Abstract

Research and/or Engineering Questions/Objective The evaluation of vehicle characteristics at an early phase of functional development is a key task in the definition of a viable system and function architecture. Today this is complicated by the fact that full vehicle characteristics, in particular those of modern hybrid and electric vehicles, are dependent on a broad range of electrical, mechanical, thermal and control-related partial aspects. In addition to the current driving status and information on the environment, modern energy management systems (e.g. control systems, range, charging and thermal management) also require predictive information on the driving route to be expected. This includes, for example, uphill road grades, curve radii, speed limits, number of lanes, urban and residential areas, intersections and traffic lights. All together, the intelligent fusion of this information provides for increased safety and energy efficiency. Methodology These additional functions however result in additional complexity in the development process, which must be controlled. Nevertheless many questions already arise in a very early phase of development, in particular in the interaction with the actual utilization profile, such as route, driver and environment characteristics in the various target regions of the future vehicle. This article shows new ways and methods of how the functions and total vehicle characteristics can be evaluated in virtual driving tests in the early phase of development. The method provides a major support for the development and evaluation of energy management systems in the complete vehicle environment with corresponding system interactions: The evaluation of energy states, losses and fuel consumptions in realistic utilization profiles, such as route, driver and environment characteristics in the various target regions of the future vehicle. Results In addition to the evaluation of the individual target functions in a broad range of different scenarios, the correct designs of the individual system components in the complete vehicle can also be verified. The performance and robustness of the operating strategy, as well as the corresponding fuel consumption or CO2 emission values in the range of worldwide conditions of use can also be predicted with the different choice of route and driver types and the amount of traffic typical for the region. Limitations of this study Furthermore, positive fuel consumption effects are identified in the virtual driving test which cannot be recognized due to the insufficient repetitive accuracy in actual traffic. During this, the method can be consistently and uniformly used in the x-in-the-loop development process. As soon as hardware components like the engine, drive train or battery are available, these actual components can already be tested in the virtual driving test in combination with the virtual vehicle in accordance with the principles described. Conclusion As a result, the system and functional architecture can already be comprehensively evaluated in a very early development phase and the degree of integration maturity in the later, actual integration levels can be raised to a considerably higher standard, minimizing time-consuming, expensive development loops.

F2012-E12-027

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The evaluation of vehicle characteristics at an early phase of functional development is a key task in the definition of a viable system and function architecture. Today, this is complicated by the fact that full vehicle characteristics, in particular those of modern hybrid and electric vehicles, are dependent on a broad range of electrical, mechanical, thermal and control-related partial aspects. In addition to the current driving status and information on the environment, modern energy management systems (e.g. control systems, range, charging and thermal management) also require predictive information on the driving route to be expected. This includes, for example, uphill road grades, curve radii, speed limits, number of lanes, urban areas, and traffic lights. All together, the intelligent fusion of this information provides increased safety and energy efficiency.

2 Challenge

These additional functions however result in additional complexity in the development process, which must be controlled. Nevertheless many questions already arise in a very early phase of development, in particular in the interaction with the actual utilization profile, such as route, driver and environment characteristics in the various target regions of the future vehicle. This article shows new ways and methods of how the functions and total vehicle characteristics can be evaluated in virtual driving tests in the early phase of development.

In hybrid and electric vehicle, especially these interactions with the utilization profile are of major importance due to the multiple drive units and energy storage modules combined with complex control and function concepts:

-

Is the system design and the operating strategy suitable for the various customer use conditions?

-

How reliable are the networked hybrid functions in realistic driving scenarios?

-

Is the determined fuel efficiency realistic? Which consumption variance results from different route profiles?

-

Which emission levels result from full vehicle testing in realistic driving scenarios?

-

How often does the change between electric driving and driving with the internal combustion engine occur?

