Abstract

Geogrid-reinforced earth walls are today’s state-of-the art for earth retaining and stabilization systems. They have proven efficient and durable with superior resistance to static, resilient and dynamic loads. Worldwide, many codified design procedures and experience are available. Beside their technical and economic advantages, they also have at least 30% lower carbon footprint than conventional walls or stabilizing systems, e.g. concrete retaining walls, coupled with a great advantage in terms of sustainability. Despite the formal design requirements, the systems are capable of adopting specific local conditions as terrain geometry, as well as aesthetic preferences, and are shown to be of high cost benefit compared to other types of structures. In these aspects, the type of the facing is of special interest as a major decision-making factor. Accordingly, a recently executed project in Saudi Arabia is described in the context mentioned above focusing on specific issues like geometry optimization, facing type, adaptation and some rare specific solutions as well as specific design requirement due to the significant wall height and value of adjacent structures. The provided solution is appropriate for different climates, including the harsh, humid and hot environment in the Middle East.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

1 Introduction

The process of implementing a specific type of reinforced soil wall or stabilization structures and the subsequent design are based on a number of factors, such as:

-

Suitability and feasibility of the system and cost benefit,

-

Safety and adequacy of the design,

-

Serviceability and performance requirements or limitations, and

-

Site requirements or limitations.

Alexiew (2012), Alexiew et al. (2013), and Guler et al. (2011, 2012) described the benefits of GRS systems in terms of stability, flexibility and sustainability. Currently, there are quite few well-acknowledged and used codes as well as methods and tools for GRS wall design (computer programs or software). Limit Equilibrium Analyses are still widely and commonly used for the design process, especially where deformations are either estimated to be small or can be predicted using other procedures or software. Deformation predictions shall take into account the construction progress stages (bottom up construction with progressive and cumulative deformation). Numerical, Finite Element (FE) programs, such as Plaxis 2D, is usually used with proper material models and stage configurations. For walls with simple geometries, simple calculations spreadsheets with cumulative stage-wise calculations are also possible (Al Mohd 2010).

For some walls or systems, excessive deformations are predicted (due to foundation formations, wall geometry etc.) or the walls are constructed in the vicinity of existing structures or having utilities within the area of influence, imposing limitations on wall deformations. As such, additional measures shall be made to either minimize deformation or control deformations occurrence in a timely manner. Minimizing deformations is typically achieved by site preparations (within foundations or retained zones) in addition to strict material specifications and compaction requirements and quality assurance. A far more feasible and cost effective procedure is to control when deformations can occur and minimize their effects on surroundings (other structures and utilities) and the wall facing. The reinforcing geogrids and reinforced fill will undertake majority of the deformation during construction (under geostatic loads) prior to attaching or installing the final protective wall facing.

A case study is presented in this paper that involves a 24.4 m high wall constructed in the hot and humid area of Riyadh, KSA, with a robust, durable and well-finished “Muralex®” steel mesh facing.

2 Case Study

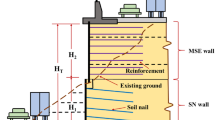

The wall described herein is constructed as part of a mega project in Riyadh, KSA. The wall is nearly 670.0 m long with a maximum height of 22.4 m with additional 1.5 m reinforced concrete wall and traffic surcharge on top (Fig. 1). He facing of the wall is inclined at a slope of 1 horizontal to 10 vertical (1 H: 10 V). The fill used for the construction of the wall (reinforced and retained fill) is rock fill. The wall is founded partly on fill and partly on rock, raising concerns on differential movements (horizontal movement and settlement). A number of alternative retaining wall systems were considered. The Muralex® wall type was selected being the most feasible and efficient system due to construction methodology and sequence which minimizes post-construction differential settlements, flexibility, site adaptability, use of site available material, and expedited construction time.

2.1 Description of Muralex GRS Wall

In the Muralex® GRS wall system, the reinforced soil mass is initially constructed with wrap around facing. Steel dowels are installed/embedded into the reinforced soil mass between the geogrid layers for a sufficient length to provide necessary lateral bracing resistance. The dowels will be connected to the final steel mesh at later stages. The general scheme and concept of the Muralex® facing is shown in Fig. 2.

The main advantages of the Muralex system are:

-

Geogrids as key reinforcing elements are “hidden”, thus protected against UV impact, fire, vandalism and high temperature impact in hot sunny climates;

-

Facing can be installed at any point in time following construction e.g. even weeks after completion of the geogrid reinforced package, thus wall deformations occur before facing installation;

-

The facing is a “hanging facade” without a bearing function for the GRS, elements can be exchanged at any time, e.g. after a vehicle crash against the facing;

-

Flexible and ductile behavior in general, which adapts to total and differential settlements, and seismic loads and impact as well.

2.2 Considerations and Design

Due to project sensitivity, wall height and configuration, foundation soil conditions, and sensitivity of adjacent buildings the wall design carefully considered both stability and deformability criteria. Thus, design calculations were conducted using limit equilibrium (LE) analyses considering allowable stress design (ASD) for overall stability, in addition to numerical simulation using finite element (FE) modeling for performance and deformations evaluations.

