Abstract

Mining is an important activity at the present time that causes severe environmental stress. The heavy metals (metalloids) easily released into the environment, surface water and groundwater contamination, and soil and air pollution are also potential risks to human health. Due to the stringent environmental rules and global thirst for achieving Sustainable Development Goals, human negligence cannot be affordable in the long run. It is time to recognize the need for people connected with safe and sustainable mining activities of lucrative precious metals like gold. Therefore, in this chapter, we assess the risks caused by the primary mining of gold and discuss mitigation routes involving various factors.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Precious metals

- Artisanal gold mining

- Amalgamation

- Cyanidation

- Acid mine drainage

- Hazard index

- Mining environmental liabilities

1 Introduction

Mining is related to the exploration of valuable geological minerals from the Earth and/or other astronomical sources that essentially cannot be grown by agriculture (Ilyas et al. 2021). For example, the exploration of coal, metals, gemstones, rock salt, oil shale, clay, petroleum, natural gas, etc. comes under mining activities. Among these, metal-related mining activities are one of the most important as they cater to our 24-hour needs (Ilyas et al. 2018). In general, the mining of minerals can be divided mainly into five stages: mining, crushing, grinding, ore concentration, and dewatering (Srivastava et al. 2023). The typical operations in any mining activities carried out at a standard condition are illustrated in Fig. 1. From these activities, mainly two types of waste are generated: waste rock piles (tailings) and wastewater. Wastewater is discharged from either the underground runoff water or the used water in grinding and ore separation, whereas tailings are produced from the grinding and ore separation processes and go to the tailing management facilities (Global Tailing Review 2020). In most cases, tailing dams are mining legacies that release potentially toxic elements (viz., Cd, As, Cu, etc.) into nearby water sources to be used in irrigation of agricultural land and sometimes uptaken by humans (Dong et al. 2020). Poor management of tailing waste has caused tailing dam failures in the past with catastrophic consequences (Grebby et al. 2021; Ouellet et al. 2022). Ideally, the wastewater should be recycled between the grinding, separation, and dewatering stages; however, it is not always easy to practice. On the other hand, the final product obtained after the mining activities, i.e., ore concentrates, is sent to the extraction and purification processes for the recovery of pure metals.

Mining activities can have both positive and negative impacts on society and the environment during the ongoing mining process or after the abandonment of a mine, both in direct and indirect ways. Exploration, construction, and operation often cause land-use change to have negative impacts on the environment due to associated issues like deforestation, soil erosion, contamination of water streams and wetlands, an increase in noise pollution due to machining, and air pollution due to dust and emissions (Cruzado-Tafur et al. 2021). Similarly, abandoned mines result in remarkable environmental footprints like soil and water contamination (Ngole-Jeme and Fantke 2017). Beyond the mining activities, the built infrastructure like roads, railways, ports, electricity, etc. can affect the flora and fauna leading toward the migratory routes (Rapant et al. 2006). Nevertheless, mining has positive impacts in terms of employment generation, not only in mining itself but also in other sectors like transportation, metallurgical and chemical industries, and mushrooming local businesses for daily needs. The concerns over environmental risks and public health issues are greater because damage cannot be compensated. Up to some extent, remediation of the potential environmental impacts by means of ecological restoration and wastewater treatment (Paniagua-López et al. 2021). As prevention is better than cure, the nations are trying to regulate the mining activities to control the damage; however, the full enforcement of regulations is always challenging.

The risk assessment of primary mining may be helpful to identify related issues, estimate the probability and severity of the consequences, and make strategies for environmental management (Cervantes Neira and Quito Quilla 2020). Accordingly, risk assessment is a process that comprises measuring the possible adversities resulting from the exposition of environmental stress, including the physical, chemical, and biological entities responsible for damaging the ecosystem (USEPA 1998). Given that mitigation measures can be implemented to avoid, eliminate, and reduce the negative or improved impacts, such measures must be outlined in environmental and social impact assessments before major mining activities (Arranz-González et al. 2021). The mitigation of environmental impacts in one system can influence other systems. For example, water or soil treatments are linked to the well-being and health of local inhabitants and biodiversity. A variety of technological advancements have been seen in the area of wastewater treatment and contaminated land (Cervantes Neira and Quito Quilla 2020; USEPA 1998). In contrast, the mitigation routes designed to alleviate negative impacts on the environment and society may not always be effective (Haddaway et al. 2019). Indeed, the risk assessment from primary mining of precious metals and possible mitigation routes have been poorly focused, as has been the aim of this chapter.

