Abstract

The potential impact of light-weight structures with multifunctional properties for engineering applications drives significant research and development activities on nanocomposites. Polymer nanocomposites especially those with carbon nanotubes (CNTs) are very attractive for conductive composites with good structural characteristics. The biggest challenge facing the commercial success of CNT based composites is the intrinsic strength of their agglomerates which prevents good filler dispersion in the matrix, a key attribute for any reinforcement. This chapter is a review of the CNT incorporated thermoplastic composites processed mainly containing economic multi-walled carbon nanotubes (MWCNTs). We present an overview of CNTs (their structure, production process, properties, surface modification, applications etc.) and the mechanism of their dispersion in thermoplastic matrices. The processing of thermoplastic matrices via the conventional twin-screw compounding approach is discussed along with the influence of process parameters on MWCNT dispersion. The role of secondary processing operation on composite properties is also highlighted. The mechanical, electrical and thermal properties of the thermoplastic-CNT composites are reviewed highlighting the key findings and shortcomings. We conclude throwing some light on the developments on multi-scale reinforcements in polymeric matrices.

An erratum to this chapter is available at 10.1007/978-3-642-40322-4_13

An erratum to this chapter can be found at http://dx.doi.org/10.1007/978-3-642-40322-4_13

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

The ever increasing demand for improved properties of polymer matrices especially for light-weight structures and multifunctional characteristics has strongly shifted the focus of researchers on nanomaterials as reinforcements. The development of polymer nanocomposites has been a significant area of research and has evolved significantly over the last two decades owing to the ability of nanoscale reinforcements to create remarkable property enhancements at relatively low filler concentrations, compared to conventional composites. Nanocomposites based on polymeric matrices gained significant interest after the report of nanoclays filled nylon-6 by Toyota in 1993 [1], but the actual mention of the term was first found in the work on Lan and Pinnavaia [2]. Surprisingly automobile tires in which carbon black acts as a reinforcement is also an example of a nanocomposite. However, the term “nanocomposite” is not generally used to describe such composites. A nanocomposite is considered to be a multiphase solid material where one of the phases has one, two or three dimensions of less than 100 nm according to Ajayan et al. [3]. According to the ISO/TS27687 standards the nanofillers are classified based on their dimensions as 1-D (e.g. platelet, lamella; thickness <100 nm), 2-D (e.g. tube, fiber; diameter <100 nm) and 3-D (e.g. bead, sphere; all dimensions <100 nm) nano-objects [4].

The growth of different types of nanomaterials starting from nanoclays, cellulose nanowhiskers, carbon nanofibers, carbon nanotubes (CNTs), graphenes, nano-oxides like nanosilica, nanoalumina, titanium dioxide etc. has led to the development of composites with extremely attractive macroscopic properties–multifunctional in most circumstances depending on their inherent characteristics. Excellent electrical, thermal, mechanical, optical, fire-retardant, barrier, anti-bacterial and scratch resistant properties of these composites have been reported and the results are only getting better with time. The high surface to volume ratio of these fillers facilitates the attainment of desired macroscopic functionality at substantially lower filler loading fractions. The biggest challenge with these nanofillers however has been with dispersing them in the host matrix to take advantage of their theoretical potential. Table 1 gives an overview of the areas of application for the well known and widely employed nanofillers.

Carbon based nanomaterials are highly attractive due to their ability to transition an insulating polymer matrix to a conductive composite, in addition to the proven advantage in achieving excellent structural properties. CNTs stand out among the other carbon based fillers like carbon fibers or carbon nanofibers which require higher filler loading fractions to exhibit similar levels of electrical conductivity. Graphene tipped to be a strong competitor for the CNTs on the other hand is still in its infancy, and large production volumes of these materials is still challenging. CNT based polymer composites have been a significant area of research in the last couple of decades owing to CNTs high aspect ratios with nanometric dimensions, low mass density and intrinsically superior electrical [5–8], mechanical [8–11], and thermal properties [8, 12, 13].

Continuously lowering costs of CNTs, especially multiwalled carbon nanotubes (MWCNTs) with increase in demand and production capabilities augments favorably for a huge polymer-CNT nanocomposite market. Interesting observations on MWCNT based composites have been plenty starting from different ways of MWCNT synthesis to its application in electromagnetic shielding (EMI) [14–17], sensors [18–20], electrostatic charge dissipation (ESD) [21], flame retardancy [22], wind turbine blades [23], photovoltaic packaging [24], electrically conducting cables [25] etc.

The potential of CNTs as fillers for multifaceted product development in polymer matrices certainly tilts the tide in its favour compared to its competitors. Due to the renown challenge involved with dispersing the CNTs in thermoplastic matrices for good macroscopic properties of the composites, thermoplastic composites with CNTs (primarily MWCNTs) is the main focus of attention in this chapter.

2 Carbon Nanotubes: An Overview

The interest in the special allotrope of carbon called CNTs was greatly stimulated by the observations of tubular forms of carbon with nanometric dimensions by Iljima [26], and succeeding reports on the capabilities to synthesize these nanoparticles in large quantities [27, 28]. CNTs belonging to the fullerene family are geometrically idealized to be a cylinder formed by concentrically rolled graphene sheets. They are typically of a few nanometers in diameter and microns in length.

2.1 Structure of CNT

Similar to the structure of graphite, the sp2 hybridized CNT has each of its atoms bonded to three neighboring atoms in an hexagonal array. As the cylindrical structure of the CNT is brought about by the rolling up of the graphene sheets, the type of CNT would depend upon the number of concentric cylinders. CNTs principally exist as SWCNTs, double-walled carbon nanotubes (DWCNTs) or as MWCNTs (Fig. 1).

Different types of CNTs—based on the number of tube walls. Reprinted from [141], Copyright (2003) with permission from Elsevier

The intrinsic properties of the CNTs would stem from their atomic arrangement (or in other terms the way their graphene sheets are rolled), the type of CNT and their individual geometric dimensions. The rolling up of the graphene sheets and hence the atomic structure of the CNTs is well defined by tube chirality. The chirality is given by the chiral vector \( C_{h } = n\vec{a}_{1} + n\vec{a}_{2} \) where \( (\vec{a}_{1} ,\;\vec{a}_{2} ) \) are the unit vectors and (n,m) are the number of steps along the unit vector of the hexagonal lattice [29]. This gives rise to three possible orientation forms for the carbon atoms of the CNTs. If n = m, it leads to the “armchair” structure while the “zigzag” structure results when m = 0. Any other orientation is referred to as the “chiral” structure. The electronic conduction of the CNTs is dependent on its chirality. CNTs possessing an “armchair” chirality are metallic, semi-metallic when (n–m)/3 = i and n ≠ m, where i is an integer and semi-conducting otherwise [30]. The chirality of a MWCNT is extremely complex as each of the concentric nanotube walls could carry different chiralities. Figure 2 shows the nomenclature system of CNTs and the different chiral forms of SWCNTs [(a) arm chair, (b) zigzag, (c) chiral].

2.2 Synthesis of CNTs

Arc discharge, laser ablation and chemical vapor deposition (CVD) are three principal techniques by which CNTs are synthesized. They are briefly described below. The schematic of the different techniques are shown in Fig. 3.

Techniques for CNT synthesis [144]. a Arc discharge, b Laser ablation, c CVD

The arc discharge approach is probably the easiest to synthesize MWCNTs, however the quality of the resulting CNTs and the pattern of growth is not the best while comparing to the production by other techniques [31]. In the arc-discharge approach, two graphite electrodes are placed 1 mm apart in an inert atmosphere and a direct current of about 50–100 A at a voltage of 20 V is applied across them. The vaporization of carbon at these conditions result in a high temperature discharge (also termed as plasma) resulting in the consumption of the anode and the formation of deposits on the surface of the cathode from where the CNT grows. The typical yield of this process ranges from 30 to 90 % and the principal advantage of this process is the economic production of MWCNTs without a catalyst. The doping of the anode with a metal catalyst would result in the formation of SWCNTs [30]. The principal drawback of the arc-discharge approach is the production of shorter and impure CNTs which mandates a purification step to generate high quality CNTs.

