Abstract

As the absorbing material composed of sole carbon is difficult to meet the comprehensive requirements of microwave applications, preparation of carbonaceous nanocomposite materials becomes an effective method to increase microwave absorption properties. In this study, a novel nanocomposite composed of Co–Ni ferrite and graphene was synthesized via a simple and rapid microwave hydrothermal method in just a few minutes. It was demonstrated that the minimum microwave reflection loss of the composite of 3 mm thickness with a low filling ratio (20 wt%) reached −13.1 dB at 17.2 GHz with an effective absorption bandwidth of 3.1 GHz. The good performance of the composite was believed to be a result of high dielectric loss of graphene associated with a multi-dielectric relaxation process and magnetic loss of the ferrite mainly originated from natural ferromagnetic resonance.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Microwave absorption materials are widely used in the television, broadcast, radar, microwave anechoic chamber and electronic devices. [1]. Graphene , periodic honeycomb shaped new carbon material [2], becomes a potential nanoscale building block for new absorbing materials due to its outstanding properties. The two dimensional conjugate structure of graphene [3] contributes to its high dielectric loss, low density, special surface properties, etc. [4]. However, its remarkable dielectric loss ability and non-magnetic feature lead to poor impedance matching and thus a low attenuation property in microwave absorption [5,6,7]. In order to improve microwave absorption properties, one of the effective approaches is to load magnetic materials, typically ferrites, on graphene [8,9,10]. For example, when reduced graphene oxide (r-GO) was coated with Fe3O4 through a co-precipitation method, the reflection loss (RL) value of rGO/Fe3O4 composite (filling ratio = 8 wt%) reached −47.9 dB at 10.1 GHz with the effective absorption bandwidth (RL < −10 dB) ranging from 6.5 to 10.3 GHz (coating layer thickness of 2.0 mm) [8]. Other ferrites are also used for improving the magnetic performance of graphene matrix composite. A recent study showed that rugby-shaped CoFe2O4/graphene composites via a vapor diffusion method had the minimum RL of −39.0 dB (filling ratio = 60 wt%) at 10.9 GHz and corresponding effective absorption bandwidth was 4.7 GHz at 2.0 mm [9]. Another report demonstrated that NiFe2O4 nanorod/graphene composites of 2.0 mm thickness (filling ratio of 60 wt%), prepared by an ionic liquid assisted one-step hydrothermal approach, achieved minimum RL of −29.2 dB with the effective absorption bandwidth of 4.4 GHz [10]. The good microwave absorption performance of those composites was largely attributed to enhanced electron transmission when two or more ions replacing Fe cations within the spinel structure [11]. For this mechanism, it is anticipated that Co–Ni ferrites may be another promising candidate to be assembled onto graphene for further improvement of absorption performance

In this paper, a novel composite constituted by Co0.5Ni0.5Fe2O4 and graphene was synthesized via microwave hydrothermal method in just several minutes. The minimum RL of the composite of 3.0 mm thickness reached −13.1 dB at 17.2 GHz with an effective absorption bandwidth of 3.1 GHz.

Experimental

Materials

All chemical reagents used in this experiment, including natural graphite powder (<48 µm), sulphuric acid (H2SO4), potassium permanganate (KMnO4), sodium nitrate (NaNO3), hydrogen peroxide (H2O2), cobalt acetate (Co(OAc)2), nickel acetate (Ni(OAc)2), ferrous chloride (FeCl2), ammonia (NH3∙H2O), and ethanol were of analytical grade and used as received without further purification.

Preparation of Co0.5Ni0.5Fe2O4/Graphene Composite

For preparation of Co0.5Ni0.5Fe2O4/graphene composite, 2.0 mmol of FeCl2, 0.5 mmol of Co(OAc)2 and 0.5 mmol of Ni(OAc)2 were mixed and dissolved in 80 mL of distilled water under magnetic stirring. Subsequently, 50 mg of GO, which was preliminarily prepared by the Hummers method using the natural graphite powder as starting material [12], was added into the above solution under ultrasonic treatment to form a homogeneous solution. The mixture was stirred for 4 h at room temperature. The pH value of the suspension was adjusted to 10 by adding NH3∙H2O. The mixture was stirred for 1 h at room temperature. Then, the reaction mixture was heated at 160 °C in a microwave reactor at power of 500 W for 25 min. The resultant precipitate was filtered, washed with deionized water and ethanol, and finally dried in a vacuum oven at 70 °C for 12 h.

