Abstract

Degradation of commercial textile dye ACID RED 18 (AR18) by Photo-Fenton reagent has been investigated under irradiation of visible light in aqueous medium. The degradation process was carried out by hydroxyl free radicals which were the most reactive chemical species in the whole process. The influence of different experimental parameters such as concentration of Dye (AR18), photocatalyst (Fenton reagent), H2O2 and pH of the experimental solutions on the initial rate and photodegradation of the dye were assessed and optimized. Complete mineralization of dye AR18 (~100 %) was achieved by Photo-Fenton reagent. The photobleaching process follows first order kinetics. A simple, efficient and environmental friendly method for the photodegradation of dye is developed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Photocatalytic Degradation

- Complete Mineralization

- Barium Chloride

- Reactive Chemical Species

- Dark Brown Solution

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Introduction

In the last two-three decades, azo dyes are produced and consumed annually in large quantities in textile industries. Most of the azo dyes are difficult to be degraded due to their complex structure. Some of them are toxic and suspected carcinogens. The untreated dyes in effluent from dyeing factories and leather industries are a group of hazardous chemicals as well as major sources of water pollution [1, 2]. The color in the waste water is an obvious indicator of water pollution due to dyes and pigments [3, 4]. Also the dyes in water affect photosynthetic activity in environment due to reduced light penetration and may be toxic to some aquatic lives [5]. The environmental concern of these potentially carcinogenic pollutants in contaminated water has drawn the attention of many research workers.

Currently, the major methods of textile wastewater treatment are advanced oxidation processes which are widely used are UV irradiation, H2O2/ UV [6], TiO2/UV [7], Ozonation [8], Fenton reagent [9] or UV- Fenton [10] process etc. Fenton reagent exhibits a number of features that make its use advantageous as compared to other methods such as high degree of catalytic efficiency, high degree of specificity, absence of side reactions and cost effectiveness. Experimental observations indicate that it can be used to degrade chemicals and dyes [11, 12].

For the present investigation, water soluble disazo dye Acid Red 18 is selected. AR18 is toxic and carcinogenic in nature. Thus it is considered worthwhile to see how textile dye AR18 could be degraded in aqueous medium by photo-Fenton reagent.

Materials

For the present studies the commercial disazo dye Acid Red 18 (C.I No. 16255, Colortex). Photocatalyst FeSO4 (Merck, 99% purity) and H2O2 (Merck, 6% purity) were used for photocatalytic degradation. 1×10–3M (0.604g/l) stock solution of dye was prepared in double distilled water and diluted as required. The desired pH of the solution was adjusted by the addition of previously standardized sulfuric acid solutions. All laboratory reagents were of analytical grade.

Procedure and Analysis

The reaction mixture was prepared by taking 3ml of stock solution of dye (1×10–3 M), 3.5ml of FeSO4 (1×10–3 M), 1.6ml of H2O2 (6%) in a round bottom flask. The total volume of the reaction mixture was made 100ml by adding double distilled water. The concentration of different ingredients in the reaction mixture was [Dye] =3×10–5 M, [FeSO4] =3.5×10–5 M and [H2O2] =3.1×10–2 M.

To carry out the photobleaching, the reaction mixture was irradiated under light source (2×200W Tungsten lamps) with stirring. A water filter was used to cut off thermal radiations. The pH of the solution was adjusted by adding acid solution. The progress of the reaction was observed at definite time intervals by measuring absorbance using spectrophotometer (Schimadzu, UV- 1700) at 506nm. The rate of decrease of absorbance with time was continuously monitored. After complete mineralization, the presence of NO2 -, NO3 -, SO4 2- ions and evolution of CO2 were tested by standard procedure.

Results and Discussion

Control experiments (in absence of photocatalyst, light) confirm the necessity of photocatalyst, light to follow the photocatalytic path for the photobleaching of dye.

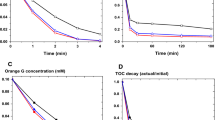

The photocatalytic degradation of Acid Red 18 was observed at 506nm. The optimum conditions for the photobleaching of dye were [Dye] =3×10–5 M, [FeSO4] =3.5×10–5 M, [H2O2] =3.1×10–2 M and pH=3.5. The results are presented graphically in Fig-1.

