Abstract

The use of fiber reinforced plastic (FRP) composite materials in the construction industry increases with each passing day. In recent years, these materials are used as carrier material or reinforcement material in the structure. Glass fiber reinforced plastic (GFRP) profiles are among the most preferred FRP composite materials. GRFP profiles stand out with their high tensile strength, light weight and high corrosion performance. The hybrid use of these materials with classical construction materials offers new advantages. The buckling behavior of the hybrid material formed by placing concrete in plastic state into GFRP box profiles with high tensile strength was investigated in this study. The buckling performance of hybrid columns formed using GFRP profile, normal concrete or reactive powder concrete (RPC) was studied. To this end, normal concrete-GFRP profile and RPC-GFRP profile hybrid columns were produced and buckling testing was performed at different slenderness values. Charts were created after buckling experiments to examine differences in the behavior of the material. As a result of the examinations, the effect of RPC and column slenderness on the buckling performance hybrid columns was identified.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Fiber reinforced plastic (FRP) composites are preferred due to their high strength and good performance against environmental factors as well as their producibility in different combinations. These new generation of composites are becoming popular due to properties such as high tensile strength, light weight, corrosion performance, resistance against chemicals and electrical insulation [1,2,3]. However, these materials are not employed in many cases where they can be used instead of other materials because they are not well known by users and designers. FRP composites are estimated to be a good solution in a large part of the available applications [4]. The use of FRPs together with traditional construction materials offer various advantages. These materials are particularly used for strengthening of reinforced concrete construction elements, as profile for carrier building elements and reinforcement in concrete (Figs. 1, 2 and 3).

FRP strengthening [5]

GFRP eyecatcher building [6]

FRP bars [7]

There has been many studies on hybrid use of concrete-filled FRP pipe elements or FRP profiles with different dimensions together with concrete [8,9,10,11,12,13,14,15,16].

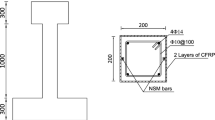

Researchers have studied various combinations regarding the hybrid use of concrete and FRP profiles, as can be seen in the literature. Concrete-FRP-steel hybrid construction elements can be seen in Figs. 4 and 5.

Hybrid beam sections [17]

GFRP-steel-concrete hybrid columns [18]

2 Experimental Studies

2.1 Materials and Method

Various experiments were carried out in order to determine buckling performances of hybrid FRP-concrete columns at different slenderness values. Normal concrete with 25 MPa compressive strength within GFRP profile was used in some of the hybrid columns and RPC concrete with a compressive strength of 200 MPa was used in the remaining samples. The dimensions of the GFRP box profile was 4–75–75 mm. The column lengths of 75–100–150–200–250–320 mm were used to determine the behavior of the material at different slenderness values.

In preparation of hybrid samples, the mixed concrete was filled in GFRP box profile in fresh form and the necessary curing treatment was performed. Once the concrete reached sufficient strength, hybrid columns were cut at aforementioned lengths for testing. Figure 6 shows concrete-filled hybrid columns at different lengths.

Horizontal and vertical displacements were recorded using data logger after the setup of additional assemblies on the axial pressure machine (Fig. 7).

After completing the experimental setup, the samples were placed and the buckling performance was tested as shown in Fig. 8. Horizontal and vertical displacement values against loads applied during tests were obtained via the Lvdt measuring instrument (Fig. 9).

2.2 Test Results

As a result of buckling tests, horizontal and vertical displacement values of 75–100–150–200–250–320 mm GFRP-concrete and GFRP-RPC hybrid columns under loading were determined and load-displacement curves were drawn. Horizontal and vertical displacement graphs against loads applied during tests are given in Figs. 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20 and 21.

Strength and slenderness values obtained for each hybrid column from graphs are given in Tables 1 and 2.

75 × 75 mm hybrid columns filled with normal concrete reached a strength of 50.3 N/mm2 at 75 mm, which corresponds to a slenderness of 1. The strength decreased with increasing slenderness and dropped to 35 N/mm2 for 32 mm hybrid columns. The strength decreased by approximately 30% compared to the initial value with increasing slenderness.

The strength of 32 mm RPC concrete hybrid columns decreased from 141.3 to 112 N/mm2 at a slenderness value of 1. The loss in strength for these columns was approximately 21%.

The stress-slenderness diagram of hybrid columns was drawn and the slenderness equation and the R2 value were found from this diagram (Figs. 22 and 23).

An examination of the strength-slenderness graph for the hybrid columns with normal concrete shows that the R2 value was 0.90 and the logarithmic curve equation of y = −1.102ln(x) + 6.2096 was obtained with increasing slenderness.

The strength-slenderness graph for the hybrid columns with RPC concrete showed that the R2 value was 0.70 and the logarithmic curve equation of y = −1.783ln(x) + 16.416 was obtained. It was found that the hybrid columns with normal concrete had a more compatible behavior at different slenderness values.