The laser ablation technique uses a high power laser to form the discharge product unlike the direct current (DC) generated electricity in the arc-discharge approach. Laser is shot on a graphite source that is placed in an oven under inert atmosphere at temperatures of around 1,100–1,200 °C. The carbon vapors formed under these conditions expands and cools resulting in the formation of CNTs and other members of the fullerene family depending upon the set process conditions. MWCNTs are the principal product and are shorter in length compared to arc-discharge process [30, 32], but the addition of a metal catalyst to graphite would result in SWCNTs. The typical yield of this process is around 70–80 % and the purity of the produced nanotubes is significantly higher. Good product control is possible; however this comes with the trade-off of high production cost due to higher power requirements for operating the laser.

CVD is the widely adopted industrial approach for producing CNTs owing to its scalability. When a carbon containing gaseous source like acetylene, methane etc. is passed over a metal catalyst at temperatures ranging from 550 to 1,200 °C it results in the freeing up of carbon atoms on the decomposition of the gas, which recombines in the form of CNTs on the metallic substrate. This method is widely adopted for flexibility in controlling the quality and exercising good control over the dimensions of the formed product. The yield varies from 20 to 100 % with minimal need for purification of the synthesized CNTs due to the negligible traces of amorphous carbon. Very long CNTs can be produced by this approach. The production of extremely pure SWCNTs is possible with controllable diameters, but the MWCNTs that are formed with the CVD process has more structural defects [33], and are highly entangled compared to the arc discharge and laser ablation approach.

2.3 Properties of CNT

CNTs are known for their intrinsically high mechanical, thermal and electrical properties. The sigma bonds which make up the C–C bonding in CNTs attributes to their excellent mechanical characteristics. Elastic modulus of 1.2 TPa and tensile strength of about 50–200 GPa have been reported for CNTs [34]. However, there does not seem to be a consensus on the reported mechanical behaviour among published literatures. Their high axial and low lateral thermal conductivity also add to their significance. Although theory predicts a room temperature thermal conductivity of 6,000 W/mK [35], Kim et al. estimate the thermal conductivity of MWCNTs to be 3,000 W/mK [36], and Pop et al. report 3,500 W/mK for SWCNTs [37]. This is significantly higher than the thermal conductivity of diamond (1,000–2,200 W/mK) which is reported to be one of the best known thermal conductors [38].The oxidative thermal stability for both MWCNTs and SWCNTs are greater than 600 °C which compares strongly with that of 450–650 °C for graphite. Their co-efficient of thermal expansion is very minimal which supports the excellent thermal conductivity of these materials. SWCNTs show electrical conductivities of the order of 102–106 S/cm, while it ranges between 103 and 105 for MWCNTs. The lower scales are very similar to the reported in-plane electrical conductivity of graphite of about 200–2,500 S/cm [39], indicating the dominative electrical properties of CNTs compared to one of the best reported electrical conductors in graphite. They also boast of extremely high intrinsic electron mobility of greater than 105 cm2/Vs [40], which is very similar or even higher than graphite.

The extraordinary multi-faceted properties of CNT confer to these materials a significant potential to be used in a wide-variety of applications. The intrinsic tendencies of the CNTs to exist as agglomerates due to their van der Waals (vdW) forces of attraction (0.5 eV/nm) [41], by large limits the realization of the complete potential of these materials as nanoscale reinforcements in different host matrices.

2.4 Commercially Available CNTs

Commercially available CNTs that primarily results out of the CVD process are highly disorganized and have a highly agglomerated morphology with a significant agglomerate strength. This inability to produce individualized and aligned morphologies severely inhibits the theoretical potential of CNTs as to what could be expected out of CNT yarns or forests. Although it is highly complicated to achieve aligned CNT morphology in a commercially viable process, the cohesive or the vdW forces of attraction that results in the agglomerated morphology of CNTs could at least be minimized in order to gain a competitive advantage with CNTs as polymeric fillers. The initial or the primary CNT agglomerates have to be broken down theoretically into individual CNTs or in other terms dispersed well into the polymer host to translate the intrinsic characteristics of the CNTs to their composites. This has remained a significant challenge over the years and any effort to maximize the quality of dispersion on industrial scale could result in taking these nanocomposites close to application.

Due to its availability in bulk and lower costs, MWCNTs would be the ideal choice for high volume industrial applications; hence attention would be focused on MWCNT dispersion in thermoplastics in this Chapter. Scanning electron micrographs (SEM) images of two of the most widely reported type of MWCNTs in literature namely Baytubes ® C150P (Bayer Material Science, Germany) and Nanocyl TM NC7000 (Nanocyl S.A., Belgium) are shown in Fig. 4.

These pictures indicate a highly entangled network of MWCNTs with sizes ranging up to a few hundred microns, unusual for a material described as nanofiller. Alig et al. describe the structure of loosely packed larger agglomerated NC7000 as a “combed yarn” structure while that of C150P as a “birds nest” with smaller tightly held primary agglomerates [42]. Although the geometries of these MWCNTs do not differ significantly, the average deformation stress (at 25 % strain) of C150P with a bulk density of 120–170 kg/m3 [43], is 0.64 MPa [44], while that of NC7000 with a bulk density of 60 kg/m3 [45], is 0.39 MPa [44]. This difference in the deformation stresses of the MWCNTs will be a critical factor in determining the magnitude of processing parameters and consequently the extent of processing shear required to create equivalent dispersion qualities with these two different CNT types.

2.5 Modification of CNT Surface

Modification of the CNT surface is an approach widely adopted to render the surface of the inert CNTs compatible to interact efficiently with the polymer and also weaken their intrinsic vdW forces of attraction. This is also termed as CNT functionalization. Functionalization both by chemical and physical means has been largely reported.

Chemical functionalization is done either on the side walls of the nanotubes or by creating defects on CNT surfaces by acid treatments. This is expected to result in a very strong matrix-CNT interaction with a trade off on the structural characteristics of CNTs. The sp2 hybridization of carbon is transformed to sp3 to create active sites for effective interaction with polymer accompanied with the loss of π conjugation bonds on the outer walls. Covalent functionalization of CNTs could modify CNT stacking morphologies by altering hydrogen bonds resulting in improved CNT solubility in solvents [46]. But, covalent functionalization tends to negatively affect the physical and chemical integrity of CNTs. Strong acid treatments affects the geometry of the CNTs resulting in increased filler percolation thresholds [47]. Covalent treatments could also negatively affect the intrinsic electrical properties of the CNTs and have a profounding effect on the metallic characteristics of metallic CNTs [48]. Enhanced reactivity between CNT and the polymer would result in wrapping or encapsulation of CNT surfaces by the polymer due to coupling or grafting lowering the bulk conductivity of the composite [49]. The phonon scattering length is also expected to be lowered leading to lower thermal conductivities [50]. Covalent treatments are mainly aimed at improving polymer-CNT compatibility and CNT dispersion. Effective achievement of this could lead to improved structural characteristics accompanied with losses in electrical and thermal conductivity of the composite.

Physical functionalization is done by polymer wrapping (vdW forces and π-π stacking), surfactant adsorption on CNT surface (physical adsorption) and endohedral techniques (capillary principle). Although this technique would not damage CNTs a weak CNT-polymer interaction could be expected out of these approaches. Non-covalent or physical treatment of CNTs result in the outer tube walls subjected to more treatment than the inner tubes [51]. This could result in the CNTs being bundled even after treatment. Hence mechanical treatments like milling, ultrasonication etc. should precede this treatment. Since physical methods don’t result in significant CNT structural damage, their composites could be expected to show enhanced electrical conductivity as the π-conjugation of the CNTs and their electron transfer paths could maintain their identities. Polymer wrapping of CNT surfaces cannot be completely ruled out resulting in lower electrical conduction. Mechanical property enhancements cannot be expected to be on a larger scale because the chance for the interfacial strength to improve is minimal because of lack of chemistry.

