Abstract

Heterogeneity of remaining oil distribution makes it difficult to recover. This paper analysed the interbed in the channel sand which is the one of the main factors to form remaining oil, and simulated respectively water and polymer flooding for channel sand with all kinds of interbeds, and then nailed down the affect to the distribution of remaining oil by different driving means. Horizontal interbed which developed mainly in the braided channel and straight distributary channel would obstruct the fluid during flowing vertically, and the remaining oil congregates under the horizontal interbed. Polymer driving can accelerate the moving of most remaining oil, but it is unconspicuous for the one under the interbed. Lateral interbed which mainly deposit in the meandering and low curving distributary river would shelter from sideway markedly. The degree of this effect is based on the relation of directions of interbed and driving.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

30.1 Introduction

In China, the Mesozoic and Cenozoic basins of continental sediments are widespread with rivers and developed sands.

The river-deltaic sandstone dominates the continental basins. It is ascertained that in China the majority of oil reserves are located in the river-delta deposition system. Songliao Basin is China’s largest continental depression-type basin of oil and gas with the typical dual-structure featured by lower rifting and upper depression. Before the early Cretaceous Denglouku it is the depression evolution stage of the basin. The Quantou Period-Neijiang Period marks the evolution stage of depression (Liu et al. 2010), in which the formation of oil and gas at the middle and lower part of Daqing Placanticline is a large river-delta depositional system of depression sediments. The channel sand is the main part of oil and gas reserves. It is found through the study of depositional mechanism of channel sand and during the oil field development process that, channel sands are not homogeneous connection (Wang et al. 2009). Changes in various factors like hydropower conditions, provenance supply and climate lead to the extensive heterogeneity (Sun et al. 2008) within the channel sand; particularly the prevalence of impermeable interbed affects the laws of fluid flow.

The knowledge of interbed of channel sands and genesis and the analysis of driving effects of various flooding means are particularly important for the development of oil fields.

In recent years, there is a growing research of interbeds. Jiao Hongbing once mentioned in the “Influences of Interbed Distribution of Meandering River on the Development Effective Driven by Water” that: factors like interbed dip angle, spaces and the ratio of interbed depth to reservoir depth. As the dip angle (3–15°) is increased, the rate of recovery driven by water is also increased and the 7–15 folds is a moderate growth; the increased interbed space (10–40 m) and the recovery driven by water exhibits a nearly linear rise; H interbed/H oil layer (0–2/3) is increased and the recovery driven by water is lowered. After the comprhesive collection of distribution features of all kinds of channel sands in Daqing Oilfield, a study of types, genesis of the channel sand interbed and their influences on the driving effects of various driving means.

30.2 Type and Genesis of Interbeds

Daqing Placanticline Puyi Formation is a well-shaped river-delta deposition, developed with flood plain, distributary plain, delta-front facies (Fig. 30.1) from north to south and various fluvial facies sands like braided river, meandering river and straight distributary (Zhang et al. 2009). The channel interbed consists of two categories: horizontal interbed and lateral interbed.

30.2.1 Horizontal Interbed

Horizontal interbeds mainly are located in braided rivers of oilfields like Lamadian and Saertu, low-bend distributary channel of oil fields like Xingshugang and straight distributary channel. There are two major genetic types: (1) due to changes in the hydropower condition or provenance supply during the deposition process, interbeds are formed among sandy laminae reservoir of fluvial facies, including the muddy intercalation and conglomerate interbed cemented by muds; (2) interbed arising from physical and chemical effects during the diagenesis of sediments. Such interbed is mainly calcareous (Yu et al. 2010). In addition, there is a marked difference in the lithology of sediments, the upper and lower part of reservoir. Because the vertical accretion of the suspended sediment featured by fine lithology, small depth, extensive distribution and wide scope, are capable of forming an vertically upward impermeable shelter (Li et al. 2009) during the crest concussion process in the flood event of braided river.

30.2.2 Lateral Interbeds

Lateral interbeds are mainly developed in the meandering rivers of oils fields like Shaertu and Xingshugang. Under the action of lateral interbeds, each flood forms a lateral accretion. An argillaceous layer can be formed during the dry season and interflood period between two floods (Zhang et al. 2008). The oblique crossing of lateral accretion with the formation boundary and of overlaying argillaceous layer with the formation boundary form the argillaceous lateral interbed in the channel. Generally, the argillaceous lateral interbed is only developed at the upper and middle part of point bar, thus forming a “semi-connection” featured by the connected bottom, disconnected upper and middle portions of the point bar of meandering river.

