Abstract

Clays are used for the construction of waste containment barriers, mainly because of its low hydraulic conductivity. In general, at several places, it may not be possible to obtain the clay satisfying the essential requirements as a liner material. Hence at many places commercially available bentonites is often used for the construction of clay liners. Bentonite undergoes significant changes in volume upon saturation. Several physical and chemical stabilization methods are in practice to stabilize the bentonite. Previous studies report that contaminants with high concentrations attack the clay minerals leading to an increase in their permeability. Exfoliated vermiculite, finds several applications in construction industry, and it is also found to be good absorbent material. Hence this study has been carried out to find the optimal percentage of vermiculite that can be added to the bentonite so that it satisfies the essential requirements of clay liners and it can also absorb the heavy metals from the contaminants. The tests for index properties and engineering properties of bentonite-vermiculite mixtures were performed. The test results show that 30% of vermiculite can be added to bentonite, so that the essential requirements of the liner can be maintained.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Bentonite, a commercially available clay, is commonly used in the construction of hydraulic barriers because of its very low hydraulic conductivity. Bentonite, composed of montmorillonite clay mineral, undergoes significant changes in volume because of which it fails to control the migration of leachate present in the dumped wastes. In order to minimize the volume change attributes several stabilization techniques are adopted, most popular being sand-bentonite mixtures. In sand-bentonite mixtures, sand is added to bentonite to a certain percentage so that the essential requirements for use as landfill liners are maintained. These requirements include permeability equals to or less than 10−7 cm/s, finer fraction greater than 30%, plasticity index greater than 10% and cation exchange capacity (CEC) greater than 10 meq/100 g (Daniel 1993; Rowe et al. 2004). Extensive research has been carried out on sand-bentonite mixtures and many correlations are available with several geotechnical properties (Stern and Shackelford 1998). Al-Rawas et al. (2006) reported that bentonite mixed with 20% sand showed very low hydraulic conductivity but the hydraulic conductivity of sand-bentonite mixture increased drastically under the permeation of chemical solutions. However due to desiccation, the bentonite present in the liner shrinks resulting in an increase in the hydraulic conductivity of the liner (Mukherjee and Mishra 2017). Several studies evaluated the use of various additives such as lime, cement, fly ash, etc. to control desiccation cracking. Initial results of these studies indicated that soil shrinkage reduced, but in many cases the additives resulted in an increased hydraulic conductivity with a decrease in soil plasticity.

Vermiculite, an interesting clay mineral, found in many parts of the world, belongs to 2:1 phyllosilicate mineral, composed of hydrated magnesium-aluminium-iron sheet silicates containing water molecules within the layered structure (Mitchell and Saga 2005). This vermiculite when heated between 870 and 1100 °C, the internal structure gets disturbed and the volume expands to several times that of the original material. This process is known as exfoliation (Marcos and Rodriguez 2014). This exfoliated vermiculite becomes light in weight under the exfoliation process with good thermo-insulating properties. Exfoliated vermiculite is used in making light-weight concrete (Silva et al. 2010), thermal insulations (Abidi et al. 2015) and also extensively used as a good adsorbent material instead of activated carbons in the removal of heavy metals because of its high CEC and reactive surfaces. Vermiculite as an absorbent has been studied for the removal of Mercury (Do Nascimento and Masini 2014), Chromium (Sis and Uysal 2014; Dultz et al. 2012), Zinc (Sis and Uysal 2014), Cadmium (Mathialagan and Veeraraghavan 2003) and even dyes from textile industries (Mysore et al. 2005; Duman et al. 2015; Da Fonseca et al. 2006, Marcos and Rodriguez 2014). As the exfoliated vermiculite is found to be an effective and excellent material used for the removal of heavy metals from the waste disposal, this paper is aimed at investigating the potential use of exfoliated vermiculite-bentonite mixtures instead of sand-bentonite mixtures as a landfill liner, so that it can absorb the heavy metals in the leachate as well as it can stabilize the volume change attributes of bentonite. The main objective of the study was to investigate the potential use of bentonite vermiculite mixtures. The present study focuses on permeability characteristics as well as swelling and shrinkage characteristics of bentonite with the addition of various percentages of exfoliated vermiculite. One of the main objective is to determine the optimum percentage of bentonite vermiculite mixture so that the essential requirements of compacted clay liner can be maintained.

2 Experimental Investigation

2.1 Test Materials

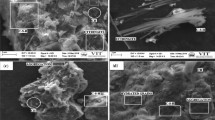

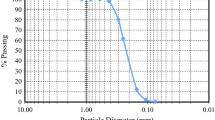

Commercially available sodium bentonite was used in the present study. Various properties of the bentonite have been determined and reported in Table 1. Exfoliated vermiculite of particle size in the range of 1–4 mm was used in the present study. The various physical and chemical properties of the vermiculite supplied by the manufacturer are reported in Table 2. The SEM analysis has also been carried out on exfoliated vermiculite sample. Figure 1 shows the SEM image of exfoliated vermiculite. Cation Exchange Capacity was determined for both bentonite and vermiculite using methyl blue test. The CEC is found to be 14 meq/100 g for bentonite and 16 meq/100 g for vermiculite. The CEC of the vermiculite is more when compared to bentonite, so addition of vermiculite will not affect the essential requirement of vermiculite.

