Abstract

Many food products which are consumed on a regular basis, can be categorized as complex colloidal systems that are created by close contact of dispersed and continuous phases. Foams are one such colloidal systems where dispersed air bubbles are incorporated and stabilized in a continuous phase. In principle, foams can be stabilized by use of either low molecular weight surfactants, amphiphilic polymers or surface-active rigid or soft particles. In food products, foams have traditionally being stabilized by biopolymers such as proteins and certain polysaccharides but lately, there has been a tremendous interest in improving the foaming functionality of biopolymers either through physical or chemical modifications and utilizing polymer-based colloidal particles for foam stabilization. The recent understanding and advances in this highly active area of foam stabilization are reviewed in this chapter with the help of illustrative examples.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

10.1 Introduction

Foams form an integral part of many edible products ranging from frothy beer head to dehydrated foam of meringues. These air-filled systems are either stabilized by molecular layers (of macromolecules or low molecular weight surfactants, LMWS) adsorbed at the energy-rich interfaces or through physical entrapment of bubbles in solid matrices. In some specific cases, the interfaces are stabilized by colloidal particles such as casein micelles and fat crystals or partially aggregated emulsion droplets. Regardless of their final state, all foams are prepared in liquid form (i.e. air bubbles dispersed in continuous liquid phase). The microstructure of bubbles dispersed in a continuous phase of these liquid foams varies from spherical (wet foam) to polyhedral (dry foam) depending on the volume fraction of gas phase. As shown in Fig. 10.1, microstructure of liquid foam evolves from spherical closely packed fine bubbles to large polyhedral shapes through an intermediate stage where the fine spherical bubbles grow into polydispersed coarse units. This non-equilibrium transition is driven both by gravitational and colloidal instabilities. Under the influence of gravity the liquid drains, while the buoyancy of large gas bubbles pushes them up. The wide distribution in the bubble size is due to the bubble growth induced both by coalescence (caused by film rupture) and Ostwald ripening or disproportionation (caused by diffusion of gas molecules through the liquid phase from smaller to larger bubbles). Figure 10.1 also shows the distinction between wet and dry foam which is characterized by the gas volume fraction. Although there is no strict criterion to distinguish wet from dry foam, it is generally accepted that a system having a gas volume fraction near 0.63 is a very wet foam, while gas fractions exceeding 0.8 constitute dry foam (Bergeron and Walstra 2005). As seen in the figure, at the very bottom sitting on the drained liquid is a zone of very wet foam. The typical length of this zone is ξ = γ/ρgD, and the liquid fraction in this zone varies from 0.36 to 0.18 (ρ is the surfactant solution density, γ is the surface tension, D is bubble diameter) (Saint-Jalmes 2006). Most of the aerated food products are wet foams with spherical bubbles that remain separated from each other. Gravitational instability (creaming or drainage) is controlled in these systems by tuning the yielding properties of the continuous phase. This is usually achieved by either gelation of continuous phase with protein/polysaccharides in aqueous foams and structuring of continuous phase with fat particles in non-aqueous foams. However, the continuous phase viscosity only has a small influence in slowing down the colloidal instability (mainly coalescence), it is majorly controlled by the properties of foam-stabilizing components. In case of small molecular weight surfactants, an easy exchange of surfactant molecule can occur between the bulk and the interface due to the low desorption energy of soluble surfactant molecules. This leads to a low resistance of surfactant monolayer to compression making the foam less resistant to coalescence. When the surfactant monomers desorb from the interface, the surface coverage may in some cases become too low to avoid the coalescence phenomenon (Fameau 2018). In case of polymers (including proteins), the adsorption energies are much higher than those for surfactants which slows down the molecular exchange at the interface. In addition, the interfaces are relatively more viscoelastic than those made up of surfactants. Together this leads to a comparatively higher stability against coalescence. When particles are used for foam stabilisation the adsorption energy increases even further and can lead to even more elastic interfaces and in some cases, particles could also lead to a complete arrest of the ageing of foams (Stocco et al. 2011).

As far as food polymers are concerned, proteins are the most widely used foaming agents, used either as such or in particulate form such as aggregates, micelles and colloidal complexes together with polysaccharides (Wierenga and Gruppen 2010). In addition to proteins, food polymers such as cellulose derivatives have also been explored for foam stabilization in form of colloidal particles (Jin et al. 2012; Patel et al. 2012, 2013b).

10.2 Protein Stabilized Foams

Proteins are macromolecules consisting of a chain of amino acids (AAs) linked by peptide bonds. There are a total of 20 AAs which can be distinguished by their side groups that can be ionic, non-ionic or hydrophobic. The primary structure of a protein refers to the sequence of AAs in the polypeptide chain. The AA chain is folded into secondary structural elements, called e.g. α-helix, β-sheet or random coil. These structural elements are further ordered into a tertiary structure stabilized by covalent (e.g. S-S bridges) and/or non-covalent bonds. Proteins can be distinguished as globular, random coil and fibrillar proteins. Globular proteins such as β-lactoglobulin and bovine serum albumin have defined structural elements in a ‘fixed’ arrangement, while flexible ‘random coil’ proteins consist predominantly of random coil elements without a fixed structure, e.g. β-casein. Fibrillar proteins (e.g. collagen or myosin) are typically insoluble in water in their ‘native’ state.

