Abstract

Hydrated mineral trioxide aggregate (MTA) is composed of calcium silicate hydrate, calcium hydroxide, ettringite, monosulphate and bismuth oxide together with unreacted tricalcium and dicalcium silicate. The presence of calcium hydroxide, which is usually leached out of the material, renders MTA reactive and thus susceptible to changes as a result of the environment in which it is placed. The specific alterations to the material will vary depending on its use and thus its relationship with other materials, tissues and fluids.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

5.1 Introduction

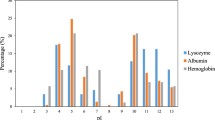

Hydrated mineral trioxide aggregate (MTA) is composed of un-hydrated cement particles, which acts as a core around which a reaction rim of hydration products is formed (Fig. 2.5). When mixed with water, the tricalcium and dicalcium silicate react forming calcium silicate hydrate (honeycomb appearance) and calcium hydroxide (hexagonal plates) (Fig. 2.6), which is leached in solution. The presence of calcium hydroxide has been verified by X-ray diffraction analysis as it produces a typical peak for portlandite at 18° 2θ (Fig. 2.9), whilst the leaching of calcium has been measured by inductively coupled plasma. The particular microstructure of MTA and the presence of calcium hydroxide in solution make the material susceptible to environmental factors. The use of MTA brings it into contact with other materials, tissues and fluids, and a number of changes occur within or on the surface of the material in various environmental conditions.

5.2 Effect of Environmental Factors on the Set Material

MTA has a variety of applications mostly in Endodontics. These various uses have been discussed [60] and are outlined in Chap. 6.

5.2.1 Dental Materials

5.2.1.1 Glass Ionomer

Covering MTA with glass ionomer cement when it is used as a pulp capping agent results in physical changes to the materials at their interface (Fig. 5.1a). A sizable gap has been observed at the interface attributed to the movement of water out of MTA into the glass ionomer. This movement of water out of MTA can inhibit its hydration and increases its porosity [9]. There is no evidence that covering MTA with a glass ionomer has an effect on the glass ionomer cement itself with regard to setting time and setting reaction [5, 36]. However, migration of strontium from glass ionomer to MTA has been observed [9], although its effects are unknown.

(a) Interaction of glass ionomer cement with MTA leading to failure of glass ionomer and (b) layering of MTA with zinc oxide eugenol with a resultant retardation of setting of MTA (Reprinted from Camilleri [9], copyright 2011, with permission from Elsevier)

5.2.1.2 Base Materials

Zinc oxide eugenol-based cements are used as temporary filling materials and come into contact with MTA when it is used for pulp capping. Zinc is a retarder of cement hydration [47], and zinc salts form calcium hydrozincate (Ca(Zn(OH)3H2O)2), an insoluble hydroxide in alkaline solution that creates a coating on MTA particles. In addition, zinc oxide retards the hydration of tricalcium silicate, although it does not interfere with the tricalcium aluminate/gypsum reaction. Zinc is incorporated into the calcium silicate hydrate gel phase [46], and the migration of zinc from zinc oxide cement into MTA has been reported. Furthermore, MTA in contact with intermediate restorative material (IRM) (Dentsply Caulk, Milford, DE, USA) exhibits a high degree of porosity resulting from incomplete hydration (Fig. 5.1b) [9].

5.2.1.3 Composite

The shear bond strengths of different composite adhesive systems to white MTA has been compared [6] with the conclusion that an etch-and-rinse adhesive system was preferred when placing compomer materials upon white MTA because it exhibited significantly higher shear bond strength values than self-etch adhesive systems. MTA used as pulp capping material necessitates the layering of MTA with composite for immediate restoration of the tooth. The use of bonding agent has been shown to reduce gaps at the material interface. Contact with both bonding agent and composite can reduce the micro-hardness of MTA in the early stages of its hydration [65].

5.2.2 Intra-canal Medicaments

When used inside the root canal for furcal repair and apexification procedures, MTA may come into contact with medicaments such as non-setting calcium hydroxide paste. No consensus has been reached on whether the calcium hydroxide in medicaments affects the sealing ability of MTA [20, 58]. However, calcium hydroxide does create an alkaline environment, which increases the porosity and un-hydrated microstructure of MTA [49], although no microstructural changes have been observed within MTA following contact with calcium hydroxide paste. On the other hand, migration of silicon and aluminium from MTA into calcium hydroxide medicaments has been observed [9].

5.2.3 Intra-canal Solutions

5.2.3.1 Bleaching Agents

MTA has been reported to be more easily displaced when in contact with sodium perborate mixed with saline, Superoxol (Sultan Healthcare, Hackensack, New Jersey, USA), and sodium perborate mixed with Superoxol, whereas IRM was not affected by the treatments used clinically for tooth bleaching [34]. Bleaching agents have also been shown to affect the elemental distribution of MTA [64]. A decrease in calcium and an increase in silicon were observed, and this tendency was especially pronounced when higher concentrations of hydrogen peroxide were used. The acidic conditions induced by bleaching agents also deteriorate the surface of MTA. Overall, these findings suggest that MTA is not an effective barrier during tooth bleaching and should be protected by a more suitable material.

