Abstract

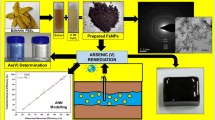

Iron nanoparticles exhibit interesting properties that can be exploited in a variety of applications such as mitigation of wastewaters. For the development of this project a typical cell of three electrodes was used, an iron working electrode was used against a ruthenium oxide mesh as dimensional stable anode and as reference electrode a saturated calomel electrode. The electrochemical techniques used were: cyclic voltammetry, chronopotentiometry and galvanostatic pulses. The characterization of the solution treated by the galvanostatic pulses technique was performed by UV-Vis, where it was possible to observe the characteristic band of iron nanoparticles. The materials deposited on the electrode were characterized by SEM-EDS to observe the size of the particles obtained by the cronopotentiometrys. To study the affinity of the iron nanoparticles on heavy metals, a solution containing arsenic was prepared; the reduction of arsenic was studied by AAS, calculating the concentration of arsenic ions contained in the solution.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

In many parts of the world, potable water is contaminated with arsenic . This element is eliminated by mining, chemical industries and refineries, etc. [1]. The presence of arsenic in groundwater can also be natural due to the leaching of rocks and sediments containing this element [2]. This groundwater contains large amounts of arsenic and are consumed by millions of people around the world in countries like Bangladesh, Cambodia, China, India, Laos, Myanmar, Nepal, Pakistan and Vietnam in Asia [3]. This problem is also present in the American continent, in countries such as Argentina, Mexico, Chile, Peru, the United States, Brazil and Canada [4, 5]. For these reasons, the US Environmental Protection Agency has established the amount of 10 μg L−1 as the maximum contamination level allowed in drinking water [6]. Therefore, several alternatives have been studied to solve this problem. An alternative is nanotechnology with the use of compounds based on zero-valent iron and iron oxide. The surface area presented by nanostructured materials is a good alternative to be able to mitigate the highest amount of arsenic contained in different aqueous environments.

Materials and Methodology

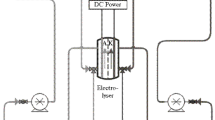

For the development of this project a typical cell of three electrodes was used, an iron working electrode against a mesh of ruthenium oxide and as reference electrode a saturated calomel electrode (SCE); taking the reported by Fajaroh et al. [7] and modifying certain variables of the process. The ferric sulfate solution was prepared using analytical grade chemicals and deionized water. The electrochemical techniques used were: cyclic voltammetry, chronopotentiometry and galvanostatic pulses, all the techniques were performed in a Princeton Applied Research Potentiostat-Galvanostat model VersaSTAT 4. The characterization of the solution treated by the galvanostatic pulses technique was performed by UV-vis and the materials deposited on the electrode by SEM-EDS.

To study the affinity of the iron nanoparticles on heavy metals, a solution with at a certain concentration was prepared using a standard of arsenic with an initial concentration of 1000 ppm. The reduction of arsenic has been studied by AAS by calculating the concentration of arsenic ions contained in the solution. Studies on the affinity of nanoparticles were carried out by adding the nanoparticles obtained through the deposition, controlling temperature, concentration and agitation. Subsequently the studies with the nanoparticles obtained by galvanostatic pulses followed the same procedure controlling the aforementioned variables.

Results and Discussion

Cyclic Voltammetry

Figure 1 shows the cyclic voltamperogram of the ferric sulfate electrolytic solution on the iron working electrode in the potential window of −1 to −1.5 V versus ECS at a scanning rate of 15 mV/s. A reduction of the ionic species can be observed from −0.382 to −0.847 mV. The information obtained from the peak of reduction was used to determine the potentials to be used in the chronopotentiometries for the electrodeposition on the working electrode.

Chronoamperometry

Chronopotentiometric studies served to know the most stable potentials. Figure 2 shows the chronamperometric analysis on an iron electrode. The macro electrolysis was carried out for 10800 S with stirring in the solution. Figure 2 shows the galvanic transient contained on the iron electrode in a current range of −2.45 × 10−5 to −5.6 × 10−3 A.