When protein is used in non-particulate form, the adsorption of protein at an air-water interface takes place in three main stages: (i) diffusion of the native protein molecules from the bulk phase to the interface and their subsequent adsorption; (ii) surface denaturation, i.e. uncoiling of the polypeptide chains at the interface (surface denaturation); and (iii) aggregation of the surface denatured protein into a coagulum which is largely devoid of surface activity.

Although proteins lower the surface tension (due to the presence of hydrophilic and hydrophobic groups), the main factor determining the stability of a foam is the cohesion and elasticity of the protein monolayer film formed at the interface, this is controlled by the denatured but uncoagulated protein at the surface and more specifically by the rate at which the protein denatures at the interface and the rate at which it is removed by coagulation. It has been found that the rate of surface denaturation does not vary greatly from one protein to another, although it does depend upon the pH of the solution (Neurath and Bull 1938), but their rates of coagulation differ markedly and is affected by the mechanical agitation to which the protein film is subjected and by the electrostatic forces between the polypeptide chains (Cumper 1953).

10.3 Foams Stabilized by Protein Aggregates

Proteins are liable to undergo conformational changes and form supramolecular structures depending on the micro environment (pH, ionic strength etc.) and the external factors such as temperature. Protein aggregates could be made by heat-treatment induced fibrillization, denaturation of proteins and gelation (Amagliani and Schmitt 2017). It can be speculated that the aggregates may have a negative influence on the foaming behaviour of proteins. First of all, they are large structures (few hundred nanometers to 10s of microns) so their diffusion to the air-water interface is limited. Secondly, the nature of protein-protein interactions in aggregates may influence their cohesiveness and consequently their spreading behaviour at the interface (Rullier et al. 2008).

However, it has been shown in some cases that the presence of aggregates increases the foaming properties of proteins. The mechanism by which aggregates contribute to foam stabilization is not completely elucidated and different hypotheses have been proposed: the protein aggregates can adsorb at the interface and increase the viscoelasticity of the interface, thus providing a better foam stabilization or if aggregates do not adsorb to the interface, they remain in the aqueous phase and can become confined into foam films and lead to the formation of a gel-like network by undergoing a percolation process (Davis and Foegeding 2004). They can further prevent destabilization of foam by reducing the drainage by acting as cork in the Plateau borders (Saint-Jalmes et al. 2005).

In addition to aggregates, protein-based fluid gels have also be explored for foam stabilization (Lazidis et al. 2016). Fluid gels are formed when a separation process is applied to a gelling polymer undergoing its sol–gel transition. More precisely, fluid gels are formed when the (bio)polymers are introduced into a gelling environment (usually by cooling) while undergoing physical disruption (shear). Gelled particles are created which, depending on the shear field experienced, are gels on the microns rather than macro length scale. The resultant properties of these systems are, therefore, fluid or paste-like rather than those of typical gels (Norton et al. 1999). Whey protein isolate (WPI) fluid gels which were produced by thermally treating WPI under shear showed interesting foaming properties that were dependent not only on the pH at which these structures were originally formed but also the pH at which they were aerated (Lazidis et al. 2016). The small aggregates formed at pH 5 (close to its iso-electric point) were able to fill effectively the spaces between the bubbles and reduce the rate of liquid drainage by the particles acting as corks anchored on the interface and by increasing the local viscosity of film around the bubbles. While, fluid gels formed at pH 8 resulted in less viscoelastic films probably due to the larger size of the aggregates, which limited their ability to pack and leading to their exclusion from the spaces around the air bubbles (Lazidis et al. 2016).

It is also worth mentioning in this section, the stabilization of foams provided by unique class of proteins called hydrophobins. These are small proteins produced by filamentous fungi, they display a strong tendency to self-assemble at the air–water interface and form highly viscoelastic layers (Green et al. 2013). A striking structural feature of the hydrophobin molecule is that it is rigid like a small solid particle; it is also amphiphilic in nature, having a hydrophobic patch on one side of the molecule. An individual hydrophobin molecule might thus be represented like a nano-sized Janus particle (Walther and Muller 2008). Due to their irreversible adsorption at the interface, they are known to produce foams at concentration as low as 0.1%wt (Green et al. 2013).

10.4 Foams Stabilized by Protein–Surfactant Mixtures

Proteins and low molecular weight surfactants (LMWS) are commonly used as foaming agents in food products. They stabilize air-water interfaces by two different mechanisms, proteins by forming a visco-elastic network and LMWS by fast adsorption and desorption and Gibbs-Marangoni mechanism. It has been suggested that for effective stabilization of foam by proteins a high dilatational interfacial elasticity is required while for foam stabilization by LMWS, a rapid increase in equilibrium interfacial pressure is needed (Damodaran 2005; Acharya et al. 2005; Saint-Jalmes et al. 2005). Because of these opposing concepts, it is difficult to predict and understand the foam stabilization behaviour of protein-LMWS mixtures. In addition, the competitive adsorption and displacement of proteins by LMWS also needs to be taken into consideration (Maldonado-Valderrama and Patino 2010). It is hypothesized that due to the relatively low adsorption energies of LMWS, they can adsorb into the protein-adsorb layer, probably at first into the packing defects. As more molecules of LMWS adsorb into the defects, LMWS-rich domains are formed that makes the interface weaker and consequently decreases the stability of foam due to increased drainage and coalescence rates (Wilde et al. 2004). However, this concept is valid when LMWS are added to a system where proteins are already adsorbed at the interface. In case where aeration is carried out with an aqueous dispersion which contains a protein-LMWS mixture, a completely different scenario is anticipated (Rodrıguez Patino et al. 2003).