5.2.3.2 Chelators

Calcium chelators used as irrigating solutions affect the strength and microstructure of MTA. It has been reported that ethylenediaminetetraacetic acid (EDTA) significantly reduced the hardness and flexural strength of MTA compared with distilled water. Indeed, when in contact with EDTA, set MTA had a reduced Ca/Si molar ratio, a reduced calcium hydroxide production, lack of biocompatibility and reduced micro-hardness [31]. Therefore, after use of EDTA in the root canal system, a final flush with distilled water is advocated before placement of MTA [1]. EDTA and BioPure MTAD (Dentsply, Tulsa Dental Specialities, Tulsa, Oklahoma, USA) decreased the sealing efficacy of MTA 24 h after placement to suggest it may be beneficial to seal furcal repair sites where MTA has been used with a protective lining material before commencement of chemo-mechanical root canal preparation [66].

5.2.3.3 BioPure MTAD

BioPure MTAD-treated MTA surfaces exhibit greater surface roughness and more calcium loss when compared with EDTA treatment. Decomposition of the particle-binding hydration phases by acid erosion raises potential concern over the strength and sealing properties of MTA-repaired perforations following final irrigation using BioPure MTAD [57]. The seal of MTA used to repair root perforations has been reported to be negatively affected by irrigating solutions. Fluid conductance was affected by the type of irrigating regime used with mixtures of sodium hypochlorite and EDTA/MTAD resulting in increased leakage using the fluid filtration method to assess sealing ability of MTA [66].

5.2.3.4 Sodium Hypochlorite

NaOCl is used routinely as an irrigant in root canal treatment. Interestingly, its interaction with MTA has not been investigated extensively. However, NaOCl has been shown to enhance the push-out bond strength of MTA in the early stages of hydration [26]. MTA exhibits dark brown discoloration in contact with sodium hypochlorite solution [10], (Fig. 5.2). It is postulated that since sodium hypochlorite is reduced to sodium chloride, the oxygen present can destabilise the bismuth oxide in MTA rendering it reactive with the atmospheric carbon dioxide to be converted to bismuth carbonate, which is light sensitive and thus turns black when exposed to light. The sensitivity of MTA to different light sources has been demonstrated [67, 68].

5.2.4 Root Canal Sealers

MTA in contact with formaldehyde exhibits black discolouration Marciano MA, Hungaro Duarte MA University of Bauru (Personal Communication). Formaldehyde is released from resin-based sealers containing hexamethylenetetramine, such as AH 26, and Sealer 26 as a result of a chemical reaction between bisphenol A resin and hexamethylenetetramine.

5.2.5 Acid Etching

It is well known that exposure of MTA to a low pH environment will influence its physical and chemical properties [14, 70]. It is therefore not surprising that in the laboratory environment application of acid etch has adverse effects in the short term, on the push-out bond strength [56], porosity, micro-hardness [37] and compressive strength [28] of MTA, suggesting it would be better to postpone restorative procedures to allow more advanced hydration of the cement. Over longer time periods after placement, the application of etchants on some brands of MTA does not appear to affect its compressive strength [29]; however, other brands were more susceptible to etchant and have a reduced strength.

Following the laboratory evaluation of acid etchant on various materials [44], it was concluded that etching of MTA did not improve its shear bond strength to composite resin and that the surface etching of MTA was not necessary prior to composite placement using a total-etch adhesive resin. Furthermore, it is advised that when MTA is used in vital pulp therapies, it is better to cover the material with glass ionomer cement. However, it must be emphasised that these reports are based on laboratory investigations and that clinical trials have not been reported on the use and effects of acid etchant on MTA in a clinical setting.

The effects of exposing MTA to acid etching have been demonstrated by SEM analysis. In general, a selective loss of matrix from around the crystalline structures of MTA has been observed resulting in a relatively uniform ‘honeycomb’ pattern without penetrating deeply or removing substantial amounts of cement. In addition, etching has revealed crystalline structures such as plate-shaped and laminated crystals on the MTA surface; however, needlelike crystals have been reported to be missing (Fig. 5.3a, b) [28]. Further investigation on the material microstructure after exposure to acid etch in order to identify crystal morphology is necessary. The significance of these morphological changes is unclear.

(a) Intact surface of unetched mineral trioxide aggregate after 24 h. Irregular needlelike crystals that cover globular formulations (a) and cross sections of several micro-channels (b) can be seen (mag. 500×). (b) Etched enamel surface after 24 h. Selective loss of matrix from around the crystalline structures and relatively uniform honeycomb etched pattern with minimal loss of the cement can be seen. No needlelike crystals were observed (mag. 500×) (Reprinted with permission from Kayahan et al. [28]. © 2009 International Endodontic Journal)

5.2.6 Blood

The contamination of MTA by blood has been investigated in a number of laboratory studies in terms of the effect on its physical properties, leakage, displacement, marginal adaptation and colour. There is little doubt that blood contamination on the surface of MTA and, in particular, when incorporated into the material is detrimental to its hydration and thus its ultimate physical properties and performance. Unfortunately, MTA is often placed in contact with vital tissues that ooze blood/serum (pulp capping) or in situations where blood pools on its surface (root-end filling), and the impact of blood contamination is important and must be minimised.

