Abstract

In Vadravadra village, Gau Island, electricity is provided by a 15 kW diesel generator which is switched on for four hours every evening, and fuel usage is approximately 3,200 L/year. The problem faced by villagers is the constant rise in the price of diesel, which is added to the transportation costs of travelling from the main islands to this remote island, resulting in villagers currently paying approximately FJ$2.80/litre. This paper attempts to determine energy produced (kWh) from wind and solar for electricity generation at the site, as well as the cost of energy (COE). The first section presents the energy supply and demand for the village. The second section gives the wind and solar resource characteristics for the site. The annual average wind speed for the site is 6.2 m/s and the average insolation is 5.50 kWh/m2/day. The third section presents the wind energy potential and size of a stand-alone solar system. Using a 15 kW wind turbine with 0.25 as the overall power coefficient, the estimated annual wind energy yield is 33,700 kWh. With five days storage, the stand-alone solar system requires 84 batteries and 308–125 W PV modules. The next section presents optimum hybrid configuration for the site using HOMER, and finally some conclusions are drawn.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Short Introduction

The main islands of Fiji have grid-connected electricity, but on small islands, electricity is provided by diesel generators. The constant rise in the price of diesel causes problems for local inhabitants, and they are looking for alternative sources of electricity production.

Currently in Fiji, there is no working stand-alone wind/solar hybrid system, though there are wind and solar resources at most sites, incl. Vadravadra village, Gau Island (e.g. the annual average wind speed for this site is 6.2 m/s). This study has found that the hybrid system—if built correctly—can provide energy, educational, health and environmental benefits to the villagers on Gau Island.

Introduction

Fiji is one of the island countries in the South Pacific region. It has approximately 330 islands, of which about one third are inhabited. The total population of Fiji is about 840,000 (Fiji Islands Bureau of Statistics 2010). The main islands of Fiji, Viti Levu and Vanua Levu, have grid-connected electricity. However, small islands get power from diesel generators through the rural electrification programme. Biodiesel and biofuel are slowly being integrated into existing diesel generator sets. One island (Koro Island) currently gets electricity from biofuel. Now, since diesel costs are constantly increasing, small, remote islands are looking for alternative sources of electricity production. Currently in Fiji there are no working stand-alone wind/solar hybrid systems. However, plans are in place to revive the Nabouwalu wind/solar/diesel hybrid system in Vanua Levu, which successfully worked for three years before the renewable component stopped working due to lack of maintenance (Developing Renewables 2006).

Gau Island is situated to the east of Viti Levu (Fig. 14.1a). Vadravadra village, belonging to the district of Sawaieke, is located on Gau Island within the Lomaiviti province (Fig. 14.1b). The location of Vadravadra village is at latitude 18°06’S and longitude 179°20.6’E.The main means of transportation to the island are a monthly boat service and a weekly flight, scheduled on Wednesdays. There is no electrical grid available on the island. Electricity is supplied by a 15 kW diesel generator for only four hours every evening.

Current Energy Supply and Demand in the Village

Vadravadra village has 44 households and a population of 174 individuals. The village currently has an 18.5 kVA (15 kW) DG set that was installed in 1999 with the support of the government of Fiji under the Rural Electrification (RE) program of the Department of Energy (DOE). This generator operates for four hours every evening, and the fuel consumption is approximately 2.2 L/h. Hence, in a month (30 days), fuel consumption is 264 L, which means 3168 litres of fuel consumed per year, at a yearly fuel cost of FJ$8870.

Table 14.1 shows the current load if electricity is assumed to be produced for 24 h. If electricity is supplied for 24 h, current electricity consumption per capita corresponds to approximately 150 kWh/year. The electricity usage for the village was collated by the Fiji Department of Energy (FDOE). Figure 14.2 shows the daily variation in load when using the information in Table 14.1.

The Problem on Gau Island

Currently, Vadravadra village’s electricity is not produced from renewable sources. People have to purchase diesel fuel from the mainland, transport it to the island and then use it in their generators for electricity to be provided for 4 h in the evenings every day. Recently, the price of diesel fuel has been rising, and varies at between FJ$2.30 and FJ$2.80/L. The total price of diesel fuel in a month would be approximately FJ$740 if FJ$2.80/litre is taken as the cost of diesel fuel. This is a huge cost in the context of people’s average monthly income. As in any ordinary village, villagers sell cash crops, for example, copra. For most households copra is the second most important crop for their income; pandanus leaves (mat selling) are the most important. Copra is sold through the village cooperative, then transported and sold in Savusavu. The villagers are beginning to plant dalo to be sold in Suva.