2 Risk Assessment

Risk assessment is related to the analysis and mitigation of risks in the form of natural disasters and mining accidents in terms of their impacts on the environment and society. The natural hazards and disaster risks include earthquakes, landslides, floods, etc., whereas the mining industrial hazards typically involve mine sliding, dam failures, fire and explosions, water leakage, the release of hazardous chemicals or radionuclides, etc. In order to assess the risk, the following approaches are desirable (EIA Guidelines 2018):

-

(i)

Identifying the category of hazards and/or disasters from the historical available data

-

(ii)

Considering the case of climate change and its implications for frequency and consequences

-

(iii)

Estimation of spatial patterns, time, frequency, and intensity

-

(iv)

Identification based on project design and layout, use and handling of hazardous substances from the case studies, available records, and media reports

-

(v)

Analyzing cause and effect and the probability of events

-

(vi)

Assessing the extent of damages by accounting for the layout and design of the project, exposure routes and environment, local inhabitants, etc.

-

(vii)

Calculating the overall risk and comparing it with the acceptable levels

-

(viii)

Identifying the need for mitigation measures

2.1 Mercury Load in Fish

Several routes exist for environmental risk assessment and modeling, along with their limitations and advantages (Kammen and Hassenzahl 2001). Determining the metal concentrations in fish and soil samples is simple to establish the safe-unsafe or maximum concentration level thresholds. Recently, Marcantonio et al. (2021) reported the mercury load in fish from a precious metal mine in Sierra Leone to be 302 ppb. Although the sampled fish were mostly short-lived freshwater species, the Hg concentration was average for albacore tuna (FDA 2018). About 87% of fish samples exceeded in Hg concentrations the FDA recommended value of 150–230 ppb for 2–3 meals/week consumption, whereas 15% of samples exceeded the zero meals/week threshold with >460 ppb Hg therein. The one-way ANOVA for Hg concentration and 95% confidence interval for the range of hazards index are shown in Fig. 2a, b, respectively.

Interval plots of testing for differences in Hg content in fish (a) and T-test results for greater probability of risk than EPA established noncarcinogenic risk acceptable risk: HI > 1 (b) (modified and adopted from the open supplementary source of Marcantonio et al. 2021)

2.2 Heavy Metals in Soil

The soils near the mining activities are always found to be severely contaminated with heavy metals and sometimes radionuclides as well, which pose potential risks to human health. The majority of soil samples near the primary mining of precious metals contain cobalt, chromium, lead, iron, and thorium in concentrations that exceed most established limits (as per Table 1). For example, the soils collected along the Pampana River in Sierra Leone (Africa) were analyzed to contain 115 ppm Th in comparison to the limit of 7.4 ppm (US-EPA 2019). Notably, the risk posed by heavy metals can be assessed by following the steps of the US-EPA (2014):

-

(i)

Hazard identification: a process that determines whether exposure to a stressor increases the likelihood of adverse health effects

-

(ii)

Exposure assessment: a process that estimates the quantity of heavy metal exposure to a human being

-

(iii)

Dosage-response assessment: a process that determines the human health problems associated with different uptakes of heavy metals

-

(iv)

Risk characterization: a process that determines the extra risk of health issues for the exposed population

For the risk assessment, determining the average daily intake (ADI) is a vital factor, which is the intake value of a particular heavy metal from soil by any means of ingestion, inhalation, or dermal intake. ADIs are calculated using exposure parameters with respect to age, body size, respiration rates, etc. Hence, adults and children have different parameters, as summarized in Table 2 (SA-DEA 2010; US-EPA 2011).

Thus, ADI for three different intakes (i.e., ingestion, inhalation, and dermal intake) can be calculated using the following equations:

Further, the noncarcinogenic hazards are characterized by a unitless hazard quotient (HQ) representing the probability of individual health adversity (US-EPA 2014). It is the ratio of ADI and chronic reference dosage (RfD) of a heavy metal (given in Table 3) that can be written as below:

Furthermore, the hazard index (HI) for n number of heavy metals can be determined as the sum of all HQ for a soil sample as follows:

If HI < 1, heavy metal exposure is unlikely to cause health adversities. If HI > 1, the exposure may be concerning for potential noncarcinogenic effects.

