Abstract

Expansive soil is a kind of geological body with special hazards to the construction engineering. It has the engineering properties of shrinkage, fracture and overconsolidation. Its engineering hazard is rich in water content in soil. The expansive geomaterials can produce wetting and shrinkage deformation, which adversely affect the subgrade, slope and tunnel support structure. In order to solve this problem, the dry and wet cycle model test device was established by simulating the “rain” and “sunshine” cycle, and the typical dry wet circulation, shrinkage and other factors, focusing on the expansion and contraction of soil tunnel rock failure instability development model, the scope and its conditions and the impact of factors such as simulated rainfall under the conditions of the tunnel excavation and support, the stress, strain and deformation of the surrounding rock of the tunnel are analyzed, and the possible damage modes are analyzed, and the mechanism of the surrounding rock disaster in the shrinkage fracture zone is revealed.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Water swelling of expansive soil or loss of water shrinkage results in unstable clay, and its distribution is extremely wide. Expansive soil is a special soil and causes harm to project activities on the soil owing to its water swelling and loss of water characteristics. This type of soil usually causes mountain collapses, landslides, debris flows, and other geological disasters. The reasons for the special properties of expansive soil are complicated. Current scholars mainly study from the three aspects of mineral composition, namely, related physical and chemical properties and physical mechanics. The expansive soil after expansion and the structure of interaction are complex, and the scene of influencing factors is difficult to study. Physical similarity simulation is an important, effective, and scientific method for solving complex geotechnical engineering problems [1,2,3]. The engineering geomechanical model testing technology pioneered by Fumagalli [4] is gradually being recognized by scholars and applied on a large scale. Ashby [5] used the model test technique to study the theory of slope dumping intensively. Baumgargarter et al. [6,7,8] also used the model test to conduct relevant research. Patton [9] used gypsum to simulate the climbing angle effect of zigzag structure. Einstein et al. [10] used gypsum to simulate the climbing phenomenon and shear mechanism of zigzag structure. Jacoby and Schmeling [11] used glycerol, fused paraffin, and other simulated mantle convection and plate-related role. Kincaid and Olson [12] also simulated the lithosphere and asthenosphere using similar materials.

For similar materials, domestic scholars have produced numerous research results. Zuo et al. [13] conducted a rock mass material simulation test using quartz sand, gypsum, and cement. Wu et al. [14] performed a weak rock simulation test using barite powder, gypsum, fine sand, laundry liquid, and water. Li et al. [15] used sand, barite powder, talc, cement, petrolatum, silicone oil, and mixed water for the flow-solid coupling of a relevant simulation test. Ye et al. [16] used cement, gypsum, and glycerol to configure similar materials and studied the effect of different mortar ratios and cement contents on the physical and mechanical properties of materials. Liu et al. [17] conducted a related study on the ratio of similar materials in rock mass. Zhang et al. [18] used barite powder, sand, industrial salt, gypsum, and bentonite in a collapsible loess simulation test. However, few studies on the ratio of expansive similar materials exist in China. Lai et al. [19] developed similar materials for expansive rocks using sand, bentonite, lime, admixture, and mixed water. Guo [20] compared the mechanical properties of the similar material with different ratio of illite, kaolinite, chlorite, and bentonite.

In this study, large-scale model tests are carried out using similar materials prepared using bentonite and gypsum (particle size is less than 0.5 mm). The stress–strain and settlement deformations of the tunnel’s surrounding rock in an expansive soil area are studied.

2 Method

The test model includes a rain simulation, a rain container, a working table, and a model frame with a length of 2 m and a width of 0.5 m, as shown in Fig. 1. Fine sand is used to fill the right, left, and bottom of test model, with a thickness of 25 cm, to ensure successful permeation of water.

Through a series of tests, expansive soil is simulated using the sands in Huang River, bentonite, and gypsum, with a mass ratio of 8:3:1. The free expansive ratio of the similar material is 68%, and its permeability coefficient is 4.2 × 10−7 cm/s when the degree of compaction is 95% and is 2.53 × 10−8 cm/s when the degree of compaction is 90%.

