Abstract

The characteristics of wind power result in unique challenges for system operators when integrating large penetrations of wind generation into power systems. This chapter discusses some of the power system operational challenges associated with large penetrations of wind generation, such as increased reserve requirements and the costs associated with increases in the variable operation of conventional generators. A number of power system optimization techniques with wind generation are discussed, namely the fuelsaver approach, deterministic optimization, rolling commitment and stochastic optimization. Also, a discussion of certain flexibility solutions which may reduce the system costs of increased wind penetration levels is provided.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Energy as a topic has recently been catapulted to the top of the global agenda. Environmental concerns, competitive pressures and security of supply make energy a multifaceted global issue and one of the greatest challenges facing mankind. The times of cheap abundant energy are rapidly coming to an end and the environmental impacts of decades of growth in energy consumption are becoming startlingly apparent. A secure, sustainable energy supply is of strategic importance to the well-being and health of a modern industrial society and requires significant innovation and research effort.

The electricity industry is heavily fossil fuel dependent, with 82 % of electricity produced by fossil fuels in 2008 [1]. This leaves the industry highly exposed to future price increases as global fossil fuel resources become more depleted. Also, the increasing concentration of the remaining resources in certain geographical areas may make fossil fuel prices more volatile.

Worldwide, the generation of electricity relies heavily on coal, the most carbon intensive of fuels, amplifying the sector’s share in global carbon dioxide emissions. In 2007, 42 % of electricity was generated through the combustion of coal worldwide and countries such as Australia, China, India and South Africa produced between 68 and 95 % of their electricity and heat through coal [1]. As such the electricity industry is a major contributor of greenhouse gas emissions with the electricity and heat sector responsible for 41 % of worldwide carbon dioxide emissions in 2007 [2].

In a bid to reduce their reliance on fossil fuels, while simultaneously reducing electricity sector emissions, there has been a move by policy makers towards the promotion of clean renewable technologies for electricity generation. For example, EU leaders have committed to producing 20 % of final energy consumption from renewable sources by 2020, encompassing a 30 % renewable generation target for the electricity sector [3].

As one of the most advanced forms of renewable generation, much emphasis has been on wind, which has grown from 9,660 MW installed worldwide in 1998 to over 120,800 MW in 2008 [4]. As the market for wind energy has grown, the costs per kilowatt hour have reduced dramatically. Ambitious renewable energy targets together with reducing costs and successes to date, will ensure that wind energy continues to grow in electricity networks worldwide.

Wind generation, like solar, tidal and wave generation, exhibits ‘variable’ output. The output of these units depend upon weather conditions that cannot be controlled by the operator of the generator. This is known as being ‘non-dispatchable’. For example, the amount of electricity generated by a wind turbine fluctuates as wind speed changes and that of a photovoltaic array with the intensity of sunlight. Thus, the control of their output is limited as operators can only reduce the potential output of such generators [5]. When significant penetrations of these forms of generation are connected to an electricity network, it can result in a requirement to alter the operation of the system to accommodate the variability of these generators.

As well as being variable, wind generation also faces a challenge of being relatively unpredictable. Since the underlying resource cannot be directly controlled, the renewable generation is high when conditions are favourable and low when unfavourable. Thus, forecasts of weather conditions are crucial when examining renewable generation sources. Unlike tidal power which can be predicted almost perfectly over long time horizons, wind generation, requires complex forecasting techniques which account for wind speed, wind direction, hub height, geographical surroundings, wind farm size, turbine dispersion, etc. Given the large number of factors which must be taken into account when forecasting wind generation, the margin for error can be significant and increases as the time horizon lengthens [6].

The function of power system operators is to supply electricity to customers in a reliable manner at a sustainable cost. Reliability of electricity supply is defined as “the ability to supply adequate electric service on a nearly continuous basis with few interruptions over an extended period of time” [7]. This involves ensuring that the generation meets the load at all times and that any short term gaps between load and generation are bridged quickly and precisely to maintain the integrity of the power system [8]. Generators are scheduled to meet the forecasted load and must alter their operating levels to follow the load as it fluctuates throughout the day. Since the output of some renewable generators, in particular wind generation, cannot be actively controlled and is difficult to predict accurately, this balancing of the generation and the load can become more challenging as the wind penetration levels increase [5].

The characteristics of wind power result in unique challenges for system operators when integrating wind generation into power systems, particularly when penetrations of wind generation become significantly large. It has thus been recognized that methodologies and tools must be developed in order to investigate the impact of large scale wind energy on power system operation. For example, Annex 25 of the International Energy Agency Research and Development Wind Agreement “Design and Operation of Power Systems with Large Amounts of Wind Power” was initiated in 2006 with the objective of providing information to facilitate the highest economically feasible wind energy penetration within electricity power systems worldwide [9]. Many other studies, such as [5, 10, 11] and [12], have highlighted the challenges associated with increased wind penetrations and [13] is a useful resource providing a comprehensive literature review of the salient studies conducted in North America.

Section 2 will discuss in further detail some of the power system operation challenges associated with increasing penetrations of wind power. Section 3 will discuss scheduling techniques of system operators for unit commitment with wind generation. Section 4 will discuss some power system characteristics which would facilitate increased penetrations of wind power.