The foaming stabilizing behaviour of protein-LMWS mixtures strongly depends on the charge of protein and LMWS as well as the mixing ratios of the two components. Depending on the conditions (pH, ionic strength, protein:LMWS ratio etc.), the mixtures may contain free proteins, free LMWS and/or protein-LMWS complexes. The relative proportions of these states and the surface activity of complexes will determine their overall contribution to foam stability (Lech et al. 2014).

10.5 Foams Stabilized by Protein-Polysaccharide Colloidal Complexes

When proteins and polysaccharides are mixed together in an aqueous environment, three different scenarios (Wijaya et al. 2017) are possible (Fig. 10.2): (i) complexation, which depending on the strength of interactions, may lead to the formation of either soluble complexes or coacervation (associative phase separation) where a colloid rich phase (of protein-polysaccharide complexes) separates from the solvent phase; (ii) cosolubility; protein-polysaccharide combination is compatible with each other and the solution is stable; and (iii) segregative phase separation; due to the incompatibility among protein and polysaccharide two phases appear, one rich in polysaccharide and poor in protein and one rich in protein and poor in polysaccharide.

Polysaccharides are generally used to enhance the colloid (emulsions and foams) stabilizing properties of proteins in foods. Most often than not, they are used simply as viscosifying agents to increase the bulk viscosity which can slow down the gravitational and colloidal instabilities in these biphasic systems. However, in some cases polysaccharide is specifically used to interact with the protein adsorbed at the interface. A classical application of such protein-polysaccharide interaction in the food industry is the use of pectin to stabilize casein micelles in acidified milk drinks. The negatively charged pectin molecules adsorb to the positively charged casein micelles due to electrostatic interactions. As a consequence, the electrostatic and steric repulsion prevent the micelles from acid-induced aggregation (Syrbe et al. 1998).

As for foaming properties, protein-polysaccharide complexes can lead to positive effect such as increased overrun and yield stress by improving the elasticity of the foam film or by altering the gelation behaviour of protein at the air-water interface (Wang et al. 2015). The mechanism of foam stabilization depends on the type of complex formed by protein-polysaccharide interaction, a soluble complex can increase the viscosity of the foam film and in the plateau region to limit the drainage and inhibit the bubble coalescence (Schmidt et al. 2010; Sadahira et al. 2016). Larger size insoluble complexes can help build an interfacial viscoelastic network at the air-water interface with reduced gas permeability, leading to greater stability concerning the disproportionation (Sadahira et al. 2014).

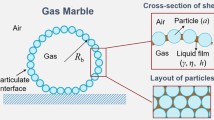

10.6 Foams Stabilized by Rigid Colloidal Particles

Rigid particles that have the required surface activity, wettability, shape and size can be utilized to create the so-called super stable foams lasting for months or even years. Stabilization of interfaces by rigid particles is also known as the Pickering stabilization mechanism and it has recently drawn a lot of scientific and industrial interest (Lam et al. 2014). Much of the research into particle-stabilized biphasic dispersions has been focused on using inorganic particles which have limited relevance for applications in foods. However, in the past few years, there has been a shift toward studying materials of biological origin for stabilization of biphasic dispersions with the goal of utilizing them for edible applications (Dickinson 2010; Lam et al. 2014). As far as Pickering stabilization of foams is concerned, most of the particles are either made from non-food grade materials or processes or their surfaces have been modified using non-edible materials or a process that involves a chemical modification (Du et al. 2003; Cervantes Martinez et al. 2008; Park et al. 2009). Only few studies have been reported with food-grade materials such as shellac, ethylcellulose (EC), calcium carbonate, cellulose nanocrystals, chitin nanocrystals, hydrophobic cellulose and some natural origin components such as bacteria, spores, cells and viruses (Lam et al. 2014; Binks et al. 2005; Campbell et al. 2008, 2009; Zhou et al. 2009; Hu et al. 2016; Wege et al. 2008; Tzoumaki et al. 2015; Yucel Falco et al. 2017).

Rigid particles from hydrophobic polymer such as EC can be prepared using a rather facile method based on controlled precipitation by altering the solvent quality. Such process is known by several names in the literature including liquid-liquid dispersion, anti-solvent precipitation, nano-precipitation, drowning-out etc. A stock solution of EC is first prepared in an organic solvent such as acetone, followed by dilution in a non-solvent such as water to trigger instant precipitation as a result of supersaturation. The resultant colloidal particles formed via nucleation and growth mechanism are in the nanoscale range (Fig. 10.3). The morphology of particles can be controlled from spherical to anisotropic shapes such as rods and fibre-like. Although EC is a neutral polymer, foam stabilizing properties of EC particles is found to be strongly influenced by pH (Jin et al. 2012). As suggested by Jin et al., at low and high pH, the electrostatic repulsion among particles is reduced by lowering of surface potential and screening of surface charges respectively. This reduction in repulsion results in efficient loading of particles at the interfaces and consequently leads to enhanced stabilization of foam.

In addition as reported by Peng et al., such rigid particles prepared from other food polymers such as natural proteins (gliadin) also display good adsorption at the air-water interface (Fig. 10.4b) and leads to an improved foam ability and foam stability of the protein (Peng et al. 2017). These discrete adsorbed particles were further found to fuse into a continuous film over storage time.