The carcinogen risk is the unitless probability of a person developing cancer from heavy metal exposure over a lifetime (US-EPA 2014). It can be determined as a total of the lifetime cancer risk of a person from the average contribution of the individual heavy metals for all the pathways as follows:

ADIk (mg/kg-day) is the average daily intake, and CSFk (mg/kg-day) is the cancer slope factor, respectively, for the kth heavy metal and the n number of heavy metals. The CSF values for the incremental risk of an individual developing cancer can be seen in Table 4. A total cancer risk can finally be calculated as the sum of each individual pathway and heavy metal for a given soil sample as follows:

where Risk(ingestion), Risk(inhalation), and Risk(dermal) are the risks posed via by ingestion, inhalation, and dermal pathways, respectively.

The exposure risk quantified by Marcantonio et al. (2021) revealed a higher hazard index value for the inhabitants living near the Lake Sonfon area of gold mining. They used heavy metal concentration and the hazard index (HI) to determine the noncarcinogenic risk to adults and children separately in wet and dry seasons (refer to Fig. 3 adopted and modified from Marcantonio et al. 2021). For adults, the mean HI was 36.8 and 28.8 in the wet and dry seasons, respectively, and 67.6 and 54.1 for children. As per the US-EPA, a HI value greater than 1 represents excessive risk; hence, significantly high noncarcinogenic risks to both adults and children were observed. The results also revealed that HI risk greatly increases by going near the Lake Sonfon gold mine site. Furthermore, the evaluated values of carcinogenic risk (CR) causing cancer due to heavy metal exposure showed high risks closest to the gold mining area. Notably, the US-EPA guidelines state the threshold of 1 × 10−4 to 10−6; however, the mean CR was found to be 1.01 × 10−3 and 9.42 × 10−3 for adults and children, respectively, indicating that the gold mining area is highly contaminated by heavy metal pollution with a great likelihood ratio.

Noncarcinogenic hazard index, risk probabilities, and likelihood ratio evaluated at two seasons of wet and dry and determined for adults and children (red line showing the threshold lines as described by Marcantonio et al. 2021)

2.3 Mining Environmental Liabilities (MEL)

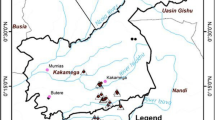

On the other side, the Spanish Geological Survey proposed a simplified risk assessment of abandoned mine sites to evaluate the mining environmental liabilities (MEL) through the associated determined probability (IP) and severity indices (IS) (refer to Fig. 4). For mine waste deposits, the risk assessment was performed by adopting the protocol designed by the Spanish Geological Survey (Alberruche del Campo et al. 2014), whereas in the case of other (i.e., non-waste) deposits, the methodology outlined in the Environmental Risk Assessment Guide of the Ministry of the Environment of Peru was followed (MINAM 2010). The cartographic information was processed using Geographic Information Systems (GIS) through ArcMap 10.8.1 to identify the areas that represent a greater risk of affecting the flora and fauna. Such information gathering allows for better management actions in each evaluated area of concern.

Simplified schematic for the risk assessment of abandoned mining sites as designed by the Spanish Geological Survey (adopted from the open access source of Salgado-Almeida et al. 2022, MDPI)

In the recent past, gold mines have gone deeper, encountering arsenopyrite-bearing gold ores that inhibit the leaching process during gold extraction. The excavated ore undergoes amalgamation or cyanidation after the fine milling operation, which produces a large quantity of tailings. These tailings contain unbroken pyrites, which may lead to slow atmospheric oxidation (Naicker et al. 2003). Near Johannesburg in South Africa, the long exposure to oxygenated rainwater with the undisturbed tailings caused the oxidation of pyrite minerals up to 5 m below the soil surface (Marsden 1986). The sulfate produced via pyrite oxidation acidifies the groundwater and enters streams along with Witwatersrand, severely polluting the groundwater and soils. The gold-tailing impoundment in the Witwatersrand can typically be understood by the scheme presented in Fig. 5 (Hansen 2015). Naicker et al. (2003) found that acid contamination in soil and groundwater varies seasonally. They found that the pH of the water near the mining area remains about 5.0, along with high concentrations of heavy metals and sulfate ions. This also leads to the precipitation of calcium as gypsum along the river banks.