5.2.6.1 Physical Properties

Mixing MTA with blood has a negative effect on its surface hardness, microstructure [41] and compressive strength [42]. Essentially, it has been reported that when blood becomes incorporated into MTA, its compressive strength is reduced with the result that in clinical situations in which blood becomes mixed with MTA, its physical properties are likely to be compromised [42], even when used with accelerators [43]. Similar effects have been reported when foetal bovine serum was used to contaminate the surface of MTA [30].

The hydration state of MTA mixed with blood has also been reported [39] with specimens partially mixed with blood being more completely hydrated than those mixed entirely with blood and less than specimens hydrated completely with water. Lack of formation of the crystalline calcium hydroxide in the early stage of the hydration process and the absent of acicular crystals, characteristic of ettringite crystals, in blood-contaminated specimens are common findings (Fig. 5.4).

Scanning electron microscopy images of mineral trioxide aggregate specimens mixed entirely with water (a), partially (b) and entirely (c) with whole, fresh human blood. Porosity (i) and presence of cross sections of micro-channels (ii) can be observed (Reprinted with permission from Nekoofar et al. [39]. © 2011 International Endodontic Journal)

5.2.6.2 Leakage

In laboratory studies, it has been reported that blood contamination of the surface of MTA increases leakage of root-end fillings when using tracer dyes [25]. An earlier study did not exhibit any leakage when root-end restorations were contaminated with blood and leakage was assessed using dyes [63].

5.2.6.3 Displacement

The push-out bond strength of MTA in the presence of blood contamination when used as a perforation repair material has been shown to be reduced [2, 69]. Conversely, other researchers reported increased values [45].

5.2.6.4 Marginal Adaptation

It has been reported that exposure to blood during setting has a negative effect on marginal adaptation of MTA [52].

5.2.6.5 Colour

Contamination of MTA with blood has been shown to have an adverse effect on tooth colour [33].

In summary, it is likely that the detrimental effects of blood on MTA will have a negative impact on its physical characteristics and thus on its performance in a variety of laboratory tests. From a clinical perspective it seems sensible to avoid blood contamination if possible.

5.2.7 Bone Grafting Materials

Demineralised and mineralised graft materials appear to have a differential effect on the micro-hardness of white MTA. White MTA micro-hardness values when in contact with Bio-Oss (Geistlich Pharma, Princeton, New Jersey, USA), MinerOss (BioHorizons, Markham, Ontario, Canada) and Puros (Zimmer Dental, Carlsbad, California, USA) have been reported to be lower than those for OraGraft (Salvin Dental Specialities, Charlotte, North Carolina, USA) and control groups regardless of incubation period [53].

5.2.8 Variable pH

A number of laboratory studies have evaluated the physical properties of MTA specimens following exposure to a range of acidic environments during hydration on the basis that in some situations the tissues or fluids that come into contact with MTA are acidic. The mean pH of pus from periapical abscesses was generally acidic, although some samples were neutral and some were alkaline [40]. It has been reported that surface hardness of MTA was reduced in an acidic environment [37] as is push-out strength [56]. Leakage of root-end fillings has also been reported to be affected by low pH [50]. The effect of acidic environment on the dislodgement resistance of MTA when used as a perforation repair material has been compared, and it was concluded that its dislodgment resistance was significantly reduced after exposure to acid [23]. Alkaline pH has also been reported to have a negative impact on push-out strength [51], surface hardness and porosity [49].

5.2.9 Saliva

Since MTA is known to have relatively poor physical properties in terms of strength and wear resistance, it has never been recommended for use when in contact with saliva. Thus, the contamination of MTA with saliva is unlikely in most situations, but may occur if the material is used to repair perforations that communicate with the mouth, i.e. in perforations occurring within periodontal pockets. Despite this, a number of laboratory studies have been conducted on salivary contamination of MTA with conflicting results. It has been reported that saliva reduces [24], increases [36] or has no effect [25] on leakage of MTA when used as a root-end filling material. The leakage of MTA when exposed to saliva and used as an orifice barrier [71] and an orthograde filling material [3] has also been evaluated with conflicting results. Overall, it must be remembered that the validity of leakage studies has been questioned and the conclusions of these and other similar studies are likely to be meaningless.

5.2.10 Tissue Fluid and Simulated Tissue Fluid

Mineral trioxide aggregate used as a root-end filling comes into contact with tissue fluid before complete hydration is achieved. When MTA is in contact with tissue fluid, the setting time is extended and in certain cases the material may not set at all [11, 19]. Immersion in tissue fluid has been reported to result in incomplete setting of MTA as the presence of phosphates in solution retards its hydration. The retardation is induced by the formation of insoluble hydroxides in the alkaline solution. The insoluble hydroxides form a coating over the cement particles. The adsorption of phosphate ions on the surface of the clinker phase or on the hydration product is thought to result in the precipitation of calcium phosphates [46]. Glucose, which is present in Hank’s balanced salt solution, is also a known retarder of cement hydration [46].