2.1 Monitoring Element

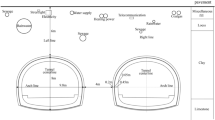

Three types of monitoring elements are present in the test model, namely, strain brick, earth pressure cell, and multipoint displacement meter. The strain brick is made with similar material, as shown in Fig. 2, which is a cube with 2 cm sides. It is used to monitor the strain of the specified part. The process of making the strain brick is shown in Fig. 3. The strain bricks are placed in the test model, as shown in Fig. 4, to monitor the strain of the surrounding rock during testing. In Fig. 4, 1 represents the monitoring point at the bottom of the tunnel; 2 and 3 represent the monitoring points at the haunch of the tunnel, with a distance of 11 cm; 4 and 5 represent the monitoring points at the spandrel of the tunnel, with a distance of is 11 cm; and 6 and 7 represent the monitoring points at the top of the tunnel, with a distance of 11 cm. Considering the special case of the test model and its purpose, the location of earth pressure cell is the same as that of the strain bricks, as shown in Fig. 4. The multipoint displacement meters are placed in the test model as shown in Fig. 5. In Fig. 5, 1 represents the monitoring point at the bottom of the tunnel; 2, 3, 4, 5, and 6 represent the monitoring points at the haunch of the tunnel, with a distance of 11 cm; and 7, 8, 9, 10 and 11 represent the monitoring points at the top of the tunnel, with a distance of 11 cm.

2.2 Experimental Process

Firstly, the similar material must be mixed at a ratio of 8(sand from Huang River):3(bentonite):1(gypsum), which is designed on the basis of a series of tests. The sand from Huang River, bentonite, and gypsum are mixed using an agitator, which can ensure the sufficient mixing of the similar material to satisfy the test demand, as shown in Fig. 6. Secondly, the seepy material must be placed at the bottom, right, and left of the model as the seepy boundary of similar material. In this test, silver sand is used as a type of seepy material, with a thickness of 25 cm. Thirdly, the similar material is poured at a thickness of 30 cm at once and compacted by a hammer. Then, the monitoring element should be placed at the proper place, as shown in Fig. 7.

When all preparatory works are done, the upper bench of the first part of the tunnel should be excavated and protected by gypsum, as shown in Fig. 8. Then, the lower bench of the first part should be excavated 25 min later when the surrounding rock has stabilized and protected by gypsum, as shown in Fig. 8. Subsequently, rain should be simulated every day until the test model is permeated by water. Then, the second part of the tunnel should be excavated in the same manner as the first part, as shown in Fig. 9. Then, sunshine should be simulated, as shown in Fig. 10. The third part of the tunnel should be excavated after the sunshine is simulated for 10 days, as shown in Fig. 11.

3 Results

3.1 Strain

For the strain brick, monitoring point 1 at the bottom of the tunnel represents the changing strain of the bottom of the tunnel. With passing time, the strain of monitoring point 1 changes, as shown in Fig. 12. The Fig. 12 shows that the strain of monitoring point 1 increases rapidly and can reach −550 με after the excavation of the first part of the tunnel with the release of the stress of the surrounding rock near the first part of the tunnel. When the strain of monitoring point 1 reaches the peak value, it decreases rapidly and can be close to 0. The reason is that the stress of the surrounding rock near the first part of the tunnel is released, the surrounding rock deforms, and then the model reaches a new balance, therefore the strain of the surrounding rock reaches its minimum value. When it rains, load can be generated by the rainwater on the entire model. Accordingly, the strain of monitoring point 1 increases with the permeating water. The strain of monitoring point 1 reaches its peak value of −900 με when rain water reaches the bottom of the model. Subsequently, the strain value of monitoring point 1 waves in approximately 200 με and then decreases to the minimum value, which may be caused by the expansion of the similar material with water immersion. Furthermore, the entire model reaches a new balance. When rainwater reaches the bottom of the model, the simulation of rain should be stopped and the second part of the tunnel should be excavated. Then, the strain of monitoring point 1 decreases rapidly until −300 με. Thereafter, sunshine should be simulated. With sunshine simulated, the strain of monitoring point 1 remains the same. After five days of simulated sunshine, the similar material loses its water and starts to shrink. The stress in the surrounding rock changes rapidly, and the strain value of monitoring point 1 changes rapidly from −300 to −1450 με. At this time, crevices develop in the surrounding rock. With passing time, the stress of the surrounding rock is released and the model gets a new balance. After the excavation of the third part of the tunnel, the strain of monitoring point 1 decreases rapidly to −500 με.

