Abstract

The influence of austenitizing temperature and austenitizing holding time on the microstructure and mechanical properties of a YP460 grade crack arrest steel was investigated. The first group specimens were austenitized at several temperatures ranging from 900 to 950 °C followed by water cooling. The second group specimens were austenitized at 900 °C with austenitizing holding time from 0.25 to 5 h followed by water cooling. Microstructure was characterized through optical microscopy. Tensile properties, hardness and plane strain fracture toughness of all these materials were determined and correlated with the microstructure. The results indicated that the austenitizing temperature influences the volume fraction of bainite and ferrite and then the mechanical properties. The volume fraction of bainite and ferrite and grain size are also affected by austenitizing time.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

With the growth of world economy and transportation volume, the need for bigger sized container ships has been expanded for the purpose of cost reduction and better transportation efficiency. Therefore, the steel plate especially applied to the upper hull structure is getting thicker in order to ensure the required structural integrity due to its large cargo opening structure. Weight saving is strongly required to increase transportation efficiency of container ships. The higher strength steel plates with heavy thickness and excellent brittle crack arrestability should be developed in terms of the enlargement of the ship size and the liability against catastrophic brittle fracture [1,2,3,4,5,6,7].

In order to homogenize the microstructure and improve the mechanical properties of the YP460 grade steel, research about heat treatments are ordinarily required. However, there is few published literature on heat treatment of the YP460 grade steel. Therefore, it is very meaningful to investigate the effect of heat treatment temperatures and times on microstructures and mechanical properties of the YP460 grade steel.

Material and Experimental Procedures

The material used in this study is fabricated by 80 kg vacuum induction melting using high purity base materials and homogenized at 1200 °C for 2 h, followed by hot rolling into 20 mm thickness plate. The chemical composition of the steel is given in Table 1.

The specimens were divided into two groups. One group was subjected to austenitizing in the temperature range of 900–950 °C for 0.5 h followed by water cooling. The other group was carried out in the austenitizing holding time range of 0.25–5 h with the austenitizing temperature of 900 °C.

Mechanical properties were evaluated by tensile, hardness and Impact tests at the room temperature. The tensile Tests were performed on a UTM5105 testing machine according to standard procedures. The hardness of specimens was measured by Rockwell (Vickers) hardometer. Each value was the average of hardness values at ten points. Impact tests were performed on a JBW-300B testing machine. Optical microscopy were used to examine the microstructural features. The volume fraction of reversed austenite was determined from X-ray diffraction tests.

Results and Discussion

Preliminary Investigations

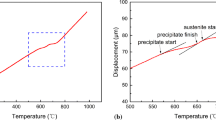

The Ac1 and Ac3 temperatures are important characteristic parameters of steel. Figure 1 shows the dilatometric curve of continuously heated specimen. In this figure, two tangent points on the curve represent starting and finishing temperature of \( \alpha \) to \( \gamma \) transformation. The Ac1 and Ac3 temperatures of this steel are 683 and 843 °C, respectively, when heating rate is 0.05 °C/s.

Effect of Austenitizing Temperature on Mechanical Properties

The results of the hardness, tensile and impact toughness tests on the water-quenched samples with different austenitizing temperature are shown in Figs. 2, 3 and 4, respectively. It can be seen that the effect of austenitizing temperature on the mechanical properties of the studied steels is not very complex. The hardness, tensile strength and yield strength increase slightly with increasing austenitizing temperature from 900 to 925 °C, while the elongation decreases significantly. With increasing the austenitizing temperature from 875 to 900 °C, the tempering process decreases the residual stress and dislocation density, which can be responsible for the slight decrease in the tensile strength and hardness [8, 9].

The plot of room temperature fracture toughness of the material against austenitizing temperature is shown in Fig. 5. With the austenitizing temperature increasing from 900 to 925 °C, the fracture toughness increases first and then increases.

Effect of Austenitizing Temperature on Microstructure

Figure 6a–c show the variation in the microstructures as the austenitizing temperature was increased from 900 °C to 950 °C, respectively. The microstructures of different austenitizing temperatures are similar consisting of ferrite and bainite. The lower the austenite temperature is, the larger the volume fraction of bainite is. With the austenitizing temperature increasing, the volume fraction of ferrite increases, and the grain size increases.

Effect of Austenitizing Holding Time on Mechanical Properties

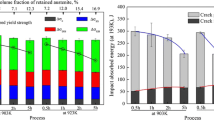

The effect of austenitizing time on tensile strength, yield strength, elongation and hardness are shown in Figs. 7, 8 and 9, respectively. With the extension of austenitizing holding time, the tensile strength, yield strength and hardness increase first and then decrease while the elongation decreasing first and then increasing. The tensile strength and yield strength reached the maximum 551 and 750 MPa, respectively, with the austenitizing holding time of 1 h and the hardness reached the maximum 234HV with the austenitizing holding time of 0.5 h. The initial increase of strength is induced by the dissolution of the interdendritic phases and the increase of solid solubility of matrix. Strength approaches the maximum value at 1 h, indicating that the interdendritic phases are dissolved sufficiently into the matrix at the temperature of 900.