Characterization of Co0.5Ni0.5Fe2O4/Graphene Composite

The electromagnetic parameters (permittivity and permeability) of the composite were measured with an AV3629 vector network analyzer using the coaxial line method. Samples were first prepared by homogeneously mixing the nanocomposite with paraffin (the weight content of the as-prepared powder was about 20 wt%), and then the mixture was pressed into a toroid with an inner diameter of 3.0 mm, an outer diameter of 7.0 mm and a height of 2.0 mm. Subsequently, the samples were embedded into a copper holder and connected between the waveguide flanges of the instrument for measurement of the parameters.

To assess the microwave absorption performance of Co0.5Ni0.5Fe2O4/graphene composite, its reflection loss (RL) was calculated by the following equations [13, 14]:

where Zin is the input impedance of the absorber, Z0 is the input impedance of the free space, εr (εr = εr′ − jεr″) is the complex relative permittivity of the absorber, μr (μr = μr′ − jμr″) is the complex relative permeability of the absorber, c is the velocity of electromagnetic waves in free space, ƒ is the frequency and d is the absorber layer thickness.

Results and Discussion

Electromagnetic Absorption Properties

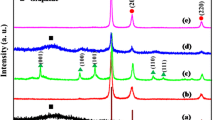

Figure 1a shows the real part (εr′) and imaginary part (εr″) of the complex relative permittivity of Co0.5Ni0.5Fe2O4/graphene composite. It is revealed that the εr′ value decreased gradually from 2.89 to 2.59 and the εr″ value increased from 0.003 to 0.479, respectively, in the frequency range of 2–18 GHz. Figure 1b shows the real part (μr′) and imaginary part (μr″) of the complex relative permeability of Co0.5Ni0.5Fe2O4/graphene composite. It reveals that the values of μr′ were in the range of 0.95–1.11 over 2–18 GHz and the μr″ values exhibited a major peak at 10.16 GHz and a minor peak at around 4.64 GHz. From Fig. 1c, it is found that most of the values of the dielectric loss tangent (tan δεr) were larger than the values of the magnetic loss tangent (tan δμr) from 2 to 18 GHz, except the frequency ranges of 4.48–6.40 and 9.60–10.88 GHz. Therefore, we can conclude that the electromagnetic wave attenuation mechanism of Co0.5Ni0.5Fe2O4/graphene composite was mainly ascribed to electrical loss in the frequency range of 2–18 GHz. The higher tan δμr values than the tan δεr values were associated with the two peaks of the μr″ value in Fig. 1b.

Figure 1d shows the RL curves of Co0.5Ni0.5Fe2O4/graphene composite with different thicknesses. Its minimum RL was up to −13.1 dB at 17.2 GHz, and the bandwidth corresponding to the RL values below −10 dB (90% of electromagnetic wave absorption) was 3.1 GHz (from 14.9 to 18.0 GHz) with a thickness of 3.0 mm. In addition, the minimum RL values obviously decreased first and then increased with increasing the layer thickness.

To investigate the possible mechanism of the enhanced microwave absorption properties of Co0.5Ni0.5Fe2O4/graphene composite, the Cole-Cole semicircle curve and the values C0 [μr″ (μr′)−2ƒ−1] versus frequency are presented in Fig. 2. As for the Debye dipolar relaxation, the complex relative permittivity can be expressed by the following equation [15]:

where ƒ, εs, ε∞ and τ are the frequency, static permittivity, relative dielectric permittivity at the high-frequency limit, and polarization relaxation time, respectively. Thus, εr′ and εr″ can be described by the following equations:

According to Eqs. (5) and (6), the relationship between εr′ and εr″ can be deduced as follows:

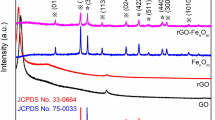

Thus, the curve of εr′ versus εr″ is a single semicircle, which is generally called the Cole-Cole semicircle. Each semicircle corresponds to one Debye relaxation process. Figure 2a shows the εr′–εr″ curve of Co0.5Ni0.5Fe2O4/graphene in the frequency range from 2 to 18 GHz. The curve of εr′ versus εr″ shows that Co0.5Ni0.5Fe2O4/graphene composite had a distinct segment of three semicircles, demonstrating that the composites had multi-dielectric relaxation processes. In other words, the Debye relaxation process played a key role in improving the dielectric properties of Co0.5Ni0.5Fe2O4/graphene composite. In general, the microwave magnetic loss of magnetic materials originates mainly from hysteresis, domain wall resonance, natural ferromagnetic resonance, and the eddy current effect [16]. The hysteresis loss comes from irreversible magnetization and is negligible in a weak applied field. The domain wall resonance occurs only in multidomain materials and usually in the 1–100 MHz range [17]. In this study, the complex relative permeability was measured in the frequency range of 2–18 GHz. Therefore, hysteresis and domain wall resonance were not the main factors that led to magnetic loss of the composite. Instead, only natural ferromagnetic resonance or the eddy current effect might contribute to the microwave magnetic loss. If the eddy current effect occurs at the absorber, the C0 (C0 = μr″ (μr′)−2ƒ−1 = 2πμ0σd2/3) will be a constant when the frequency varies. It is shown in Fig. 2b that these C0 values were not constant with the increasing frequency. Therefore, the magnetic loss of the composite was considered to be originated from natural ferromagnetic resonance.

The mechanism of excellent electromagnetic absorbing performance for Co0.5Ni0.5Fe2O4/graphene composite was investigated in detail (Fig. 3). The excellent wave absorption properties and wider absorption bandwidth of Co0.5Ni0.5Fe2O4/graphene composite can be explained as follows. Firstly, the remarkable dielectric loss ability of graphene was conducive to absorbing electromagnetic waves. Loading Co0.5Ni0.5Fe2O4 nanoparticles not only effectively reduced the excessive dielectric loss of graphene but also enhance good magnetic properties of the composite, contributing to impedance matching. More interfaces and defects could be induced after the introduction of Co0.5Ni0.5Fe2O4 nanoparticles, which caused more interface polarization [18]. Secondly, the multiple reflection could occur at defect of the graphene and Co0.5Ni0.5Fe2O4 nanoparticles, extending the propagative routes of electromagnetic wave. In addition, the natural resonances produced by Co0.5Ni0.5Fe2O4 could greatly increase magnetic losses and convert electromagnetic energy into thermal energy, thus absorbing electromagnetic waves.

Compared with other absorbers, the Co0.5Ni0.5Fe2O4/graphene composite exhibited significantly enhanced electromagnetic absorbing ability, as shown in Table 1. Furthermore, it was only 20 wt% of the filling ratio for the Co0.5Ni0.5Fe2O4/graphene composite. The above results demonstrated that the Co0.5Ni0.5Fe2O4/graphene composite had strong absorption, wide absorption bandwidth and light weight.

Conclusions

A Co0.5Ni0.5Fe2O4/graphene composite was synthesized via a simple and rapid microwave method. It was shown that the Co0.5Ni0.5Fe2O4/graphene composite had good dielectric and magnetic properties. The minimum RL of Co0.5Ni0.5Fe2O4/graphene composite was −13.1 dB at 17.2 GHz and the absorption bandwidth with the reflection loss below −10 dB was 3.1 GHz with a thickness of 3.0 mm. The good performance of the composite was attributed to the high dielectric loss of graphene in association with multi-dielectric relaxation processes and magnetic loss of the ferrite mainly originated from natural ferromagnetic resonance.

References

Wu X, Che Y (1992) Foreign microwave absorbing materials. National University of Defense Technology press

Geim AK, Novoselov KS (2007) The rise of graphene. Nat Mater 6:183–191

Loh KP, Bao Q, Ang PK, Yang J (2010) The chemistry of graphene. J Mater Chem 20:2277–2289

Ma E, Li J, Zhao N, Liu E, He C, Shi C (2013) Preparation of reduced graphene oxide/Fe3O4 nanocomposite and its microwave electromagnetic properties. Mater Lett 91:209–212

Lv H, Ji G, Li X, Chang X, Wang M, Zhang H, Du Y (2015) Microwave absorbing properties and enhanced infrared reflectance of FeAl mixture synthesized by two-step ball-milling method. J Magn Magn Mater 374:225–229

Shang C, Ji G, Liu W, Zhang X, Lv H, Du Y (2015) One-pot in situ molten salt synthesis of octahedral Fe3O4 for efficient microwave absorption application. Rsc Adv 5:80450–80456

Zhao B, Shao G, Fan B, Zhao W, Zhang R (2015) Facile synthesis and enhanced microwave absorption properties of novel hierarchical heterostructures based on a Ni microsphere-CuO nano-rice core-shell composite. Phys Chem Chem Phys 17:6044–6052