Images of interfacial (air-water interface) accumulation of spherical (a, b) and anisotropic particles (c) created using anti-solvent precipitation. Figures a and c are adapted from (Jin et al. 2012; Campbell et al. 2009) with permission of the Royal Society of Chemistry, Figure b is reproduced with permission from Peng et al. (2017). Copyright (2017) American Chemical Society

In some cases, a combination of rigid particles and polymers have also been utilized to stabilize foams, e.g. cellulose nanocrystals + methylcellulose (CNC + MCE) and crystalline α-cellulose + EC (Fig. 10.5).

Nano materials derived from cellulose such as nanocrystals (CNC) and nanofibers (CNF) have recently gained a lot of popularity as ‘green’ components with multiple functionalities. With respect to foam stabilization, CNC on their own does not show lowering of surface tension and hence are not capable of stabilizing air-water interfaces. In some cases, hydrophobic modification of CNF and CNC have been explored to make them more suitable for foam stabilization (Cervin et al. 2013, 2015). Hu et al. observed that when unmodified CNC was used together with a interfacial active component – MCE, the nanocrystal particles did not drain in the serum phase and were retained in the foam phase (Fig. 10.5a). The authors of the study speculated two possible mechanisms: (i) MCE bound CNC particles mechanically stabilized the interface and inhibit MCE desorption and (ii) in the aqueous phase, the CNC-MCE mixture forms a weak gel that inhibit bubble coalescence and slow down the drainage (Hu et al. 2016).

In case of cellulose complexes, the crystalline α cellulose particles were made hydrophobic by precipitating EC on their surface through anti-solvent precipitation. These surface active particles were found to display a good foam stabilization properties (Fig. 10.5b). Further, by combining these particles with proteins, a synergistic enhancement in foam stabilization could be obtained by just using a 0.1%wt concentration of particles in combination with proteins such as sodium caseinate and whey protein isolate (Murray et al. 2011).

10.7 Foams Stabilized by Gelled Particles of Cellulose–Polyphenol Complexes

Hydrophilic cellulose derivatives such as methylcellulose (MCE) and hydroxyl propyl methylcellulose (HPMC) display interesting associative behaviour in aqueous environment. They are also surface active and are known to stabilize oil-water and air-water interfaces (Patel et al. 2013a, 2014). However, when used as foaming agents, although they show good foamability (high air incorporation), the stability of foam is quite limited. For instance, lower viscosity grades of HPMC can even give an overrun of over 300% but these foams have a very short life span (Patel et al. 2013a). The foam stabilization property of cellulose derivatives is attributed to the gelled film formation of polymer at the air-water interface and therefore the higher viscosity grade of these polymers provide a comparatively better stabilization as compared to lower viscosity grades due to the formation of the interfacial film of relatively higher stiffness (Patel et al. 2013a). In one of our previously reported work we found that the functionality of cellulose derivatives (including foaming properties) could be significantly improved by complexing them with natural polyphenols. For our experiments we selected MCE with molecular weight of 40,000 gmol−1 (viscosity grade 2%, 20 °C = 400 cP) and degree of substitution of 1.8. Complexes of MCE and tannic acid, TA (one of the most researched natural polyphenol) were prepared at varying proportion of MCE: TA (10:1, 5:1, 2.5:1 and 1:1 wt/wt) while keeping the concentration of MCE constant at 2%wt. The MCE-TA complexes were compared to un-complexed MCE in terms of foam properties (Fig. 10.6a) such as foam expansion (or overrun = [(Vt − V0)/V0] × 100), foam stability (= 100 × [F2/F1]), and foam liquid stability (= 100 − [100 × V60/V0]), where Vt and V0 are the total foam and liquid volumes respectively; F1 and F2 are gas volume at t = 0 and t = 60 min respectively and V60 is liquid volume at 60 min.

(a) Foaming parameters (foam expansion, foam stability and foam liquid stability) for foams prepared using MCE (2%wt) and MCE:TA complexes (at MCE:TA ratios of 10:1, 5:1, 2.5:1 and 1:1 wt/wt); (b) Histograms showing the distribution of the mean CE diameter of bubbles in foams prepared from MCE and MCE:TA (10:1 wt/wt); (c, d) Microscopy images of diluted foams prepared from MCE and MCE:TA (10:1 wt/wt) respectively (scale bars = 100 μm). Reproduced from Patel et al. (2013b) with permission from The Royal Society of Chemistry

As seen from Fig. 10.6a, MCE was a weak foaming agent showing a good foam expansion but a quick drop in foam volume within 60 min along with a high drainage which is reflected in poor foam liquid stability. In contrast, complexes prepared at all MCE: TA ratios showed improvement in both foamability as well as foam stability. The enhanced foam stabilization could be attributed to a combination of multiple factors such as an increased bulk viscosity due to the gelation of MCE: TA complexes, enhancement in interfacial gelation, and adsorption of colloidal particles at the air–water interface. Further, the increased proportion of TA resulted in a decreased foam expansion, with MCE: TA 1: 1 wt/wt showing a drop of over 100%, the most efficient system was MCE: TA 10: 1 wt/wt and was thus selected for further comparative studies. The average bubble size of foam was obtained by measuring the mean circular equivalent (CE) diameter on an automated microscope (Fig. 10.6b). The average bubble sizes for foams prepared using MCE and MCE: TA complexes were 118 and 96 μm, respectively. For visual comparison the representative microscopy images of foams stabilized by MCE and MCE: TA complexes are also shown in Fig. 10.6c, d. The stability of foams was also followed by measuring the coarsening time using the backscattering and transmission of light. A comparative graph of coarsening time, τ (from model d2(t)/d2(0) = 1 + t/τ) is shown in Fig. 10.7a. The average coarsening times calculated from the plots (27.8 and 83.3 min for MCE and MCE: TA foams respectively) confirms the significant enhancement in the foam stabilizing property of MCE due to its interaction with TA. As the study was done on diluted foams, the increased stability can be at least partly attributed to the enhancement of the interfacial stiffness due to the surface gelation invoked by the MCE: TA complexes. The microscopy image of the MCE: TA foam is presented in Fig. 10.7b; as seen from the image, the increased interfacial stiffness could be attributed to the layer of MCE: TA complexes gelled at the air–water interface.