A schematic of a typical gold-tailing impoundment in the Witwatersrand (modified and adopted from Hansen 2015 with copyright permission from Elsevier)

3 Mitigation of Environmental Risks

In order to avoid and/or reduce environmental impacts, designing mitigation measures is an imperative action. In the case of non-avoidable environmental impacts, the restoration and rehabilitation plan should be considered on a priority basis. Additionally, the impacts should be offset through programs to improve lands, water streams, and/or facilities to offset biodiversity impacts, along with providing the facilities or compensation to offset the societal and economic impacts. Table 5 indicates the mitigation hierarchy for handling the environmental risks due to mining activities (EIA Guidelines 2018). As prevention is always better than expensive remediation, the proactive avoidance of negative impacts with precautionary steps is welcomed when the environmental consequences of mining activities can’t be predicted and thus reliably managed.

A risk assessment study of MEL for their categorization and prioritization in gold-mining areas of Macuchi, Tenguel-Ponce Enriquez, and the Puyango River Basin in Ecuador, conducted by Salgado-Almeida et al. (2022), revealed that the impacts are mainly associated with artisanal and small-scale gold mining. Lack of regulations in many illegal mining activities (Rivera-Parra et al. 2021) has caused MEL accumulation. The same accumulation has facilitated the transportation of pollutants in different environmental compartments to spread severe anthropogenic contamination (SENAGUA 2011).

Table 6 belongs to the strategies and actions proposed for MEL management to mitigate the high risk for the flora and fauna (Salgado-Almeida et al. 2022). Puyango and Tenguel-Ponce Enriquez have been identified as priority control areas and urgently require a solid restoration and rehabilitation plan. To ensure the ecological restoration of the abandoned mine sites, actions like phytoremediation (Lam et al. 2017; Vela-García et al. 2019) and the creation of geoparks in low-risk areas (Franco et al. 2020), along with a continuous control and monitoring plan, could ensure the identical recovery and restitution of the land. In the entire restoration process, the collaborative efforts of different parties that involve mining companies, mine planners, investing organizations, local bodies, and societies (Popovic et al. 2015 are greatly required to achieve the Sustainable Development Goals. Lack of which may lead to an inefficient output. For a sustainable handling of mine tailings, their reutilization in metal recovery and reuse in other forms, like in the construction industry to fabricate bricks, cement, and ceramic materials, can lead toward a circular economy (Srivastava et al. 2023). Finally, a risk communication plan must exist to reduce exposure to potentially hazardous materials.

In order to respect human rights as a fundamental operating principle for mine workers and other actors as well, a typical compliance program can be designed as depicted in Fig. 6. In accordance with the Sustainable Development Goals, leading from the top and embedded throughout the organization, shared learning, partnership, and collaboration are the key factors to mitigate the negative impacts and ensure close monitoring of the mining activities.

4 Mitigation of Water Pollution Risks

In addition to the large-scale mines, about 15%–20% of gold is extracted by artisanal and small-scale miners without any facilities or mechanical supports. Due to their informal activities, they often do not follow safety and environmental regulations, mainly resulting in cyanide and mercury pollution of water bodies and soils (Ilyas and Lee 2018). Even the highly toxic cyanidation is an industrial process of gold production, whereas the artisanal miners use mercury for dissolving the gold traces from the collected mud, soil, and rocks. As an estimate, about 140 kg of cyanide and a massive consumption of 700 tons of water are required to produce 1 kg of gold (Mudd 2007). The leached cake or slurry often contains waste rocks with heavy metals like arsenic and copper (biodegradation paper), which are stored either in open dumping or within a dam. On the other side, it is estimated that more than 2000 tons of mercury have been released into the Amazon River since the 1980s from mining activities (Malm 1998). Porcella et al. (1997) additionally claim to release 460 tons of mercury per year from small-scale mining alone. Arsenic is another toxicant of greatest concern because of its carcinogenic potential (RAIS 2021). As concentration in freshwater varies in the range of 0.15–0.45 μg/L (Singh et al. 2015), which can exceed in mining environments (Guzmán-Martínez et al. 2020). For example, the Central Andes region of Peru contains 14–23 μg/L of arsenic (Custodio et al. 2020), artisanal gold mine areas of Colombia contain 0.6–52 μg/L arsenic (Alonso et al. 2020), and mine sites in Slovakia contain 0.5–103 μg/L arsenic (Rapant et al. 2006).