The techniques of chemical and physical modifications are however, relatively expensive which limits modification of the CNT for large scale applications. A review by Bose et al. [52], discusses the positives and the drawbacks of both physical and chemical functionalization in detail on the properties of CNT based polymer composites.

2.6 Applications of CNTs

The intriguing properties of CNTs have led to many research efforts leading to uncovering the potential prospects of employing CNTs in practical applications. Although it has been very complex to translate the theoretical potential of CNTs till date into potential applications, efforts are still ongoing towards understanding the intrinsic properties of CNT and ways to implement them in real life. The benefits of CNTs are expected to be significantly realized from an economical perspective when they are used as functional fillers for materials like plastics, ceramics etc., however their potential to be used as such (especially SWCNTs in flexible electronics applications) is also being widely worked on. This is supported from the finding that 69 % of the global CNT market share of $472.9 million in 2010 was the contribution of the plastics and composites industry [53].

Although a wide variety of applications could result owing to superior CNT properties, they can principally be classified into three main categories of mechanical (structural composites for aerospace and automotive industries, textiles, sport goods, etc.), thermal (flame retardant additives, coatings, electronic circuitry etc.) and electrical & electronics (semi-conducting materials, electronic circuitry, fuel supply systems of automobiles, navigation systems etc.). The multi-functional derivates that stems out by a combination of these properties on the final part application adds significant value to the applications of CNTs.

The European Chemical Industrial Council (CEFIC) classifies the potential applications of CNT on the basis of time into short term—those products based on CNT already available or will shortly be available (e.g. conductive composites, sensors, electromagnetic shielding, sport goods), mid-term (e.g. coatings, lithium-ion battery, fuel cells, semiconducting materials, petrochemical catalysts etc.) and long term—those currently under the scope of research & development (e.g. drug delivery, microwave antennas, medical implants etc.) [54].

Some of the existing commercial applications of the CNTs include the long range vessel LRV-17 from Zyvex Marine made of a carbon fiber-nanocomposite system consisting of carbon fiber reinforced plastic (CFRP) and CNTs which enables reduction in structural weight, efficient fuel usage and increased range [55], and a 25 times stronger tennis racket by Völkl made of CNT compared to carbon fibers (at same weight) which would eventually result in more kinetic energy returned to the ball [56]. Aldila have also reported to have used CNT based epoxy composites for golf shafts for vibration damping [57].

2.7 CNTs: A Market Outlook

The production capacity of CNTs is expected to grow globally from 3,141 to 12,806 metric tons in 2016 at a Compound Annual Growth Rate (CAGR) of 10.5 % according to Centre for Knowledge Management of Nanoscience and Technology (CKMNT), India [53]. As per their 2011 forecast the total CNT market is to yield around $1.1 billion by 2016 at a CAGR of 10.5 %.

A Frost and Sullivan report published in 2011 forecasts a $35.52 million market for CNT in the automotive composites by 2015, indicative of a market share of 3.6 % at 1 % CNT loading [58]. The report also predicts a 10 % penetration of CNT in the construction industry, 15 % in the fibers and textile domain, and about 25 % in the intumescent coating market. From an electronics industries' standpoint, the largest share for CNT is expected for the displays (1 - >5 %) and flexible displays (1–10 %), whereas only 1 % penetration in the sensor market is foreseen. Significantly, CNTs are also expected to gain a 1–5 % share in the total authentication market. With recent developments in research, it is expected that these numbers will continue to rise in spite of a foreseen potential threat by graphene which is expected to gain a significant market share especially in the electronics industry.

3 Processing of CNT Incorporated Thermoplastic Nanocomposites

The level of CNT dispersion visible on the composite morphology is a direct function of the type of polymer and CNT employed, the processing approach and the process factors. The morphology and therein the macroscopic properties of the composite are dictated by the thermo-mechanical history during processing. Several processing methodologies such as solution casting [59–61], melt mixing [62–67], solution mixing [59, 60, 68], different methods of in situ polymerization of the monomer in the presence of CNTs [69, 70], coagulation spinning [71], mechano-chemical pulverization [72], solid-state shear pulverization [73], electro spinning [74] etc. have been adopted for the synthesis of polymer-MWCNT composites. In this section only the predominantly preferred approaches namely solution processing, in situ polymerization and melt mixing would be discussed in brief.

Solution processing is one of the widely utilized approaches owing to its simplicity. It involves dispersion of the CNT in a suitable solvent by sonication and/or stirring followed by mixing with a solution of the polymer host, evaporation of the solvent and drying with or without vacuum. Ultrasonication is widely employed to break the CNT agglomerates as the shear in the solution mixing process is significantly low. The type of ultrasonication (ultrasonic bath or horn), bath temperature, rate of sonication (frequency and time) and the nature of the solvent could have a strong influence on the properties of the product. This method can be successful with the right choice of solvent and complete removal of the solvent during the drying stage, however it is not easily scalable. It is widely adopted for preparing composites based on thermosetting matrices where a significant magnitude of shear is not required as the low viscosity of the host would result in good infiltration of the CNT agglomerates facilitating dispersion.

In situ polymerization of monomers in the presence of CNTs is another widely used technique for composite preparation. This technique is proposed to form a very good chemical affinity between the polymer chains and the CNTs in most cases, but depending on the nature of the reactants a non covalent interaction is a definite probability. The polymerization of the monomer in the presence of an initiator is carried out with CNTs in the vicinity enabling the production of composites with high CNT loadings. A mix of polymer grafted CNTs and free polymer chains are obtained which creates a favorable environment for the development of a highly compatible polymer-CNT interface. The low viscosity of the starting monomer facilitates better infiltration into the CNTs and consequently their dispersion. CNT based composites of polystyrene (PS), poly (methyl methacrylate) (PMMA), and vinyl monomers are commonly produced using this approach. Yuan et al. show significant enhancement in the mechanical properties of PS-MWCNT composites prepared by a combination of in situ polymerization followed by melt mixing owing to strong interfacial adhesion between the CNT grafted PS and the PS matrix [75].

Owing to its simplicity and adaptability for a commercial scale up melt mixing/compounding seems to be the most commonly employed approach for thermoplastic polymer/MWCNT nanocomposites. This method is most suitable for polymers that cannot be processed with the solution processing approach owing to its inability to dissolve in commonly employed solvents. The higher magnitude of shear during the melt mixing process facilitates the breakup of the CNT agglomerates followed by simultaneous dispersion and distribution in the polymer melt. For a melt mixing process to give optimum dispersion quality optimization of all the process parameters like the screw configuration, screw speed, throughput/residence time, barrel temperatures, filler feeding position etc. is imperative.

3.1 Mechanism of CNT Dispersion in Thermoplastics

Dispersion of CNT in thermoplastics is a simultaneous sequential process starting with the wetting of the CNT agglomerates by the polymer melt, infiltration of the polymer melt into the CNT agglomerates, disintegration of agglomerate fractions weakened by the infiltration process and shear forces into small fractals by mechanisms of erosion and/or rupture followed by their distribution in the polymer host (Fig. 5). This mechanism of filler dispersion is strongly influenced by the processing approach, associated process parameters and the nature of the polymer and the CNTs.

For effective wetting of the primary CNT agglomerates by the polymer melt, the interfacial energy difference between the polymer and the CNT should be at its minimum. As the interfacial energy difference between polar thermoplastics like polycarbonate (PC), polyvinyl chloride (PVC) etc. with the hydrophilic CNTs is significantly low, excellent CNT dispersion is achievable with these matrices resulting in extremely low filler percolation thresholds for the final macroscopic properties [67, 76–78]. On the other hand polyolefins exhibit a very high interfacial energy difference with the CNT limiting the level of CNT dispersion in the composite [62, 79]. Incorporation of surface functionalities to the CNT is a solution to render compatibility with the polymer; however this is an expensive approach as detailed earlier.

