emissions could represent over 5 % of Pt and Pd production (>10 tons Pd yr−1 and >9 tons Pd yr−1). In contrast, Pt and Pd emissions estimated using Cu emissions rates from Cu-Ni production (Pacyna 1984) amount to 0.3–0.7 metric tons per year. Although these numbers are approximate, the emission rates indicate substantial economic losses. Measured PGE concentrations in soil near the smelters in South Africa and Russia also indicate that it would be possible to recover part of the emitted PGE. More detailed feasibility studies should be made to determine the area from which PGE could be recovered.

5 Conclusion

PGE mining and production industries are important local PGE sources. Elevated PGE concentrations have been reported near mining and production operations in South Africa and Russia, raising concern over exposure of the local population and environmental degradation. While the emission of PGE may represent a substantial economic loss, environmental levels near PGE smelters indicate that it would be possible to recover PGE from contaminated soil. There is also some indication that PGE emissions from PGE production operations contribute to the global biogeochemical cycle of these elements. Studies on PGE emission from mining and production activities are few; there is for instance no published data for the Norilsk/Talnakh operations. Further studies are needed to determine emission rates and assess environmental contamination at local, regional and scales.

References

Barbante C, Veysseyre A, Ferrari C, Van de Velde K, Morel C, Capodaglio G, Cescon P, Scarponi G, Boutron C (2001) Greenland snow evidence of large scale atmospheric contamination for platinum, palladium, and rhodium. Environ Sci Technol 35:835–839

Blacksmith Institute (2013) The worlds worst 2013: the top ten toxic threats. blacksmith institute, New York, USA. http://www.worstpolluted.org/. Accessed 20 Dec 2013

Boyd R, Niskavaara H, Kontas E, Chekushin V, Pavlov V, Often M, Reimann C (1997) Anthropogenic noble-metal enrichment of topsoil in the Monchegorsk area, Kola peninsula, northwest Russia. Geochem Explor 58:283–289

Boyd R, Barnes S-J, de Caritat P, Chekushin VA, Melezhik V, Reimann C, Zientek M (2009) Emissions from the copper-nickel industry on the Kola Peninsula and at Noril’sk, Russia. Atmos Environ 43:1474–1480

Cawthorn RG (1999) The platinum and palladium resources of the Bushweld Complex. S Afr J Sci 95:481–489

Dudka S, Adriano DC (1997) Environmental impacts of metal ore mining and processing: a review. J Environ Qual 26:590–602

Ek KH, Morrison GM, Rauch S (2004) Environmental routes for platinum group elements to biological materials—a review. Sci Total Environ 334:21–38

Gregurek D, Melcher F, Niskavaara H, Pavlov VA, Reimann C, Stumpfl EF (1999) Platinum-group elements (Rh, Pt, Pd) and Au distribution in snow samples from the Kola Peninsula, NW Russia. Atmos Environ 33:3281–3290

Gregurek D, Reimann C, Stumpfl EF (1998) Trace elements and precious metals in snow samples from the immediate vicinity of nickel processing plants, Kola Peninsula, northwest Russia. Environ Pollut 102:221–232

Haus DN, Zimmermann S, Wiegand J, Sures B (2007) Occurrence of platinum and additional traffic related heavy metals in sediments and biota. Chemosphere 66:619–629

Johnson-Matthey (2003) The expansion of platinum mining in South Africa. In: platinum 2003. Johnson-Matthey, London, UK. pp 14–17

Johnson-Matthey (2004) PGM mining in Russia. In: Platinum 2004. Johnson-Matthey, London, UK. pp 16–21

Johnson-Matthey (2013) Platinum 2013. Johnson-Matthey, London, UK

Moldovan M, Rauch S, Gómez M, Palacios MA, Morrison GM (2001) Bioaccumulation of palladium, platinum and rhodium from urban particulates and sediments by the freshwater isopod Asellus aquaticus. Water Res 35:4175–4183

Moldovan M, Veschambre S, Amouroux D, Benech B, Donard OFX (2007) Platinum, palladium, and rhodium in fresh snow from the aspe valley (Pyrenees Mountains, France). Environ Sci Technol 41:66–73

