Abstract

Two finite element models are coupled, with the aim of computing the mutual interactions between fluids and floating solids. The fluid and solid domains are discretised differently in space and time, and at every time step, the solid mesh is mapped onto the fluid mesh. The effect of the solid on the fluid dynamics, and vice versa, is modelled through a volumetric penalty force added to the momentum balances of the fluids and solids. A novel algorithm ensures that the action-reaction principle is satisfied at the discrete level. The coupled models are used to simulate uniform flow past a wind turbine, which is represented as a fixed actuator disc. Preliminary results on a floating pile also demonstrate the applicability of the models to fully coupled simulation of a floating spar. This work is a first-step towards the fully coupled modelling of floating wind turbines.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Fluid-structure interactions

- Immersed-body approach

- Finite element method

- Actuator disc

- Floating pile

- Floating wind turbines

1 Introduction

The numerical modelling of fluid–structure interactions is important in the context of offshore renewables. This work targets floating wind turbines, where the turbine is supported by a floating pile moored to the seabed. Such devices are attractive in deep seas (typically deeper than 50 m), where bottom-mounted foundations are too expensive. The numerical modelling of floating wind turbines is very challenging because of the dynamic interaction between the moving air–water and fluid–solid interfaces, and the presence of both rigid (i.e. the wind turbine) and deformable (i.e. the moorings) solids. Computer models are, however, attractive in studying such coupled fluid–solid problems, because they can analyse different configurations while limiting expensive laboratory or onsite testing. In this work, two finite element models are coupled in order to represent the mutual interactions between fluids and floating solids. The use of separate models, based on different spatial and temporal discretisations, allows for the mesh resolution to be tailored to the specific needs of the fluids and solids, respectively.

2 Numerical Models

Consider a solid V s immersed in a fluid domain V f . In this work, the interactions between fluids and solids are modelled by filling the regions covered by solids with the surrounding fluid and relaxing the flow to the behaviour of the solids in those regions. The Navier–Stokes equations describing the fluid dynamics are thus modified in two ways. First, they are expressed in terms of monolithic fields, which are defined over the extended domain \( V = V_{f} \cup V_{s} \). In particular, the monolithic velocity field is given by \( u = \alpha_{f} u_{f} + \alpha_{s} u_{s} \), where \( \alpha_{f} = V_{f} /V \) and \( \alpha_{s} = V_{s} /V \) are the volume fractions of the fluid and solid, respectively. Second, the monolithic velocity is relaxed to the solid velocity in V s . This is achieved by adding a volumetric penalty force to the right-hand side of the momentum balance. Considering incompressible fluids, the fluid-dynamics equations are given by:

and

where p is the pressure field, \( \mu \) is the dynamic viscosity of the fluid, \( \overline{{\overline{S} }}^{*} \) is the deviatoric part of the strain-rate tensor \( S_{ij} = \partial_{j} u_{i} + \partial_{i} u_{j} ,B \) represents external body forces (e.g. buoyancy), and F f is the penalty force. The latter is non-zero close to the fluid–solid interface only, and is expressed as

where \( \widehat{u}_{s} = \alpha_{s} u_{s} ,\beta = \rho_{f} /\Updelta t \) is a factor which dictates how fast the fluid and solid velocities relax to one another at the interface, and \( \Updelta t \) is the time step. The magnitude of the relaxation factor is driven solely by inertial effects. The extension to viscous effects is the subject of further work.

Equations 1–2 are solved using the open-source model ‘Fluidity-ICOM’ (Pain et al. 2001). This fluid/ocean dynamics model uses unstructured finite elements and has the capability of adapting the mesh dynamically in time. The fluid mesh is therefore modified, either to track accurately the fluid–solid interfaces when a solid moves, or to refine the resolution around specific flow features which develop in the wake of a fixed solid.

The finite-element model ‘Y3D’ (Xiang et al. 2009) solves the solid-dynamics equations on a separate solid mesh, which covers the regions Vs. The solid-dynamics equations are expressed as

where \( d_{s} \) denotes the solid displacement, \( \mathcal{L} \) is an operator dependent on the velocity gradient, \( F_{\text{int}} \) stands for the internal forces, \( F_{c} \) is the contact force when multiple solids impact on each other, and \( F_{\text{ext}} \) is the external force including the surface traction force and all the body forces other than the action–reaction force exerted by the fluid. A novel algorithm was implemented in order to ensure that the action–reaction principle is satisfied at a discrete level, when coupling `Fluidity-ICOM’ and `Y3D’(Viré et al. 2012). The models are applied to two different cases, which are relevant for the modelling of floating wind turbines: (1) a fixed wind turbine modelled as a thin actuator-disc, and (2) a pile floating at the interface between air and water.

