Abstract

Energy Saving is a serious challenge faced by mankind due to rapid increase in energy depletion. Geothermal energy along with nanotechnology is used in the proposed air conditioning model. This paper reports the design and experimental investigation of a vertical closed loop geothermal air conditioner. The system operates under different ground water condition at different mass flow rate. Nanofluid Al2O3R134a has been used as a working fluid. The result reports that the geothermal air conditioning system using refrigerant R134a is better than the conventional air conditioning system both in terms of performance and power saving. Although the best output characteristics are achieved by using geothermal air conditioner by means of nanofluid. The COP is showing some promising results and shows outgrowth of nanotechnology in renewable energy system.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

13.1 Introduction

Now a day energy requirement is increasing rapidly due to the high population rate all over the world. As the energy consumption is growing fast, energy crisis is one of the major topics of concern in the society. Energy resources can be divided into three categories including fossil fuels, renewable energy and nuclear energy. Fossil fuel causes a tremendous amount of air pollution whereas Nuclear energy can cause serious problems for the environment and human health. But in other hand Renewable energy sources, which are sustainable and environmental friendly, are hence under emerging exploitation. Geothermal energy, has profuse quantity of storage as well as significant base-load potential, expected to make an increasing contribution for energy supply in a near future.

Large amount of electric power is consumed by thermal systems like air conditioner and refrigerators. Heat exchanger is an important member in this group. Modification of heat exchanger design can improve the efficiency of the system and enhance heat transfer [1,2,3,4,5,6]. Heat exchanger is an integrated component of condenser. As a result, many researchers investigate to reduce the power consumption using alternative ways. Misra et al. [7] prepared an experiment of EAHE system in hybrid with air conditioner (AC) at Ajmer in India. From the experiment it was concluded that suitable combination of EAHE system with conventional AC in mode-III could preserve substantial amount of energy. Said et al. [8] experimented feasibility of air-conditioning systems by using ground fixed condensers. When compared to original air cooled condenser it was found that there is an increment in COP and reduced electrical power consumption. Wang et al. [9] experienced performance of a DX-GCHP system in heating mode. The values of COP of the heat pump and the whole system are found to be 3.55, 3.28 and 0.599, 0.553 respectively. Coumaressin and Palaniradja [10] use CuO-R134a in the vapour compression system and found that evaporator heat transfer coefficient increases due to the use of nanoCuO. Shafahi et al. [11] by utilizing nanofluids study the thermal performance of a cylindrical heat pipe and establish that particles that are smaller in size have a more prominent outcome on the temperature gradient along the heat pipe.

So as to have effective refrigeration and air conditioning nanofluids are used along with conventional refrigerant. Nanofluids are a new class of fluid that are prepared by suspending nano size particles in base fluid having a good increment in the heat transfer rate. R134a is widely used refrigerant for cooling purpose. Nanoparticles of Al2O3 having 0.2% concentration is mixed with the base fluid, refrigerant R134a. This nanofluid is used as a refrigerant in the geothermal air conditioner in order to have a renewable system with an enhancement of coefficient of performance (COP) of the air conditioner and promising decrement in power consumption. This experiment is a step towards sustainable development and a cleaner environment.

13.2 Experimental Setup and Procedure

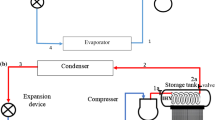

Figure 13.1 shows the experimental set-up which consists of mainly 5 components—Compressor (1.5 ton capacity), extended surface heat exchanger, water maintained condenser (Capacity—80 L), expansion valve and an evaporator unit. The electrical circuit contains ammeter, voltmeter, energy meter and automated cut-off control. For precious measurement of temperature and pressure of various sections in that setup 4 thermocouples and 4 pressure sensors are used.

Figure 13.2 shows the schematic diagram of the experimental test rig in which it is clearly seen that the condenser is dipped in water having constant temperature which acts as geothermal sink for the rejection of heat.

The underground water act as a fixed temperature infinite source or fixed temperature sink. In conventional air refrigeration heat rejection is performed incorporating forced convectional heat transfer, which can be at high temperature at some instant. But in this case underground water at constant temperature is used as sink to reject the heat in the water maintained condenser. So the heat transfer in the condenser will be enhanced by increased temperature difference and therefore the load on the compressor as well as the blower power consumption in case of conventional AC will be decreased. A comparative study with conventional air conditioning, which uses blower forced convection heat transfer mechanism is also carried out.

Water in condenser is maintained at constant temperature and varied in between 15°–20°C, simulating the constant temperature sink, (which is the groundwater in actual scenario). The condenser coils will run through this water reservoir for rejecting heat. The water in the reservoir will be recirculated through the cooling chamber in order to be cooled for maintaining the temperature close to mean groundwater temperature.