3 Research Method

Innovative virtual methods are to enable different subsystems to be integrated in the complete vehicle in order to evaluate the complete vehicle characteristics in virtual driving tests. Therefore, a powerful, interdisciplinary, multi-domain modeling and simulation environment like CarMaker is required in order to model the complex systems and to make these use cases in the complete vehicle, which are as realistic as possible, available in the virtual driving test.

This virtual driving test is to be established according to the same basic principles as the actual driving test. Here a virtual driver carries out the test instructions in a complete vehicle and an environment as realistically as possible. In addition, the virtual driver shall be capable of independently driving a broad range of different 3D routes, of maintaining distance to a vehicle ahead, and of controlling innovative systems.

For example, the virtual driver must be able to follow driving recommendations, such as “foot off the accelerator” in order to use the sailing function and the ACC function (on/off, distance, GreenACC function, etc.). In addition, the choice of driver types (sporty, normal, energy-saving, defensive, etc.) is to simulate the entire range of customer use later.

4 Open Integration and Test Platform

The integration of a hybrid drive train, predictive energy management, driver assistance system and navigation in the complete vehicle simulation is illustrated using the example of a hybrid vehicle. Here a hybrid powertrain based on the AVL CRUISE drive train simulation was integrated in the functional mock-up prototype of the CarMaker total vehicle simulation [1]. In addition, the complete vehicle was expanded with the energy management and driver assistance functions by means of MATLAB/SIMULINK. To provide the predictive energy management functions with the information of detailed digital maps and an anticipatory horizon (most probable path) in advance, the NAVTEQ ADAS RP development platform was integrated in the full vehicle simulation ([3, 4], Fig. 1). With this virtual hybrid vehicle virtual driving tests were then conducted in a wide variety of scenarios in order to evaluate the functions and vehicle characteristics in realistic use cases.

5 Functional Mock-Up Prototype

The full vehicle model is a completely non-linear 3D driving dynamics model with a body, axles, suspension, steering, engine mounts, powertrain, service brakes, tires and aerodynamics. In addition, the vehicle is equipped with a freely scalable sensor kit for slip angle/side-slip, IMUs (inertia measurement units), ADAS sensors (radar, lidar, ultrasonic) and a RoadPreView sensor. The concept of the ModelManager, with which models of different domains can be integrated in the complete vehicle, is of major importance.

Therefore different model classes were defined with standardized signal interfaces (I/O) and naming conventions. The models can be automatically generated for CarMaker from different environments and can be assigned to the corresponding model classes. The simulation environment automatically registers these models through cyclical monitoring of the model library. This makes it possible to manage and organize many different models at the same time. These can be conveniently changed over with the user interface or “on the fly” within the test automation. The parameterization, the initialization, the cyclical call and the concluding clean-up are automatically assumed by the ModelManager. The models, but also hardware components and systems (e.g. different control units, engines, drive train, steering) can be integrated very simply in the functional mock-up prototype from a hardware-in-the-loop (HIL) environment (Fig. 2, [2, 5].

6 Powertrain Model

To make a statement which influences preview functions have on the energy management in the vehicle in the driving maneuver, it is necessary to simulate the complexity of modern drive trains in a suitable degree of detail. This is the precondition for taking these functions into account in the virtual driving test or for being able to actively influence an increase in efficiency using control and closed-loop control algorithms. The goal is to create a uniform, bidirectional information structure which permits communication between the driver, the vehicle, the drive train and control and closed-loop control algorithms in such a way that route indicators determined in advance [4] (e.g. speed limitations, uphill grade, light signals) can have a direct effect on the engine management and therefore in turn significantly affect the maneuver retroactively. Due to the almost exclusive consideration of longitudinal dynamics and the evaluation based on standardized cycles, most attempts so far are no longer suitable for simulating realistic driving with realistic route, driver and regional information. The load requirements are unrealistic and in some cases faulty, which can lead to poorer efficiency, higher expenses and at worst to incorrect designs.