Infiltration of the polymer melt is principally governed by the mobility of the polymer chains (dependent on viscosity), the available pore radius or in other terms the agglomerate density of the CNTs, the strength and size of the CNT agglomerates and surface tension variations between the polymer and the CNT. Lower polymer viscosity or high melt temperatures and low agglomerate density would aid faster infiltration, while minimal interfacial energy difference between the polymer and the CNT would enhance the efficiency of infiltration. The infiltration process can be manipulated by the choice of the raw-materials and the process parameters which will be discussed in detail later in Sects. 3.2 and 3.3.

The magnitude of applied shear stresses arising due to the viscous flow on the CNT agglomerates during processing must be above the inherent strength of the agglomerates (σa) for dispersion to occur. The dispersion of the weakened primary agglomerates by preceeding wetting and infiltration would take place by mechanisms of rupture/and or erosion governed by a dimensionless fragmentation number (F) which is directly proportional to the product of the melt viscosity (η) and the shear rate (γr) and inversely proportional to the inherent maximum agglomerate strength (σam). The magnitude of contribution of the infiltration step towards the reduction in σa could play a role in regulating the maximum shear stress that has to be exerted on the agglomerates. It is to be remembered that enhanced shear stress could result in tube breakage and also could lead to possible polymer degradation. Though rupture and erosion would co-occur, a significantly larger magnitude of F (F ≫ 1) would result in a situation where rupture would dominate while lower F (F ≪ 1) would result in dispersion dominated by erosion [80]. The mechanism of rupture is comparatively faster than erosion owing to the instantaneous breakage of primary agglomerates into smaller fractals in the former, while a slowly peeling of individualized CNTs occurs from the outer surface of the primary agglomerate fraction in the latter. Distribution of the dispersed agglomerate fractals takes place simultaneously with the disintegration or the rupture of remaining agglomerates over the course of the process. Idealizing this in the context of twin-screw extrusion, the residence time in the extruder would determine the extent of filler dispersion for a given set of process parameters and material combination.

3.2 Influence of Raw Materials

The selection of a suitable polymer host and the intrinsic characteristics of that polymer host is one of the critical factors affecting the quality of filler dispersion in the final composite. An increased affinity between the polymer and the CNT would result in better wetting of the CNT agglomerates which is the preliminary step in the mechanism of dispersion. Polymers like PC and PA which has lower interfacial energy difference could result in better wetting of the CNT agglomerates and hence better dispersion while the quality of dispersion in polyolefins is poor owing to its hydrophobic nature and higher interfacial energy difference with CNT. Exceptionally polystyrene (PS) presenting a polar characteristic shows poor CNT dispersion morphology owing to the high chain stiffness due to its phenyl groups.

The viscosity of the polymer melt governs the extent of melt infiltration into the agglomerates and the dominating mechanism of filler dispersion via rupture or erosion. Lower polymer viscosity would result in better melt infiltration, but could result in lower magnitude of viscous flow shear stresses during processing. Higher polymer viscosity would hinder easier and faster melt infiltration but can result in increased shear stresses for agglomerate breakage. Magnitude of the shear stresses required for dispersion of CNT is also dictated by the intrinsic characteristics of the CNT. Kasaliwal et al. discuss the influence of PC melt viscosity and molecular weight on the level of MWCNT dispersion and conclude that lower matrix viscosity resulted in better melt infiltration leading to better MWCNT dispersion and hence lower electrical resistivities in the composite [81].

The type of CNT especially its number of walls, length, aspect ratio, agglomerate strength and morphology, and the nature of surface functionalization are factors to be considered while designing the process and the associate parameters for its dispersion in a polymer matrix. A CNT with higher agglomerate strength would present increased difficulties to melt infiltration compared to a CNT type with more loosely packed agglomerates even if larger agglomerate size fractions are present in the latter. High aspect ratios of CNT are beneficial for efficient load transfer and hence improved mechanical properties at low percolation thresholds. However, it could complicate dispersion owing to the enhanced available surface area for intra-CNT interactions compared to employing CNTs with low aspect ratios. A balance between the level of dispersion and the aspect ratios of the CNT are quite critical for the end properties as elucidated by Castillo et al. on their work on PC incorporated with different types of CNTs [78]. The enhancement in the compatibility of the CNT with the polymer by functionalization techniques also plays a role in dictating the level of MWCNT dispersion in the polymer host. Menzer et al. found that the altering of the CNT lengths by ball milling resulted in compact agglomerate morphologies and reduction in CNT lengths contributing to higher electrical and rheological percolation thresholds in the composite [62]. Idealizing this to the reduction in the length of CNTs as a function of processing, it would be wise to prefer CNTs with longer average lengths.

3.3 Influence of Process Parameters

The typical melt mixing or compounding parameters namely screw speed, barrel temperature, material throughput, screw configuration and residence time would have to be tailored to specific thermoplastic polymer-CNT system in order to achieve the desired CNT dispersion quality for maximum composite performance [65, 67, 82]. As dispersion is a continuous mechanism influenced by the shear stresses generated by the viscous flow governed by these parameters, addressing the individual contribution of these factors is complicated. This section briefly outlines the individual effects and complementary influences these factors would have on the level of CNT dispersion from a processing perspective.

A higher screw speed would result in an increased specific mechanical energy input (SME) of the process resulting in enhanced shear stresses and thereby dominant dispersion mechanism by rupture. A higher screw speed also would result in a decreased level of screw fill and a lower residence time for the melt in the extruder at a condition where the other parameters are kept constant. Higher screw speeds could also result lower polymer viscosity aiding faster melt infiltration, but at the same time can result in polymer degradation and also negatively affect the aspect ratio of the CNTs [82]. Lower speeds on the other hand would act opposite to what has been detailed with significant limitation on the level of generated shear stresses. A higher screw speed was found to be helpful in achieving good filler dispersion when employing matrices that are not known to be compatible with the CNTs like PS, PP and when using CNTs with a high agglomerate strength [65, 83].

Melt or barrel temperatures influence the melt viscosity of the polymer and thereby the level of infiltration and the magnitude of generated shear stresses for agglomerate dispersion. Lower melt viscosities are highly recommended for faster and better infiltration of the CNT agglomerates while higher melt viscosities are important for enhanced shear stresses. The desired level of dispersion would determine the domination of the melt infiltration step or the creation of enhanced shear stresses for higher fragmentation numbers.

Low material throughputs would result in higher SMEs, lower degree of screw fill, and higher local melt residence time leading to improved CNT dispersion quality with trade-off on production volume. Throughput levels are also regulated by the feeding capacity of the nanomaterial feeder owing to very low bulk density of the CNT along with a very low volume fraction of filler feed.

An optimum screw design must be able to provide the desired level of SME for the pre-set extrusion parameters and is generally a combination of mixing, kneading and transportation elements. The magnitude of SME, the nature of the CNT agglomerates and the desired residence time of the melt in the extruder would dictate the screw configuration. The screw configuration should be designed keeping in mind of the other process factors. When a high speed is required for processing composites containing high agglomerate strength CNT, the screw design must be able to accommodate this process with a sufficient residence time to allow for other dispersion steps like wetting and infiltration. An enhanced residence time is bound to result in polymer degradation while shorter residence times may not provide the desired level of dispersion.

The position of filler feeding becomes important when dealing with CNTs. CNTs with enhanced intrinsic agglomerate strength like the Baytubes® C150P are recommended to be fed along with the polymer in the principle feeding port in order to allow for increased residence time for agglomerate dispersion. Side feeding of the filler NanocylTM NC7000 which has a lower agglomerate strength is recommended owing to its loosely packed agglomerate structure with better dispersion envisioned by a dominant melt infiltration [84].

We have carried out comprehensive investigations on the influence of the twin-screw process parameters on MWCNT dispersion in PP, PS, PPE/PS and PC and have understood that the ideal processing parameters is strongly dependant on the nature of the matrix and its compatibility with the CNTs [65–67, 83].