The retardation of setting is apparent under the scanning electron microscope when the surface microstructure of MTA in contact with Hank’s balanced salt solution was investigated. MTA in contact with simulated body fluid exhibits no evidence of hydration (Fig. 5.5). The cement in contact with simulated body fluid exhibits micro-cracking, which is caused by expansion of the cement [11].

Scanning electron micrographs of MTA stored in different environmental conditions (a, b) dry, (c, d) immersed in water (e, f) immersed in HBSS. (a, c, e) Depict the outer region whilst (b, d, f) the core region (Reprinted from Camilleri et al. [11]. © 2013 International Endodontic Journal. Published by John Wiley & Sons Ltd)

When set MTA is stored in Hank’s balanced salt solution, the pH of the storage solution becomes less alkaline. This could be due to the presence of buffers in simulated body fluids. These buffers are added to these solutions to maintain their pH. Regardless of the less alkaline pH, calcium ion release has been demonstrated in Hank’s balanced salt solution. The leaching of calcium is higher in simulated body fluid than in distilled water both when tested after 1 day of immersion and at 28 days of material contact with the solution [8, 17].

The compressive strength of MTA stored in Hank’s balanced salt solution is lower than when stored in a humid environment or immersed in water [18]. The dimensional stability of MTA in contact with different soaking solutions has been investigated and a net expansion has been reported when the materials were placed in contact with physiological solutions [8, 59]. MTA materials achieved approximately half of their final linear setting expansion by 300 min, with approximately 75 % of expansion occurring by 460 min and the final 25 % of total expansion occurring between 460 min and 24 h [59].

5.2.11 Effect on Dentine and Pulp

MTA releases calcium hydroxide as a by-product of hydration. The calcium hydroxide has a beneficial effect on the pulp, and dentine bridge formation has been reported. Random controlled clinical trials have shown that MTA is associated with the best clinical outcomes when used as a pulp capping material and for apexification/apexogenesis procedures (as discussed in Chap. 3; Table 3.1). The metallic ions released by set and setting MTA when placed clinically, may release dentine matrix components that potentially influence cellular events for dentine repair and regeneration [61].

When in contact with dentine, MTA altered the toughness more than the strength and stiffness of dentine after ageing in 100 % relative humidity. Dentine toughness is attributed to its collagen matrix; thus, MTA seems to affect the dentine collagen matrix [54]. Prolonged contact of mineralised dentine with MTA has an adverse effect on the integrity of the dentine collagen matrix. However, the amount of collagen extracted was limited to the contact surface. Clinicians are thus advised to use MTA with caution when it is applied to thin dentinal walls [32].

Along the material-dentine interface, MTA forms a taglike structure that is composed of either Ca- and P-rich crystalline deposits or the material itself. The width of a Ca- and Si-rich layer detected along the dentine layer of the material-dentine interface increases over time [21]. The selective diffusion of silicon, calcium and phosphorous across the cement-dentine interface has been demonstrated [16]. The movement of calcium is difficult to show using scanning electron microscopy and elemental mapping since calcium is present in both the material and dentine. However, elemental migration is clearly shown across the interface (Fig. 5.6). Together with calcium, silicon and phosphorus, migration of bismuth is also evident. Migration of bismuth into dentine can be problematic as bismuth oxide has been shown to react with collagen resulting in a change in colour of both MTA and the tooth [35] (Fig. 5.7).

(a) Labial surface of bovine tooth filled with MTA showing grey staining highlighted in the dotted rectangle; (b) section through tooth showing marked dentin staining. The dark discolouration was concentrated near dentin surface (Reprinted from Marciano et al. [35])

5.2.12 Chemical Reagents

Subjecting MTA to phosphate-buffered glutaraldehyde, a reagent used routinely for fixing cells in biocompatibility studies, results in the production of calcium phosphate crystals, which are deposited on the MTA surface [12]. The structure of set MTA is severely affected when subjected to acidic dyes such as rhodamine B used to test its sealing ability. The use of rhodamine B as a tracer increased the apparent leakage of MTA as the acidity affected the material and the dye preferentially passed into and through it rather than along the tooth to material interface [14]. Furthermore, subjecting MTA to critical point drying, which is also a routine procedure used to dry cells for biocompatibility studies using osteoblasts, results in changes to the MTA surface. Critical point drying uses high temperatures, pressure and carbon dioxide to dry the material. This reacts with the calcium hydroxide depositing calcium carbonate over the MTA surface. Due to the low pressure, the calcium carbonate is deposited in various crystalline forms, namely, as calcite vaterite and aragonite [13]. Changes on the surface of set MTA have also been reported in the presence of foetal bovine serum with the material surface having a homogenous distribution of chemicals and a relatively smooth globular appearance. The surface of the MTA/water was biphasic, containing large hexagonal crystalline plates composed of calcium embedded in a pool of globular crystals [60]. In addition, a recent study investigating the setting of MTA Angelus and ProRoot MTA in the presence of foetal bovine serum demonstrated a lack of hydration in contact with the solution [30]. The micro-hardness of MTA was adversely affected when the material was placed in contact with foetal bovine serum [27]. The glucose leakage model was shown to be inappropriate for use with MTA and related materials as MTA reacts with the glucose thus producing erroneous results for sealing ability [55].