The strain values of monitoring points 2 and 3, as shown in Figs. 13 and 14, respectively, represent the strain of the haunch of the tunnel. The corresponding graphs show that the trend of the strain data of monitoring points 2 and 3 is similar to the monitoring point 1 at the bottom of arch. The change patterns of monitoring point 2 are similar with those of monitoring point 1. The change rules of monitoring points 2 and 1 are the same and the only difference is the strain value. Monitoring point 2 achieves a minimum value of −500 με and a maximum value of 800 με for strain. Given that monitoring point 3 is 11 cm from the tunnel arch position, its corresponding strain curve shape differs from those of monitoring points 1 and 2, mainly because that the strain of monitoring point 3 changes less when similar material being permeated. Monitoring point 3 does not show any fluctuation in the process of water infiltration because it is 11 cm from the outside of the tunnel arch on the vertical section and 15 cm on the horizontal section from the exposed surface of the first ring. The distance is still relatively far. And the effect of excavation of first ring tunnel coupled with the internal stress redistribution caused by the infiltration of water on monitoring point 3 is relatively less than the monitoring point 2.

The strain values of monitoring points 4 and 5, as shown in Figs. 15 and 16, respectively, represent the strain of the haunch of the tunnel. Monitoring points 4 and 5 are located at the 45° direction of the haunch and the top of the tunnel, and the curves of monitoring points 4 and 5 show that monitoring point 4 is the same as monitoring point 5 and also as the monitoring points 1 and 2. And the total change range of monitoring points 4 and 5 with a maximum value of 200 με and a minimum value of −1000 με is relatively smaller than that of monitoring point 2.

The strain values of monitoring points 6 and 7, as shown as Figs. 17 and 18, respectively, represent the strain of the haunch of the tunnel. Monitoring point 6 is the same as monitoring point 7 and also same as monitoring points 1, 2, 4, and 5, with the only difference of the specific strain values. Monitoring point 6 possesses a minimum strain value of −1600 με and a maximum value of −150 με, while monitoring point 7 possesses a minimum strain value of −2800 με and a maximum value of 800 με. Monitoring point 6 is located at the tunnel dome, and the change in the strain change value is not too much from the change value of the other position. Monitoring point 7 is located 11 cm above monitoring point 6 and is largely affected by the model surface relative to the other monitoring points. This effect is reflected in the simulated rainfall and sunshine. Monitoring point 7 significantly changes in range and fluctuations.

3.2 Stress

For earth pressure cells, monitoring points 2 and 3 at the haunch of the tunnel represent the stress change of the haunch of the tunnel. With time passing by, the stresses of monitoring points 2 and 3 change, respectively, as shown in Figs. 19 and 20. The data of the earth pressure sensor 2 is not so good due to several conditions in the experiment, but the curve shape is very similar to that of earth pressure sensor 3. For the arch pressure analysis of the location of the arch, the earth pressure sensor 3 is used. The curve of earth pressure sensor 3 shows that the absolute value of the pressure at the earth pressure monitoring point 3 increases after the tunnel is excavated, and the maximum value is −120 Pa under the simulated rainfall. After the simulated rainfall, the absolute value of the earth pressure at monitoring point 3 gradually decreases to approximately 30 Pa because of the rainfall. Thus, the water load on the top of the expansive soil’s similar material gradually decreases. With the penetration of rainwater in the similar material, the stress distribution in the expansive soil is completed. Furthermore, the absolute value of the earth pressure increases first to approximately 250 Pa and then decreases at the full penetration of rain, and the absolute value of the earth pressure decreases to approximately 0 Pa. After the simulated rainfall on November 6, the second ring is excavated and then sunshine is simulated. With the water swelling of expansive soil, the absolute value of earth pressure gradually increases to approximately 70 Pa. However, the expansion of the expansive soil is completed. With the further development of the simulated sunshine, the cracks inside the similar materials of the expansive soil gradually develop and the stress is further redistributed. Finally, the stress value is maintained at −25 Pa. When the tunnel is excavated, the absolute value of the earth pressure fluctuates by approximately 120 Pa. This finding is due to that the excavation of the last ring further breaks the stress balance within the similar material, the pressure of the expansive soil is released, and the moisture can be removed from the tunnel through evaporation. The gradual dehydration contraction in the tunnel around the material results in fluctuations in the curve of the situation. For similar materials, cracks develop further and eventually penetrate.