3 Results

3.1 Uniform Flow Past a Fixed Actuator Disc

Wind turbines can be parameterised by thin discs, which exert a constant thrust force on the flow. The force is derived from actuator disc theory (Conway 1995), which assumes that the flow is homogeneous, incompressible, steady, frictionless and that no external force acts on the fluid upstream or downstream of the rotor. This formalism is used to model a fixed wind turbine subjected to a uniform flow. As described in the previous section, two meshes are used: the fluid mesh covers the whole computational domain, while the solid mesh only discretises the disc. Because the disc is fixed, the solid model does not solve the solid-dynamics equations. A solid-concentration field is defined on the fluid mesh, in order to identify the region occupied by the disc. This field is obtained by projecting a unitary field from the solid to fluid mesh. A thrust force acting on the fluid is spread uniformly across the disc, and is given by:

where \( \rho \) is the fluid density, \( C_{T} \) is the thrust coefficient of the wind turbine, \( A_{d} \) is the frontal area of the disc, and \( u_{0} \) is the far-upstream velocity. The size of the computational domain is \( 25D \times 10D \times 10D \), where D is the disc diameter. The disc centre is placed at a distance 5D from the domain inlet and sides. The disc normal is aligned with the flow. The Reynolds number is set to \( Re_{D} = u_{0} D/\nu = 10^{3} \), where \( \nu \) is the kinematic viscosity of the fluid. Three values of the thrust coefficients are considered (\( C_{T} = 0. 2; \, 0. 4 5; \, 0. 7 \)). The fluid mesh adapts every T = 1 s, in order to refine the regions of high curvatures in the velocity and pressure fields. The total number of mesh nodes at steady state is of the order of 106. The time step is such that the Courant number is fixed at 0.3. The streamwise evolution of the streamwise velocity at the disc centreline is shown in Fig. 1 where the numerical results are indicated by dashed lines and the continuous lines represent the semi-analytical solution (Conway 1995). The velocity deficit induced by the disc is well predicted by the present algorithm. The discrepancy between numerical and theoretical results in the far-wake is explained by the role of the fluid viscosity in the numerical simulation. No wake recovery is observed in the theoretical results, which are derived in the inviscid approximation. The effect of the resolution on the numerical results is under further investigation.

Streamwise evolution of the streamwise velocity (non-dimensionalised by the far-upstream velocity) for an actuator disc of diameter D, centred at x = 0, and three values of thrust coefficient C T . The lines represent the semi-analytical solution (Conway 1995), while the dashed lines show the numerical results

4 Dynamics of a Floating Pile

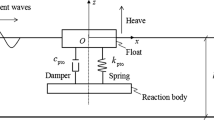

The dynamic response of a pile is analysed when placed at the interface between air \( (\rho_{1} = 1.2\,{\text{kg}}\cdot{\text{m}}^{ - 3} ,\mu_{1} = 18.27\mu {\text{Pa}} \cdot {\text{s)}} \) and water (\( \rho_{2} = 1000\,{\text{kg}}\cdot{\text{m}}^{ - 3} ,\mu_{2} = 1.002\,m{\text{Pa}}\cdot{\text{s}} \)). The pile density is uniform and equals half the water density. It is centred in a box of edge length 20D, where D is the pile diameter and 4D is its length. Initially, the fluids are at rest and the pile lies vertically across the fluid interface (Fig. 2 left). As time evolves, the pile moves in heave before falling into water. The pile eventually reaches an equilibrium position, that is horizontal and half submerged in water, in accordance with Archimedes’ principle.

5 Conclusions

This work presents a novel algorithm to couple two finite element models and demonstrates their ability to simulate: (1) the flow past a fixed wind turbine represented as an actuator disc, and (2) the dynamics of a cylindrical pile floating at the interface between air and water. Results in both cases are shown to be in good agreement with theoretical predictions, and the effect of different parameters will be the subject of further work. This study is a first step towards the fully coupled numerical simulation of floating solids, applicable to the next generation of offshore renewables.

References

Conway J (1995) Analytical solutions for the actuator disk with variable radial distribution of load. J Fluid Mech 297:327–355

Pain C, Umpleby A, de Oliveira C, Goddard A (2001) Tetrahedral mesh optimisation and adaptivity for steady-state and transient finite element calculations. Comput Methods Appl Mech Engrg 190:3771–3796

Viré A, Xiang J, Milthaler F, Farrell P, Piggott M, Latham JP, Pavlidis D, Pain C (2012) Modelling of fluid-solid interactions using an adaptive-mesh fluid model coupled with a combined finite-discrete element model. Ocean Dyn 62:1487–1501

Xiang J, Munjiza A, Latham JP (2009) Modelling of fluid-solid interactions using an adaptive-mesh fluid model coupled with a combined finite-discrete element model. Int J Numer Meth Engng 79:946–978

Acknowledgments

This work is supported by the European Union Seventh Framework Programme (FP7/2007-2013) under a Marie-Curie Intra-European Fellowship (grant agreement PIEF-GA-2010-272437). The authors also wish to acknowledge support from EPSRC, NERC, the Grantham Institute for Climate Change and the High Performance Computing Service at Imperial College London. The content of this paper reflects only the authors′ views and not those of the European Commission.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Viré, A., Xiang, J., Piggott, M.D., Cotter, C.J., Latham, JP., Pain, C.C. (2014). Towards the Numerical Modelling of Floating Offshore Renewables. In: Zhou, Y., Liu, Y., Huang, L., Hodges, D. (eds) Fluid-Structure-Sound Interactions and Control. Lecture Notes in Mechanical Engineering. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-40371-2_59

Download citation

DOI: https://doi.org/10.1007/978-3-642-40371-2_59

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-40370-5

Online ISBN: 978-3-642-40371-2

eBook Packages: EngineeringEngineering (R0)