5.2.13 Exposure to Air and Distilled Water

The calcium hydroxide produced as a by-product of hydration is susceptible to reaction when exposed to air and water or other liquids. When MTA is placed in water, it leaches calcium ions in solution [7] and the surface is modified. When viewed under the scanning electron microscope, MTA pastes show patterns of leaching, which are not uniform throughout the material surface. The surface area in contact with the fluid is strongly leached with no calcium hydroxide present and the calcium silicate hydrate is substantially decalcified (Fig. 5.8a). In the region approximately 200 μm from the surface, the leaching is less evident (Fig. 5.8b) [7]. Humidity significantly increased the push-out strength of MTA fillings [19].

Cross section through hydrated MTA showing (a) the surface area in contact with the fluid that was strongly leached with no calcium hydroxide present and the calcium silicate hydrate was strongly decalcified; (b) less leaching evident in the region approximately 200 μm from the surface. PC: cement particle; CH: calcium hydroxide; C-S-H: calcium silicate hydrate; Bi: bismuth oxide (Reprinted with permission from Camilleri [7]. © 2008 International Endodontic Journal)

MTA immersed in saline solution exhibits no crystalline deposits on its surface [4]. In distilled water, the material surface exhibits cubic crystals containing approximately 17 % calcium, 66 % oxygen and 17 % carbon. Phase analysis has revealed the presence of calcium hydroxide in the precipitate as well as calcium carbonate [22]. The surface carbonation of MTA exposed to air in humid conditions has not been well documented. This phenomenon is well known in the concrete industry where concrete structures undergo surface carbonation. Carbonation occurs on the surface of a Portland cement-based material when the carbon dioxide present in the air reacts with the calcium hydroxide produced by the cement with calcium carbonate being deposited over the surface (Fig. 5.9). Clinically, this would imply that the material surface is likely to be modified with less calcium hydroxide being available for reaction with tissue fluid. In summary, it is important to avoid surface carbonation of MTA.

5.2.14 Storage Temperature

Set MTA surface hardness is affected by storage temperature with lower temperatures leading to a decreased micro-hardness value. More voids and a disorganised flake-like topography were observed in specimens stored at 4 °C in comparison with those stored at 25 and 40 °C. Phase analysis evaluated by X-ray diffraction revealed differences in the material stored at low temperatures [48] with a reduction in peak intensity at 29.3° 2θ using a copper tube. The reduction in intensity was caused by a decreased amount of calcium silicate hydrate since the hydration process slows down at lower temperatures. Since calcium silicate hydrate is amorphous, a reduction in peak intensity at 29.3° 2θ would imply hydration of the tricalcium silicate to calcium silicate hydrate rather than the opposite. A reduction in temperature would in fact slow down the hydration process [15]. The slowing down of hydration was evident from the absence of the portlandite peak at 18° 2θ which was not reported by the authors [48]. The low temperatures also reduced the production of calcium hydroxide.

5.3 Conclusions

Set mineral trioxide aggregate is composed primarily of calcium silicate hydrate, calcium hydroxide and bismuth oxide with some minor inclusions of ettringite and monosulphate phases. Both the presence of calcium hydroxide and bismuth oxide present in the set material affect the reactivity of MTA. The multifaceted clinical use of MTA brings the material in contact with other materials used in both Restorative Dentistry and Endodontics together with the different environment it is placed in during use, namely, blood and tissue fluid when used as a root-end filling material and the temperature and pH of the environment. MTA is adversely affected mostly by the different environmental factors and contact with dental materials exhibiting reduced or incomplete hydration, increased porosity, retardation of setting, reduced strength and micro-hardness and reduced sealing ability. In turn, MTA reduces dentine toughness as it affects the integrity of the dentine collagen matrix. The bismuth oxide causes both material and tooth discolouration. MTA is also adversely affected by materials used in in vitro testing demonstrating retardation in setting and surface carbonation.

References

Aggarwal V, Jain A, Kabi D. In vitro evaluation of effect of various endodontic solutions on selected physical properties of white mineral trioxide aggregate. Aust Endod J. 2011;37(2):61–4.

Aggarwal V, Singla M, Miglani S, Kohli S. Comparative evaluation of push-out bond strength of ProRoot MTA, Biodentine, and MTA Plus in furcation perforation repair. J Conserv Dent. 2013;16(5):462–5.

Al-Hezaimi K, Naghshbandi J, Oglesby S, Simon JH, Rotstein IJ. Human saliva penetration of root canals obturated with two types of mineral trioxide aggregate cements. J Endod. 2005;31(6):453–6.

Asgary S, Eghbal MJ, Parirokh M, Ghoddusi J. Effect of two storage solutions on surface topography of two root-end fillings. Aust Endod J. 2009;35(3):147–52.