Figure 21 shows that the fluctuation of monitoring point 5 is smaller than that of monitoring points 3 and 2, but it can be seen that the change shape is similar. The difference is that impact of the tunnel excavation on the monitoring point 5 is not as obvious as that of monitoring points 2 and 3 because its distance from the tunnel position is further. At the beginning of the test, the change trend of monitoring point 5 is the same as that of monitoring point 3. However, when the simulated sunshine is carried out, the earth pressure value of monitoring point 5 gradually increases and finally reaches approximately 200 Pa. And then the earth pressure value of monitoring point 5 gradually decreases to 0 Pa. With the development of the apparent fractures, the earth pressure value increases again.

The graphs of earth pressure monitoring points 6 and 7 (Figs. 22 and 23) show that the curve shape is substantially the same as that of monitoring point 5, except that the specific values of the earth pressure are different. As the position of the monitoring point gradually is closing to the top of the expansive soil, the stress value gradually decreases. Earth pressure monitoring point 6 can reach a maximum value of approximately 150 Pa and a minimum value of approximately −100 Pa. The pressure value of the earth pressure monitoring point 7 is smaller than that of monitoring point 6, and its maximum value is 100 Pa and minimum value is approximately 50 Pa.

3.3 Multipoint Displacement Meter

Figure 24 shows that, after excavation of the first ring on November 1, the bottom of the arch exhibits an uplift phenomenon. After the simulated rainfall on November 6, the expansion in the model of expansive soil gradually develops. When the material gradually penetrated completely, the displacement of the bottom of the arch reaches a maximum value of 0.3 mm. In the early stage, the bottom of the arch presents an uplift phenomenon mainly due to the excavation of the first ring. Then, with the gradual infiltration of rainfall in the expansive soil similar material, water swelling gradually increases the amount of uplift. As a result, the arch uplift gradually increases to 0.3 mm in the simulation of sunshine. On November 14, displacement increases due to the construction crane operation. The sunshine exhibits slight effect on the displacement of the arch. In the final ring, the uplift of the arch increases from 0.45 to 0.7 mm. The effect of sunshine on the displacement of the arch is very small, and the effect of rainfall on the displacement of the arch is relatively larger.

Figures 25, 26, 27 and 28 show that, the influence of excavation of the first ring on the displacement of the monitoring points 2 to 5 is very small because the position of the monitoring section has not been excavated. However, after the rainfall, the displacement on the monitoring point 2 and 3 represent upheaval, while the monitoring point 4 and 5 represent settlement. After the second ring is excavated, the absolute displacement value of monitoring point 2 increases to approximately 0.45, the absolute displacement value of monitoring point 3 increases to approximately 0.2, and the displacement absolute values of monitoring points 4 and 5 are negligible. After the excavation of the second ring, the displacement of the monitoring point 2, 3, 4 and 5 gradually develops under simulated sunshine. Monitoring points 2 and 3 reach approximately 1 cm before the third ring excavation, While the absolute displacement values of monitoring points 4 and 5 reach 0.6 and 0.7 cm, respectively. After the excavation of the third ring, the displacement value of each monitoring point of the arch gradually increases. Moreover, the displacement values of monitoring point 2 and 3 reach 1.3 cm, while those of monitoring points 4 and 5 reach 1.1 and 0.9 cm, respectively.

From the displacement curve of the monitoring points of the vaults, shown as Figs. 29, 30 and 31, the displacement of monitoring points does not increase immediately after the excavation of the first ring of the tunnel. However, with the gradual infiltration of the rainfall in the similar material, the settlement values of monitoring points 7 and 8 reach 0.8 cm and the settlement of monitoring point 9 reaches 0.5 cm. Given that the second ring of tunnel is far away from the monitoring part, its influence on the displacement of monitoring points of the vault is relatively small. Before the excavation of the third ring, the settlement values of monitoring point 7, 8, and 9 reach 1.2, 1.0, and 0.7 cm, respectively. After the excavation of the third ring, the settlement of each monitoring point obviously increases. This result is due to the relatively small boundary of the model and the large settlement deformation of the arch after the tunnel has been passed through. Finally, the settlement values of monitoring points 7, 8, and 9 reach 1.5, 1.3, and nearly 1.0 cm, respectively.

4 Conclusion

From the simulation of excavation, rainfall, and sunshine of expansive soil tunnel, the following conclusions are obtained:

-

(1)

After tunnel excavation, the stress release level of the test model is relatively high;

-

(2)

The influence of rainwater infiltration on the stress redistribution of expansive soils is relatively large;

-

(3)

The influence of sunshine on the stress distribution within similar materials is obvious;

-

(4)

The impact of rainwater infiltration on the displacement of the vaults of the expansive soil tunnel is obvious and extremely unfavorable.