News recently appeared in the local newspaper that Gau Secondary School does not have access to electricity, meaning that boarding students have to use kerosene lamps in order to study (Avinesh 2011). This shows the energy security issues on remote islands in Fiji. People on remote islands are desperate for access to electricity just to cover their basic needs.

Wind and Solar Resource Characteristics

Wind Characteristics

For the Vadravadra site, wind speed and direction data were analysed for three consecutive years (2003–2005), recorded by the FDOE at a height of 27 m on the 137 m Delainasinu hill. Wind characteristics, such as monthly variation in wind speed, diurnal variation in wind speed, wind speed frequency and duration curves and turbulence intensity curves, all help wind energy developers make better decisions in installing a wind turbine at a particular site.

From the three-year wind data analysis, the annual average wind speed for the site is 6.2 m/s and the average turbulence intensity is 0.174. The wind-speed frequency for the site is shown in Fig. 14.3. This curve will be used to estimate the wind energy output from the site using the selected wind turbines’ power curve.

It can be observed in Fig. 14.3 that, for the majority of the time (75 %), wind speed is between 3.5 m/s and 8.5 m/s. This graph can be used while choosing an appropriate wind turbine by looking at its cut-in \( \left( {v_{c} } \right) \), rated \( \left( {v_{r} } \right) \) and furling \( \left( {v_{f} } \right) \) wind speed. It would not be desirable to have large \( v_{r} \;and\;v_{c} \) compared to the wind-speed characteristics for the site, since this would decrease the capacity factor for wind turbine. \( \;v_{c} = 3.5\;{\text{m/s}} \) and \( v_{r} \; = 8 - 10\;{\text{m/s}} \) can be chosen for the site.

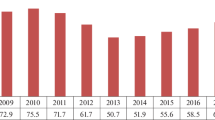

In Fig. 14.4, the highest wind speed of 8.50 m/s is in June, and the lowest wind speed is 4.60 m/s, recorded in March. This graph can be used to plan for monthly wind-energy production and determine months when backup power would be needed, and when excess energy will be generated.

From the daily variation in wind speed (Fig. 14.5), it is seen that during the day, wind speed is lower, while during the night, wind speed increases. There is a peak in wind speed in the middle of the day, but even this is much less than wind speed late at night. High wind speeds around midnight would mean more wind energy production. However, the load requirement for villagers at midnight is not great, so the excess wind energy produced could be stored in a battery bank, for example.

From the wind rose for the Vadravadra site (Fig. 14.6), the prevalent wind is from the east. This should help planners in the installation of the wind turbine at the site by enabling them to orient an upwind wind turbine in the correct direction in order to reduce fatigue, and other loads, on the wind turbine and its blades.

Solar Resources

Since the solar insolation data is not recorded for Vadravadra, the data has been obtained from the NASA website (NASA 2011) by entering the latitude and longitude of the site.

The 22-year average solar radiation for Vadravadra, for a solar panel tilted at 18° towards the equator, is 5.50 kWh/m2/day. The monthly variation in solar radiation data is shown in Fig. 14.7. Comparison of Figs. 14.4, 14.5, 14.6, 14.7 shows that when the solar radiation is less, during the middle of the year, the wind speed values are high, and when wind speed is low (during the beginning of the year) the solar radiation is high. This means that solar and wind-speed data complement each other. Hence, for an energy planner it would be wise to set up a solar PV/wind hybrid system to fully exploit the renewable energy resources.

Wind and Solar Energy Potential

Selecting the Wind Turbine

Not just any wind turbine should be installed at the proposed site. The wind-speed characteristics for the site should match the wind speed specifications of the wind turbine. This means that the cut-in and rated wind speed \( \left( {v_{c} \;and\;v_{r} } \right) \) of the wind turbine should not be very high. Also, the chosen wind turbine should be able to meet b oth actual energy demand for the site, and to compensate for a 10 % increase.

Considering the wind-speed characteristics at the site, the electrical demand (~26,000 kWh/year), and the fact that, once electricity is available for 24 h a day, electrical demand will increase, a Hannevind 15 kW, three-bladed wind turbine has been chosen for the site. The specifications of this wind turbine are: \( v_{c} = 2.5\,{\text{m}}/{\text{s}};\;v_{r} = 9\,{\text{m}}/{\text{s}}; \) diameter of blades = 10 m; a permanent-magnet generator and a self-supporting lattice tower is recommended with height options of 21/27/33 m. This wind turbine has been chosen because it has a low cut-in wind speed, a low-rated wind speed, and a 10 m wind-blade diameter. The diameter of wind turbine blades is directly proportional to the electrical power output (P e ) from the wind turbine, because P e output from any wind turbine is given by Manwell et al. (2002) and Prasad et al. (2009).

where

- \( C_{op} \) :

-

is the overall power coefficient of the wind turbine, which takes into account the aerodynamic efficiency, mechanical efficiency and electrical efficiency;

- \( \rho \) :

-

is the density of air (1.2 kg/m3);

- A :

-

is the area of the turbine blades;

- v :

-

is the wind speed

From Eq. (14.1) it can also be noted that wind speed plays a major role in the P e output. If the wind speed doubles then the output power from the wind turbine is multiplied by eight. The power output curve is shown in Fig. 14.8.