Throughout this article, reference is made to the power system of Ireland as a case study. Located on the edge of the Atlantic Ocean, Ireland has a vast wind resource potential as evidenced in Fig. 1. In 2008, wind generation represented 11.1 % of electricity generation and in 2010 this is expected to exceed 15 % [14].Footnote 1 In fact, the island of Ireland as a single synchronous power system has arguably the largest penetrations of wind power in the world [15] and the Irish Government has recently set a target of 40 % of electricity from renewables by 2020, the majority of which is expected to come from wind generation [16].

Average global wind speeds [17]

The Irish power system is a small island system with no synchronous interconnection with other systems. As such it is a good case study system as it allows issues surrounding power system operation with large penetrations of wind generation to be evaluated in isolation and without being influenced by the operation of other systems. It also implies that any challenges associated with balancing load, wind output and conventional generation must be dealt with locally. As such the Irish system can be considered as an indicator of the challenges that other larger power systems may experience with large wind penetrations in the future.

2 Power System Operation Challenges with Large Penetrations of Wind

The interaction of wind energy and the electricity system is complex and there are significant challenges posed to system operators when large amounts of variable generation are introduced [11, 18]. This section discusses some of the main system operational challenges associated with increased penetrations of wind.

2.1 Reserve Provision

Under the European Union Directive 96/92/EC [19] the Transmission System Operator is responsible for “ensuring a secure, reliable and efficient electricity system and, in that context, for ensuring the availability of all necessary ancillary services”. These ancillary services include the provision of sufficient reserve capacity to meet the load under unexpected system operating conditions [20]. As shown in [21] these unexpected system conditions can include the loss of a unit, a transmission line trip and unexpected load fluctuations. It was shown in [22] that an increase in the capacity of wind generation on an electricity system increases the uncertainty in the system, as wind generation is relatively unpredictable and non-dispatchable, which results in a requirement to carry additional reserve capacity in order to maintain system security.

Depending on the electricity system, there are a number of reserve categories which a system operator must carry—from fast acting reserve, with a reaction time in the order of seconds, to reserve which responds more slowly [23, 24]. It has been shown in [25] and [26], that the standard deviation of wind power forecast errors over short time frames are small. As such [27], found that increasing wind power capacity has little effect on the reserve categories that operate over a short time frame (seconds to minutes), however, wind capacity causes a greater increase in the need for categories of reserve that act over longer periods of time. For example, Fig. 2 illustrates the different reserve categories required for the case study power system of Ireland with increasing wind generation [27]. In Fig. 2 the categories are defined as follows: ‘One hour reserve’ refers to reserve responding in the time frame of 20 min to 1 h; ‘Tertiary 2’ reserve responds in 5–20 min; ‘Tertiary 1’ in 90 s to 5 min; ‘Secondary’ in 15–90 s; and ‘Primary’ in 5–15 s.

Conventional reserve categories versus installed wind capacity for Ireland [27]

In [28, 29] the reserve costs attributable to the stochastic nature of the wind energy output for a number of different US utilities were quantified. It was found that in many cases the costs of providing these services was in fact relatively small. The costs of additional reserve in the Pennsylvania, New Jersey and Maryland (PJM) market was of the order of $0.05–0.30/MWh. Also [18] found that the additional reserve costs represented less than 4 % of the total additional system costs imposed by wind generation. A comprehensive summary of similar studies conducted for electricity utilities around the United States is provided in [12].

2.2 Variable Operation of Conventional Power Stations

In addition to the added reserve requirement with increases in wind generation, an increase in variable generation on an electricity system may require the system operator to alter how conventional generation is dispatched [30]. Conventional generation may be obliged to operate at lower operating levels in order to be available to ramp up to accommodate the inherent variability of the wind generation [5]. There may also be an increase in the number of start-ups and shut-downs of conventional units as system operators attempt to coordinate the following of the fluctuating load throughout the day and the variable output of the wind generation [31, 32].

Thermal units are designed to be at their most efficient when online and running at a stable load [33]. It has been shown in [34], that in general, units are optimized for continuous rather than cyclical operation and when operating in their normal range can operate for relatively long periods with relatively low risk of failure and loss of equipment life. When a generating unit is required to vary its output to meet the demand and balance the wind output, the components in the unit are subject to stresses and strains. This is known as cycling and includes ramping up and down and switching on and off.

When a unit is turned off and on, the boiler, steam lines, turbine and auxiliary components undergo large temperature and pressure stresses which result in damage. This damage accumulates over time and eventually leads to accelerated component failures, forced outages and a shortening of the life span of the unit [35]. It is estimated that one on–off cycle for a single unit can cost as much as $500,000 [36] when these additional wear and tear damages are included, thus an increase in cycling associated with increased wind generation could result in significant cost increases.

This wear and tear on the components of the generating units is exacerbated by a phenomenon known as creep-fatigue interaction. Creep is the change in the size or shape of a material due to constant stress on the material over time. This is likely in units which are operated at continuous output over long periods of time, such as baseloaded units. Creep stems from continuous exposure to elevated temperatures and high pressures [36]. Fatigue occurs when a material is exposed to fluctuating stresses resulting in fractures and failures. Fatigue is likely during cyclical operation when the materials experience large transients in both pressures and temperatures [35].