References

Wang, H., Li, S., Zhang, Q., et al.: Development of a new geomechanical similar material. Chin. J. Rock Mech. Eng. 25(9), 1842–1847 (2006)

Chen, F., Kusaka, H., Bornstein, R., et al.: The integrated WRF/urban modelling system: development, evaluation, and applications to urban environmental problems. Int. J. Climatol. 31(2), 273–288 (2011)

Ren, W., Guo, C., Peng, Z., et al. Model experimental research on deformation and subsidence characteristics of ground and wall rock due to mining under thick overlying terrane. Int. J. Rock Mech. Min. Sci. 47(4), 614-624 (2010)

Fumagalli, E.: Model Simulation of Rock Mechanics Problem. Rock Mechanics in Engineering Practice. London (1968)

Ashby, J.: Sliding and toppling modes of failure in model and jointed rock slope. M. S. thesis, Imperial College Royal School of Mines, London (1971)

Baumgargarter, P., Stimpson, B.: Development of a tiltable base friction frame for kinematics studies of caving at various depths. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 16(4), 265–267 (1979)

Bray, J.W., Goodman, R.E.: The theory of base friction models. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 18(6), 453–468 (1981)

Stewart, D.P., Adhikary, D.P., Jewell, R.J.: Study on the stability of model rock slope. In: Proceedings of the International Conference Centrifuge, vol. 94, pp. 629–634. Singapore (1994)

Patton, F.D.: Multiple modes of shear failure in rock. In: Proceedings of the 1st Congress of International Society of Rock Mechanics, pp. 509–513. Lisbon (1966)

Einstein, H.H., Veneziano, D., Baecher, G.B., et al.: The effect of discontinuity persistence on rock slope stability. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 20(5), 227–236 (1983)

Jacoby, W.R., Schmeling, H.: Convection experiments and driving mechanism. Geologische Rundsch. 70(1), 207–230 (1981)

Kincaid C., Olson, P.: An experimental study of subducting slab migration. J. Geophys. Res. 92(3), 13832–13840 (1987)

Zuo, B., Chen, C., Liu, C., et al.: Research on similar material of slope simulation experiment. Rock Soil Mech. 25(11), 1805–1808 (2004)

Wu, B.-T., Zhu, H., Xu, Q., et al.: Experimental study of similar material for weak surrounding rock mass of class IV. Rock Soil Mech. 34(1), 109–116 (2004)

Li, S., Zhou, Y., Li, L., et al.: Development and application of a new similar material for underground engineering fluid-solid coupling model test. Chin. J. Rock Mech. Eng. 31(6), 1128–1137 (2012)

Ye, Y., Shi, Y., Wang, Q., et al.: Test model research on low strength similar material of Shanghengshan multilayer shale deposit. Rock Soil Mech. 35(2), 114–120 (2014)

Liu, X., Sheng, Q., Chen, J., et al.: Seismic shaking table test for large-scale underground cavern group (I): Proportioning test on similar materials of surrounding rock. Rock Soil Mech. 36(1), 83–88 (2015)

Zhang, Y., Wang, X., Liang, Q., et al.: Development of model test similar material of collapsible loess. Chin. J. Rock Mech. Eng. 32(2), 4019–4024 (2013)

Lai, J., Diao, X.: Experimental investigation of similar material of swelling rock on the basis of orthogonal design. J. Lanzhou Univ. Technol. 40(4), 131–135 (2014)

Guo, Z.: Artificial Preparation and Experimental Study on Physical and Mechanics Properties of Hanzhong Expansive Soil. Xi’an Technological University, Xi-an (2015)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer International Publishing AG, part of Springer Nature

About this paper

Cite this paper

Wu, K., Wang, Y., Yu, Y., Cui, S., Zhang, Q. (2019). Deformation Law of Surrounding Rock of Expansive Soil Tunnel Based on Dry–Wet Cycle Model Test. In: Cheng, WC., Yang, J., Wang, J. (eds) Tunneling in Soft Ground, Ground Conditioning and Modification Techniques. GeoChina 2018. Sustainable Civil Infrastructures. Springer, Cham. https://doi.org/10.1007/978-3-319-95783-8_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-95783-8_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-95782-1

Online ISBN: 978-3-319-95783-8

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)