Niskavaara H, Kontas E, Reimann C (2004) Regional distribution and sources of Au, Pd and Pt in moss and O-, B- and C-horizon podzol samples in the European arctic. Geochem Explor Environ Anal 4:143–159

Nriagu JO, Pacyna JM (1988) Quantitative assessment of worldwide contamination of air, water and soils by trace metals. Nature 333:134–139

Pacyna JM (1984) Estimation of the atmospheric emissions of trace elements from anthropogenic sources in Europé. Atmos Environ 18:41–50

Peucker-Ehrenbrink B, Jahn BM (2001) Rhenium-osmium isotope systematics and platinum group element concentrations: loess and the upper continental crust. Geochem Geophys Geosyst 2, 1061

Rauch S, Hemond HF, Barbante C, Owari M, Morrison GM, Peucker-Ehrenbrink B, Wass U (2005) Importance of automobile exhaust catalyst emissions for the deposition of platinum, palladium, and rhodium in the Northern Hemisphere. Environ Sci Technol 39:8156–8162

Rauch S, Morrison GM (2008) The environmental relevance of platinum group elements. Elements 4:259–263

Rauch S, Fatoki OS (2010) Platinum and lead in South African road dust. In: Rauch et al. (Eds) Highway and Urban Environment. Springer, The Netherlands. ISBN 978-90-481-3043-6

Rauch S, Fatoki OS (2013) Anthropogenic platinum enrichment in the vicinity of mines in the bushveld igneous complex. S Afr Water Air Soil Pollut 224:1395

Rauch S, Peucker-Ehrenbrink B, Kylander ME, Weiss DJ, Martinez-Cortizas A, Heslop D, Olid C, Mighall TM, Hemond HF (2010) Anthropogenic forcings on the surficial osmium cycle. Environ Sci Technol 44:881–887

Ravindra K, Bencs L, Van Grieken R (2004) Platinum group elements in the environment and their health risk. Sci Total Environ 318:1–43

Reimann C, Äyräs M, Chekushin VA, Bogatyrev I, Boyd R, de Caritat P, Dutter R, Finne TE, Halleraker JH, Jäger Ø, Lehto O, Niskavaara H, Räisänen ML, Starnd T, Volden T (1998) Environmental Geochemical Atlas of the Central Barents Region. NGU-GTK-CKE Special Publication, Geological Survey of Norway, Trondheim, Norway

Reimann C, Niskavaara H (2006) Regional distribution of Pd, Pt and Au-emissions from the Nickel Industry on the Kola Peninsula, NW-Russia, as seen in moss and hummus samples. In: Zereini F, Alt F (Eds) Palladium emissions into the environment. Springer, Heidelberg, ISBN 978-3-540-29219-7

Sen IS, Peucker-Ehrenbrink B, Geboy N (2013) Complex anthropogenic sources of platinum group elements in aerosols on Cape Cod, USA. Environ Sci Technol 47:10188–10196

Wilhelm HJ, Zhang H, Chen FL, Elsenbroek JH, Lombard M, deBruin D (1997) Geochemical exploration for platinum-group elements in the Bushveld complex, South Africa. Miner Deposita 32:349–361

Zhulidov AV, Robarts RD, Pavlov DF, Kämäri J, Gurtovaya TY, Meriläinen JJ, Pospelov IN (2011) Long-term changes of heavy metal and sulphur concentrations in ecosystems of the Taymyr Peninsula (Russian Federation) North of the Norilsk Industrial Complex. Environ Monit Assess 181:539–553

Acknowledgements

The study of PGE contamination by PGE production activities in South Africa was funded by the Swedish International Development Agency (SIDA) under the Swedish Research Links programme and the South African National Research Foundation (NRF).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Rauch, S., Fatoki, O.S. (2015). Impact of Platinum Group Element Emissions from Mining and Production Activities. In: Zereini, F., Wiseman, C. (eds) Platinum Metals in the Environment. Environmental Science and Engineering(). Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-44559-4_2

Download citation

DOI: https://doi.org/10.1007/978-3-662-44559-4_2

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-44558-7

Online ISBN: 978-3-662-44559-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)