Older units which were designed and used for baseloaded operation over a number of years and are then forced to cycle on a regular basis are very susceptible to component failure through creep and fatigue damage interaction. This depletion of the life expectancy of conventional units is a serious issue when analysing wind generation penetration as it is likely that wind generation will alter the merit order and some units will switch from being baseloaded to being required to be more flexible. An analysis of the impact of wind generation on baseload unit cycling was conducted for a case study of the Irish power system by [32] and their results show that baseloaded combined cycle gas turbines (CCGT) are significantly adversely affected by increasing penetrations of wind generation as illustrated in Fig. 3.

Number of annual start-ups and capacity factor for an average 400 MW CCGT unit with increasing wind penetration [32]

2.2.1 Wind and Emissions

A further issue relating to the variable operation of conventional power stations is the impact of cycling on emissions. While wind generation can result in a reduction in the output of conventional units on the system, it is not necessarily the case that a reduction in output will result in a reduction in emissions [37].

Carbon dioxide (CO2) is generated by the combustion of fuels containing carbon. The amount of carbon dioxide released is in direct relation with the amount of carbon in the fuel and the quantity of fuel burnt [38]. Thus a generation plant which burns a carbon intensive fuel will generate more carbon dioxide at increased levels of operation. Thus, if wind generation reduces the operating level of a carbon intensive unit, CO2 emissions should fall. However, it is important to note that conventional power stations consume large levels of fuel when starting up. Thus, if wind generation results in an increase in start-ups, emissions of CO2 could be adversely affected. In fact [31] showed that the carbon cost of a start-up can actually exceed the fuel cost of a start-up at a price of €30/ton CO2.

Sulphur Dioxide (SO2) is produced in a similar way to carbon dioxide and the emissions produced depend on the sulphur content of the fuel and the quantity of fuel burnt. It should be noted that natural gas contains a negligible amount of sulphur, thus emissions of SO2 are not significant for gas turbines [39].

The production of Nitrogen Oxide (NOX) differs from CO2 and SO2 production and does not depend solely on the nitrogen content of the fuel. It is also significantly affected by the flame temperature, the oxygen concentration and the residence time in the combustion chamber. The formation of NOX can be attributed to four distinct chemical kinetic processes: thermal NOX formation, prompt NOX formation, fuel NOX formation and reburning. Thermal NOX is formed by the oxidation of atmospheric nitrogen present in the combustion air. Prompt NOX is produced by high-speed reactions at the flame front, and fuel NOX is produced by oxidation of nitrogen contained in the fuel. The reburning mechanism reduces the total NOX formation by accounting for the reaction of NO with hydrocarbons [40]. Fuel NOX is the major source of NOX emissions from the combustion of nitrogen bearing fuels such as heavy oils, coal and peat [41].

Thermal NOX is the predominant source of NOX emissions from a gas turbines. In order to achieve reduced emissions, gas turbine manufacturers have adopted lean premixed combustion as a standard technique. This premix (of fuel and air) achieves low levels of pollutant emissions without the need for additional hardware for steam injection or selective catalytic reduction [42]. Lean premixed combustion is limited by the presence of combustion instabilities which can produce turbine damage, flame instability and even flame extinction [43]. For this reason the fuel and air premix is not possible during startup and at reduced load levels (below about 65–70 % of maximum capacity). As a result, NOX emissions in a CCGT increase significantly at lower loads. Figure 4 shows the NOX characteristics of a CCGT and an open cycle gas turbine (OCGT).

Typical NOX emissions from a CCGT and an OCGT [37]

From Fig. 4 it is clear that if a CCGT is forced to operate below approximately 70 % of its maximum rated capacity, its NOX emissions will increase threefold. For an OCGT, operation below 60 %, will result in NOX emissions increasing by up to six times. The NOX characteristics of these units are important when examining the impact of wind generation on emissions. As discussed previously, wind generation may result in the system operator requiring more units to operate at lower efficiencies due to the increased reserve requirement. In addition, wind generation causes an increase in the cycling of marginal units. Thus, an increase in wind generation may result in more CCGT units operating at lower loads (as seen in Fig. 3), and as a result increasing their NOX emissions. In other words, although wind generation itself does not produce any harmful emissions, it may in fact result in an increase in NOX emissions through the reduced operation of gas fired units. This has been shown to be the case under certain system operation strategies, such as the fuelsaver strategy, discussed further in Sect. 3 [37].

2.3 Power System Stability and Other Issues

Related to the issue of reserve provision is the ability of wind generators to stay connected to the system after a fault i.e. fault ride-through capabilities. Currently many wind turbines have protection equipment installed which disconnects the turbine following a fault [44]. This sympathetic tripping can cause serious problems for system security, increasingly so with larger numbers of wind generators connecting to the system [45]. This is especially true for small, relatively isolated systems. Essentially, this sympathetic tripping aggravates a fault event resulting in increasing pressure on reserves and reliability standards.

In periods of low demand and high wind speeds (e.g. during windy nights) a significant contribution of wind power can be reached even when the overall share of wind power in the electricity supply is still modest. When the wind power penetration level is considerable it will no longer be feasible for wind turbines to disconnect during voltage or frequency disturbances, as this would lead to a large generation deficit and could lead to a reduction in the stability of the system [46, 47]. This issue has led to a review of many grid codes across Europe and now most include a necessity for wind turbines to have fault ride through capabilities [48, 49].