Ballal S, Venkateshbabu N, Nandini S, Kandaswamy D. An in vitro study to assess the setting and surface crazing of conventional glass ionomer cement when layered over partially set mineral trioxide aggregate. J Endod. 2008;34:478–80.

Bayrak S, Tunç ES, Saroğlu I, Eğilmez T. Shear bond strengths of different adhesive systems to white mineral trioxide aggregate. Dent Mater J. 2009;28(1):62–7.

Camilleri J. Characterization of hydration products of mineral trioxide aggregate. Int Endod J. 2008;41:408–17.

Camilleri J. Evaluation of the effect of intrinsic material properties and ambient conditions on the dimensional stability of white mineral trioxide aggregate and Portland cement. J Endod. 2011;37:239–45.

Camilleri J. Scanning electron microscopic evaluation of the material interface of adjacent layers of dental materials. Dent Mater. 2011;27:870–8.

Camilleri J. The color stability of white mineral trioxide aggregate in contact with sodium hypochlorite solution. J Endod. 2014;40(3):436–40.

Camilleri J, Formosa L, Damidot D. The setting characteristics of MTA Plus in different environmental conditions. Int Endod J. 2013;46(9):831–40.

Camilleri J, Montesin FE, Brady K, Sweeney R, Curtis RV, Pitt Ford TR. The constitution of mineral trioxide aggregate. Dent Mater. 2005;21:297–303.

Camilleri J, Montesin FE, Papaioannou S, McDonald F, Pitt Ford TR. Biocompatibility of two commercial forms of mineral trioxide aggregate. Int Endod J. 2004;37:699–704.

Camilleri J, Pitt Ford TR. Evaluation of the effect of tracer pH on the sealing ability of glass ionomer cement and mineral trioxide aggregate. J Mater Sci Mater Med. 2008;19:2941–8.

Taylor HFW. Chapter 11: Admixtures and special uses of cements. In: Cement chemistry. 2nd ed. London: Thomas Telford Publishing; 1997. p. 341.

Formosa LM, Damidot D, Camilleri J. Mercury intrusion porosimetry and assessment of cement-dentin interface of anti-washout type mineral trioxide aggregate. J Endod. 2014 10.1016/j.joen.2013.11.015.

Formosa LM, Mallia B, Bull T, Camilleri J. The microstructure and surface morphology of radiopaque tricalcium silicate cement exposed to different curing conditions. Dent Mater. 2012;28(5):584–95.

Formosa LM, Mallia B, Camilleri J. The effect of curing conditions on the physical properties of tricalcium silicate cement for use as a dental biomaterial. Int Endod J. 2012;45:326–36.

Gancedo-Caravia L, Garcia-Barbero E. Influence of humidity and setting time on the push-out strength of mineral trioxide aggregate obturations. J Endod. 2006;32(9):894–6.

Hachmeister DR, Schindler WG, Walker 3rd WA, Thomas DD. The sealing ability and retention characteristics of mineral trioxide aggregate in a model of apexification. J Endod. 2002;28:386–90.

Han L, Okiji T. Uptake of calcium and silicon released from calcium silicate-based endodontic materials into root canal dentine. Int Endod J. 2011;44(12):1081–7.

Han L, Okiji T, Okawa S. Morphological and chemical analysis of different precipitates on mineral trioxide aggregate immersed in different fluids. Dent Mater J. 2010;29(5):512–7.

Hashem AA, Wanees Amin SA. The effect of acidity on dislodgment resistance of mineral trioxide aggregate and bioaggregate in furcation perforations: an in vitro comparative study. J Endod. 2012;38(2):245–9.

Hasheminia M, Loriaei Nejad S, Asgary S. Sealing ability of MTA and CEM cement as root-end fillings of human teeth in dry, saliva or blood-contaminated conditions. Iran Endod J. 2010;5(4):151–6.

Hasheminia SM, Nejad SL, Dianat O, Modaresi J, Mahjour F. Comparing the sealing properties of mineral trioxide aggregate and an experimental ceramic based root end filling material in different environments. Indian J Dent Res. 2013;24(4):474–7.

Hong ST, Bae KS, Baek SH, Kum KY, Shon WJ, Lee W. Effects of root canal irrigants on the push-out strength and hydration behavior of accelerated mineral trioxide aggregate in its early setting phase. J Endod. 2010;36(12):1995–9.

Kang JS, Rhim EM, Huh SY, Ahn SJ, Kim DS, Kim SY, Park SH. The effects of humidity and serum on the surface microhardness and morphology of five retrograde filling materials. Scanning. 2012;34(4):207–14.

Kayahan MB, Nekoofar MH, Kazandağ M, Canpolat C, Malkondu O, Kaptan F, Dummer PM. Effect of acid-etching procedure on selected physical properties of mineral trioxide aggregate. Int Endod J. 2009;42(11):1004–14.

Kayahan MB, Nekoofar MH, McCann A, Sunay H, Kaptan RF, Meraji N, Dummer PM. Effect of acid etching procedures on the compressive strength of 4 calcium silicate-based endodontic cements. J Endod. 2013;39(12):1646–8.