(a) Comparative coarsening data for foams prepared using MCE and MCE: TA (10:1 wt/wt) complexes. MCE concentration in all cases was kept constant at 2 wt%; and (b) Microscopy image showing the air bubbles surrounded by a microscopic layer of MCE: TA complexes gelled at the air–water interface (scale bar = 20 μm). Reproduced from Patel et al. (2013b) with permission from The Royal Society of Chemistry

10.8 Some Innovative Applications of Polymer Stabilized Food Foams

10.8.1 Polymer Foams as Templates for Edible Oil Structuring

As a research domain, edible oil structuring is still in its infancy but it has already received a great deal of interest from academic researchers and industrial scientists. The goal of oil structuring is to replace solid fats in food products with components that can immobilize and structure liquid oil to provide a fat-mimicking functionality. Although this strategy has a huge potential, it is faced with a major drawback of identifying food-grade components which could be used in edible products. Among several components tried for oil structuring, polymers appear to be the most promising candidates. However, most food-approved polymers are inherently hydrophilic in nature and therefore cannot be dispersed easily in oil to achieve the necessary structure/network formation which is required for gelation. Hydrophilic polymers play an important role in providing structural framework to water-based gels and the functionality of polymers to form structural framework in aqueous solvent is attributed to their hydration into an extended conformation which result in stronger molecular interactions with the solvent. Therefore, in order to use hydrophilic polymers for oil structuring, it is important to first prehydrate them in water phase and arrest these hydrated conformations in dehydrated form such that they can be used for physical entrapment of oils (Patel 2015). Working on this principle, conformational framework of some food polymers such as proteins and modified polysaccharides have been created from their water dispersions by first promoting their adsorption to air–water interfaces followed by stripping-off the water to obtain dried microstructures. These microstructures can then be used for oil structuring to create oleogels (Patel et al. 2013a). The strength and rheological properties of these oleogels can be controlled by choosing the suitable viscosity grade and the by altering the concentration of polymer in the oleogels (Fig. 10.8).

(a) Photographic representation of steps involved in formulating oleogels using aqueous foams of HPMC as templates and (b) A series of photographs displaying the quick oil absorption by porous dried foam. Sunflower oil with Nile red dye was used for clear representation and images were captured every 60 s. Reproduced with permission from Royal Society of Chemistry (Patel et al. 2013a)

The approach of using polymer foam as templates for structure oil has also been explored for practical applications in real food systems such as peanut butter and sandwich cookie cream (Tanti et al. 2016a, b). The authors found that up to 75% of saturated fats could be replaced with polymer structured liquid oil without affecting the texture and stability of cookie creams (Tanti et al. 2016a). In case of peanut butter (Fig. 10.9), freeze dried polymer foam of HPMC and MCE was used as a replacement of fully hydrogenated oil stabilizer. It was observed that desirable oil stability and textural properties of commercial products could be achieved at just 1 and 2% level of addition of freeze dried foams (Tanti et al. 2016b).

10.8.2 Intensely Coloured Edible Foams Stabilized by Polymer-Polyphenol Complexes

Intensely coloured foams are of a large industrial interest as they have huge potential for applications in food products. However, it is difficult to impart intense colour to aqueous foams because foaming in the presence of water-soluble colorants typically results in weak colour intensity in the bubble phase as the majority of colorants are retained in the bulk solution or the serum phase. The colour intensity of the very thin foam films is insufficient to impart intense colour to the foam phase (Kim et al. 2009).

In one of our earlier published work (Patel et al. 2012), it was found that MCE-TA complexes (discussed in previous section) could stabilize foamulsions (foamed emulsions) at high oil volume fraction (φoil > 0.5). These foamulsions which were found to be stable against collapse for several days, showed a close packing of oil droplets around the air bubbles in the foam phase (Fig. 10.10a, b). This microstructure arrangement was further exploited to load oil-soluble pigments to generate intensely coloured foams (Fig. 10.10c) due to the preferential localization of the hydrophobic colorants in the foam phase and absence of any soluble colour in the serum phase. The foamulsions showed excellent stability without showing any significant macroscopic collapse after 4 weeks of storage.