A complete replacement of the longitudinal dynamics simulation approaches used up until now would be justified by the established development phases in the product development cycle; however, this would not lead to success. As the evaluation based on standardized cycles for the concept analysis, basic design, component development and homologation of new vehicles will continue to play an important role in the future, AVL CRUISE was expanded so that it can be easily integrated in the CarMaker integration and test platform. In this context, the previous scope of software functions can be completely used “stand alone”, but it can also be integrated in a complete vehicle “at a click of the mouse” (Fig. 3). This is possible both in the pure office application and in real-time applications like CarMaker/HIL, AVL InMotion or on drive train test benches by means of PUMA Open. To do this, a fully-developed interface concept was required on both sides in order to not only exchange values on the signal level, but instead also messages for driver information, log functions, error handling, etc. By evaluating preview information from the realistic driving scenario, this system concept offers the option of completely taking the complex system and subsystem interaction into account.

7 Connecting Digital Maps

To supply these functions with the necessary information about the “most probable” future, digital maps, navigation devices and algorithms are required (MPP; Most Probable Path) and make it available to the controller functions and control units as a corresponding “horizon” [4]. The connection to ADAS RP from NAVTEQ, a development platform for functions of digital cards, was realized for this purpose. In the process, the map data of the actual course of the road are imported into simulation environment (Fig. 4). As a result the complete detailed geo data of customer-specific test routes as well as that of any route are available for the simulation. The route data also contain information on the road infrastructure (e.g. signing, curve characteristics). The data are available in such a high quality that they can be used directly in the simulation environment: The virtual driver can start the virtual vehicle immediately for the desired test drive. It drives the specified route completely independently and observes the traffic signs. Both the driving and the course strategy are parameterized quite simply. To exchange the information of the digital maps a connection to the CAN-based ADASIS protocol was realized [3]. The virtual vehicle transfers the GPS position with a corresponding emulation of the GPS receiver and receives the MPP back from the navigation device (horizon provider). Here, a distinction is made between the single path (1D horizon) and multi path (2D horizon).

8 Different Driving Strategies

Different drivers use different driving strategies (e.g. defensive, fuel-efficient, sporty, and aggressive). Each of them affects certain vehicle functions. If this effect is ignored, this will lead to altered results when determining fuel consumption values or when examining battery charging states. The drivers are distinguished by a different selection of trajectory, course steering, steering, braking and acceleration strategies. To be able to make valid statements on the fuel consumption, it is important that the virtual driver model can realistically simulate these differences. For this reason, a main focus of the development of the IPG driver model was on the realistic reconstruction of the driver input. Therefore IPGDriver was equipped with a repertoire of driving styles and driving strategies which the user selects with the user interface. The new traffic follow model plays an important role here. The virtual driver is now capable of “seeing” so that it can actively follow a preceding vehicle. Among other things, the temporal and spatial distance window and the desired following strategy are freely defined. The possible driving styles range from fuel-saving gliders to the gas-guzzler. Together these parameters lead to different fuel consumption. These options make systematic testing of integrated functions and of anticipatory energy management strategies possible for different driver types. The high adaptability of the driver model provides for a very exact simulation of reality in the virtual driving test.

9 Virtual Driving Test for Actual Use Cases

To effectively test the target functions, they must be assigned to corresponding actual use cases. There are situations in which the function is to work as desired and situations in which it must “not” work. In addition, there are error events (e.g. incomplete information or incorrect reactions of the driver) which the function must react to. The reconstruction of the actual use case can mainly take place in three different ways:

-

1.

Maneuver and event-based scenarios for evaluating the target function with permanent assignment of the function and the driving maneuver.

-

2.

Unobstructed driving on long city, country and motorway routes with different driver types and driving strategies for the integral evaluation of the complete vehicle characteristic (e.g. emission, fuel consumption, share of electric driving).

-

3.

Combination of unobstructed driving with maneuver and event-based scenarios plus situations and events that are purposely included to integrally evaluate the full vehicle characteristic.