The most ideal sites for wind generation often coincide with remote locations which are frequently in weak areas of the electricity grid. This can result in connection challenges for wind generation with issues such as voltage control, harmonic emissions, short circuit levels and losses playing a significant role [50]. This has led to the possibility of distribution networks switching to ‘active’ rather than ‘passive’ systems through the installation of complex control systems and by equipping transformers with tap changers that can control voltage locally [51]. Rural locations for wind farms also cause problems for developers. For cost minimisation the location of plant is very important and there is often a trade-off between the windiest sites and easy access to the distribution network. There are large economies of scale associated with wind farm development which often cannot be realized in remote areas due to limitations on access.

Network congestion can also be an issue with high levels of wind power. An increase in wind generation, like any conventional generation, will increase the flows on the lines which may have a knock on effect on congestion [52]. Congestion limits the system operator’s ability to make the most economic decisions in planning, sourcing and supplying electricity to customers and can result in increased costs. However, as stated by [53], ‘no general rules apply to transmission congestion economics, which can only be studied on a case-by-case basis’. This is because congestion is highly system specific and depends on the location of the generators and loads on the network. Thus, without modelling the exact location of generators and the network characteristics, it is difficult to quantify congestion costs in a generic manner. Network reinforcement with increasing penetrations of wind generation can help ameliorates potential bottlenecks and congestion, and reduce costs.

This is not an exhaustive summary of the impacts of wind generation on power system operation but rather an illustration of some of the more direct impacts. Depending on the scope of an analysis, the external costs of wind generation could be much further reaching. It should also be noted that wind generation also provides significant benefits to the system such as a reduction in harmful emissions, fuel savings, capacity benefits, a hedge against imported fuel prices and supply concerns etc. However, for the purposes of this article we will concentrate on the system operational challenges and the following Sect. 3 will discuss some operational scheduling techniques used to minimize some of these costs and Sect. 4 will discuss system characteristics that can also reduce the system costs of wind.

3 Scheduling Tools

This section discusses some techniques for determining conventional generation schedules in the presence of large penetrations of wind generation. It begins with a simplistic approach which may be feasible when wind penetrations are low but is sub-optimal with larger wind penetrations. The second and third approaches are more sophisticated and result in lower system costs than the first approach.

3.1 Fuelsaver Approach to Unit Commitment

A simple approach to operating a power system with wind generation, known as the fuelsaver approach, has been presented in [54, 55]. Under this approach, wind generation is not considered in the scheduling of the plants and the unit commitment decisions are made ignoring any installed wind capacity. Once the commitment decision has been made, the wind generation is considered. If wind generation is available it is used and marginal conventional plants which were dispatched are deloaded to accommodate the wind generation. A conventional plant can be deloaded as far as its minimum but no plants are switched off. If wind production reaches a level such that no more conventional generation can be deloaded, then any further wind production is curtailed.

This operational strategy considers that the only benefit of wind generation is a fuel-saving one and it assumes that wind generation has a capacity value of zero. This is a simplistic approach and it allows issues of forecasting and reliability of wind production to be ignored.

The impact of operating the power system using a fuelsaver approach is discussed in [37] and it is shown that it is a highly inefficient way to operate the system with significant wind power penetration. The fuelsaver method of power system operation with wind generation results in an over commitment of conventional units, and these units will be running at low efficiencies. This has a knock on impact on the emissions and fuel savings of wind generation. In fact, under the fuelsaver approach, NO X emissions can actually be greater than in the absence of any wind generation [37]. In addition, the fuelsaver approach results in large amounts of wind energy curtailment, of up to 30 % of the annual output at high levels of installed wind power [37]. Except in the case of very small penetrations of wind generation, operating the system in a fuelsaver manner is not recommended.

3.2 Deterministic Unit Commitment with Wind Generation

An improvement to the fuelsaver approach is to account for wind power forecasts in the unit commitment decision. One common software package which uses a deterministic approach to wind power is PLEXOS [56]. This is a unit commitment package which allows the user to model the plant on the system using various attributes such as the fuel use, startup time and costs, availability of reserve, etc. In the PLEXOS optimization model, the forecasted wind on the system is treated as a negative load, and is subtracted from the load. PLEXOS then uses either a mixed integer solver or rounded relaxation method to solve the unit commitment problem. However, the main limitation of this type of deterministic approach is that the wind forecast is considered as perfect and the stochastic nature of forecast errors are not taken into account and a surplus level of reserve capacity must be carried.

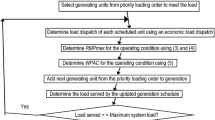

3.2.1 Rolling Unit Commitment

Models such as PLEXOS can be improved by conducting what is known as ‘rolling planning’, whereby the unit commitment is carried out more frequently, for example every 6 h instead of every 24 h [57]. For instance, 6-hour rolling commitment is carried out as follows: the first commitment is carried out, then the system is ‘rolled’ forward 6 h and the relevant details (wind forecasts, load forecasts, plant availability, and current state of system) are updated, before the system is once again committed. Figure 5 shows this in the case of the units being committed every 24 h and every 6 h over a 48 h period.

Example of rolling unit commitment [57]

This ‘rolling planning’ approach means wind and load forecasts are being updated with greater frequency and more of the uncertainty of wind is captured in the model. This means more of the costs due to uncertainty will be minimized, leading to improved results and better performing schedules. However, while this ‘rolling planning’ approach is an improvement on the perfect forecast approach it still does not adequately account for the stochastic element in the errors of wind power forecasting. Thus, while a deterministic approach such as this may be utilized in systems with relatively low levels of installed wind generation, the omission of the stochastic element will cause more problems as wind penetrations grow.