3.4 Strategies for Improving CNT Dispersion During Processing

Functionalization of CNTs by physical or chemical means as discussed earlier has been reported to result in improved CNT dispersion in polymer matrices. This approach is however not commercially viable owing to the high costs, scale up limitations and environmental issues. Hence, it becomes important to focus on alternative strategies via which CNT dispersion in a polymer matrix can be improved.

“Nanodirekt” is an approach involving the dispersion of nanomaterials in water or solvents followed by a direct addition of this homogeneous dispersion into the polymer melt [85]. The dispersing medium will evaporate immediately and the nanoparticles will stay finely dispersed in the polymer matrix. This method ensures that the dry nanofiller is not fed directly into the extruder eliminating potential health hazards associated with handling of nanofillers.

Subjecting the polymer-CNT melt to ultrasonic waves in the extruder has resulted in improved CNT dispersion in PEEK (polyether ether ketone) in the work of Lewis and Isayev [86]. Isayev et al. have demonstrated this approach also on polyetherimide (PEI)/MWCNT composites [87]. Weiss et al. on their work on PP-CNT composites with two different types of CNT however state that the efficiency of employing an ultrasound during the extrusion process is strongly dependant on the type of the CNT employed [88].

Enhanced nanofiller dispersion in a polymer matrix is aided by supercritical carbon dioxide (sc-CO2) assisted processing. Different variants of this method have been adopted by research groups. Nguyen and Baird propose an approach in which a pressurized CO2 chamber is employed to assist in the exfoliation and delivery of the clay into a stream of polymer melt in the extruder [89]. A modified hopper in the feed section of the extruder to allow polymer and clay to interact with sc-CO2 before processing was proposed in the work of Zerda et al. [90]. Clay particles were pre-treated with sc-CO2 in a pressurized vessel and then rapidly depressurized into another vessel at atmospheric pressure to force the clay platelets apart in the work of Manke et al. [91]. Though this approach has been widely reported for nanoclays, there exists a possibility for extending it to the CNTs. Chen et al. demonstrated an identical process employed by Nguyen and Baird for the processing of CNT/poly(phenylsulfone) (PPSF) composites [92].

Incorporation of processing additives is a simple and economical strategy for enhancing CNT dispersion in thermoplastics. The addition of peroxide during twin-screw compounding led to a substantial improvement in the quality of MWCNT dispersion in PP owing to the reduction in PP melt viscosity (facilitating better melt infiltration into the agglomerates), reduction in ther interfacial tension between PP and CNTs (leading to better melt wetting of the agglomerates), and surface functionalization of carbon nanotubes (resulting in weakening the intra-filler attractive forces) [64]. Better wetting and infiltration of the MWCNTs by polyethylene glycol resulted in a significant improvement in MWCNT dispersion in PE [93].

3.5 Influence of Secondary Processing on Composite Properties

Though good primary filler dispersion is a pre-requisite for good macroscopic characteristics of the composite, widely employed secondary processing or finishing operations for nanocomposites like injection or compression molding also have a major role in regulating final composite properties. The thermo-mechanical history generated on the composites due to these operations has an effect on the level of primary CNT dispersion (created with the extrusion process). Compression molding results in the re-agglomeration of the previously dispersed CNTs facilitated by the reduction in the viscosity of the matrix at a specific process temperature, pressure and holding time. A network of re-agglomerated CNTs forms multiple conductive pathways in the polymer leading to good composite electrical properties, though theoretically one such pathway is sufficient for achieving conductive properties. Higher melt temperatures and longer holding times have been reported to result in lower electrical percolation threshold and better composite conductivity [76]. It must however be remembered that the re-agglomeration of the dispersed CNTs could negatively affect the mechanical characteristics. Injection molding on the other hand is associated with a significant magnitude of secondary shear compared to the compression molding process resulting in filler orientation. The temperature gradient existing between the low temperature mold wall and the high temperature melt results in the freezing of the outer core, lowering the bulk conductivity of the composite. Injection molding is widely preferred from an industrial perspective being a high volume manufacturing process and hence the tailoring of the process parameters to achieve good macroscopic characteristics of the composite becomes important. Villmow et al. recommend lower injection velocities to limit orientation effects and higher melt temperatures for good electrical conductivity [94]. Mold temperature and holding pressure had a minimal influence in their work. Elevated mold temperatures could minimize the effect of temperature gradient. Some of the important factors to be considered during the production of a CNT incorporated thermoplastic composite are summarized in Fig. 6.

4 Effect of CNT Dispersion and Functionalization on Composite Properties

The properties of CNT incorporated thermoplastic composites are mainly dependent on the level of CNT dispersion in the host matrix and the nature of polymer-CNT interaction. These two factors in turn is a complicated function of the type of host matrix and its inherent characteristics, the type and surface functionality of the CNTs, processing methodology and associated parameters as detailed in the previous section. Hence, the important macroscopic properties of the CNT filled nanocomposites namely mechanical, electrical, and thermal properties would be elucidated upon in this section.

4.1 Mechanical Properties

Carbon nanotubes are envisaged to be ideal reinforcements for polymeric matrices owing to their exceptional mechanical properties. However, this does not alone ensure composites with excellent structural characteristics. The extent of dispersion and distribution of CNTs in the polymer host, alignment/orientation of CNTs in the matrix, the aspect ratio of the CNTs in the final composite, and the nature of the interface between the polymer and CNTs are considered to be crucial factors having an effect on the mechanical properties of the polymer-CNT composite.

In the case of reinforcements with nanofillers, the quality of filler dispersion is extremely important as the presence of large scale agglomerates would substantially lower the efficiency of load transfer. The level of CNT dispersion is primarily determined by the compatibility between the polymer and the CNTs, in addition to the methodology of composite processing. Achieving a good dispersion of CNTs in a thermoplastic matrix has been a perennial problem, but matrices like PC, PVA, PA etc. [67, 95, 96], show very good CNT dispersion morphologies. This is probably due to their polar nature and lower interfacial energy difference with the CNTs. On the other hand, the polyolefins have been so far considered the hardest of the thermoplastic matrices to achieve a good CNT dispersion. But recent results on PP and PE [64, 93], show that this challenge could be overcome by the employment of functional additives. Controlling or characterizing distribution of nanofillers in the matrix has so far been almost impossible, but is very critical to tune composite functionality. Prashantha et al. report an increase of the modulus and tensile strength of PP containing 1 wt% MWCNT (due to significantly enhanced MWCNT dispersion in PP processed by masterbatch containing 20 wt% MWCNT) by 1.27 and 1.18 times respectively [97], further additions of MWCNT did not improve the structural characteristics significantly. Castillo et al. [78], and Sathyanarayana et al. [98], report minimal/no increase in the tensile properties of PC-CNT composites, inspite of achieving excellent CNT dispersion in PC.

The interfacial shear strength (IFSS) which governs the maximum stress transfer from the polymer to the CNTs is strongly dependant on the nature of the polymer-CNT interface. If the interface is strong (due to good polymer-CNT adhesion), the external load applied on the composite is efficiently transferred across the interface to be borne by the CNTs. Coleman et al. report an increase in the Young’s modulus, tensile strength and toughness of PP by 3.1, 3.9 and 4.4 times respectively on the addition of 1 wt% thin-walled MWCNTs. The CNTs were chemically grafted with chlorinated PP chains [95], which could have possibly contributed to enhanced load transfer via a strong interface. In another example of a development of a strong interface, the CNTs modified by grafting with PS via in situ polymerization and melt mixed with PS resulted in an increase of impact strength by 250 % at 0.32 wt% MWCNT loading compared to pristine PS while the un-modified CNTs resulted in 150 % increase of impact properties at an identical CNT loading [75]. However, there are many instances in which functionalization have resulted in the deterioration of composite properties [52].