The efficiency of the 15 kW wind turbine is shown in Fig. 14.9 (Better Generation 2011). In terms of the efficiency variation of the Hannevind 15 kW wind turbine, with respect to wind speed, the turbine has high efficiency (more than 30 %) at 3–10 m/s. In Fig. 14.3 it can be seen that most of the time, wind speed is 3–10 m/s, which implies a high wind-energy yield.

Estimated Wind Energy Output

The annual energy \( \left( {E_{ann} } \right) \) yield was calculated using Eq. (14.2).

where

- i :

-

is the wind speed;

- \( P_{{e_{i} }} \) :

-

is the electrical power from the wind turbine at a particular wind speed i;

- T i :

-

is the number of hours in a year for which wind speed is i

When the overall power coefficient of the 15 kW wind turbine is taken as 0.25, the estimated annual wind energy yield is 33,700 kWh. However, considering the manufacturer’s power curve, the annual energy output from the wind turbine is estimated to be 42,900 kWh. Using error analysis, the annual mean energy yield from the Hannevind 15 kW in Vadravadra could be \( 38,300\;{\text{kWh}} \pm 20\,\% \). Considering Fig. 14.10, energy output of more than 1,000 kWh is mostly for a wind speed of 5–11 m/s.

Sizing the Stand-Alone Solar System

The annual average number of consecutive “no-sun days” for the site is calculated to be 5.2 days. However, Table 14.2 (NASA, 2011) also shows that in August there are nine no-sun days. To calculate the battery storage size, the maximum number of no sun days should be taken so as to not to undersize the system. However, during design, the tradeoff has to be between supplying electricity continuously (i.e. 100 % of the time) and cost.

A stand-alone system will have the components shown in Fig. 14.11. To size the system, one needs to work back from the AC load and try to determine the size of battery bank and the size of the solar panels. The number of batteries and PV modules needed in a stand-alone system is determined during sizing. In sizing the stand-alone solar system for Vadravadra, the following data will be used:

The AC load for the village is 72 kWh/day. There will be five days of storage with a Surrette 12 V battery of capacity 600 Ah. The coulomb efficiency is taken as 80 %. The system voltage will be 24 V. A 12 V, 125 W solar module, which has a rated current of 7.2 A, is to be considered. The efficiency of the inverter is taken as 90 %. According to Fig. 14.7, June has the lowest solar insolation, 4.47 kWh/m2/day, and hence 4.47 h of full sun per day.

-

Step: 1.

Total daily AC load

72 kWh/day + (20 % × 72) = 86.4 kWh/day = 86,400 kWh/day

20 % is taken to cater for any unexpected rise in energy demand during the day.

-

Step: 2.

DC load input to inverter

-

Step: 3.

Battery storage capacity

-

Step: 4.

Calculating the size of battery

-

1.

Since the system voltage is 24 V, two batteries will be placed in series.

-

2.

Battery Ah for storage

Number of parallel strings:

Altogether, there are two batteries in series with 42 parallel strings = 84 batteries in total.

Masters (2004) gave the following formulae for storage capacity providing electricity 99 % of the time and 95 % of the time:

From Eq. (14.3) nine storage days is calculated; Eq. (14.4) calculates 3.1 storage days.

With nine days storage, the number of batteries comes to 150, which would increase the cost of the system; with three days storage the number of batteries comes to 50.

-

Step: 5.

PV sizing

Number of PV modules in series is

Since the AC load is 86,400 Wh/day, and the DC load for input to inverter is 96,000 Wh/day, the ampere-hours needed at the inverter is

One string has two modules; therefore, Ah to inverter is

Hence, the number of parallel strings is

Therefore the PV array will have two modules in series with 154 parallel strings, giving a total of 308 PV modules. Since one module is 125 W, the rated power of the whole array would be 38.5 kW. Having this huge number of PV modules will also increase the cost of the system. Hence, the next section analyses the possibility of wind/solar hybrid systems.