In fact [58] found that including the stochastic element of wind power forecasts in unit commitment modelling results in significantly better performing and less costly schedules than deterministic optimization.

3.3 Stochastic Unit Commitment with Wind Generation

A far superior approach than the fuelsaver and deterministic approaches to unit commitment with wind generation is to include the stochastic element of the wind power forecasts in the scheduling decisions. Large amounts of installed wind power add a significant stochastic element to the planning of the system, due to the uncertainty associated with wind power forecasts [25]. By explicitly taking into account the stochastic nature of wind in the unit commitment algorithm, more robust schedules will be produced.Footnote 2

Stochastic optimization was used in unit commitment problems before wind generation became a significant concern for power system operation, as in [59] and [60]. In [59], a long term security-constrained stochastic unit commitment (SCUC) model is described, which models unit and transmission line outages, as well as load forecasting inaccuracies. In [60], a method was developed to solve unit commitment problems when demand is not known with certainty. Both of these approaches show the benefits of using stochastic methods to solve the unit commitment problem. However, wind power as a stochastic input is not examined.

Stochastic security with wind generation is examined in [61], which formulates a market-clearing problem capable of accounting for wind power. The WILMAR project [62] developed a stochastic scheduling tool to examine the impact of the variability of wind in energy markets. The Wilmar Planning Tool was originally developed to model the Nordic electricity system and was later adapted to the Irish system as part of the All Island Grid Study [63]. It is currently employed in the European Wind Integration Study [64] and is considered to be the state of the art model for stochastic unit commitment with large penetrations of wind generation.

In the Wilmar model, the system is rescheduled as more precise wind and load forecasts are made available, giving a ‘rolling planning’ type of operation as discussed previously. Because more robust schedules are provided to cater for stochastic wind and load, the total expected costs of operating the system are lower than under the deterministic or fuelsaver approaches [58].

3.3.1 The WILMAR Stochastic Unit Commitment Model with Large Wind Penetrations

The main functionality of the WILMAR model is in two parts: a Scenario Tree Tool (STT) and a Scheduling Model. The STT is used to generate the scenarios that are used as inputs in the scheduling model. Possible future wind and load are represented by scenario trees, as shown in Fig. 6. The STT also produces time series for the forced unit outages. Each branch of the scenario tree corresponds to a different forecast of wind and load, as well as probability of occurrence. The wind and load scenarios are generated by Monte Carlo simulations of the wind and load forecast error, based on an auto-regressive moving average model describing the wind speed forecast error [58]. The high number of possible scenarios produced is then reduced using a scenario reduction approach, similar to [65].Footnote 3

Rolling planning with scenario trees [58]

The Scheduling Model used is a mixed integer, stochastic optimization model [67] and the objective function being minimized, given in Eq. (1), is the expected cost of the system over the optimization period, covering all of the scenarios in Fig. 6.Footnote 4

A. Indices | B. Parameters | C. Variables | |||

|---|---|---|---|---|---|

F | Fuel | EMISSION | Rate of emission | CONS | Fuel consumed |

i, I | Unit group | END | End time of optimization period | U | Relaxation variable |

r, R | Region | k | Probability of scenario | V | Decision variable |

s, S | Scenario | L | Infeasibility penalty | ONLINE | Integer on/off for unit |

START | Units with start up fuel consumption | LOAD | Penalty for loss of load | QDAY | Day ahead demand not met |

t, T | Time | PRICE | Fuel price | QINTRA | Intra day demand not met |

USEFUEL | Units using fuel | REP | Penalty for not meeting replacement reserve | QREP | Replacement reserve not met |

SPIN | Penalty for not meeting primary reserve | QSPIN | Primary reserve not met | ||

TAX | Emission tax | +, − | Up, down regulation | ||

The minimization covers fuel costs, carbon costs and startup costs. This is subject to constraints on units, such as startup time, minimum up and down times, ramping rates, and minimum and maximum generation, as well as interconnection constraints and losses, spinning and replacement reserve targets, and penalties for not being able to meet load or reserve targets.

It was found in [58] that utilizing a stochastic rather than a deterministic approach significantly reduces both the reserve requirement and the cycling of conventional units on the power system. In addition, [58] compared the use of currently available state of the art wind forecasts in a stochastic unit commitment model to perfect wind forecasts and found that using perfect wind forecasts reduces annual system costs by just 0.25–0.9 %. In other words, using a stochastic unit commitment technique is almost as good as having perfect wind power forecasts and perhaps efforts at improving wind power forecasting should not be a primary concern of system operators. In fact, if the cost of research, development and equipment to improve wind power forecasts were included, the cost of improved accuracy could be greater than the benefits it provides. Instead, system operators should focus efforts on employing stochastic unit commitment techniques with currently available forecasts.

4 System Planning: Flexibility

In general, the system costs of wind generation will be highly dependent on the underlying plant mix. Looking into the future, if it is envisaged that wind generation will play a major role in a plant portfolio, then the conventional plant mix should be optimized to accommodate this wind generation. In particular, a more flexible power system will be required [9].