30.3 Impacts of Horizontal Interbeds on Different Means of Driving Effects

30.3.1 Mechanism of the Horizontal Interbed Affecting Infiltrating Fluid

The presence of horizontal interbeds affects the flow of reservoir fluids and changes the distribution of entire field of infiltrating fluid (Wang and Zeng 2008). The higher the development frequency of interbeds, the more complex distribution of oil and water movement. The development of a large number of unstable interbeds reduces the sinking speed and gravity action of injected water along the moving direction for the sand bed of fining upwards sands, favorable for the vertical swept volume and and oil driving efficiency; but for coarsening upward sands, it prevents the the effect of gravity sinkage on the swept volume during the water driving oil process. The fining upwards sands without interbeds are greater than the those with interbeds in the flooded intensities. The flooded intervals of the bottom appears earlier. While the unstable interbeds of the coarse upward sands reduces the oil scavenging cofficients and oil driving efficiency of gravity in the coarse upward sands. It is of severe implications on the development effects. The longer or more interbeds, the worse development effects. It mainly lies in that the oil driving efficiency near the lower part of interbeds is far less than other regions. The dead oil area is formed during the latter stage of high water content.

30.3.2 Impacts of Horizontal Interbeds on the Remaining Oil During the Water Flooding and Polymer Flooding Process

According to the reservoir distribution characteristics of major oil reservoirs of Daqing Placanticline Lamadian and Saertu Puyi Formation, the three-dimensional geological model of braided river sand of developed interbeds are set up to carry out the numerical simulation of water flooding and polymer flooding.

During the water flooding process, when the water content accounts for 92.5 %, the region of oil saturation from 0.4 to 0.6 is narrow, the line of 0.6 and line of 0.7 are basically coincident. If the water content reaches 0.98 with the sustained water driving, the remaining oil will continue to “be floated”. The obstruction effect of interbeds remains obvious. But generally, the remaining oil is floated on the upper layer (Fig. 30.2). The horizontal interbeds under specific conditions (within a small area) can serve to prevent crossflow between layers and expand swept volume. A portion of water advances along the upper side of interbeds, so that the recovery of reservoir above the interbed is high (Su 2004). But if the hydropower is not strong, a lot of crude oil will remain under interbeds, particularly those at the middle and lower part of reservoirs with most obvious blockage. The more interbed area, the more remaining oils.

If polymer flooding is used when the water content is 0.925, the profile control of polymers changes the original fluid direction, the above crude oil will move downwardly and then upwardly. If the crude oil moves downwardly and meets the blockage of interbedds, it is favorable for the recovery. If the crude oil moves downwardly below the interbeds, then rises and is blocked by interbeds, then it is unfavorable for the enhanced oil recovery. The interbed itself also blocks the polymer and exerts negative impacts on the expanded swept volume of the polymer profile control.

Through the comparison of Fig. 30.2 (3) with (4), it can be seen in the polymer flooding process, the remaining oil near the interbeds is not significantly improved. Through the comparison of Fig. 30.2 (1) with (4), the remaining oil is diffused in the local areas after the polymer flooding. The region with the oil saturation of between 0.4 and 0.6 is much wider than the that before the polymer flooding. Only in local aeras like interbed bottom and top, etc., the oil saturation of remaining oil is as same as that before polymer flooding. It shows the polymer flooding can develop remaining oil in most regions within the braided channel sands. But due to the presence of the horizontal interbeds, the remaining oil at the bottom has not been significantly improved.

30.4 Impacts of Lateral Interbed on Different Means of Driving Effects

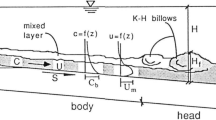

The impacts of lateral interbed on the distribution of the remaining oil are closely related to the combination of direction of dip and injection direction (Ling et al. 2008). There are three major combination relationship of the injection direction and interbed inclination, namely the direction, against along the interbeds, or the extension direction of interbeds fluvial ldirection) (see Fig. 30.3). For the study of different combinations of direction and the impact of lateral interbeds on the distribution of remaining oils, three dimensional conceptual model of three combinational directions are set up for the numerical simulation.