With the increase of the austenite holding time, the amount of alloying elements in the austenite increases resulting in solid solution strengthening, thus the strength and hardness of the material improving and the impact energy reducing. With the austenitizing holding time continues to increase, the solution of the alloying elements to further increase. The solution of excess alloying elements in austenite would improve the stability of austenite and the amount of retained austenite in microstructure increased which reducing the hardness and strength of the material. In addition, with increasing of the holding time, the distribution of carbon and alloying elements in the austenite is further homogenized and the segregation degree of the structure is reduced resulting in the impact energy of the material increasing.

The influences of austenitizing holding time on impact toughness is shown in Fig. 10. It can be seen that the effect of austenitizing holding time on impact toughness of the studied steels is very complex.

Effect of Austenitizing Holding Time on Microstructure

Figure 11a–e show the variation in the microstructures as the austenitizing holding time was increased from 0.25 to 5 h with the austenitizing temperature of 900 °C, respectively. The microstructures of different austenitizing times are similar consisting of ferrite and bainite. With the austenitizing holding time increasing, the volume fraction of bainite decreased and the volume fraction of ferrite increased, Gradually. Moreover, The grain size increases slowly with the austenitizing holding time was increased from 0.25 to 5 h. This is mainly due to the addition of Nb and Ti to form Ti, Nb rich carbonitride particles and these can restrict austenite grain growth at high temperature [10,11,12].

Conclusions

The Ac1 and Ac3 temperatures were determined by dilatometric analysis as 683 and 843 °C, respectively.

Varying the austenitizing temperature in the range of 900–950 °C has no influence on the microstructure composition and only a slightly influence on the volume fraction of bainite and ferrite and mechanical properties . The best properties were obtained for the steel austenitized at 950 °C.

Varying the austenitizing holding time from 0.25 to 5 h with the austenitizing temperature of 900 °C has no influence on the microstructure composition and greater influence on the volume fraction of bainite and ferrite, grain size and mechanical properties . The best properties were obtained for the steel austenitized for 1 h.

References

Lee C-S, Kim S, Suh I-S, Um K-K, Kwon O (2011) High strength steel plates for large container ships. Int J Iron Steel Res 18:796–802

Choo W-Y, Suh I-S, Kim S, An G-B, Lee C-S (2011) High performance structural steels for shipbuilding and offshore structures. Int J Iron Steel Res 18:90–98

Kyokai NK (2009) Guidelines of the application of YP47 steel for hull structures of large container carriers

Wu W-M, Lin J-R (2015) Productivity growth, scale economies, ship size economies and technical progress for the container shipping industry in Taiwan. Transp Res Part E 73:1–16

UR S33, Requirements for use of extremely thick steel plates, Jan 2013

UR W31, Application of YP47 steel plates, Jan 2013

Murakami Y, Takeuchi Y, Hase K, Endo S (2014) Development of YP460 class steel plate with excellent brittle crack arrestability for large container ships. Int J Offshore Polar Eng 24(4):286–291

Qin B, Wang ZY, Sun QS (2008) Effect of tempering temperature on properties of 00Cr16Ni5Mo stainless steel. Mater Charact 59(8):1096–1100

Zou D, Liu X, Han Y, Zhang W, Li J, Kun W (2014) Influence of heat treatment temperature on microstructure and property of 00Cr13Ni5Mo2 supermartensitic stainless steel. Int J Iron Steel Res 21(3):364–368

Craven AJ, He K, Garvie LAJ, Baker TN (2000) Complex heterogeneous precipitation in titanium-niobium microalloyed Al-killed HSLA steels—I. (Ti,Nb)(C,N) particles. Acta Mater 48:3857–3868

Kanasawa S, Nakashima A, Okamoto K, Kanaya K (1976) Improvement of weld fusion zone toughness by fine TiN. Trans Iron Steel Inst Japan 16:486

Wang GR, Lau TW, Weatherly GC, North TH (1989) Weld thermal cycles and precipitation effects in Ti-V-containing HSLA steels. Metall Trans 20A:2093–2100

Acknowledgements

This work was supported by the Fundamental Research Funds for the Central Universities (HEUCFJ171005, HEUCFJ171001 and HEUCFP201703), NSFC Funding (51371062 and U1460102), NSFHLJ (JC2017012), the High-Tech Ship Research Projects Sponsored by MIIT and the International Exchange Program of Harbin Engineering University for Innovation-oriented.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Chen, D. et al. (2018). Influence of Austenitizing Temperature and Time on Microstructure and Mechanical Properties of an YP460 Grade Crack Arrest Steel. In: & Materials Society, T. (eds) TMS 2018 147th Annual Meeting & Exhibition Supplemental Proceedings. TMS 2018. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-72526-0_13

Download citation

DOI: https://doi.org/10.1007/978-3-319-72526-0_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-72525-3

Online ISBN: 978-3-319-72526-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)