13.3 Data Reduction

Refrigerating Effect,

Compressor Work,

Theoretical COP,

The density of conditioned air,

Mass flow rate of air,

Actual Ref. Effect,

Actual Compressor Work,

Actual COP,

Heat rejected by the condenser to the water due to convection,

Density of nanofluid,

Specific heat of nanofluids,

13.4 Results and Discussion

From the Fig. 13.3, one can easily say that the geothermal copper tube is more efficient at any flow rate of refrigerant through the cycle. COP is higher in water maintained condenser in any flow rate than that of the conventional blower forced convectional air conditioning setup. Though using more amount of refrigerant in the test set-up do not increase the COP at the same rate after a certain amount. But when R134a is substituted by using nanofluid Al2O3R134a theoretical COP shows a significant growth in COP. The nature of the curve of actual COP curve is almost similar like the theoretical COP curve. From the figure one can see that mass flow rate up to 0.03 there is not much variations between geo-thermal COP and the conventional one, this is because at lower mass flow rate geo-thermal air conditioner machine is not that much promising as compared to conventional air conditioning machine. But, at higher mass flow rate COP is higher in water maintained condenser than that of the conventional blower forced convectional air conditioning setup. While using nanofluid Al2O3R134a as a refrigerant the actual COP though decreases due to some losses through pipes, ducts, etc. but still its value is more as compared toR134a refrigerant based geothermal one. It can be seen that for all the cases COP increase with the increase of mass flow rate.

Electrical energy consumption (kW) for different ground water temperatures (20o, 18o, 16o and 13o) in summer season is presented in Fig. 13.4. It is observed from Fig. 13.4 that power consumption is higher for 20 °C ground water temperature as compared to other tested ground water temperature. It is also observed as per percentage change in electrical energy consumption w.r.t. all the tested ground water temperature, ground water temperature at 13 °C provides better results.

13.5 Conclusion

In present era growth in construction sector is remarkable, which impacts on increase in energy demand mainly due to space heating and cooling. For space heating and cooling Geo-thermal air-conditioner system is the proficient and energy efficient equipment. Incorporation of nanofluid Al2O3R134a as a refrigerant along with the geothermal system shows some significant result. The most interesting ones are:

-

saving energy and reduce the problem regarding heat rejected to surrounding air;

-

reducing the noise of condensing fan;

-

reducing electrical energy by reducing compressor’s load of 1.5 TR window AC. Electrical energy consumption as compared to conventional 1.5 TR window AC is reduced by 9.77% during summer season in vertical configuration with nanofluid Al2O3R134a as a refrigerant.

References

S. Bhattacharyya, H. Chattopadhyay, Computational of studies of heat transfer enhancement in turbulent channel flow with twisted strip inserts, in Proceedings of CHT-15, ICHMT International Symposium on Advances in Computational Heat Transfer, Rutgers University, Piscataway, USA (2015)

S. Bhattacharyya, A. Roy, A. Bhattacharyya, K. Dey, D. Seth, Computational heat transfer analysis of a counter-flow heat exchanger with fins, in Proceedings of Recent Developments in Mechanical Engineering, Pune (2015)

S. Bhattacharyya, H. Chattopadhyay, S.K. Saha, Numerical study on heat transfer enhancement of laminar flow through a circular tube with artificial rib roughness. J. Refrig. Air Cond. Heat Vent. 1(3), 14– 19 (2014)

S. Bhattacharyya, A. Roy, H. Chattopadhyay, A. Rakshit, A numerical investigation based on heat transfer and fluid flow characteristics of air in a circular tube heat exchanger with inclined ribs, in Proceedings of ICACE 2015, Recent Advances in Chemical Engineering (2016), pp. 11–20

S. Bhattacharyya, H. Chattopadhyay, S. Bandyopadhyay, Numerical study on heat transfer enhancement through a circular duct fitted with centretrimmed twisted tape. Int. J. Heat Technol. 34(3), 401–406 (2016)

S. Bhattacharyya, H. Chattopadhyay, A. Roy, A.A. Rakshit, I.R. Chowdhury, Thermohydraulic transport characteristics of micro mixer in micro channel, in Proceedings of ICACE 2015, Recent Advances in Chemical Engineering (2016), pp. 29–39

R. Misra, V. Bansal, G.D. Agarwal, J. Mathur, T. Aseri, Thermal performance investigation of hybrid earth air tunnel heat exchanger. Energy Build. 49, 531–535 (2012)

S. Said, M. Habib, E. Mokheimer, M. El-Sharqawi, Feasibility of using groundcoupled condensers in A/C systems. Geothermics 39(2), 201–204 (2010)

X. Wang, C. Ma, Y. Lu, An experimental study of a direct expansion ground-coupled heat pump system in heating mode. Int. J. Energy Res. 33, 1367–1383 (2009)

T. Coumaressin, K. Palaniradja, Performance analysis of a refrigeration system using nano fluid. Int. J. Adv. Mech. Eng. 4(4), 459–470 (2014). ISSN 2250-3234

M. Shafahi, V. Bianco, K. Vafai, O. Manca, An investigation of the thermal performance of cylindrical heat pipes using nanofluids. Int. J. Heat Mass Transf. 53, 376–383 (2010)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Bhattacharyya, S., Das, P., Haldar, A., Rakshit, A. (2018). Performance Analysis of a Geothermal Air Conditioner Using Nanofluid. In: Anand, G., Pandey, J., Rana, S. (eds) Nanotechnology for Energy and Water . ICNEW 2017. Springer Proceedings in Energy. Springer, Cham. https://doi.org/10.1007/978-3-319-63085-4_13

Download citation

DOI: https://doi.org/10.1007/978-3-319-63085-4_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-63084-7

Online ISBN: 978-3-319-63085-4

eBook Packages: EnergyEnergy (R0)