Therefore, an effective treatment of mine water, especially in abandoned mines, is desperately sought. However, the current practices of mine water treatment are not ideal as they are based on the composition and volumes of water entering the plant (refer to Fig. 7a). It means that the treatment plant needs to react instantly whenever the volumes or chemistry of mine water change (More et al. 2020). Usually, no interaction is observed between water inflow into the mine, technological changes within the mine, water analyses, and outflow of treated water (More and Wolkersdorfer 2019). Here, the application of digital technologies can have a timely response by interacting with the factors involved, proving the need for a technological solution (as shown in Fig. 7b).

Comparing the past and current mine water treatment practices with the future proposed digitized management of mine water (modified and adopted from More et al. 2020 with copyright permission from Elsevier)

The polluting effect of acid mine drainage is particularly pronounced in the upper catchments of the Blesbokspruit and Klip Rivers in South Africa, which drain the southern Witwatersrand escarpment (Ilyas and Lee 2018). The water discharge of the accumulated volume in the voids of closed gold mines on the Witwatersrand to neighboring mines, generally of low quality, necessitates basic additional treatment by lime to raise the pH and air blowing to oxidize and precipitate the iron and other heavy metals. The iron was allowed to settle and disposed of on tailing dumps while discharging the water into local rivers. Although the water discharge has a neutral pH, it also has a very high sulfate (1500 mg/L) concentration and thus adds more pollution to the load already carried by the rivers in mining areas. The pollution arising from gold mines in the Central and Western Basins is well illustrated by the salinity of the Vaal River; a periodic release of water from Vaal Dam significantly reduces the salinity for downstream Vaal River users.

5 Sustainability in the Artisanal Mining and Amalgamation of Precious Metals

As per the definition of the term “sustainability,” it depends upon the factors like society, environment (including socio-ecological factors), and the economy (related to the cost-effectiveness of the mining activities). Despite the issues in defining a sustainable mining operation, the experiences from the past and current activities can be helpful to design the ideal condition of artisanal mining, which include the following points of:

-

(i)

Positive contribution of ASGM activities in development of rural area and regional empowerment

-

(ii)

Legal framework in harmony with the national mining sector policies

-

(iii)

Operation within international social standards, including the social security, occupational health and safety, and labor laws (that includes child labor), education and medical facilities, etc.

-

(iv)

Environmentally sound operation with scientific and mechanized inputs

-

(v)

Harmony between the small operations and large-scale mining operations

-

(vi)

Ensuring high recovery yield, including a systematic development of the deposits and continuous operation

5.1 Technical Aspects

It has been observed that many problems existing with the artisanal mining can be resolved by the use of appropriate technical solutions. A prominent example can be of mercury emissions in an artisanal practice which can be resolved by using the end-of-pipe technology (involving filter, retort, and trap system). Technological issues often require technical solutions albeit an integral approach is crucial. In contrast to the traditional use of low and non-mechanized activities, the design of new milling and alternative to simple stone mortar amalgamation mills does not involve very high level of technological understanding. Hence, the conventional mining equipment are frequently modified and maneuvered by the miners to fulfill their demands for the high throughput and efficiency; however, in most cases, the suppression of security features are very unfortunate (e.g., water supply for drilling hammers). It is noteworthy that although it remained in practice since several centuries, it has been labeled as an unorganized practice, which makes it imperative to pay attention by the researchers and environmentalists as well.

5.2 Policy and Legal Framework

To achieve sustainability in artisanal mining of precious metals via integrating the rural development with the associated economic benefits, a policy framework development is desirable that can be based on the following strategies (Ilyas and Lee 2018):

-

(i)

Poverty alleviation

-

(ii)

Optimization of the business climate for the small mining sector

-

(iii)

Insurance of sustainability

-

(iv)

Stabilization of government revenues from the sector

Numerous reasons exist for the continuation of artisanal mining within the informal sector, majorly because of less understanding on the legal requirements. Lacking capacity to enforce penalties and to provide benefits, which should be associated with legalization, acts as a further disincentive to miners to be legalized. By recognizing the capability and contribution of the sector in the precious metal mining and metallurgy, the governments need to develop a consistent and holistic approach. In the recent times, the reforms in national policy has initiated the drive toward enabling a legal framework in the countries like Colombia, Peru, South Africa, and Tanzania, mainly beneficial to the sustainable management and exploitation of mineral resources along with the promotion of investment and licensing of the artisanal mining (Ilyas and Lee 2018). Additionally, the organization of this sector as a community or society should be promoted by the local administrations to formalize the informal structures via coordination and a harmonized management of the natural resources.