2.2 Index Properties Tests

Tests for index properties such as liquid limit, plastic limit, shrinkage limit and shrinkage strain tests have been conducted on bentonite-vermiculite blends as per the ASTM standards. Liquid limit and Plastic limit tests were conducted as per ASTM D 4318-10 (1996). Shrinkage limit test was determined according to ASTM D427-04 (2007). After determining shrinkage limit, diameter and thickness of the soil pat were measured using digital calliper to determine radial and axial shrinkage strains. The axial and radial shrinkage strains were calculated using the following expressions.

Axial shrinkage strain

where: hi is the initial thickness, and hf is the final thickness.

Radial shrinkage strain

where: Di is the initial diameter, and Df is the final diameter.

2.3 Shrinkage Limit Tests

Standard Proctor compaction, hydraulic conductivity and swelling tests have been conducted on bentonite and bentonite mixed with various percentages of vermiculite as discussed earlier. Initially Standard Proctor compaction tests have been conducted as per ASTM D 698-12 (1996) for determining the optimum moisture content for the bentonite blended with different percentages of vermiculite. After performing compaction tests, hydraulic conductivity tests were performed for the bentonite and bentonite-vermiculite blends compacted at their respective optimum moisture content and maximum dry density obtained from compaction tests. Hydraulic conductivity tests were performed using rigid wall permeameter according to ASTM D5856 (1996). Soil was compacted in the mould and the mould was placed in the water bath for four days to allow for full saturation of the sample. The permeability tests were performed using de-aired tap water. Swelling tests were conducted in the prefabricated mould of diameter 10 cm and 15 cm height. Soil was compacted in the mould in three layers of thickness of 2.5 cm. A dial gauge was fitted at the top of the soil layer. After setting the dial gauge reading to zero, water was added continuously at the top of the clay bed and the swelling was monitoring continuously at various time intervals until the swelling attained equilibrium.

3 Discussion of Test Results

Figure 2 shows the variation of liquid limit and plastic limit for varying vermiculite content. It is observed that the liquid limit of the bentonite reduced marginally when compared to plastic limit. The plastic limit tends to increase with percentage of vermiculite. Upon addition of 30% vermiculite to bentonite the liquid limit was found to be 120%, whereas the plastic limit found to be 62%, resulted in a plasticity index of 58%. Figure 3 shows the variation of shrinkage limit of bentonite blended with varying percentage of vermiculite. The shrinkage limit of the bentonite is 1.8%, which is considered to undergo large volume changes (Holtz and Gibbs 1956). Upon addition of vermiculite, the shrinkage limit tends to increase rapidly. The shrinkage limit of bentonite blended with 20% vermiculite is 17.9% and beyond 20% vermiculite there is no significant increase in shrinkage limit. According to Holtz (1956), if the shrinkage limit is greater than 16%, the soil does not undergo significant volume change. Addition of vermiculite also reduces the shrinkage strains of bentonite (Fig. 4). Both axial and radial shrinkage tends to decrease with increase in vermiculite content. Axial strain reduced to 47.3% and radial shrinkage reduced to 39.4%, when 30% vermiculite content was blended with bentonite.

Figure 5 shows the variation of maximum dry density and optimum moisture content (OMC) of bentonite with different percentage of exfoliated vermiculite contents. The reduction in dry unit weight of bentonite with an increase in vermiculite content is due to the replacement of soil with vermiculite of lower specific gravity leading to increase in volume and decrease in unit weight. Conversely, the OMC increased with higher vermiculite content. The increase in OMC with increased vermiculite content was likely due to the larger amount of water absorbed by the vermiculite because of its inherent water retention capacity.

Achieving specific value of permeability is one of the important criteria for the clay to be used as a liner material. Permeability of the clay should be less than 1 × 10−7 cm/s. Variation in the hydraulic conductivity of vermiculite-bentonite mixtures is reported in Fig. 6. For bentonite sample, the hydraulic conductivity was found to be 3.86 × 10−09 cm/s. The hydraulic conductivity reduced to 7.10 × 10−9 cm/s, when vermiculite content was 10%, beyond 10% vermiculite content, the permeability tends to increase. For bentonite blended with 30% vermiculite, the permeability was found to be 1.93 × 10−07 cm/s. Beyond 30% vermiculite, the permeability was found to be high, which is greater than the essential requirement of the clay liner. Swelling of bentonite was also reduced due to the addition of vermiculite (Fig. 7). Swelling decreased from 14.1 to 6.9 mm when vermiculite was varied from 0 to 30%.

4 Conclusions

Based on the results and discussion presented here, the following conclusions can be made.

With addition of 30% vermiculite to bentonite, the liquid limit is found to be 120% and the plastic limit found to be 62%; resulting in a plasticity index of 58%. The shrinkage limit tends to increase rapidly. The shrinkage limit of bentonite blended with 20% vermiculite is 17.9% and beyond 20% vermiculite, there is no significant increase in shrinkage limit.