(a) Optical microscope image of foamulsion showing the closely packed oil droplets around the air bubble (Scale bar = 100 μm); (b) 3D construction based on confocal microscopy images where air bubble (shown in blue) is surrounded by oil droplets (shown in green); (c, d) Photographs of foams (from left to right) containing no pigment, curcumin and β-carotene taken on day one and after 4 weeks of storage respectively. Reproduced with permission from Patel et al. (2012)

10.8.3 Air Filled Emulsions as Fat Replacers in Food Products

Fat reduction is a growing area of interest to food manufacturers as consumers are increasingly turning to low-fat, low-calorie versions of their favourite foods. The key challenge in formulating these product types is retaining the sensorial properties provided by fat globules/oil droplets in lipid containing food products. It has been proposed that a new generation of food products can be developed by designing air bubbles that resemble oil droplets or fat globules which could be subsequently used to replace a part of lipid with air in the food products (Tchuenbou-Magaia et al. 2009). However, it is quite a challenge to produce an air based fat mimic with acceptable shelf-life for soft solid or liquid foods. Researchers from Birmingham were successful in fabricating air filled emulsions comprising of fat globule mimics constructed by coating air cells with hydrophobin proteins and subsequently used them in prototype triphasic air/oil/water emulsions (Tchuenbou-Magaia et al. 2009). Air filled emulsion or air cells with hydrophobin coats were first prepared by ultrasonic irradiation of hydrophobin rich solution. Air cells ranging in the size from 1 to 100 μm (with approximately 40% of air cells falling in the range of 1–2 μm) were first prepared (Fig. 10.11). Triphasic air/oil/water emulsions were then created by mixing the air filled emulsion with oil in water emulsion with different level of total included phase volumes. The tri-phasic emulsions allowed the fat content of the model food to be reduced by more than 50% and they were found to be stable in terms of both volume and air content for up to 45 days.

Phase contrast optical micrograph of A/W emulsion showing bubbles size (a) is a brightfield image of a 1 day old sample; (b) a phase contrast image of a 13 day old sample and (c) etched Cryo-SEM micrograph of a 5 day old sample. Reprinted from Tchuenbou-Magaia et al. Hydrophobins stabilised air-filled emulsions for the food industry, Food Hydrocoll 23(7):1877–1885. Copyright (2009), with permission from Elsevier

10.9 Conclusion

Proteins are the commonest polymers used for stabilization of foam in food formulations. Some traditional food proteins such as milk, egg, plant and meat proteins have been extensively used in food formulations. Due to their inherent amphiphilicity, proteins and certain polysaccharides (cellulose derivatives) are able to reduce the surface tension and adsorb at the air-water interface to form an immobile viscoelastic film. However, these foams usually have a rather short life span due to the limited resistance provided by interfacial films which makes them susceptible to instabilities such as coalescence and disproportionation. This poor foaming functionality of proteins and polysaccharides can be improved by physical modifications such as formation of aggregates or by chemical modification through formation of complexes with LMWS or other reactive molecules such as polyphenols. A more bold approach is to stabilize foams by rigid particles created from these polymers. The advantage of using rigid particles over soluble polymers is that fluid interfaces can be effectively stabilized against disproportionation and coalescence on a longer time scale. The disadvantage however, is that a lot of energy is required to create a foam. Furthermore, rigid particles are very specific with regard to the type of interface to which they can adsorb. In contrast, soft gelled particles fabricated from polymers, have been found to spontaneously adsorb to a variety of fluid interfaces and are effective at resisting colloidal instabilities. In some cases, rigid particles and proteins can also be used in combination where the proteins can influence and promote the accumulation of particles at the interface, giving rise to increased jamming of the particles at the interface.

In my opinion, long term objectives of research in this area should focus on: (i) improvement of the foaming functionality of food proteins (especially the lesser explored plant proteins); (ii) understanding the foaming behaviour of binary mixtures (protein-LMWS, protein-polysaccharides etc.); (iii) studying the influence of product matrix on foaming behaviour of polymer and complex mixtures of polymers with other components; (iv) identifying new (industrially-feasible) methods to create rigid and soft particles from a range of food polymers and understanding their interfacial adsorption properties; and (v) exploring innovative applications of polymer stabilized foams to solve long standing and emerging industrial challenges in food formulation.

References

Acharya DP et al (2005) Interfacial properties and foam stability effect of novel gemini-type surfactants in aqueous solutions. J Colloid Interface Sci 291(1):236–243 Available at: http://www.sciencedirect.com/science/article/pii/S0021979705004996

Amagliani L, Schmitt C (2017) Globular plant protein aggregates for stabilization of food foams and emulsions. Trends Food Sci Technol 67(Supplement C):248–259 Available at http://www.sciencedirect.com/science/article/pii/S0924224417302649

Bergeron V, Walstra P (2005) Foams. Fundamentals of interface and colloid science, 5(C), pp 1–38. Available at http://www.sciencedirect.com/science/article/pii/S187456790580011X. Accessed 11 Oct 2017

Binks BP et al (2005) Naturally occurring spore particles at planar fluid interfaces and in emulsions. Langmuir 21(18):8161–8167. https://doi.org/10.1021/la0513858

Campbell AL et al (2008) Scalable fabrication of anisotropic micro-rods from food-grade materials using an in shear flow dispersion-solvent attrition technique. J Mater Chem 18(34):4074–4078. https://doi.org/10.1039/B807738J

Campbell AL, Stoyanov SD, Paunov VN (2009) Fabrication of functional anisotropic food-grade micro-rods with micro-particle inclusions with potential application for enhanced stability of food foams. Soft Matter 5(5):1019–1023. https://doi.org/10.1039/B812706A

Cervantes Martinez A et al (2008) On the origin of the remarkable stability of aqueous foams stabilised by nanoparticles: link with microscopic surface properties. Soft Matter 4(7):1531–1535. https://doi.org/10.1039/B804177F