Kim Y, Kim S, Shin YS, Jung IY, Lee SJ. Failure of setting of mineral trioxide aggregate in the presence of fetal bovine serum and its prevention. J Endod. 2012;38(4):536–40.

Lee YL, Lin FH, Wang WH, Ritchie HH, Lan WH, Lin CP. Effects of EDTA on the hydration mechanism of mineral trioxide aggregate. J Dent Res. 2007;86:534–8.

Leiendecker AP, Qi YP, Sawyer AN, Niu LN, Agee KA, Loushine RJ, Weller RN, Pashley DH, Tay FR. Effects of calcium silicate-based materials on collagen matrix integrity of mineralized dentin. J Endod. 2012;38(6):829–33.

Lenherr P, Allgayer N, Weiger R, Filippi A, Attin T, Krastl G. Tooth discoloration induced by endodontic materials: a laboratory study. Int Endod J. 2012;45(10):942–9.

Loxley EC, Liewehr FR, Buxton TB, McPherson 3rd JC. The effect of various intracanal oxidizing agents on the push-out strength of various perforation repair materials. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2003;95(4):490–4.

Marciano MA, Camilleri J, Hungaro Duarte MA. Assessment of color stability of white MTA Angelus and bismuth oxide in contact with tooth structure. J Endod. 2014 (10.1016/j.joen.2014.01.044).

Montellano AM, Schwartz SA, Beeson TJ. Contamination of tooth-colored mineral trioxide aggregate used as a root-end filling material: a bacterial leakage study. J Endod. 2006;32(5):452–5.

Namazikhah MS, Nekoofar MH, Sheykhrezae MS, Salariyeh S, Hayes SJ, Bryant ST, Mohammadi MM, Dummer PM. The effect of pH on surface hardness and microstructure of mineral trioxide aggregate. Int Endod J. 2008;41:108–16.

Nandini S, Ballal S, Kandaswamy D. Influence of glass-ionomer cement on the interface and setting reaction of mineral trioxide aggregate when used as a furcal repair material using laser Raman spectroscopic analysis. J Endod. 2007;33:167–72.

Nekoofar MH, Davies TE, Stone D, Basturk FB, Dummer PM. Microstructure and chemical analysis of blood-contaminated mineral trioxide aggregate. Int Endod J. 2011;44(11):1011–8.

Nekoofar MH, Namazikhah MS, Sheykhrezae MS, Mohammadi MM, Kazemi A, Aseeley Z, Dummer PM. pH of pus collected from periapical abscesses. Int Endod J. 2009;42:534–8.

Nekoofar MH, Oloomi K, Sheykhrezae MS, Tabor R, Stone DF, Dummer PM. An evaluation of the effect of blood and human serum on the surface microhardness and surface microstructure of mineral trioxide aggregate. Int Endod J. 2010;43(10):849–58.

Nekoofar MH, Stone DF, Dummer PM. The effect of blood contamination on the compressive strength and surface microstructure of mineral trioxide aggregate. Int Endod J. 2010;43(9):782–91.

Oloomi K, Saberi E, Mokhtari H, Mokhtari Zonouzi HR, Nosrat A, Nekoofar MH, Dummer PM. Evaluation of the effect of blood contamination on the compressive strength of MTA modified with hydration accelerators. Restor Dent Endod. 2013;38:128–33.

Oskoee SS, Kimyai S, Bahari M, Motahari P, Eghbal MJ, Asgary S. Comparison of shear bond strength of calcium-enriched mixture cement and mineral trioxide aggregate to composite resin. J Contemp Dent Pract. 2011;12(6):457–62.

Rahimi S, Ghasemi N, Shahi S, Lotfi M, Froughreyhani M, Milani AS, Bahari M. Effect of blood contamination on the retention characteristics of two endodontic biomaterials in simulated furcation perforations. J Endod. 2013;39(5):697–700.

Ramachandran VS. Chapter 1: Interaction of admixtures in the cement-water system. In: Paillere AME, Spon FN, editors. Application of admixtures in concrete. 1st ed. Rilem report no. 10. London: CRC Press; 1992.

Ramachandran VS. Interaction of chemical admixtures in the cement – water system by research on the manufacture and use of cements. In: Proceedings of the Engineering Foundation Conference. Henniker, July 28–Aug 2, 1985. p. 121–31.

Saghiri MA, Lotfi M, Joupari MD, Aeinehchi M, Saghiri AM. Effects of storage temperature on surface hardness, microstructure, and phase formation of white mineral trioxide aggregate. J Endod. 2010;36(8):1414–8.

Saghiri MA, Lotfi M, Saghiri AM, Vosoughhosseini S, Aeinehchi M, Ranjkesh B. Scanning electron micrograph and surface hardness of mineral trioxide aggregate in the presence of alkaline pH. J Endod. 2009;35(5):706–10.

Saghiri MA, Lotfi M, Saghiri AM, Vosoughhosseini S, Fatemi A, Shiezadeh V, Ranjkesh B. Effect of pH on sealing ability of white mineral trioxide aggregate as a root-end filling material. J Endod. 2008;34(10):1226–9.