Currently, in many countries, the mining laws or other legal instruments do not support the development of small industries based on local mining production. This is especially valid for the production of informal artisanal mining activities, which is difficult to integrate into the formal economy. Training resources for healthcare providers that directly address artisanal- and amalgamation-related health issues are scarce. However, case studies, toxicology, and occupational health literature and publications from governmental and nongovernmental organizations do contain or suggest health components that could be developed further for use in this context. By using the principles of fair-trading, small-scale producers in developing countries are given the opportunity to trade their products under better selling terms and conditions. An improved awareness on health hazards is needed to practice a better, healthier, eco-friendly, and sustainable technologies in the mining of precious metals.

6 Conclusions

Looking at the importance of mining, despite the fact that it poses a threat to the environment and human health, this chapter provides a preliminary assessment of the risks associated with the present mining activities of gold involving artisanal, small-scale, and industrial gold mining. It has been found that heavy metals (metalloids) are easily released into the environment through surface water and groundwater contamination and soil and air pollution. Therefore, it is necessary to remediate the polluted mine sites and practice continuous monitoring to restore the ecosystems properly. In addition, the population’s exposure must be restricted to high-risk areas through a communication plan about the risks. The mitigation hierarchy for mining activities is discussed to avoid, reduce, restore and rehabilitate, offset, and enhance communities, along with the proposed strategies for pollution control. For the potential mitigation of the risks, digitized mine water treatment and a compliance program for mine workers have been suggested to achieve the Sustainable Development Goals in the field of primary gold mining.

References

Alberruche del Campo ME, Arranz-González JC, Rodríguez-Pacheco R (2014) Manual Para La Evaluación de Riesgos de Instalaciones de Residuos de Industrias Extractivas Cerradas o Abandonadas, IGME

Alonso DL, Pérez R, Okio CK, Castillo E (2020) Assessment of mining activity on arsenic contamination in surface water and sediments in southwestern area of Santurbán paramo, Colombia. J Environ Manage 264:110478

Arranz-González JC, Rodríguez-Gómez V, Fernández-Naranjo FJ, Vadillo-Fernández L (2021) Assessment of the pollution potential of a special case of abandoned sulfide tailings impoundment in Riotinto mining district (SW Spain). Environ Sci Pollut Res 28:14054–14067

Atanassov I (2008) New Bulgarian soil pollution standards. Soil Chemical Pollution, Risk Assessment, Remediation and Security. Springer, Cham, pp 129–138

Canada-MoE (2011) Soil, ground water and sediment standards for use under Part XV.1 of the Environmental Protection Act. Ministry of Environment and Climate Change

Cervantes Neira JJ, Quito Quilla SJ (2020) Evaluación de riesgo ambiental generado por pasivo ambiental minero en la calidad de agua superficial. Natura@economía 5(1):1–14

Cruzado-Tafur E, Torró L, Bierla K, Szpunar J, Tauler E (2021) Heavy metal contents in soils and native flora inventory at mining environmental liabilities in the Peruvian Andes. J South Am Earth Sci 106:103107

Custodio M, Cuadrado W, Peñaloza R, Montalvo R, Ochoa S, Quispe J (2020, 1946) Human risk from exposure to heavy metals and arsenic in water from rivers with mining influence in the Central Andes of Peru. Water 12(7)

Dong L, Deng S, Wang F (2020) Some developments and new insights for environmental sustainability and disaster control of tailings dam. J Clean Prod 269:122270

EIA Guidelines (2018) Environmental Impact Assessment Guidelines for the Mining Sector. Prepared by Myanmar Mining EIA Guidelines Working Group with the technical assistance of ADB TA 8786-MYA: Environmental Safeguard Institutional Strengthening