The need for power system flexibility was recognized by the North American Electric Reliability Cooperation (NERC) in the formation of their Integration of Variable Generation Task Force (IVGTF) and by the International Energy Agency in their Grid Integration of Variable Renewable Energy (GIVAR) project. The GIVAR project is specifically aimed at assessing the power system flexibility requirements associated with increasing penetrations of renewable energy [68]. The project is broken into the following 5 strands: identification of the variability profiles of variable renewable energy technologies; development of a toolbox of measures to increase power system flexibility; definition of power system paradigms; development of a flexibility assessment method; and to review the costs and benefits of renewable energy integration.

A study conducted by [69] examines the optimal future conventional plant portfolios with high levels of installed wind generation. Their analysis shows that with increasing penetrations of wind generation, there is a reduction in the necessity for baseloaded generation and an increase in peaking capacity. In particular, the results point towards a reduction in coal fired generation and an increase in the need for open cycle gas turbines with increasing wind generation penetrations. Open cycle gas turbines have short start-up times and can ramp up and down with much greater ease than typical baseload units.

The system considered by [69] did not include any nuclear generation, however, for systems with large penetrations of inflexible baseload nuclear generation, flexibility will be a significant concern. Large penetrations of wind generation require system flexibility which cannot be provided by nuclear generation. As such, policy makers need to decide whether to pursue a policy of large scale renewable promotion or nuclear generation as the two are not necessarily complementary.

Increased interconnection to other systems has also been highlighted as facilitating the integration of wind generation by introducing more flexibility to help balance the variable wind output. The experiences of integrating wind generation in a number of different countries is discussed in [15], and in particular the challenges faced by isolated power systems are highlighted. The conclusions of this study illustrated the importance of interconnection in providing the range of services required to maintain a secure electricity system with large penetrations of wind generation, such as sufficient generation capacity, fast acting reserve provision, and control of excess wind generation.

Energy storage used in conjunction with renewable energy has also been suggested as a means to increase the use of renewable energy while maintaining a high quality of service reliability [70, 71]. The use of storage devices can help balance the wind generation output and can also be used to transfer energy from low-use periods to peak-use periods, allowing the system to operate at a more constant level and reducing energy supply costs. When increasing penetrations of electricity storage are being considered a key concern is the peak:off-peak price differential. This must be sufficient to cover the losses due to the round trip efficiency of the storage unit as well as the significant capital costs of storage. It should also be noted that on relatively small systems the storage unit can actually impact the electricity price by increasing the price during off-peak hours and decreasing it at peak times and thereby further decreasing its profit opportunities.

Active demand management can also provide a valuable source of flexibility to a power system. The traditional view of demand has been to place it in a different category to generation in the scheduling of power system operation [72]. However, if demand is considered as a flexible, responsive resource then these traditional divisions could be broken down and demand side resources utilized to improve overall system flexibility. Currently, it is mainly commercial and industrial customers that participate in demand side management schemes. As a result, the main types of demand which currently provide demand responses are on-site generation (diesel), refrigeration and deferral of production [73]. However, through the use of smart electricity meters, domestic customers can also lower their demand by reducing their discretionary loads, air conditioning or electric heating or deferring the usage of appliances until a later time or date. Any micro-generation connected within the home also offers itself as a means to reduce net consumption when required. The residential sector has been under utilized to date as a source of power system flexibility and into the future offers a potentially large resource to be exploited.

This article has provided a discussion of some of the main power system operation challenges associated with wind generation, as well as the optimal unit commitment techniques and system characteristics which can help minimize these costs. While each power system is different it is likely that if wind generation is to be pursued on a large scale the issues raised here will be relevant in many power systems worldwide. It is also clear that transmission system operators will be required to significantly alter traditional operating techniques to ensure wind generation can play a significant role in future electricity supply at minimal system cost.

Notes

- 1.

On 22nd November 2009 Ireland achieved a world record of over 45 % of electricity demand produced from wind energy during the hours of 4 and 6 am while the installed wind capacity represented just 10 % of installed generation.

- 2.

The issue of stochastic unit commitment with wind generation is discussed in detail in [58] and is summarized here.

- 3.

More detailed information about the Scenario Tree Tool can be found in [66].

- 4.

Further details on the formulation of the unit commitment problem are given in [58].

References

International Energy Agency (2009) Key world energy statistics. Available http://www.iea.org

International Energy Agency Statistics (2009) CO2 emissions from fuel consumption—highlights. Available http://www.iea.org/co2highlights

European Commission (2009) Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009: on the promotion of the use of energy from renewable sources and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC. Available http://www.europa.eu/

European Wind Energy Agency (2009) Global statistics. Available http://www.ewea.org/index.php?id=180

Gross R, Heptonstall P, Anderson D, Green T, Leach M, Skea J (2006) The costs and impacts of intermittency: an assessment of the evidence on the costs and impacts of intermittent generation on the British electricity network. A report of the technology and policy assessment function of the UK Energy Research Centre

Ummels B, Gibescu M, Pelgrum E, Kling K, Brand A (2007) Impacts of wind power on thermal generation unit commitment and dispatch. IEEE Trans Energy Conv 22:44–51

Kundur P, Paserba J, Ajjarapu V, Andersson G, Bose A, Canizares C, Vittal V (2004) Definition and classification of power system stability IEEE/CIGRE joint task force on stability terms and definitions. IEEE Trans Power Syst 19(3):1387–1401 (IEEE/CIGRE: The Institute of Electrical and Electronics Engineers (IEEE)/International Council on Large Electric Systems (CIGRE))

