Zusammenfassung

Turbocharger (TC) bearing friction mostly affects the “low speed” operation of the turbocharger and is therefore relevant for the transient response and part load emissions of modern combustion engines. Further optimization of TC friction has to be supported by sophisticated simulation tools to shorten developmental time and reducing the costs for prototyping and testing.

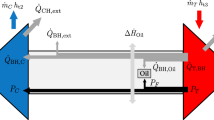

In this paper, a detailed analysis on the mechanical losses occurring in the bearing system of automotive turbochargers is presented. The measurement data is obtained using FEV’s unique test bench customized for TC bearing friction analysis. Friction losses have been measured experimentally up to rotational speeds of 120 000 1/min. Special focus was placed on the thrust bearing characteristics and its contribution to total friction losses. This information is used to validate a modern simulation tool. Furthermore, the current potential and limits of the existing simulation methods are described. The state-of-the-art simulation method shown in this paper is based on elastic-multi-body simulation and elasto-hydrodynamic bearing approaches. The aim is to investigate rotor dynamics, load bearing capacity and friction losses in an integrated simulation environment.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

Literatur

[1] H. Nguyen-Schäfer, Rotordynamics of Automotive Turbochargers, Berlin Heidelberg: Springer-Verlag, 2012.

[2] N. Baines, „Fundamentals of Turbocharging,“ Concepts NREC, 2005.

[3] S. Schmitt, „Untersuchungen zum Reibleistungsverhalten von Wellen-Lagerungen für PKW-Abgasturbolader,“ Dissertation, Universität Stuttgart, 2007.

[4] B. Hoepke, T. Uhlmann, S. Pischinger, B. Lueddecke und D. Filsinger, „Analysis of Thrust Bearing Impcact on Friction Losses in Automotive Turbochargers,“ in J. Eng. Gas Turbines Power 137(8), ASME, 2015.

[5] D. Dowson, „A generalized Reynolds equation for fluid-film lubrication,“ International Journal of Mechanical Sciences 4, pp. 159-170, 1962.

[6] A. Rienäcker, „Instationäre Elastohydrodynamik von Gleitlagern mit rauhen Oberflächen und inverse Bestimmung der Warmkonturen,“ Dissertation, RWTH Aachen, 1995.

[7] V. Lagemann, „Numerische Verfahren zur tribologischen Charakterisierung bearbeitungsbedingter rauher Oberflächen bei Mikrohydrodynamik und Mischreibung,“ Dissertation, Universität Kassel, 2000.

[8] J. A. Greenwood und J. H. Tripp, „The Contact of Two Nominally Flat Rough Surfaces,“ Proceedings of the Instution of Mechanical Engineers 185, pp. 625-633, 1970.

[9] J. W. Daily und R. E. Nece, „Chamber Dimension Effects on Induced Flow and Frictional Resistance of Enclosed Rotating Disks,“ ASME Journal of Basic Engineering, 1960.

[10] M. Deligant, P. Podevin und G. Descombes, „Experimental identification of turbocharger mechanical friction losses,“ Journal of Energy, pp. 388-394, 2012.

[11] M. Deligant, P. Podevin und G. Descombes, „CFD model for turbocharger journal bearing performances,“ Journal of Applied Thermal Engineering, pp. 811-819, 2011.

[12] F. Shi und D. Deng, „An Analysis for Floating Bearings in a Turbocharger,“ SAE Technical Paper 2011-01-0375, 2011.

[13] L. San Andres, J. C. Rivadeneira, K. Gjika, C. Groves und G. LaRue, „Rotordynamics of Small Turbochargers Supported on Floating Ring Bearings—Highlights in Bearing Analysis and Experimental Validation,“ Journal of Tribology 129(2), pp. 391-397, 2006.

[14] L. San Andres, J. C. Rivadeneira, K. Gijka, C. Groves und G. LaRue, „A Virtual Tool for Prediction of Turbocharger Nonlinear Dynamic Response Validation Against Test Data,“ Journal of Engineering for Gas Turbines and Power 129(4), pp. 1035-1046, 2006.

[15] L. San Andres und J. Kerth, „Thermal effects on the performance of floating ring bearings for turbochargers,“ Proc. Instn Mech. Engrs. Vol. 218 Part J: Journal of Engineering Tribology, pp. 437-450, 2004.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Fachmedien Wiesbaden GmbH, ein Teil von Springer Nature

About this paper

Cite this paper

Perge, J., Hoepke, B., Uhlmann, T., Dohmen, J., Lehmann, J. (2018). Turbocharger Bearing Friction Measurement and Simulation. In: Liebl, J. (eds) Reibungsminimierung im Antriebsstrang 2015. Proceedings. Springer Vieweg, Wiesbaden. https://doi.org/10.1007/978-3-658-23189-7_9

Download citation

DOI: https://doi.org/10.1007/978-3-658-23189-7_9

Published:

Publisher Name: Springer Vieweg, Wiesbaden

Print ISBN: 978-3-658-23188-0

Online ISBN: 978-3-658-23189-7

eBook Packages: Computer Science and Engineering (German Language)