30.4.1 No Interbed Development

It is relatively homogeneous in the channel sand without the interbed development. In the water flooding process, without the blockage of interbeds, the water flooding process is mainly controlled by the channel deposition model and is easier based on sedimentary rhythm. Figure 30.4 is a profile of oil saturation at different stages of water flooding. In Fig. 30.4 (2) the unused remaining oil distributed in the triangular area formed by the connecting line of the middle part of oil well and water well and the reservoir top when the water content is 0.925. If you continue with the water flooding, the unused remaining oil only stays on the reservoir top (see Fig. 30.4 (3)). When the water content is 0.925, the recovery rate is 35.51 %; when the water content by the water flooding reaches 0.98, the recovery rate is 41.28 %.

If polymer driving is used when the water content is 0.925, the phenomenon of “Oil Wall” will appear.

Because the viscosity of polymer solution is greater than that of water, the pressure on the water well should be increased from 15 to 26 MPa at the time of water driving during the polymer injection. At the same time the injection grout is increased by folds. After the polymer solution enters the formation, the pressure cannot be transferred quickly, the pressure gradient surrounding the water well is great, the dip angle of water testing surface becomes bigger. Based on the Hubbert potential formula, the dip angle of oil–water interface dip angle will also become larger, thus a part of oil will move downwardly. As the pressure advances towards the oil well, an oil wall is formed in front of polymer aggregation with the V-shaped profile which appears to move downwardly driven by polymers. When the oil wells arrive at the oil well, a sudden peak will appear in the oil well yield while the rear oil wall disappears gradually and the oil well output is decreased dramatically. The appearance of oil walls or the obvious oil wall is related to the reservoir non-homogeneity and well spacing. In general, the more severe heterogeneity, the greater differences in the positive rhythm, the less likely to appear the oil wall. The braided channel sand due to sound connectivity of reservoir has less penetration rate differences, thus the obvious oil wall appears. At the same time the appearance of oil wall is controlled by well space. Due to the upper lateral interbed and lower belts of high permeability of meandering river sands, the injected polymer solution suddenly ingresses along the bottom. In addition, when the remaining oil in the interbed is displaced, it only flows out of the bottom of lateral interbed, thus no V-shaped oil wall will be formed.

The polymer flooding is used when the water content is 0.925. Figure 30.4 (4) and (5), respectively show the profile of oil saturation when stopping the polymer injection and the follow-up water driving until the water content reaches 0.98, the remaining oil is still distributed on the top of reservoir near to the oil well. The ultimate recovery rate for 0.70 PV of injected polymer is 42.43 %. (Table 30.1 shows the equivalent of the relationship between the injection of different volume of polymers and recovery rate. The ultimate recovery rate after displacement refers to the corresponding value of ultimate recovery when the follow-up water driving enables the water content to be 0.98 after the injection of polymer of 0.70 PV). Compared with the water driving, the ultimate recovery rate only grows by 1.15 %. It can be seen that the effects of water driving is significant. Under this circumstance, the effects of polymer driving are insignificant and may be uneconomical.

30.4.2 Driving Along the Interbeds

When injection is along the direction of interbeds, the impact of interbeds on the development of remaining oils can be seen in Fig. 30.5. After the polymer driving, more distribution of remaining oil at one side of the water well towards the lateral interbed and the structural top formed by two interbeds is related to the tilting direction of oil–water interface and hydrodynamic direction. Due to the obstruction of interbeds, the recovery rate for the water content of 0.925 by water driving is 26.00 %. The recovery rate for the water content of 0.98 by complete water driving is 30.96 %. The recovery rate can reach 37.26 % when the polymer driving is employed. The three values drop 9.51, 10.12 and 5.17 % in comparison with those without interbeds. It can be seen that due to the obstruction of interbeds, the recovery rate decreases around 10 % compared with those without interbeds. After the polymer driving, the obstructed crude oil has been remarkably improved. The differential value in the crude oil recovery is reduced to 5 % or so.

30.4.3 Driving Against the Interbeds

Figure 30.6 is a cross-sectional view of oil saturation at all stages of injection against the interbed. Compared with the injection along the interbed, there are more remaining oil, mainly due to the more surrounding area of oil–water interface and the interbed at the time of injection against the interbeds. The included angle formed by the interbed and the top is a “dead area” which is also the remaining oil enriched region. Due to the obstruction of interbeds, the recovery ratio for water content of 0.925 with water driving is 23.38 %. The recovery rate is 28.57 % when the complete water driving with the water content up to 0.98. The recovery rate can reach 36.78 if the polymer driving is used. The three values drop 11.13, 12.71 and 5.65 % in comparison with those without interbeds. It can be seen that due to the obstruction of interbeds, the recovery rate decreases around 10 % compared with those without interbeds. Through the polymer driving, the differences in the crude oil recovery is reduced by over five percents.