Cervin NT et al (2013) Lightweight and strong cellulose materials made from aqueous foams stabilized by nanofibrillated cellulose. Biomacromolecules 14(2):503–511. https://doi.org/10.1021/bm301755u

Cervin NT et al (2015) Mechanisms behind the stabilizing action of cellulose nanofibrils in wet-stable cellulose foams. Biomacromolecules 16(3):822–831. https://doi.org/10.1021/bm5017173

Cumper CWN (1953) The stabilization of foams by proteins. Trans Faraday Soc 49(0):1360–1369. https://doi.org/10.1039/TF9534901360

Damodaran S (2005) Protein stabilization of emulsions and foams. J Food Sci 70(3):R54–R66. https://doi.org/10.1111/j.1365-2621.2005.tb07150.x

Davis JP, Foegeding EA (2004) Foaming and interfacial properties of polymerized whey protein isolate. J Food Sci 69(5):C404–C410. https://doi.org/10.1111/j.1365-2621.2004.tb10706.x

Dickinson E (2010) Food emulsions and foams: stabilization by particles. Curr Opin Colloid Interface Sci 15(1):40–49 http://www.sciencedirect.com/science/article/pii/S1359029409001010

Du Z et al (2003) Outstanding stability of particle-stabilized bubbles. Langmuir 19(8):3106–3108. https://doi.org/10.1021/la034042n

Fameau A-L (2018) Non-aqueous foams based on edible oils. In: Edible oil structuring: concepts, methods and applications. The Royal Society of Chemistry, London, pp 275–307. https://doi.org/10.1039/9781788010184-00275

Green AJ et al (2013) Formation and stability of food foams and aerated emulsions: hydrophobins as novel functional ingredients. Curr Opin Colloid Interface Sci 18(4):292–301 http://www.sciencedirect.com/science/article/pii/S1359029413000563

Hu Z et al (2016) Stable aqueous foams from cellulose nanocrystals and methyl cellulose. Biomacromolecules 17(12):4095–4099. https://doi.org/10.1021/acs.biomac.6b01641

Jin H et al (2012) Super stable foams stabilized by colloidal ethyl cellulose particles. Soft Matter 8(7):2194–2205. https://doi.org/10.1039/C1SM06518A

Kim S, Barraza H, Velev OD (2009) Intense and selective coloration of foams stabilized with functionalized particles. J Mater Chem 19(38):7043–7049. https://doi.org/10.1039/B908054F

Lam S, Velikov KP, Velev OD (2014) Pickering stabilization of foams and emulsions with particles of biological origin. Curr Opin Colloid Interface Sci 19(5):490–500 http://www.sciencedirect.com/science/article/pii/S1359029414000806

Lazidis A et al (2016) Whey protein fluid gels for the stabilisation of foams. Food Hydrocoll 53(Supplement C):209–217 http://www.sciencedirect.com/science/article/pii/S0268005X15000831

Lech FJ et al (2014) Identifying changes in chemical, interfacial and foam properties of β-lactoglobulin–sodium dodecyl sulphate mixtures. Colloids Surf A Physicochem Eng Asp 462(Supplement C):34–44 http://www.sciencedirect.com/science/article/pii/S0927775714006931

Maldonado-Valderrama J, Patino JMR (2010) Interfacial rheology of protein–surfactant mixtures. Curr Opin Colloid Interface Sci 15(4):271–282 http://www.sciencedirect.com/science/article/pii/S1359029409001150

Murray BS et al (2011) Preparation and characterization of the foam-stabilizing properties of cellulose–ethyl cellulose complexes for use in foods. J Agric Food Chem 59(24):13277–13288. https://doi.org/10.1021/jf203501p

Neurath H, Bull HB (1938) The surface activity of proteins. Chem Rev 23(3):391–435 http://pubs.acs.org/doi/abs/10.1021/cr60076a001

Norton IT, Jarvis DA, Foster TJ (1999) A molecular model for the formation and properties of fluid gels. Int J Biol Macromol 26(4):255–261 http://www.sciencedirect.com/science/article/pii/S0141813099000914

Park JI et al (2009) A microfluidic approach to chemically driven assembly of colloidal particles at gas–liquid interfaces. Angew Chem Int Ed 48(29):5300–5304. https://doi.org/10.1002/anie.200805204

Patel AR (2015) In: Patel AR (ed) Polymer-based oleogels created using indirect methods. Springer International, Cham, pp 29–39. https://doi.org/10.1007/978-3-319-19138-6_3

Patel AR et al (2012) Stable and temperature-responsive surfactant-free foamulsions with high oil-volume fraction. ChemPhysChem 13(17):3777–3781. https://doi.org/10.1002/cphc.201200564

Patel AR, Schatteman D et al (2013a) A foam-templated approach for fabricating organogels using a water-soluble polymer. RSC Adv 3(45):22900–22903. https://doi.org/10.1039/C3RA44763D

Patel AR, Seijen ten-Hoorn J et al (2013b) Colloidal complexation of a macromolecule with a small molecular weight natural polyphenol: implications in modulating polymer functionalities. Soft Matter 9(5):1428–1436. https://doi.org/10.1039/C2SM27200H

Patel AR et al (2014) Edible oleogels based on water soluble food polymers: preparation, characterization and potential application. Food Funct 5(11):2833–2841. https://doi.org/10.1039/C4FO00624K