Stand-Alone Wind/Solar Hybrid Configuration

Since there is no grid connection to the island, to make the system reliable and efficient, a wind/solar/diesel hybrid configuration has to be analysed using HOMER software. Wind and solar data were available during the writing of this paper, and these data have therefore been used to run the software. The daily load for the site was taken as shown in Fig. 14.2. This was used for weekdays and weekends. The hybrid components that were considered in HOMER were wind turbine, solar panel, battery, diesel generator and converter. A Hannevind 15 kW wind turbine was the type considered, and the power curve was taken from the manufacturer’s data. A diesel generator was considered for the simulation to make the whole hybrid system more reliable. It was assumed that two batteries were in series and the bus voltage was 12 V. Two types of load were considered during HOMER simulations: (1) current load and (2) 20 % increase in load. Furthermore, for each load, three different kinds of stand-alone hybrid systems were considered: (1) wind/solar/diesel generator, (2) wind/diesel generator and (3) wind/solar. All hybrid systems used batteries as the storage system.

The cost of the different equipment is shown in Table 14.3. The operation and maintenance costs are taken as 3 % of the capital cost, and the replacement cost is taken as the capital cost. The project lifetime was taken as 20 years, with an interest rate of 10 %; the diesel fuel cost was taken as FJ$3.00/L. Table 14.4 summarises the outcome of the optimised results in HOMER, and Fig. 14.12 shows the monthly energy yield from wind and solar when the electrical load for the site was 71 kWh/day.

For each of the different scenarios in Table 14.4, the diesel fuel consumed per year is less than what is actually being used at the village. This would imply that the burden on diesel fuel would be less. Considering Table 14.4, the cost of energy (COE) for the wind/solar hybrid system is the highest (FJ$2.308/kWh for the Case 1 load and FJ$2.302/kWh for the Case 2 load) due to the high number of batteries needed, large converter size and the greater number of PV modules. Hence, the option of just solar/wind hybrid is not very financially viable. For the two cases of electric load, wind/diesel generator gives the lowest COE of FJ$1.532/kWh for Case 1 and FJ$1.370/kWh for Case 2 with ten batteries and 5 kW converters in both cases. The wind/solar/diesel generator hybrid system is not very different from the wind/diesel system, since the percent of electricity from PV is less than from wind.

In addition, comparing the cost of energy generation from each of the three sources (wind, PV and diesel generator), wind has the lowest COE, FJ$0.286/kWh. PV costs FJ$0.857/kWh and the diesel generator costs FJ$0.750/kWh.

Conclusions

Vadravadra village on Gau Island is remote and not connected to any grid electricity. Energy is provided for four hours every evening by a 15 kW diesel generator. Due to rising fuel costs and the irregular supply of fuel to the island, the villagers are looking for alternative sources of electricity. This study has found that the site has an abundance of wind and solar resources. The HOMER simulation results show that wind/diesel hybrid configuration is the best option for the site, with the cost of energy ranging from FJ$1.37 to FJ$1.53/kWh with an increase in electrical load. Now, with the preliminary wind and solar resource survey carried out, the Fiji Department of Energy is looking for funds to implement this hybrid system to benefit the villagers on Gau Island in terms of education and health, as well as to reduce their carbon footprint.

References

Avinesh G (2011) No electricity. Fiji Times Online. http://www.fijitimes.com/story.aspx?id=177662 Available (August 2011)

Better Generation (2011) Hannevind 15 kW wind turbine. http://www.bettergeneration.com/wind-turbine-reviews/hannevind-15kw-wind-turbine.html. Available (Sept 2011)

Developing Renewables (2006) Pacific Islands Country study: part D—RE projects. http://www.energyrecipes.org/reports/reports/Pacific%20Islands%20-%20Part%20D%20-%20RE%20Projects%20060209.pdf. Available (June 2011)

Fiji Islands Bureau of Statistics (2010) Fiji Facts and Figures as at 31st July 2010. http://www.statsfiji.gov.fj. Available (Aug 2011)

Manwell JF, McGowan J, Rogers G (2002) Wind energy explained: THEORY, design and applications. Wiley, England

Masters GM (2004) Renewable and efficient electric power systems. Wiley, New Jersey

NASA (2011) Surface meteorology and Solar Energy. http://eosweb.larc.nasa.gov/sse. Available (August 2011)

Prasad RD, Bansal RC, Sauturaga M (2009) Wind characteristics and power density analysis for Vadravadra site in Fiji Islands. Int. J. Model, Identif Control 6(3)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Prasad, R.D. (2013). A Comprehensive Study of the Wind and Solar Potential of Gau Island, Fiji. In: Leal Filho, W., Mannke, F., Mohee, R., Schulte, V., Surroop, D. (eds) Climate-Smart Technologies. Climate Change Management. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-37753-2_14

Download citation

DOI: https://doi.org/10.1007/978-3-642-37753-2_14

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-37752-5

Online ISBN: 978-3-642-37753-2

eBook Packages: Business and EconomicsEconomics and Finance (R0)