2.2.1 Limit Equilibrium Analyses - ASD Design

The LE analyses were initially performed to verify the adequacy of the initially assumed geogrid reinforcement configuration and layout (types, strength, lengths and spacing) considering all design/analyses failure modes (global, internal, compound, sliding, bearing capacity and eccentricity). A customized version of the computer program GGU-international (Huesker stability), was used for design and stability evaluations. This program is capable of analyzing complex geometries with up to 150 layers and types of geogrid reinforcements at variable strength and lengths. The software takes into account both, the stresses and strength of single layers as well as combined reinforcement effects, thus allowing for variable reinforcement lengths. The software also calculates the foundation’s bearing capacity, eccentricity, overturning and sliding stability. It utilizes the limit equilibrium analyses for internal stability, external stability and the compound (internal and external) stability. The ASD was used for different sections with different heights, foundation material (fill or bedrock) and boundary conditions. Typical results of the LE analyses for internal and compound stability are presented in Figs. 3 and 4.

2.2.2 Numerical Simulation

In addition to the LE analyses for safety and strength design, numerical modeling using FE-analyses was performed to verify the safety and evaluate deformations of the proposed retaining structure. FE analyses were performed using the computer program Plaxis (v. 8.5) on selected sections that are considered critical either in terms of stability/safety or where deformations are expected to be highest. The FE analyses modeled the planned construction stages to represent the progressive loading nature and accommodate the actual construction steps, which were provided in the construction method statement.

Plaxis includes a linear-elastic perfectly plastic material model for geogrids based on the axial tensile stiffness of the geogrids in unit of kN/m. The steel mesh is modeled as a plate for which the equivalent Young’s modulus (E), cross-sectional area (A) and moment of inertia (I) are provided. Steel mesh properties were calculated based on the bar diameter and horizontal spacing. The steel anchors (embedded dowels) are also modeled as linear-elastic material. The Hardening Soil (HS) model was selected to simulate the behavior of existing soil strata. The hardening soil model is a non-linear isotropic hardening plasticity model capable of simulating the non-linear behavior of existing soils and accounts for variation of stiffness with effective stress. This modeling approach is capable of capturing behavior of complex walls (El-Sherbiny et al. 2013). The computer program Plaxis evaluates the stability using the friction and cohesion (phi-c) reduction method. Fifteen node triangular elements were used to generate a computer generated randomized mesh with local refinements to optimize calculation time.

The geometric model and layer description are depicted in Fig. 4. Some of the FE analyses results are also enclosed in Figs. 5, 6 and 7. Based on these results, the maximum horizontal deformations were estimated to be in the range of 11.0 to 12.0 cm, and the factor of safety is 2.0 (Fig. 8). The maximum vertical displacement is about 10.0 cm, which is mainly compression of the thick fill mass Fig. 7.

The wall was completed by end of 2015. Survey measurements made during and after completion of the wall revealed horizontal deformations of less than 5.0 cm within the upper parts of the wall, which is less than predicted values. Photographs taken at different stages of construction are depicted in Figs. 9, 10, 11, 12, 13, 14 and 15. In our opinion, they are more useful than any long textual description.

3 Conclusions

A practical case study of an innovative, robust yet flexible, durable, and environmental friendly earth retaining and stabilization system was presented. The wall is of significant height, constructed in high humidity, high temperature area using the Muralex® system. The design process of the wall included numerical simulation for evaluating the deformations and verifying stability and high safety. The measured surveys during construction and after completion showed small deformations, which were lower than calculated from numerical simulations. The wall featured an engineering monument with well-finished surface, and accurate and straight face. This is mainly attributed to the construction methodology of the innovative Muralex® system for which the final facing is installed after wall deformations are mostly completed.

References

Al Mohd, I.A.: Non-typical designs in reinforced earth walls. In: 3rd International Conference on Geosynthetics Middle East, Abu Dhabi, United Arab Emirates, November 2010

Alexiew, D.: High geogrid-reinforced walls with a flexible stone filled facing in a mountainous seismic region. In: Proceedings of the 2nd Pan American Geosynthetics Conference & Exhibition, Lima, Peru (2012)

Alexiew, D., Ayasrah, I.M., Abu-Hassan, M.: Geogrid-reinforced walls with almost vertical facings: specific solutions in different environments. In: 6th International Conference on Geosynthetics Middle East, Abu Dhabi, United Arab Emirates (2013)

El-Sherbiny, R., Ibrahim, E., Salem, A.: Stability of back-to-back mechanically stabilized earth walls. In: Geocongress 2013, Stability and Performance of Slopes and Embankments III, San Diego, California, ASCE, pp. 555–565 (2013)

Guler, E., Alexiew, D., Basbug, E.: Dynamic behavior of geogrid reinforced segmental block walls under earthquake loads. In: Proceedings of the 5th International Conference on Earthquake Geotechnical Engineering, Santiago, Chile (2011)

Guler, E., Alexiew, D., Basbug, E.: The behavior of geogrid reinforced segmental block walls under earthquake loads. Topic: soil improvement and reinforcement. In: Proceedings of the 5th European Geosynthetics Congress, Valencia, Spain, vol. 5, pp. 265–269 (2012)

Acknowledgements

The project and this paper would not be successful without the competence, enthusiasm and informal collaboration of designers, consultants, owner and contractor involved which is highly appreciated and acknowledged. The authors would like to show gratitude to the Applied Science Private University in Jordan for the supporting the first author in time needed for preparation of this paper.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Almohd, I.M., Alexiew, D., El-Sherbiny, R.M. (2018). A Case Study of Efficient Solution for Very High Geogrid-Reinforced Retaining Wall. In: Bouassida, M., Meguid, M. (eds) Ground Improvement and Earth Structures. GeoMEast 2017. Sustainable Civil Infrastructures. Springer, Cham. https://doi.org/10.1007/978-3-319-63889-8_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-63889-8_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-63888-1

Online ISBN: 978-3-319-63889-8

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)