It was observed that absorbance decreases with time, indicating that the dye is degraded on irradiation. A graph between 2+log Abs and time has been plotted. The linearity of the plot indicates that the photocatalytic bleaching follows a first order kinetics. The rate constant of this photobleaching process was determined using the expression.

Rate (k) = 2.303 x Slope = 10.47×10–5 sec-1

The effect of variation in various reaction parameters has been studied, e.g. pH, concentration of the dye, FeSO4 and H2O2.

Effect of Variation in pH

The effect of pH on the rate of photocatalytic bleaching of dye was observed. The photodegradation was performed at different pH (1.5–5). The results (Fig-2) reveals that the rates of photobleaching of dye increases with an increase in pH up to 3.5, after which it decreases with increasing pH. At pH >3.5, Fe2+ gets converted into Fe3+ which decomposes H2O2 into water and oxygen, instead of forming •OH radicals. Thus, all subsequent experiments were carried out at pH 3.5.

Effect of variation in Dye concentration

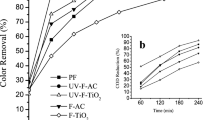

The effect of [Dye] on the degradation of Acid Red 18 was studied at different concentrations varying from 1.0×10–5 M to 8.0×10–5 M keeping all other factors identical.

The result (Fig-3) reveals that the rate of photobleaching of dye decreases with the increase in the concentration of dye. It can be explained on the basis of the observations that as the concentration of the dye is increased, the dye itself may act as a filter for the incident light, preventing sufficient intensity of light from reaching the dye molecule in the solution.

Effect of variation in catalyst concentration

Keeping all other factors identical, the concentration of catalyst was changed and its effect on the rate of photochemical degradation was observed. The result of Fig-4 reveals that the rate of photobleaching of dye increases with the increase in the concentration of catalyst up to 3.5×10–5 M. The increase in ferrous ions in the reaction mixture is accompanied by enhanced generation of •OH radicals, consequently increasing the rate of photodegradation. After the optimal Fe+2 addition, the higher dose of Fe+2 resulted in a brown turbidity that causes the recombination of •OH radicals and Fe+2 reacts with •OH as a scavenger. Therefore, on further increase, the rate becomes almost constant.

Effect of H2O2 concentration

Keeping all other factors constant, the concentration of H2O2 was changed and its effect on the rate of photobleaching was studied. The result reported in Fig-5 reveals that the rate of photobleaching of dye increases with the increase in the concentration of H2O2 up to 3.10×10–2 M. Further increase in concentration has negligible effect as the reagent itself reacts with •OH radicals to produce •O2H which has much lower oxidation capacities.

Mechanism

The mechanism of photo-Fenton oxidation is based on the generation of ·OH radicals by the catalytic decomposition of H2O2 in acidic media [13]. In presence of Fe2+, the peroxide breaks down to ·OH and OH−, according to the following reactions (Eqn. 1, 2, 3).

Fe2+ + H2O2 → Fe3+ + ·OH + OH− (1)

Fe3+ + H2O →hv Fe2+ + ·OOH + H+ (2)

2 H2O2 → H2O + •OH + •O2H(3)

The incorporation of ·OH radicals with H2O2 also produces ·OOH radicals (Eqn. 4).

•OH + H2O2 → •O2H + H2O(4)

Ferrous ions will undergo oxidation to ferric ions by the addition of ·OH radicals (Eqn. 5), while ferric ions are reduced to ferrous ions by the incorporation of ·OOH radicals producing H+ ions (Eqn. 6).

Fe2+ + •OH → Fe3+ + OH- (5)

Fe3+ + •O2H → Fe2+ + O2 + H+ (6)

·OOH radicals are highly unstable in water and undergo facile disproportionation rather than reacting slowly with the dye molecules. The participation of the ·OH radical as an active oxidizing species was confirmed. The hydroxyl radical scavengers like 2-Propanol or t-Butyl Alcohol were used, which drastically reduced rate of degradation.