Saghiri MA, Shokouhinejad N, Lotfi M, Aminsobhani M, Saghiri AM. Push-out bond strength of mineral trioxide aggregate in the presence of alkaline pH. J Endod. 2010;36(11):1856–9.

Salem Milani A, Rahimi S, Froughreyhani M, Vahid Pakdel M. Effect of blood contamination on marginal adaptation and surface microstructure of mineral trioxide aggregate: a SEM study. J Dent Res Dent Clin Dent Prospects. 2013;7(3):157–63.

Sato EY, Svec T, Whitten B, Sedgley CM. Effects of bone graft materials on the microhardness of mineral trioxide aggregate. J Endod. 2012;38(5):700–3.

Sawyer AN, Nikonov SY, Pancio AK, Niu LN, Agee KA, Loushine RJ, Weller RN, Pashley DH, Tay FR. Effects of calcium silicate-based materials on the flexural properties of dentin. J Endod. 2012;38(5):680–3.

Shemesh H, Souza EM, Wu MK, Wesselink PR. Glucose reactivity with filling materials as a limitation for using the glucose leakage model. Int Endod J. 2008;41(10):869–72.

Shokouhinejad N, Nekoofar MH, Iravani A, Kharrazifard MJ, Dummer PM. Effect of acidic environment on the push-out bond strength of mineral trioxide aggregate. J Endod. 2010;36(5):871–4.

Smith JB, Loushine RJ, Weller RN, Rueggeberg FA, Whitford GM, Pashley DH, Tay FR. Metrologic evaluation of the surface of white MTA after the use of two endodontic irrigants. J Endod. 2007;33:463–7.

Stefopoulos S, Tsatsas DV, Kerezoudis NP, Eliades G. Comparative in vitro study of the sealing efficiency of white vs grey ProRoot mineral trioxide aggregate formulas as apical barriers. Dent Traumatol. 2008;24:207–13.

Storm B, Eichmiller FC, Tordik PA, Goodell GG. Setting expansion of gray and white mineral trioxide aggregate and Portland cement. J Endod. 2008;34(1):80–2.

Tingey MC, Bush P, Levine MS. Analysis of mineral trioxide aggregate surface when set in the presence of fetal bovine serum. J Endod. 2008;34:45–9.

Tomson PL, Grover LM, Lumley PJ, Sloan AJ, Smith AJ, Cooper PR. Dissolution of bio-active dentine matrix components by mineral trioxide aggregate. J Dent. 2007;35(8):636–42.

Torabinejad M, Chivian N. Clinical applications of mineral trioxide aggregate. J Endod. 1999;25(3):197–205.

Torabinejad M, Higa RK, McKendry DJ, Pitt Ford TR. Dye leakage of four root end filling materials: effects of blood contamination. J Endod. 1994;20(4):159–63.

Tsujimoto M, Ookubo A, Wada Y, Matsunaga T, Tsujimoto Y, Hayashi Y. Surface changes of mineral trioxide aggregate after the application of bleaching agents: electron microscopy and an energy-dispersive X-ray microanalysis. J Endod. 2011;37(2):231–4.

Tsujimoto M, Tsujimoto Y, Ookubo A, Shiraishi T, Watanabe I, Yamada S, Hayashi Y. Timing for composite resin placement on mineral trioxide aggregate. J Endod. 2013;39(9):1167–70.

Uyanik MO, Nagas E, Sahin C, Dagli F, Cehreli ZC. Effects of different irrigation regimens on the sealing properties of repaired furcal perforations. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2009;107(3):e91–5.

Vallés M, Mercadé M, Duran-Sindreu F, Bourdelande JL, Roig M. Influence of light and oxygen on the color stability of five calcium silicate-based materials. J Endod. 2013;39(4):525–8.

Vallés M, Mercadé M, Duran-Sindreu F, Bourdelande JL, Roig M. Color stability of white mineral trioxide aggregate. Clin Oral Investig. 2013;17(4):1155–9.

Vanderweele RA, Schwartz SA, Beeson TJ. Effect of blood contamination on retention characteristics of MTA when mixed with different liquids. J Endod. 2006;32(5):421–4.

Watts JD, Holt DM, Beeson TJ, Kirkpatrick TC, Rutledge RE. Effects of pH and mixing agents on the temporal setting of tooth-colored and gray mineral trioxide aggregate. J Endod. 2007;33(8):970–3.

Zakizadeh P, Marshall SJ, Hoover CI, Peters OA, Noblett WC, Gansky SA, Goodis HE. A novel approach in assessment of coronal leakage of intraorifice barriers: a saliva leakage and micro-computed tomographic evaluation. J Endod. 2008;34(7):871–5.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Camilleri, J., Dummer, P. (2014). Reactivity and Environmental Factors. In: Camilleri, J. (eds) Mineral Trioxide Aggregate in Dentistry. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-55157-4_5

Download citation

DOI: https://doi.org/10.1007/978-3-642-55157-4_5

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-55156-7

Online ISBN: 978-3-642-55157-4

eBook Packages: MedicineMedicine (R0)