As the load transfer efficiency is also determined by the length of the CNTs, it is important to maintain the aspect ratio of CNTs as high as possible after composite processing. Krause et al. [99], and Castillo et al. [78], have demonstrated the reduction in the length (and subsequently the aspect ratio of the CNTs) on melt processing. Figure 7 shows the comparison of length distribution of as-received MWCNTs and that of the PC-MWCNT composite processed by melt mixing containing 2 wt% of identical MWCNTs. Reduction in aspect ratio would lead to a case where long fibers would have to be treated as short fiber reinforcements and hence substantial increase in the composite modulus cannot be expected [100]. Incorporation of CNTs with high aspect ratios in PLA resulted in improved structural characteristics of the melt processed PLA-CNT composites than those observed on the composites containing low aspect ratio CNTs [101]. This holds true over the whole range of investigated CNT concentrations from 0.5 to 3 wt%. The authors claim that the higher hydrodynamic radii of the high aspect ratio CNTs present as randomly bent fibers (to an extent) and as self-entangled flocs is responsible for higher effective filler volume fraction and hence improved mechanical properties.

Length distribution comparsion of Nanocyl™ NC7000: before (pristine MWCNTs) and after processing (as recovered from a melt processed PC composite with 2 wt% MWCNTs. x 10, x 50 and x 90 were calculated indicating that 10, 50, and 90 % of the nanotubes lengths are smaller than the given value. Reprinted from [99], Copyright (2011) with permission from Elsevier

Idealizing reinforcements with endless glass/carbon fibers, it is known that long aligned fibers are important for high structural characteristics. Hence, it becomes important to create and/preserve the alignment of the CNTs in the composite. It is important to mention here that aligned CNTs are seldom available commercially due to the complexities and costs involved with their production. Orientation of CNTs during composite processing on the other hand has also been reported to negatively affect the electrical properties of the composites [94]. The importance of straightening and aligning the CNTs on the mechanical properties of the PA66-CNT composites produced by rotational winding is illustrated in the work of Wang et al. [102] (Fig. 8). The reduction in CNT waviness and their presence as individual filaments on stretching the composite by 7 % resulted in a substantial improvement in the elastic modulus of the un-stretched composite (E = 14 GPa) by 290 %. The corresponding tensile strength increased from 225 to 630 MPa, a 190 % improvement on stretching. CNT alignment, long CNTs and decreased waviness all simultaneously result in significant improvements in mechanical behavior. These results significantly outnumber the properties achieved on other CNT incorporated PA composites processed by conventional composite processing techniques [103, 104]. However, the production of composites by this approach is not conventional.

Top: SEM images of a as-drawn CNT dry ribbon showing wavy nanotubes, b stretched CNT dry ribbon representing reduced CNT waviness, c non-stretched CNT/nylon 6,6 composites showing wavy nanotubes, and CNT/nylon 6,6 composite after stretching with different ratios: d stretched for 2 %, e stretched for 4 % and f stretched for 7 %. Bottom: Enhancement in the mechanical properties of the composites as a function of stretching. Reprinted from [102], Copyright (2011) with permission from Elsevier

Reports on substantial improvements on mechanical properties of the composites do exist, but are very rare. In most cases it is not close to anywhere as to what theories predict. There is no doubt that the researchers working in this area would unanimously agree that most literatures on thermoplastic CNT nanocomposites do not tend to report on the mechanical properties of the composites. Results on melt processing of composites especially with those considering MWCNTs however are not very encouraging. Analyzing the reviews on mechanical properties and other related literature on thermoplastic-CNT composites reports it is very evident that the theoretical potential of CNTs has so far not been transferred to substantially enhance structural characteristics of its composite. This could be attributed to the following reasons:

-

Irrespective of how well the composites have been processed, achieving individually dispersed CNTs is not realistic.

-

Aggregated morphologies of the CNTs in the polymer host are ubiquitous. Due to the cohesive strength of the agglomerates, there exists a small agglomerate fraction irrespective of the extent of shear stresses exerted on the composite melt during processing.

-

Increasing magnitude of shear stresses applied to break up the CNT agglomerates could result in a trade-off of the aspect ratio of the CNTs. Reduction in the CNT length would have a significant effect on the surface area and the effective load bearing length (or the critical length) of the CNTs.

-

Functionalization of CNTs carried out to weaken their intrinsic vdW forces could lead to increasing defect density on the CNTs (or disturbing the perfect C–C bond of graphene responsible for high mechanical characteristics), thereby reducing the efficiency of reinforcement.

-

The polymer-CNT interface is weak/not significantly developed to efficiently transfer the external load from the polymer to the reinforcing filler.

-

Small, wavy and randomly oriented CNTs do not carry the same inherent mechanical characteristics as long, straight and unidirectional CNTs, thereby idealizing CNT reinforcement in a thermoplastic as reinforcement with short fibers instead endless fibers.

It is also very important to point out that the mechanical properties reported here are just to illustrate the potential of CNTs as reinforcements. While interpreting the results from mechanical testing, it is important to consider all the accompanying factors like the type of processing, raw materials, type of testing etc. Bryne and Gun’ko in their review have summarized the huge variations in the mechanical property observations on a similar matrix material that can be brought about by employing different processing routes [105]. Castillo et al. report the influence of five different types of commercially available MWCNTs on the mechanical properties of PC-MWCNT composites at different filler loadings [78]. For a comprehensive reading on the mechanical properties of polymer-CNT composites, and positive and negative influences of functionalization on composite properties we would like to divert the attention of the readers to some interesting reviews [52, 105–108].

4.2 Electrical Properties

The extremely attractive electrical characteristics of CNTs have lived up to their potential as excellent conductive fillers for the insulating polymer matrices. Substantially high electrical properties have been widely reported on polymer-CNT composites. CNTs claim their advantage over conventional carbon black as conductive fillers for polymer matrices due to their high aspect ratio and consequently electrical properties at much lower filler percolation thresholds without compromising on the density, mechanical properties, thermal properties etc. of their host matrices.

The electrical percolation threshold is the critical filler concentration at which the insulator to conductor transition occurs. At this juncture, the electrical conductivity of the composite jumps significantly due to the formation of a conductive pathway. The electrical percolation can be at its theoretical lowest with only one such conductive pathway when well dispersed CNTs are present with a shorter tunneling distance of less than 1.8 nm [109], in a specified matrix free volume. Figure 9 shows the evolution of the conductive characteristics in CNT filled polymer composites. While the electrical properties of the composites is a result of dominative behaviour of the insulating polymer below the percolation threshold, the formation of multiple conductive pathways by individual CNTs and conglomeration of agglomerates beyond percolation saturates the conductive characteristic of the composites.

The percolation threshold is estimated using the scaling law which describes the statistical percolation behavior in the vicinity of percolation. It is given by

where: σ—experimental volume conductivity for w ≥ wc, w—MWCNT concentration (wt%), wc—critical/percolation MWCNT concentration (wt%), t—critical exponent governing the dimensionality of the system.

Munson-McGee predict that the critical volume fraction for the formation of the percolation network will vary from less than 1 % to more than 20 % depending on filler orientation and aspect ratio from a formulation based on statistical arguments [110]. Celzard et al. also emphasize the fact that the theoretical percolation equation must be modified for fillers having higher aspect ratios based on their interpretations of the excluded volume concept [111]. Although the usage of the equation for statistical percolation is common, possibilities of kinetic percolation (filler mobility due to mechanisms like diffusion, convection etc.) should not be excluded which was the main reason for contradicting results reported in the work on Bai and Allaoui [112], and Martin et al. [113]. Electrical percolation of CNTs in polymer matrices vary from as little as 0.0025 wt% to as high as 15 wt% as could be seen from Fig. 10. This huge variation is due to the fact that electrical percolation is dependent on the nature of matrix [63–67] and the type of CNT [78, 84], aspect ratio of the CNTs [47, 114], extent of CNT dispersion [64, 65], CNT functionalization [49, 115], processing approach and parameters [65, 84], and alignment and orientation of the fillers [94, 102].