The hydroxyl radical (oxidation potential 2.8 eV) attacks dye by either abstracting a hydrogen atom or adding itself to double bonds. Initially the hydroxyl radicals attack on the azo linkage of the dye molecule and break down to produce Sodium 4-nitronaphthalene-1-sulfonate (A) and Disodium 7-hydroxy-8-nitronaphthalene-1, 3-disulfonate (B). These further undergo continuous attack of •OH radicals and oxygen to produce toluene and naphthalene derivatives and finally oxidize to CO2 After continuous irradiation, the complete mineralization of dye occurred via converting into CO2, H2O, NO2 -, NO3 -, SO4 2- .

The end products are simple molecules and harmless to the environment (Eqn.7).

(CO2 + H+ + H2O + NO2 – + NO3 – + SO4 2–)(7)

The end products were detected and their presence in the reaction mixture was ascertained by chemical physical method.

Nitrate ions were detected by nitrate ion selective electrode having a solid-state PVC polymer membrane. Nitrite ions were confirmed by using H2SO4 and FeSO4 (a dark brown solution, arising from the iron nitric oxide complex). Sulfate ions were detected by gravimetric analysis (barium chloride solution). CO2 was confirmed by introducing the gas to freshly prepared limewater.

Effect of addition of homogeneous catalyst Uranyl Acetate

The effect of addition of homogeneous photocatalyst U (VI) on photodegradation has been investigated. A search was made to suggest the combination of ferrous ions by some other active metals, which have special oxygen transfer properties to generate more highly reactive hydroxyl radicals.

So the effect of UO2 2+ (3.5×10–5 M) with H2O2 was studied (Fig.6) which shown appreciable increase in photodegradation of the dye at optimum conditions. The reaction rate was faster as it generates two hydroxyl radicals per uranyl ion (Eqn.8, 9).

2UO2 2+ + 2H2O2 →2+ + 4•OH + O2 (8)

2UO2+ + O2 →hv 2 2+ (9)

References

C. Radulescu, A.M. Hossu, I. Ionita, and E.I Moater; Dyes and Pigments 76(2) (2008) 366

A.S. Stasinakis; Global Nest Journal 10(3) (2008) 376

P. Mehta, R. Mehta, M. Surana and B.V. Kabra; J. Ind. Council Chem. 26(2) (2009) 158

A. Kumar, M. Paliwal, , R. Ameta, and Ameta, S. C; J. Iran. Chem. Soc. 5(2) (2008) 346

Li. Huang, D. Gu, L. Yang, L. Xia, R. Zhang, and H. Hou; J. Environ. Sci. 20 (2008) 183

M. Ugurlu and I. Kula; Environ. Sci. Poll. Res. 14 (2007) 319

D. Chatterjee and S. Dasgupta, J. Photochem. Photobiol. 6 (2005) 186

C.J. Haperman, B.G. Anderson, A. Torrents and A.J. Acher Aric; Food Chem. 45 (1997) 1006

M. Surana, P. Mehta, K. Pamecha and B.V. Kabra; Der Pharma Chemica. 3 (2) (2011) 39

H. Gabriel and J. Hon; Research J. App. Sci. 3 (2008) 216

M.M. Rahman, M.A. Hasnat and K. Sawada; J. Sci. Res. 1(1) (2009) 108

T.R. Sundararaman, V. Ramamurthi and N. Partha; Modern Applied Science 3(8) (2009) 15

R.J. Bigdha; Chem. Eng. Prog. 12 (1995) 62

Author information

Authors and Affiliations

Editor information

Rights and permissions

Copyright information

© 2012 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Surana, M., Kabra, B. (2012). Decolorization and Mineralization of Commercial Textile Dye Acid Red 18 by Photo-Fenton Reagent and Study of Effect of Homogeneous Catalyst Uranyl Acetate. In: Khemani, L., Srivastava, M., Srivastava, S. (eds) Chemistry of Phytopotentials: Health, Energy and Environmental Perspectives. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-23394-4_68

Download citation

DOI: https://doi.org/10.1007/978-3-642-23394-4_68

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-23393-7

Online ISBN: 978-3-642-23394-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)