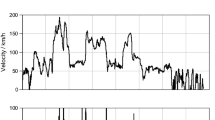

10 Predictive Operating Strategy of Hybrid Vehicles

With hybrid vehicles, the central operating strategy, especially the SOC—State of Charge strategy of the battery—is very important. This operating strategy and controller functions were integrated in the complete vehicle. Here the predictive hybrid strategies are tested. In the process it is possible, for example, to use the route as a decision-making criterion for how much energy must be provided for boosting. If an uphill grade is anticipated, as much energy as possible will get stored in the battery, e.g. for electric drive support (Fig. 5). On the other hand, with probable downhill grades, the operating strategy can foresee that, despite a low SOC, no load point increase of the engine is necessary, as energy is fed into the battery through recuperation anyway when driving downhill. Thus the SOC span can be optimally utilized. And with a knowledge of upcoming city zones it is possible to increase the SOC in due time in order to glide through these zones electrically with little noise and emissions.

With the methods and tools created, the interaction with the actual utilization profile, such as route, driver and environment characteristics [6], can also be evaluated for the different target regions of the future vehicle. For this purpose, the vehicle concept complete with different driver types is sent on virtual test drives in various target regions. For example, Fig. 6 shows how fuel consumption varies depending on how different driver types maintain the distance to a preceding car.

11 Conclusion

The method presented here provides a major support for the development of energy management systems in the complete vehicle environment with corresponding system interactions: The evaluation of energy states, losses and fuel consumptions in realistic utilization profiles, such as route, driver and environment characteristics in the various target regions of the future vehicle. In addition the correct designs of the individual system components in the complete vehicle can also be verified.

The performance and robustness of the operating strategy, as well as the energy consumption or CO2 emission values in the range of worldwide conditions of use can also be predicted—with different routes, driver types and the amount of traffic. During this, the method can be consistently and uniformly used in the x-in-the-loop development process. As soon as hardware components like the engine, drive train or battery are available, these actual components can already be tested in the virtual driving test in combination with the virtual vehicle in accordance with the principles described [2].

As a result, the system and functional architecture can already be comprehensively evaluated in a very early development phase and the degree of integration maturity in the later, actual integration levels can be raised to a higher standard, minimizing time-consuming, expensive development loops.

References

Bernhard Schick, Leonhard V, Klein-Ridder B, IPG Automotive GmbH, Karlsruhe (2008) Holistic inspection of hybrid drivetrains and chassis control systems in a continious Mil/Sil/Hil Process. In: AVEC 2008 Kobe/Japan

Christian Schyr, Thomas Schaden, Stefan Jakubek, Bernhard Schick (2008) New frontloading potentials through coupling of hil-simulation and engine test bed. In: FISITA world congress 2008 Munich

Christian Ress, Dirk Balzer, Alexander Bracht, Sinisa Durekovic, Jan Löwenau on behalf of the ADASIS Forum Adasis protocol for advanced in-vehicle applications

Wilde A, Schneider J, Herzog H-G (2008) Fahrstil- und fahrsituationsabhängige ladestrategie bei hybridfahrzeugen, In: ATZ 110, pp 412–421

Pfister F, AVL List GmbH, Graz; Schick B, IPG Automotive GmbH, Karlsruhe (2011) The future has a sensor. location awareness meets powertrain controls. In: 4th international symposium on development methodology, Wiesbaden

Tetsunori H, Toyota Motor Corporation (2011) Reducing fuel consumption by improved vehicle efficiency. In: ATZ 113(2011) No. 4, pp 274–279

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Kunz, A., Schick, B., Lange, S. (2013). Predictive Energy Management Strategies in Virtual Driving Tests: Early Evaluation of Networked Controller Functions in Realistic Use Cases. In: Proceedings of the FISITA 2012 World Automotive Congress. Lecture Notes in Electrical Engineering, vol 196. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-33738-3_35

Download citation

DOI: https://doi.org/10.1007/978-3-642-33738-3_35

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-33737-6

Online ISBN: 978-3-642-33738-3

eBook Packages: EngineeringEngineering (R0)