Zhang H, Xie A, Wang C, Wang H, Shen Y, Tian X (2014) Room temperature fabrication of an RGO–Fe3O4 composite hydrogel and its excellent wave absorption properties. Rsc Adv 4:14441–14446

Zhang S, Jiao Q, Hua J, Li J, Zhao Y, Li H, Wu Q (2015) Vapor diffusion synthesis of rugby-shaped CoFe2O4/graphene composites as absorbing materials. J Alloy Compd 630:195–201

Fu M, Jiao Q, Zhao Y (2013) Preparation of NiFe2O4 nanorod–graphene composites via an ionic liquid assisted one-step hydrothermal approach and their microwave absorbing properties. J Mater Chem A 1:5577–5586

Ji R, Cao C, Chen Z, Zhai H, Bai J (2014) Solvothermal synthesis of CoxFe3−xO4 spheres and their microwave absorption properties. J Mater Chem C 2:5944–5953

Hummers WS, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339

Wang LN, Jia XL, Li YF, Yang F, Zhang LQ, Liu LP (2014) Synthesis and microwave absorption property of flexible magnetic film based on graphene oxide/carbon nanotubes and Fe3O4 nanoparticles. J Mater Chem A 2:14940–14946

Kim SS, Jo SB, Gueon KI, Choi KK, Kim JM, Churn KS (1991) Complex permeability and permittivity and microwave absorption of ferrite-rubber composite at X-band frequencies. IEEE Trans Magn 27:5462–5464

Zhao B, Zhao WY, Shao G, Fan BB, Zhang R (2015) Morphology-control synthesis of a core-shell structured NiCu alloy with tunable electromagnetic-wave absorption capabilities. ACS Appl Mater Interfaces 7:12951–12960

Peng Z, Hwang JY (2015) Microwave-assisted metallurgy. Int Mater Rev 60:30–63

Wu M, Zhang Y, Hui S, Xiao T, Ge S, Hines W, Budnick J, Taylor G (2002) Microwave magnetic properties of Co50/(SiO2)50 nanoparticles. Appl Phys Lett 80:4404–4406

Qu B, Zhu C, Li C, Zhang X, Chen Y (2016) Coupling hollow Fe3O4-Fe nanoparticles with graphene sheets for high-performance electromagnetic wave absorbing material. ACS Appl Mater Interfaces 8:3730–3735

Liu P, Yao Z, Ng, VMH, Zhou J, Yang Z, Kong L (2017) Enhanced microwave absorption properties of double-layer absorbers based on spherical NiO and Co0.2Ni0.4Zn0.4Fe2O4 ferrite composites. Acta Metallurgica Sinica https://doi.org/10.1007/s40195-017-0612-5

Tong SY, Wu JM, Tung MJ, Ko WS, Huang YT, Wang YP (2012) Effect of Ni concentration on electromagnetic wave absorption of (Ni, Mn, Zn)Fe2O4/resin particulate composites. J Alloy Compd 525:143–148

Bueno AR, Gregori ML, No´brega MCS (2008) Microwave-absorbing properties of Ni0.50−xZn0.50−xMe2xFe2O4 (Me = Cu, Mn, Mg) ferrite-wax composite in X-band frequencies. J Magn Magn Mater 320:864–870

Zheng Y, Wang X, Wei S, Zhang B, Yu M, Zhao W, Liu J (2017) Fabrication of porous graphene-Fe3O4 hybrid composites with outstanding microwave absorption performance. Compos A 95:237–247

Fu M, Jiao Q, Zhao Y, Li H (2014) Vapor diffusion synthesis of CoFe2O4 hollow sphere/graphene composites as absorbing materials. J Mater Chem A 2:735–744

Acknowledgements

This work was partially supported by the National Natural Science Foundation of China under Grant 51774337, the innovation-driven Program of Central South University under Grant 2016CXS021 and the Shenghua Lieying Program of Central South University under Grant 502035001.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Peng, Z. et al. (2018). Microwave Synthesis of Co–Ni Ferrite/Graphene Nanocomposite for Microwave Absorption. In: Li, B., et al. Characterization of Minerals, Metals, and Materials 2018 . TMS 2018. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-72484-3_38

Download citation

DOI: https://doi.org/10.1007/978-3-319-72484-3_38

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-72483-6

Online ISBN: 978-3-319-72484-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)