30.4.4 Driving Along the Extension of Interbeds

The injection along the interbed has the least resistance in theory (maximum permeability along the fluvial direction without direct obstruction of lateral interbed) and excellent water driving effects. Figure 30.7 shows a profile of oil saturation at all stages of injection in the direction. The remaining oil is mainly located on the reservoir top near to the oil well when the water content is 0.98 with the follow-up water driving. On the profile, the remaining oil between two oil wells is V-shaped. The unobvious obstruction can be seen near some lateral interbed. The recovery rate is up to 34.94 % when the water content is 0.925. The ultimate recovery rates for the follow-up water driving and polymer driving are high, reaching respectively 41.11 and 41.94 %. The water injection along the interbed has higher recovery rates than those without interbeds. But under this situation the recovery rate improvement is small, only 0.83 % for the polymer driving effects. Within less than 7 years of polymer driving, the recovery rate can even be lowered.

30.5 Conclusion

The distribution location, scale, injection mean, recovery means and reservoir rhythm of horizontal interbeds have direct bearing on the distribution law of remaining oil, capable of preventing upward movement of oil and gas while obstructing the downward movement of water on the interbeds, thereby expanding the swept volume. It is an important reason for the formation of remaining oils. The horizontal interbeds can serve to flood in intervals and prevent the interbed water breakthrough to a certain extent. During the polymer driving, the horizontal interbeds can change the fluid direction to prevent oil and gas flow, reducing the displacement effects.

The lateral interbed in the meandering river is a major factor for the formation of remaining oil. Although the rise of bottom water can not be obstructed, but at the upper part of lateral interbed, especially the acute angle formed by the interbed and top surface is the highest concentration of remaining oils. In most cases, the closer to oil wells, the more remaining oils in the angle.The lateral interbed will increase the resistance to oil driving and make the polymer injection difficult. At a certain time of polymer injection, the recovery rate of crude oil at some stages may be lower than that at the time of complete water driving. In the sand of developed lateral interbed, different directions of water injection affect the recovery rate of crude oils and also make the distribution location of remaining oil in the interbeds different. In general, the injection directions leading to crude oil recovering rate from high to low are: driving along the extension of interbeds (river direction), along the lateral interbed and against the lateral interbed.

References

Li M, Zhao Y, Liu X (2009) Distribution of petroleum enriched areas, Changling Sag, southern Songliao Basin. Pet Explor Dev 36(4):413–418

Ling Z-f, Wang L-j, HU Y-l (2008) Flood pattern optimization of horizontal well injection. Pet Explor Dev 35(1):85–91

Liu Z, Sa L, Dong S (2010) Current situation and trend of geophysical technology in CNPC. Pet Explor Dev 37(1):1–10

Su Q (2004) Distribution mode of remaining oil in the positive rhythm sand and development by horizontal well. Pet Geol Recovery 11(6):34–38

Sun C, ZHU X-m, ZAN G-j (2008) Sand body types and reservoir properties in Cretaceous Jiufotang Formation in Luxi Sag. Pet Explor Dev 35(5):569–575

Wang X-z, Zeng L-f (2008) Effect of practical techniques in producing remaining oil in Gudong Oilfield. Pet Explor Dev 35(4):467–475

Wang H, Liu G, Chen G (2009) Development of mm-level mud-films and significance for reservoirs in Yingtai area, Daqing Oilfield. Pet Explor Dev 36(4):442–447

Yu J, Yang Y, Du J (2010) Sedimentation during the transgression period in Late Triassic Yanchang Formation, Ordos Basin. Pet Explor Dev 37(2):181–187

Zhang Q-g, Bao Z-d, Song X-m (2008) Hierarchical division and origin of single sand bodies in Fuyu oil layer, Fuyu Oilfield. Pet Explor Dev 35(2):157–163

Zhang G, Lan Z, Liu P (2009) Fracturing control method for deep volcanic rock gas reservoirs in Daqing exploration area. Pet Explor Dev 36(4):529–534

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Zhao, L., Wang, Sq., Fan, Zf., Zhang, L., Li, Bw. (2013). Effectiveness to Driving by Interbeds in Channel Sand of River Delta System. In: Qi, E., Shen, J., Dou, R. (eds) The 19th International Conference on Industrial Engineering and Engineering Management. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-38391-5_30

Download citation

DOI: https://doi.org/10.1007/978-3-642-38391-5_30

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-38390-8

Online ISBN: 978-3-642-38391-5

eBook Packages: Business and EconomicsBusiness and Management (R0)