FDA (2018) Mercury levels in commercial fish and shellfish (1990–2012). US Food and Drug Administration, Washington, DC

Franco GH, Mero PC, Carballo FM, Narváez GH, Bitar JB, Torrens RB (2020) Strategies for the development of the value of the mining-industrial heritage of the Zaruma-Portovelo, Ecuador, in the context of a Geopark project. Int J Energy Prod Manag 5:48–59

Global Tailing Review (2020) Global industry standard on tailings management

Grebby S, Sowter A, Gluyas J, Toll D, Gee D, Athab A, Girindran R (2021) Advanced analysis of satellite data reveals ground deformation precursors to the Brumadinho Tailings Dam collapse. Communications Earth & Environment 2(1):2

Guzmán-Martínez F, Arranz-González JC, Ortega MF, García-Martínez MJ, Rodríguez-Gómez V (2020) A new ranking scale for assessing leaching potential pollution from abandoned mining wastes based on the Mexican official leaching test. J Environ Manage 273:111139

Haddaway NR, Cooke SJ, Lesser P, Macura B, Nilsson AE, Taylor JJ, Raito K (2019) Evidence of the impacts of metal mining and the effectiveness of mining mitigation measures on social–ecological systems in Arctic and boreal regions: a systematic map protocol. Environ Evid 8(1):9

Hansen RN (2015) Contaminant leaching from gold mining tailings dams in the Witwatersrand basin, South Africa: a new geochemical modelling approach. Appl Geochem 61:217–223

Ilyas S, Kim H, Srivastava RR (2021) Sustainable Urban mining of precious metals.1st edn. CRC Press

Ilyas S, Kim MS, Lee JC (2018) Integration of microbial and chemical processing for a sustainable metallurgy. J Chem Technol 93(2):320–332

Ilyas S, Lee JC (2018) Gold metallurgy and the environment. CRC Press, Taylor & Francis

Kammen DM, Hassenzahl DM (2001) Should we risk it?: exploring environmental, health, and technological problem solving. Princeton University Press, Princeton

Kamunda C, Mathuthu M, Madhuku M (2016) Health risk assessment of heavy metals in soils from Witwatersrand Gold Mining Basin, South Africa. Int J Environ Health Res 13(7):663

Lam EJ, Cánovas M, Gálvez ME, Montofré ÍL, Keith BF, Faz Á (2017) Evaluation of the phytoremediation potential of native plants growing on a copper mine tailing in northern Chile. J Geochem Explor 182:210–217

Li T, Liu Y, Lin S, Liu Y, Xie Y (2019) Soil pollution management in China: a brief introduction. Sustainability 11(3):556

Malm O (1998) Gold mining as a source of mercury exposure in the Brazilian amazon. Environ Res 77(2):73–78

Marcantonio RA, Field SP, Sesay PB, Lamberti GA (2021) Identifying human health risks from precious metal mining in Sierra Leone. Reg Environ Chang 21:1–12

Marsden DD (1986) The current limited impact of Witwatersrand gold-mine residues on water pollution in the Vaal River system. J South Afr Inst Min Metall 86(12):481–504

MINAM (2010) Guía de Evaluación de Riesgos Ambientales. MINAM, Magdalena del Mar, Peru

More K, Wolkersdorfer C (2019) Disruptive technologies in mine water management–the future. In: Wolkersdorfer C, Khayrulina E, Polyakova S, Bogush A (eds) Mine water–technological and ecological challenges. Perm, pp 597–602

More KS, Wolkersdorfer C, Kang N, Elmaghraby AS (2020) Automated measurement systems in mine water management and mine workings—a review of potential methods. Water Resour Ind 24:100136

Mudd GM (2007) Global trends in gold mining. Resour Policy 32(1–2):42–56

Ngole-Jeme VM, Fantke P (2017) Ecological and human health risks associated with abandoned gold mine tailings contaminated soil. PloS One 12(2):e0172517

Naicker K, Cukrowska E, McCarthy TS (2003) Acid mine drainage arising from gold mining activity in Johannesburg, South Africa. Environs Environ Pollut 122(1):29–40

Ouellet SM, Dettmer J, Olivier G, DeWit T, Lato M (2022) Advanced monitoring of tailings dam performance using seismic noise and stress models. Commun Earth Environ 3(1):301