Axial strain reduces to 47.3% and radial shrinkage reduces to 39.4%, when 30% vermiculite content is blended with bentonite. Swelling also tends to decrease with an increase in vermiculite content. The swelling reduces to 51%, when 30% of vermiculite content is added to bentonite.

The hydraulic conductivity reduces to 7.10 × 10−9 cm/s, when vermiculite content is 10%, beyond 10% vermiculite content, the permeability tends to increase. For bentonite blended with 30% vermiculite, the permeability is found to be 1.93 × 10−07 cm/s. Beyond 30% vermiculite the permeability is found to be high, which is greater than the essential requirements of the clay liner.

References

Abidi, S., Nait-Ali, B., Joliff, Y., Favotto, C.: Impact of perlite, vermiculite and cement on the thermal conductivity of a plaster composite material: experimental and numerical approaches. Compos. B Eng. 68, 392–400 (2015)

Al-Rawas, A.A., et al.: Sand-attapulgite clay mixtures as a landfill liner. Geotech. Geol. Eng. 24(5), 1365–1383 (2006)

ASTM D 4318-10: Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International, West Conshohocken (1996)

ASTM D 698-12: Standard Test Method for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM International, West Conshohocken (1996)

Da Fonseca, M.G., Wanderley, A.F., Sousa, K., Arakaki, L.N.H., Espinola, J.G.P.: Interaction of aliphatic diamines with vermiculite in aqueous solution. Appl. Clay Sci. 32, 94–98 (2006)

Daniel, D.E., Shan, H.Y., Anderson, J.D.: Effects of partial wetting on the performance of the bentonite component of a geosynthetic clay liner. Geosynthetics’ 93. Industrial Fabrics ASSA. Int. St. Paul Minn. 32, 1483–1496 (1993)

Do Nascimento, F.H., Masini, J.C.: Influence of humic acid on adsorption of Hg(II) by vermiculite. J. Environ. Manag. 143, 1–7 (2014)

Dultz, S., An, J.H., Riebe, B.: Organic cation exchanged montmorillonite and vermiculite as adsorbents for Cr(VI): effect of layer charge on adsorption properties. Appl. Clay Sci. 67–68, 125–133 (2012)

Duman, O., Tunç, S., Polat, T.G.: Determination of adsorptive properties of expanded vermiculite for the removal of C. I. Basic Red 9 from aqueous solution: kinetic, isotherm and thermodynamic studies. Appl. Clay Sci. 109–110, 22–32 (2015)

Holtz, W.G., Gibbs, H.J.: Engineering properties of expansive clays. Trans. ASCE 121, 641–677 (1956)

Marcos, C., Rodríguez, I.: Applied Clay Science Some effects of trivalent chromium exchange of thermo-exfoliated commercial vermiculite. Appl. Clay Sci. 90, 96–100 (2014)

Mathialagan, T., Vararaghavan, : Adsorption of cadmium from aqueous solution by vermiculite. Sep. Sci. Techol. 38(2003), 57 (2003)

Mitchell, J.K., Soga, K.: Fundamentals of soil behavior. Wiley, Hoboken, NJ (2005)

Mukherjee, K., Mishra, A.K.: Performance enhancement of sand-bentonite mixture due to addition of fiber and geosynthetic clay liner. Int. J. Geotech. Eng. 11(2), 107–113 (2017)

Mysore, D., Viraraghavan, T., Jin, Y.C.: Treatment of oily waters using vermiculite. numerical approaches. Compos. B Eng. 68, 392–400 (2005)

Rowe, J.K., Quigley, R.M., Brachman, R.W.I., Booker, J.R.: Barrier Systems for Waste Disposal Facilities, vol. 95, 2nd edn, pp. 1–8. Spon Press, London (2004)

Silva, L., Ribeiro, R., Labrincha, J., Ferreira, V.: Role of lightweight fillers on the properties of a mixed-binder mortar. Cement Concr. Compos. 32(1), 19–24 (2010)

Sis, H., Uysal, T.: Removal of heavy metal ions from aqueous medium using vermiculite. J. Environ. Manag. 143, 1–7 (2014)

Stern, R.T., Shackelford, C.D.: Permeation of sand-processed clay mixtures with calcium chloride solutions. J. Geotech. Geoenviron. Eng. 124(3), 231–241 (1998)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer International Publishing AG, part of Springer Nature

About this paper

Cite this paper

Pradeep, P.S., Muthukumar, M., Shukla, S.K. (2019). Geotechnical Investigation on Compacted Clay Liner Blended with Reactive Material. In: Weng, MC., Lee, J., Liu, Y. (eds) Current Geotechnical Engineering Aspects of Civil Infrastructures . GeoChina 2018. Sustainable Civil Infrastructures. Springer, Cham. https://doi.org/10.1007/978-3-319-95750-0_10

Download citation

DOI: https://doi.org/10.1007/978-3-319-95750-0_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-95749-4

Online ISBN: 978-3-319-95750-0

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)