Higher filler percolation thresholds in the range of 1–3 wt% CNT content are common in melt mixed thermoplastic-CNT composites processed with commercially available CNTs [65, 93, 97, 98]. It is generally lower for matrices presenting a favorable environment for a good CNT dispersion. The variation in the electrical resistivity in different thermoplastic matrices (with varying viscosities) containing an identical CNT type is illustrated in Fig. 11. The significant reduction in the aspect ratio of the composites due to their exposure to higher magnitudes of shear stress whilst melt processing as compared to other production approaches is also attributed to be another major reason for higher filler percolation thresholds. This shear stress is however important for achieving good filler dispersion, also an important criterion for good electrical properties of the composites at lower filler loadings.

Electrical volume resistivity of different thermoplastic matrices containing Baytubes® C150P. Reprinted from [63], Copyright (2012) with permission from Elsevier

Although, the dispersion morphology of the CNTs is primarily affected by extrusion, the widely employed secondary processing or the final shaping step for thermoplastic matrices namely compression molding or injection molding have been reported to have a substantial influence on the electrical properties of the composites. The reasons for difference in the electrical properties of the composites resulting out of these production techniques had been discussed earlier. The influence of process parameters of the compression molding [64, 76] and the injection molding [94, 116] have been studied in detail, and has been reported to have an overwhelming influence on the electrical properties of the composites. Figure 12 shows the influence of CNT dispersion (as a function of extruder process conditions) and the nature of the secondary shaping operation on the electrical properties of the composites

Influence of CNT dispersion in PP from the compounding process on volume resistivity (=1/conductivity) of the compression molded composites—composites were processed at 500 rpm with and without peroxides “Px” as additives and 1,100 rpm (Left). Difference in the electrical properties between injection molded and compression molded composites—C1 and C2 represent 1 and 2 wt% CNT content in PP (Right). Adapted from [64], Copyright (2013) with permission from Elsevier

Although a wide variety of factors have been listed for its influence on the electrical properties of the composites, consensus cannot be arrived on which has the pivotal role. Lot of contradicting reports does exist in literature. Bauhofer and Kovacs in their review find that the nature and type of the polymer host along with the technique of composite production are much more significant for good electrical properties compared to the influence that the type of CNTs and their production process could have [117].

4.3 Thermal Properties

The extraordinarily high intrinsic thermal conductivity and excellent thermal stability of the CNTs are of considerable interest for applications like nano-electronics and conductive polymer films. The high thermal conductivity of the CNTs is owing to the atomic vibrations or phonons while the increase in the thermal stability of the composites due to the incorporation of CNTs is a result of its high electron affinity (of 2.65 eV [118]) enabling them to act as radical scavengers.

The expected improvements in the thermal properties of the polymers with CNT addition, especially in the context of good thermal conductivity has however not been achieved. The transportation of phonons is more likely to occur through the insulating matrix rather than that of the ideally visualized case through CNTs as the difference in the thermal conductivities between the CNT and polymer is very small, i.e. of the order 104 W/(m.K) [119]. Compare this to the 15–19 orders of magnitude difference in the electrical conductivity! The interfacial or the boundary resistance between the CNTs and the matrix acts as a barrier to heat flow decreasing the overall conductivity of the composite. CNT surface functionalization [120], and aspect ratio [121], along with CNT dispersion in the polymer host are considered to be important factors regulating the thermal conductivity of the composites. Reports on thermal conductivities of epoxy-SWCNT composites are handful [122–124], while on thermoplastic matrices with MWCNTs are seldom to illustrate any conductivity increase/decrease.

The strong radical accepting capacities of the CNTs interrupt the released radicals from oxidation of the polymer, delay the rate of radical propagation and hence decrease the rate of degradation. This results in substantially enhanced thermal stability of the composites containing CNTs. The onset of degradation and temperature of maximum degradation of PS at 300 and 365 °C respectively were enhanced to 313 and 398 °C and 337 and 407 °C respectively on the addition of 1 and 2 wt% MWCNT [65]. Increasing additions of CNT did not further enhance the thermal stability of the composites as enhanced intra-filler interactions due to CNT agglomeration at higher filler loading reduces the effective CNT surface area available for accepting free radicals. Similarly, the addition of 2 wt% MWCNT to PP enhances the thermal stability of the composite with an increase in the onset and maximum temperature of degradation by 40 and 85 °C, the increase also dictated by the enhanced quality of MWCNT dispersion in PP [64]. These results also highlight the importance of having a good CNT dispersion in the matrix.

CNTs have been reported to act as nucleating agents in semi-crystalline matrices [47, 82, 95]. The incorporation of CNTs to the polymers also affects the glass transition temperature, as the part of the polymer in close proximity to the CNTs will have properties much different than the bulk matrix owing to the restrictions imposed on its mobility due to the alterations of the conformational entropy and chain kinetics. An increase of glass transition temperature at lower filler loadings and a decrease at higher loading fractions (due to predominant intra-filler interactions contributing to the development of an interphase) has also been reported [65].

Wu et al. demonstrate a significant improvement in the flame retardancy of melt mixed PET (polyethylene terephthalate)-MWCNT composites with liquid bisphenol A bis(diphenyl phosphate) (BDP) as a dispersing additive. The uniformly dispersed CNTs in PET acted as a support for the char released by the oxidation of PET and BDP. The network layer consisting of the CNTs and char acted as a heat shield effectively reducing the exposure of PET to external atmosphere and the heat feedback of the heat flux [125] (Fig. 13). Kashiwagi et al. have also demonstrated similar effects with MWCNT incorporated PP composites [126]. A good CNT dispersion and a better polymer-CNT interface along with increasing filler content could augur well for excellent flame retardant characteristics [127].

Schematic of the network of CNT-char network acting as a heat shield for PET. Reprinted from [125], Copyright (2013) with permission from Elsevier

In addition to the aforementioned commonly listed characteristics of CNTs in composites, their functionalities also extend to tuning the non-linear property [128] and improve the photoluminescence of polymer-CNT composites [129]. These areas are subjected to very less research inspite of their tremendous potential for engineering applications.

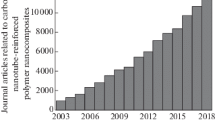

From an outlook on the analysis of the mechanical, electrical and thermal properties of CNT incorporated polymer matrices in this chapter and also by analyzing reviews (recommended for further reading in this manuscript) it seems that the potential of CNTs as fillers for polymer matrices is not fully realized. CNT dispersion in thermoplastics and consequently improved polymer-filler interactions seem to be key criterion influencing the macroscopic properties of the composites. Employing as-received CNTs mandates high shear stresses on processing leading to reduction in CNT aspect ratio. In order to compromise this, CNT functionalization or the use of dispersing additives are widely recommended. The statistic presented in Fig. 14 is from a review on the effect of functionalization on the electrical and mechanical properties of polymer-CNT composites. It is seen that in most cases the increase in electrical property comes with a trade-off of a potential reduction in structural characteristics and vice versa. This complicates scenario for advising a particular approach to tailor the desired composite functionality with CNTs as fillers.

a Overall statistics of the journal papers reviewed in this article which addresses the influence of various pre-treatment in polymer/CNT composites and compares with respect to pristine CNT; b Statistics showing the strengths (+) and weaknesses (−) of covalent and non-covalent types of pre-treatment on the composite properties (statistics also includes paper which report simultaneous improvement in both structural and electrical properties). Reprinted from [52], Copyright (2010) with permission from Elsevier

At this juncture, the reader ponders about the potential of CNTs as fillers for thermoplastic matrices. Although excellent electrical properties and (to an extent) thermal properties have been achieved on thermoplastic polymer-CNT composites, substantial improvements in the mechanical properties of these composites are far from being realized due to the various reasons detailed earlier. Long, aligned, perfectly grown infinite CNTs would be ideal; current research has been led in this direction however the economics of scale up and production on a sustainable scale have not been successfully realized thus far. Hence, there is now a desperate need to look for alternate solutions to tap the multifaceted properties of CNTs into commercial applications. The fact that enhancing the structural properties of the composites is the challenge focuses our attention towards multi-scale reinforcements. The established success of conventional glass or carbon fibers as fillers for structural reinforcements positions them as strong contenders for incorporation as secondary fillers in addition to CNTs for the development of a composite with multi-functional properties. It is however important to ensure that the addition of glass/carbon fibers do not significantly alter the electrical and thermal characteristics of the composites brought in by the presence of CNT networks.