Peng D et al (2017) Adsorption and distribution of edible gliadin nanoparticles at the air/water interface. J Agric Food Chem 65(11):2454–2460. https://doi.org/10.1021/acs.jafc.6b05757

Rodrıguez Patino JM, Rodrıguez Niño MR, Sánchez CC (2003) Protein–emulsifier interactions at the air–water interface. Curr Opin Colloid Interface Sci 8(4):387–395 http://www.sciencedirect.com/science/article/pii/S1359029403000955

Rullier B, Novales B, Axelos MAV (2008) Effect of protein aggregates on foaming properties of β-lactoglobulin. Colloids Surf A Physicochem Eng Asp 330(2):96–102 http://www.sciencedirect.com/science/article/pii/S0927775708004925

Sadahira MS et al (2014) Influence of protein–pectin electrostatic interaction on the foam stability mechanism. Carbohydr Polym 103(Supplement C):55–61 http://www.sciencedirect.com/science/article/pii/S0144861713012101

Sadahira MS et al (2016) Effect of egg white protein-pectin electrostatic interactions in a high sugar content system on foaming and foam rheological properties. Food Hydrocoll 58(Supplement C):1–10 http://www.sciencedirect.com/science/article/pii/S0268005X16300376

Saint-Jalmes A (2006) Physical chemistry in foam drainage and coarsening. Soft Matter 2(10):836–849. https://doi.org/10.1039/B606780H

Saint-Jalmes A et al (2005) Differences between protein and surfactant foams: microscopic properties, stability and coarsening. Colloids Surf A Physicochem Eng Aspects 263(1):219–225 http://www.sciencedirect.com/science/article/pii/S0927775705001226

Schmidt I et al (2010) Foaming properties of protein/pectin electrostatic complexes and foam structure at nanoscale. J Colloid Interface Sci 345(2):316–324 http://www.sciencedirect.com/science/article/pii/S0021979710000482

Stocco A et al (2011) Aqueous foams stabilized solely by particles. Soft Matter 7(4):1260–1267. https://doi.org/10.1039/C0SM01290D

Syrbe A, Bauer WJ, Klostermeyer H (1998) Polymer science concepts in dairy systems—an overview of milk protein and food hydrocolloid interaction. Int Dairy J 8(3):179–193 http://www.sciencedirect.com/science/article/pii/S0958694698000417

Tanti R, Barbut S, Marangoni AG (2016a) Hydroxypropyl methylcellulose and methylcellulose structured oil as a replacement for shortening in sandwich cookie creams. Food Hydrocoll 61:329–337 http://www.sciencedirect.com/science/article/pii/S0268005X16302387

Tanti R, Barbut S, Marangoni AG (2016b) Oil stabilization of natural peanut butter using food grade polymers. Food Hydrocoll 61(Supplement C):399–408 http://www.sciencedirect.com/science/article/pii/S0268005X16302429

Tchuenbou-Magaia FL, Norton IT, Cox PW (2009) Hydrophobins stabilised air-filled emulsions for the food industry. Food Hydrocoll 23(7):1877–1885 http://www.sciencedirect.com/science/article/pii/S0268005X09000605

Tzoumaki MV et al (2015) Aqueous foams stabilized by chitin nanocrystals. Soft Matter 11(31):6245–6253. https://doi.org/10.1039/C5SM00720H

Walther A, Muller AHE (2008) Janus particles. Soft Matter 4(4):663–668. https://doi.org/10.1039/B718131K

Wang Z, Zhang S, Vardhanabhuti B (2015) Foaming properties of whey protein isolate and λ-carrageenan mixed systems. J Food Sci 80(8):N1893–N1902. https://doi.org/10.1111/1750-3841.12940

Wege HA et al (2008) Long-term stabilization of foams and emulsions with in-situ formed microparticles from hydrophobic cellulose. Langmuir 24(17):9245–9253. https://doi.org/10.1021/la801634j

Wierenga PA, Gruppen H (2010) New views on foams from protein solutions. Curr Opin Colloid Interface Sci 15(5):365–373 http://www.sciencedirect.com/science/article/pii/S1359029410000592

Wijaya W et al (2017) Functional colloids from proteins and polysaccharides for food applications. Trends Food Sci Technol 68(Supplement C):56–69 http://www.sciencedirect.com/science/article/pii/S0924224417301577

Wilde P et al (2004) Proteins and emulsifiers at liquid interfaces. Adv Colloid Interf Sci 108–109(Supplement C):63–71 http://www.sciencedirect.com/science/article/pii/S0001868603001386

Yucel Falco C et al (2017) Edible foam based on pickering effect of probiotic bacteria and milk proteins. Food Hydrocoll 70(Supplement C):211–218 http://www.sciencedirect.com/science/article/pii/S0268005X17302278

Zhou W et al (2009) How rigid rods self-assemble at curved surfaces. Angew Chem Int Ed 48(2):378–381. https://doi.org/10.1002/anie.200804194

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG, part of Springer Nature

About this chapter

Cite this chapter

Patel, A.R. (2018). Edible Foams Stabilized by Food-Grade Polymers. In: Gutiérrez, T. (eds) Polymers for Food Applications . Springer, Cham. https://doi.org/10.1007/978-3-319-94625-2_10

Download citation

DOI: https://doi.org/10.1007/978-3-319-94625-2_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-94624-5

Online ISBN: 978-3-319-94625-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)