Kirschen D, Strbac G (2004) Fundamentals of power system economics. Wiley, West Sussex

International Energy Agency Annex 25 (2009) Power systems with large amounts of wind power. Available http://www.ieawind.org

Holttinen H et al (2006) Design and operation of power systems with large amounts of wind power, IEA collaboration. In: Nordic wind power conference. Espoo, Finland

ILEX, Strbac G (2002) Quantifying the system cost of additional renewable generation in 2020. Available http://www.dti.gov.uk

Smith J, Milligan M, DeMeo E, Parsons B (2007) Utility wind integration and operating impact state of the art. IEEE Trans Power Syst 22(3):900–908

Smith J (2006) North American literature and project review for all-island wind penetration study. Report prepared for SONI and ESB NG

Eirgrid (2009) Generation adequacy report 2010–2016. Available www.eirgrid.com

Söder L, Hofmann L, Orths A, Holttinen H, Wan Y, Tuohy A (2007) Experience from wind integration in some high penetration areas. IEEE Trans Power Syst 22:4–12

Commission for Energy Regulation Ireland (2008) Press release: CER announces unprecedented increase in renewable electricity. http://www.cer.ie

National Aeronautics and Space Administration (NASA) (2008) Visible earth: a catalogue of images and animations of our home planet. Available http://visibleearth.nasa.gov

Denny E, O’Malley M (2007) Quantifying the total net benefits of grid integrated wind. IEEE Trans Power Syst 22(2):605–615

European Commission (1996) Directive 96/92/EC of the European Parliament and of the Council of 19 December 1996 concerning common rules for the internal market in electricity. Available http://www.europa.eu

Wang P, Billington R (2004) Reliability assessment of a restructured power system considering reserve agreements. IEEE Trans Power Syst 19(2):972–978

Zhu J, Jordan G, Ihara S (2000) The market for spinning reserve and its impact on energy prices. In: IEEE PES winter meeting, Singapore, pp 1202–1207

Söder L (1993) Reserve margin planning in a wind-hydro-thermal power system. IEEE Trans Power Syst 8:564–571

Kundur P (2004) Power system stability and control. McGraw Hill Inc., New York

Rashidi-Nejad M, Song Y, Javidi-Dasht-Bayaz M (2002) Operating reserve provision in deregulated power markets. In: IEEE PES winter meeting, New York, pp 1305–1310

Marti I, Kariniotakis G, Pinson P, Sanchez I, Nielsen T, Madsen H, Giebel G, Usaola J, Palomares A, Brownsword R, Tambke J, Focken U, Lange M, Sideratos G, Descombes G (2006) Evaluation of advanced wind power forecasting models—results of the Anemos project. Available http://anemos.cma.fr

Kariniotakis G, Pinson P (2003) Evaluation of the MORE-CARE wind power prediction platform. Performance of the fuzzy logic based models. In: Proceedings of European Wind Energy Association Conference, Madrid, Spain

Doherty R, O’Malley M (2005) New approach to quantify reserve demand in systems with significant installed wind capacity. IEEE Trans Power Syst 20(2):587–595

Hirst E (2001) Interactions of wind farms with bulk-power operations and markets. Prepared for the project for Sustainable FERC Energy Policy

Hirst E (2002) Integrating wind energy with the BPA power system: preliminary study. Prepared for Power Business Line Bonneville Power Administration

Gardner P, Snodin H, Higgins A, Goldrick SM (2003) The impacts of increased levels of wind penetration on the electricity systems of the Republic of Ireland and Northern Ireland. Final Report to the Commission for Energy Regulation/OFREG by Garrad Hassan 3096/GR/04

Denny E, O’Malley M (2009) The impact of carbon prices on generation cycling costs. Energy Policy 37(4):1204–1212

Troy N, Denny E, O’Malley M (2010) Base-load cycling on a system with significant wind penetration. IEEE Trans Power Sys 25(2):1088–1097

Flynn D (2003) Thermal power plant simulation and control, vol 43, 1st edn., IEE power and energy seriesIEE, London

Subcommittee IEEE (1990) Current operating problems subcommittee: a report on the operational aspects of generation cycling. IEEE Trans Power Syst 5(4):1194–1203

Lefton S, Besuner P, Grimsrud G (1997) Understand what it really costs to cycle fossil-fired units. Power 141(2):41–42

Grimsrud P, Lefton S (1995) Economics of cycling 101: what do you need to know about cycling costs and why? APTECH engineering technical paper TP098, http://www.aptecheng.com

Denny E, O’Malley M (2006) Wind generation, power system operation, and emissions reduction. IEEE Trans Power Syst 21(1):341–347

Energy Information Administration (EIA) (2010) Energy glossary. Available http://www.eia.doe.gov/glossary

Energy Information Administration (EIA) (2000) Electric power annual 2000. Available www.eia.doe.gov

Kesgin U (2003) Study on prediction of the effects of design and operating parameters on NOx emissions from a leanburn natural gas engine. Energy Convers Manage 44:907–921

Li K, Thompson S, Peng J (2004) Modelling and prediction of NOx emission in a coal-fired power generation plant. Control Eng Pract 12:707–723