5 Multifunctional Composites with Multi-Scale Reinforcements

Fiber reinforced composites (FRC) have revolutionized engineering structures over the last three decades owing to high-strength to weight ratio, flexibility and ease of processing with conventional techniques, and prospects of tuning their functionality. Although the in-plane properties of the FRC’s are extremely high, the contribution to its load bearing capacity along the z-direction primarily arises from that of the matrix (which has much lower mechanical properties). Nanometric dimensions of the nanofillers could facilitate their easy infiltration between the micron-sized fillers leading to better interlaminar properties. In addition to this, the attractive nature of CNTs to impart good electrical and thermal properties offers enormous scope for development of multi-functional light weight composites structures to compete for engineering dominance with metallic and ceramic reinforcements. Two possible forms of multi-scale reinforcements could be thought of (Fig. 15):

-

Individual addition of the fillers into the polymer host [98, 130].

-

Employment of hybrid fillers wherein the nanostructures are grown insitu on the surface of the carbon/glass fibers (parent structures) via the CVD process [131–133], coated on woven parent surfaces [134], and deposited on fiber surfaces using electrophoresis [135, 136].

Figures (16, 17, 18) illustrates micrographs of hybrid fillers processed via different techniques.

MWCNTs grown on glass fiber surface through CVD—morphology of the hybrid fibers is observed in different forms: through scanning electron microscopy (SEM) of the fibers (a and b) and optical microscopy of the cured, polished composite (c). Reprinted from [132], Copyright (2012) with permission from Elsevier

Hybrid fillers prepared via coating of nanofillers on parent surfaces—fracture surface of fiberglass/vinyl ester composites with silane-SWNTs: a 50 μm scale bar magnification and b 5 μm scale bar magnification. Reprinted from [134], Copyright (2007) with permission from Elsevier

SEM images of carbon fibers with (a) SWNTs and (b, c) MWNTs deposited by electrophoresis. Reprinted from [135], Copyright (2007) with permission from American Chemical Society

The employment of hybrid filler structures in literature is widely discussed in the context of composites based on thermoset matrices. Considering the scope of production of multi-scale composites, the use of these hybrid fillers for thermoset composites is justifiable as the integrity of the nanostructure on the parent could be easily preserved during composite processing. On the contrary, with the processing approach for thermoplastic composites (especially polyolefins) and the harsh conditions involved there is a strong possibility for the nanostructures to detach from their parent surfaces consequently leading to reduction in the reinforcement efficiency. The addition of glass fibers to the polymer-CNT masterbatch stands out as the most feasible approach for the production of thermoplastic composites taking advantage of the properties of both glass fibers and CNTs.

Sathyanarayana et al. demonstrated individual addition of the bi-filler system of MWCNTs and short glass fibers (two variants: one with a compatible sizing to PC and the other with an incompatible sizing) to PC via melt compounding and injection molding [98]. Whilst 2 wt% MWCNT addition to PC resulted in a elastic modulus and tensile strength increase of a meager 10 % and 5 % respectively, addition of 20 wt% short glass fibers to this composite resulted in a substantial 187 % and 86 % increase of the corresponding properties. The increase in the modulus was independent of the type of the glass used, but the tensile strength improvement was significant only when the glass fiber with a compatible sizing with PC was employed. Glass fiber addition however lowered the impact properties of PC, but the presence CNTs compensated for the decrease. The contribution to enhancement in the thermal and electrical properties of the bi-filler composite arose due to the presence of CNTs, with increasing glass fiber additions slightly lowering the efficiency of reinforcement. The SEM micrographs of these composites are presented in Fig. 19.

a Good CNT dispersion in PC, b PC with 20 wt% glass fibers with PC compatible sizing, c Individual morphologies of the filler kept in the bi-filler composite, d Magnified view of a single glass fiber with a polymer sheathing (some CNTs were also identified on the sheathing) from the bi-filler composite [98]

A short reference to some interesting results with thermoset based multi-scale composites is being made here to illustrate the potential of these materials. Lv et al. grafted MWCNTs of varying lengths on carbon fibers using the injection CVD approach [137]. The MWCNT lengths and the orientation were controlled by the nanostructure growth time and the adopted surface treatment on the carbon fibers. Single fiber fragmentation tests showed an 175 % improvement in the interfacial shear strength of the hybrid fiber (containing 47.2 μm of aligned nanostructure on the parent) compare to the pristine carbon fiber. The SEM morphologies from their work are presented in Fig. 20. Zhang et al. achieved 150 % improvement in the IFSS of CNT-CF reinforced epoxy composites [138]. Zhu et al. report an increase of 45 % in the shear strength in their effort to increase the properties along the z-axis for carrying transverse loads on a glass fiber reinforced vinyl ester composite with nanotube integration. The CNT loading was 0.015 wt% in the midplane ply [134]. Gojny et al. carried out resin transfer molding for the production of glass-fibre-reinforced polymers (GFRP) with nanotube/epoxy matrix. They report enhancements in the modulus, tensile strength, fracture toughness and the anisotropic electrical properties of the composites containing 0.3 wt% MWCNTs (modified by amine functionalization) [139].

SEM images of unsized CFs (a) before and (b) after the surface treatment, and CFs grafted by (c) entangled MWCNTs and (d–f) aligned CNTs. Reprinted from [137], Copyright (2011) with permission from Elsevier

Irrespective of how good the hybrid-filler is, the macroscopic property enhancements of the composites would strongly depend on the extent to which the nanostructures are dispersed in the matrix. The strength of the nano-filler-parent interface and the linkage between the nanostructure and the host matrix are considered to be crucial. The biggest challenge facing the multi-scale composites especially on thermoset matrices is the fact that high volume fraction of nanofillers would lead to processing difficulties due to its ability to enhance the viscosity of the resin significantly. The need for environmentally benign applications for example light weight structures with multifunctional characteristics will no doubt drive the market towards the development of composites with multi-faceted properties.

6 Synopsis

The principal objective of this chapter was to give a comprehensive overview on the potential of CNTs as fillers for thermoplastic polymer matrices processed by techniques suitable for large scale production. Thermoplastic matrices present significant challenges for achieving a good CNT dispersion primarily due to its high melt viscosity and high interfacial tension between the polymer and the CNTs as compared to thermosets. As a consequence the efficiency of CNTs as fillers for thermoplastic matrices is far off from what theory would predict.

We have elucidated in short the world of CNTs starting from its production, properties, surface modification, applications and a brief market outlook. Although understanding of the complicated mechanism of CNT dispersion in thermoplastic is crucial, equally important is to understand the influence of raw-materials and the process parameters. The complex picture of achieving a good CNT dispersion that was presented in terms of processing with the twin-screw extruder, and the influence that the secondary shaping operation could have on the composite properties present a strong case that mandates a careful selection of the raw-materials and process conditions. Functionalization of CNTs as a technique to improve CNT dispersion is widely discussed in literature, but is very expensive and present problems of scale up for large scale production. Hence, we focused on special techniques like the use of ultrasound, supercritical fluids, processing additives etc. whilst processing in the extruder as non-conventional approaches to enhance CNT dispersion in a thermoplastic matrix.

Although the potential of CNTs as fillers for mechanical reinforcements do not look promising after analyzing many literature reports, Loos and Schulte claim that CNTs are the most viable strengthening option for composites with strengths up to 11.61 GPa on analysis of their cost versus property relation compared to carbon fibers [140]. The latter could be beneficial for producing composites with strengths up to 4.18 GPa, Young’s modulus up to 383 GPa with a possible compromise on toughness. However, according to them and most literatures, in order for CNTs to be competitive enough they would have to be produced with high purity as long aligned structures with high aspect ratio, in large volumes and at low cost. Also, issues such as CNT dispersion, distribution and orientation in the matrix and enhanced polymer-filler compatibility must be addressed quickly for competitiveness and commercial success.