Electrodeposition

A coating was made to the anode of iron by immersing it in the cell, with solution of ferric sulphate and controlling the current and the electrical tension to cover or deposit a layer. As a result a very fine black powder was obtained, washed with deionized water and dried in a muffle at 170 °C until all traces of moisture were removed. Subsequently, it was analyzed by SEM to know the particle size and EDS to know the composition of the results obtained.

SEM-EDS

The powder obtained by electrochemical deposition was analyzed by scanning electron microscopy, which shows the iron NPs, which have a size between 40 and 60 nm (Fig. 3).

X-ray dispersive energy spectroscopy (EDS) confirmed the presence of iron in the reservoir, which is considered to be zero-valent iron because no oxygen is present in the EDS spectrum (Fig. 4).

UV-VIS

Next, the UV-Vis spectrogram for colloidal Fe NP’s obtained by means of the galvanostatic pulses technique is presented. Wavelengths are plotted against absorbance. It is possible to observe an absorbance band from 250 to 330 nm attributed to Fe colloidal nanoparticles. Due to the lack of uniformity at the absorbance band it is speculated the presence of a variety of sizes and different iron oxides.

Studies of the Affinity of Arsenic with Synthetized Iron Nanoparticles

Due to the small amount of powder obtained during th electrodeposition it was decided to continue the studies only with the nanoparticles synthetized by the galvonostatic pulses. For the following studies, a solution with arsenic was prepared, later, colloidal iron nanoparticles obtained by galvanostatic pulses were added. The results presented below show a small decrease in the concentration of the arsenic ions contained in the solution (Fig. 5). The contaminated solution was heated to 60 °C with constant magnetic stirring. During one hour, every 10 min 2 mL of the solution was added with iron nanoparticles . It’s estimated that the reduction of arsenic ions in the solution is close to 40% (Fig. 6).

Conclusion

According to the results of cyclic voltammetry , the current and potential ranges were obtained where the reduction of the ionic species of iron takes place. By means of the chronopotentiometries an iron deposit was obtained on the surface of the working electrode, characterized by scanning electron microscopy (SEM-EDS), the technique of galvanostatic pulses allowed to obtain iron NPs that were characterized by UV-vis. The result showed the obtaining of spherical nanoparticles of sizes ranging from 20 to 60 nm, grouped in agglomerates, throughout the electrode. The presence of iron and the absence of oxygen have been verified through EDS, suggesting that nanoparticles of zero-valent iron have been obtained. The results obtained by AAS showed that a considerable amount of arsenic was removed from the solution; a later characterization by TEM would confirm the absorption of arsenic by the nanoparticles synthetized.

References

Korngold E, Belayev LA (2001) Removal of arsenic from drinking water by anion exchangers. Desalination 141:81

Choong TSY, Chuah TG, Robiah Y, Lé Gregory Koay F, Azni I (2007) Arsenic toxicity, health hazards and removal techniques from water: an overview. Desalination 217:139–166

Santra SC, Samal AC, Bhattacharya P, Banerjee S, Biswas A, Majumdar J (2017) Arsenic in foodchain and community healt risk: a study in gangetic west bengal. Procedia Environ Sci 18:2–13

Mandal BK, Suzuki KT (2002) Arsenic around the world: a review. Talanta 58:201–235

Ning RY (2002) Arsenic removal by reverse osmosis. Desalination 143:237

EPA (2002) EPA Office of groundwater and drinking water. Implementation guidance for the arsenic rule. Report-816-D-02-005, Cincinnati, USA

Fajaroh F, Widiyastuti H, Winardi S (2012) Synthesis of magnetite by surfactant-free electrochemical method in aqueous system. Adv Powder Technol 23:328–333

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Barrón-Romero, D. et al. (2018). Obtaining of Iron Nanoparticles (Fe NP’s) for Treatment of Water Contaminated with As. In: & Materials Society, T. (eds) TMS 2018 147th Annual Meeting & Exhibition Supplemental Proceedings. TMS 2018. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-72526-0_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-72526-0_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-72525-3

Online ISBN: 978-3-319-72526-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)