Paniagua-López M, Vela-Cano M, Correa-Galeote D, Martín-Peinado F, Garzón FM, Pozo C, González-López J, Aragón MS (2021) Soil remediation approach and bacterial community structure in a long-term contaminated soil by a mining spill (Aznalcóllar, Spain). Sci Total Environ 777:145128

Popovic V, Miljkovic J, Subic J, Jean-Vasile A, Adrian N, Nicolăescu E (2015) Sustainable land management in mining areas in Serbia and Romania. Sustainability 7:11857–11877

Porcella DB, Ramel C, Jernelov A (1997) Global mercury pollution and the role of gold mining. Water Air Soil Pollut 97(3–4):205–207

RAIS (2021) Toxicity profiles. Risk Assessment Information System

Rapant S, Dietzová Z, Cicmanová S (2006) Environmental and health risk assessment in abandoned mining area, Zlata Idka, Slovakia. Environ Geol 51:387–397

Rivera-Parra JL, Beate B, Diaz X, Ochoa MB (2021) Artisanal and small gold mining and petroleum production as potential sources of heavy metal contamination in Ecuador: a call to action. Int J Environ Res Public Health 18:2794

Rodríguez-Eugenio N, McLaughlin M, Pennock D (2018) Soil pollution: a hidden reality. FAO

SA-DEA (2010) The framework for the management of contaminated land, South Africa. Republic of South Africa Department of Environmental Affairs, Cape Town

Salgado-Almeida B, Falquez-Torres DA, Romero-Crespo PL, Valverde-Armas PE, Guzmán Martínez F, Jiménez-Oyola S (2022) Risk assessment of mining environmental liabilities for their categorization and prioritization in gold-mining areas of Ecuador. Sustainability 14:6089

SENAGUA (2011) Informe Técnico Muestreo y Análisis de La Calidad Del Agua En La Cuenca Del Río Puyango. SENAGUA, Quito, Ecuador

Singh R, Singh S, Parihar P, Singh VP, Prasad SM (2015) Arsenic contamination, consequences and remediation techniques: a review. Ecotoxicol Environ Saf 112:247–270

Srivastava RR, Rajak DK, Ilyas S, Kim H, Pathak P (2023) Challenges, regulations, and case studies on sustainable management of industrial waste. Fortschr Mineral 13(1):51

Tóth G, Hermann T, Da Silva MR, Montanarella L (2016) Heavy metals in agricultural soils of the European Union with implications for food safety. Environ Int 88:299–309

UK-DoE (2009) Contaminated land exposure assessment: heavy metal guidelines in soil, UK. UK Department of Environment

US-EPA (2011) Default use of body weight 3/4 as the default method in derivation of the oral reference dose. US Environmental Protection Agency, Washington, DC

US-EPA (2014) Framework for human health risk assessment to inform decision making. US Environmental Protection Agency, Washington, DC

US-EPA (2018) Regional screening levels (RSLs)—resident soil tables [data and tools]. US Environmental Protection Agency

US-EPA (2019) EPA facts about thorium. US Environmental Protection Agency, Washington, DC

USEPA (1998) Ecological risk assessment guidance for superfund: process for designing and conducting risk assessments. USEPA, Washington, DC

Vela-García N, Guamán-Burneo MC, González-Romero NP (2019) Efficient bioremediation from metallurgical effluents through the use of microalgae isolated from the Amazonic and highlands of Ecuador. Rev Int Contam Ambient 35:917–929

Acknowledgments

The authors SI and HK acknowledge their contributions through the Basic Science Research Program, National Research Foundation of Korea (NRF), funded by the Ministry of Education (Project no. 2023-00243477), and grant funded by the Korea Government (MSIT) (No. 2022R1A5A1032539).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Ilyas, S., Kim, H., Pathak, P., Srivastava, R.R. (2023). Risk Assessment from Primary Mining of Precious Metal (Gold) and Possible Mitigation Route. In: Pathak, P., Srivastava, R.R., Ilyas, S. (eds) Anthropogenic Environmental Hazards. Springer, Cham. https://doi.org/10.1007/978-3-031-41013-0_1

Download citation

DOI: https://doi.org/10.1007/978-3-031-41013-0_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-41012-3

Online ISBN: 978-3-031-41013-0

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)