Mansour A, Benjamin M, Straub D, Richards G (2001) Application of macrolamination technology to lean, premix combustion. AMSE J Eng Gas Turbines Power 123(4):796–802

Cabot G, Vauchelles D, Taupin B, Boukhalfa A (2004) Experimental study of lean premixed turbulent combustion in a scale gas turbine chamber. Exp Thermal Fluid Sci 28:683–690

Mullane A, Lightbody G, Yacamini R (2005) Wind-turbine fault ride-through enhancement. IEEE Trans Power Syst 20(4):1929–1937

Xiang D, Ran L, Tavner PJ, Yang S (2006) Control of doubly fed induction generator in a wind turbine during grid fault ride-through. IEEE Trans Energy Conv 21(3):652–662

Lalor G, Mullane A, O’Malley M (2005) Frequency control and wind turbine technologies. IEEE Trans Power Syst 20(4):1905–1913

McArdle J (2004) Dynamic modelling of wind turbine generators and the impact on small lightly interconnected grids. Wind Eng 28(1)

Causebrook A, Fox B (2004) Decoding grid codes to accommodate diverse generation technologies

Johnson A, Urdal H (2004) Technical connection requirements for wind farms. Wind Eng 28(1)

Keane A, O’Malley M (2005) Optimal allocation of embedded generation on distribution networks. IEEE Trans Power Syst 20(3):1640–1646

IEE (2003) Embedded generation issues—a briefing note. An Energy and Environment Fact Sheet provided by the IEE

Ackermann T (2005) Wind power in power systems. Wiley, West Sussex

Milborrow D (2006) No limits to high wind penetration. Wind Power Mon 22(9)

Department of the Enterprise Trade and Investment (DETI) (2003) A study into the economic renewable energy resource in Northern Ireland and the ability of the electricity network to accommodate renewable generation up to 2010. Available www.energy.detini.gov.uk

Gardiner P, Snodin H, Higgins A, Goldrick SM (2003) The impacts of increased levels of wind penetration on the electricity systems of the Republic of Ireland and Northern Ireland (3096/GR/04)

PLEXOS for Power Systems (2006) Electricity market simulation. Available www.draytonanalytics.com

Tuohy, A, Denny E, O’Malley M (2007) Rolling unit commitment for systems with significant installed wind capacity. In: IEEE PES power technology Lausanne, Switzerland

Tuohy A, Meibom P, Denny E, O’Malley M (2009) Unit commitment for systems with significant wind penetration. IEEE Trans Power Syst 24(2):592–601

Wu L, Shahidehpour M, Li T (2007) Stochastic security-constrained unit commitment. IEEE Trans Power Syst 22(2):800–811

Takriti S, Birge J, Long E (1996) A stochastic model for the unit commitment problem. IEEE Trans Power Syst 11(3):1497–1508

Bouffard F, Galiana F (2006) Stochastic security for operations planning with significant wind power generation. IEEE Trans Power Syst 23(2):306–316

Wind Power Association (2010) Wind power integration in liberalised electricity markets (Wilmar) project. Available www.wilmar.risoe.dk

All Island Renewable Grid Study—Workstream 2B (2008) Wind variability management studies. Available http://www.dcmnr.gov.ie

European Wind Energy Association (2010) European wind integration study. Available http://www.windintegration.eu

Dupacova J, Grwe-Kuska N, Rmisch W (2003) Scenario reduction in stochastic programming: an approach using probability metrics. Math Program 96(3):493–511

Barth R, Söder L, Weber C, Brand H, Swider D (2006) Deliverable d6.2 (b) documentation methodology of the scenario tree tool. Institute of Energy Economics and the Rational Use of Energy (IER), University of Stuttgart, Stuttgart, Germany, 2006. Available www.wilmar.risoe.dk

Kall P, Wallace S (1994) Stochastic programming. Wiley, Chichester

Lannoye E, Milligan M, Adams J, Tuohy A, Chandler H, Flynn D, O’Malley M (2010) NERC integration of variable generation task force (IVGTF). Integration of variable generation: capacity value and evaluation of flexibility. Available http://www.nerc.com

Doherty R, Outhred H, O’Malley M (2006) Establishing the role that wind may have in future generation portfolios. IEEE Trans Power Syst 21(3):1415–1422

Barton J, Infield D (2004) Energy storage and its use with intermittent renewable energy. IEEE Trans Energy Convers 19(2):441–448

Brown P, Lopes J, Matos M (2008) Optimization of pumped storage capacity in an isolated power system with large renewable penetration. IEEE Trans Power Syst 23(2):523–531

Gellings C, Smith W (1989) Integration demand-side management into utility planning. Proc IEEE 77(6):1908–1918

Papagiannis G, Lettas N, Dokopoulos P (2008) Economic and environmental impacts from the implementation of an intelligent demand side management system at the European level. Energy Policy 36(1):163–180

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Denny, E. (2013). Power System Operation with Large Penetrations of Wind Power. In: Pardalos, P., Rebennack, S., Pereira, M., Iliadis, N., Pappu, V. (eds) Handbook of Wind Power Systems. Energy Systems. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-41080-2_11

Download citation

DOI: https://doi.org/10.1007/978-3-642-41080-2_11

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-41079-6

Online ISBN: 978-3-642-41080-2

eBook Packages: EnergyEnergy (R0)