3 Conclusions and Recommendations

The results obtained from buckling testing of hybrid columns with normal concrete and RPC concrete are as follows:

-

The hybrid column system offers many advantages such as permanent mold for concrete, hear and water insulation, corrosion strength and improved mechanical performance.

-

The strength of 32 mm RPC concrete hybrid columns decreased from 50.3 to 35 N/mm2 at a slenderness value of 1. The strength of hybrid column at slenderness of 1 taken as reference, the strength decreased with increasing slenderness by 11–22–31–30–30% respectively.

-

The strength decreased from 141.3 to 112.4 N/mm2 for hybrid columns with RPC concrete. The decrease in strength compared to the hybrid column at a slenderness of 1 was 7–0.2–15–13–20.5%.

-

A good fit was observed in stress-slenderness graphs of the hybrid columns with normal concrete. The R2 value was 0.90 and the logarithmic curve equation was y = −1.102ln(x) + 6.2096.

-

The R2 value of the hybrid columns with RPC concrete was 0.70 and the logarithmic curve equation was y = −1.783ln(x) + 16.416.

-

The strength of the RPC concrete hybrid columns with high strength increased and the decrease in strength of columns with increasing slenderness occurred only slightly for RPC columns.

-

The hybrid construction systems formed by combining traditional construction materials and new generation composites improve inadequate aspects of available construction materials. The use of these new generation composites as alternative materials may provide a solution for many problems related to construction materials.

References

Aydın F (2011) Investigation of mechanic performance of hybrid structural element produced using glass fibre reinforced plastic (GFRP) composite and concrete. Ph.D. thesis, Sakarya University, Science Institute, Sakarya

Aydın F, Sarıbıyık M (2013) Investigation of flexural behaviors of hybrid beams formed with GFRP box section and concrete. Constr Build Mater 41:563–569

Aydın F (2016) Effects of various temperatures on the mechanical strength of GFRP box profiles. Constr Build Mater 127:843–849

Cripps A (2002) Fiber reinforced polymer composites in construction, construction. Industry Research & Information Association (CIRIA)

https://www.luckett-farley.com/Blog/Article/119/FRP-Concrete-Strengthening-101. 1 Jan 2017

http://cclab.epfl.ch/page-13730-en.html. 1 Jan 2017

http://www.aslanfrp.com/. 1 Jan 2017

Mirmiran A, Shahawy M (1997) Behavior of concrete columns confined by fiber composites. J Struct Eng 123:583–590

Fam AZ, Rızkalla SH (2001) Confinement model for axially loaded concrete confined by circular FRP tubes. ACI Struct J 98(4):251–461

Becque J, Patnaık AK, Rızkalla SH (2003) Analytical models for concrete confined with FRP tubes. J Compos Constr 7(1):31–38

Yu T, Wong YL, Teng JG, Dong SL, Lam ESS (2006) Flexural behavior of hybrid FRP-concrete-steel double-skin tubular members. J Compos Constr ASCE 10(5):443–452

Gautam B, Matsumoto T (2009) Shear deformation and interface behaviour of concrete-filled CFRP box beams. Compos Struct 89:20–27

Correıa JR, Branco A, Ferreıra JG (2009) Flexural behaviour of multi-span GFRP-concrete hybrid beams. Eng Struct 31:1369–1381

Wenlxıao L, Zhıshen W (2004) Flexural performance of newly developed hybrid FRP concrete beams. In: FRP composites in civil engineering, CICE, pp 819–826

Nordin H, Taljstena B (2003) Testing of hybrid FRP composite beams in bending. Compos B 35:27–33

Hulatt J, Hollaway L, Thorne A (2003) The use of advanced polymer composites to form an economic structural unit. Constr Build Mater 17:55–68

Leo B (2009) Design of a fibre-reinforced polymer (FRP) bridge. University of New South Wales at the Australian Defence Force Academy. Second Lieutenant (Singapore Armed Forces), School of Aerospace, Civil & Mechanical Engineering, final thesis report

Teng JG, Yu T, Wong YL (2004) Behavior of hybrid FRP-concrete-steel double-skin tubular columns. In: FRP composites in civil engineering, CICE, pp 811–818

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG, part of Springer Nature

About this paper

Cite this paper

Aydın, F., Akgül, T., Aydın, E. (2018). Investigation of Buckling Behavior of FRP-Concrete Hybrid Columns. In: Fırat, S., Kinuthia, J., Abu-Tair, A. (eds) Proceedings of 3rd International Sustainable Buildings Symposium (ISBS 2017). ISBS 2017. Lecture Notes in Civil Engineering , vol 7. Springer, Cham. https://doi.org/10.1007/978-3-319-64349-6_35

Download citation

DOI: https://doi.org/10.1007/978-3-319-64349-6_35

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-64348-9

Online ISBN: 978-3-319-64349-6

eBook Packages: EngineeringEngineering (R0)