Abstract

The objective of this technical paper was to propose the optimum partial replacement of cement (PRC) by rice husk ash (RHA) and fly ash (FA) based on the complete consumption (CC) of calcium hydroxide (CH) from hydration and the strength activity index (SAI) based on equivalent calcium silicate hydrate (C-S-H) as well as the propagation of uncertainty due to randomness inherent in main chemical compositions in cement, RHA and FA. Firstly the hydration and pozzolanic reactions as well as stoichiometry were reviewed. Then the optimum PRC by RHA and FA based on CC of CH was formulated.

The long-term SAI would be proposed based on equivalent C-S-H. Contribution to strength by calcium aluminate hydrate and calcium ferrite hydrate would be transformed to equivalent C-S-H. Based on the reasons mentioned above and the given values of strength for the age of 360 days, the long-term SAI could be defined. This concept could be extended for the SAI at any age based on Bogue’s curve and nano-structures of C-H-S gel.

After that the propagation of uncertainty due to main chemical compositions in cement, RHA and FA was discussed. The linear characteristic of the gradient of a function was derived for an estimate. Monte-Carlo simulations together with Goodness-Of-Fit tests were proposed for the better estimates. The reliability analyses for applying the suitable PRC were reviewed.

Finally an applicability of the concepts mentioned above based on statistical data of materials available was demonstrated. The results from analyses were consistent with the tested results by the authors and other researchers. The results of this study provided guidelines of suitable utilization of RHA and FA for PRC. It was interesting to note that these concepts could be extended to optimize PRC by combination of other types of pozzolan which were described in the other papers of the authors.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

- Calcium Hydroxide (CH)

- Strength Activity Index (SAI)

- Calcium Silicate Hydrate (C-S-H)

- Pozzolanic Reaction

- Main Chemical Composition

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Cement content in concrete is the main cost for the concrete production. The reduction of cement content in concrete mix proportion would lower the cost of concrete and would increase the competitiveness in marketing. Therefore the probabilistic concrete mix design for mass production of concrete has been commercially applied (Kamollertvara and Ouypornprasert 2015). Dumrongsil et al. (2000) studied the suitable partial replacement of cement by rice husk ash (RHA). In this study the optimum replacement of cement by RHA was derived by the concept of calcium oxide equivalent. Results showed that the values of compressive strength of concrete mixed with RHA of the age less than 28 days tend to be lower than those of concrete mixed with Ordinary Portland Cement (OPC). However with suitable replacements of cement by RHA the values of compressive strength of concrete can be higher than those of ordinary concrete even at the early age (Habeeb and Mahmud 2010). The major reason might be the heat of hydration of cement mixed with pozzolan could surpass that of OPC (Langan et al. 2002).

In this technical paper the optimum replacement of cement by RHA and fly ash based on stoichiometry of the complete consumption of calcium hydroxide from hydration of cement and pozzolanic reactions of pozzolanic substances as well as the long-term strength activity index based on Equivalent Strength of Calcium Silicate Hydrates (C-S-H) would be proposed. This concept could be extended for the strength activity index at any age based on nano-structures of C-S-H gel. Since the chemical compositions of cement and RHA might vary because of the production process, propagation of uncertainty with respect to main chemical compositions would also be discussed. To assure the quality of concrete mixed with RHA the suitable replacement of cement by RHA should be determined with the target confidence interval. Once the particular replacement would be selected the distribution of the long-term strength activity index could be obtained. Then reliability of the selected replacement could be determined accurately by Monte-Carlo simulations or approximately by the advanced First-Order Second-Moment (FOSM) method. The applicability of the proposed formulations could be demonstrated by a set of data available in hand.

2 Chemical Reactions and Stoichiometry

2.1 General Remarks

It is usual for the cement chemist to use the following abbreviations for discussions about hydration reactions of cement and pozzolanic reactions of pozzolan: C for calcium oxide (CaO), S for silicon dioxide (SiO2), H for water (H2O), A for aluminum oxide \( (Al_{2} O{}_{3}) \), F for ferric oxide \( (Fe_{2} O{}_{3}) \), \( CH \) for calcium hydroxide \( (Ca(OH){}_{2}) \), \( C_{3} S \) for tricalcium silicate \( (3CaO \cdot SiO{}_{2}) \), \( C_{2} S \) for dicalcium silicate \( (2CaO \cdot SiO{}_{2}) \), \( C_{3} A \) for tricalcium aluminate \( (3CaO \cdot Al_{2} O{}_{3}) \), \( C_{4} AF \) for tetracalcium alumino ferrite \( (4CaO \cdot Al_{2} O{}_{3} \cdot Fe_{2} O_{3} ) \), \( C_{3} S_{2} H_{3} \) or \( C - S - H \) for calcium silicate hydrate \( (3CaO \cdot 2SiO{}_{2}.3H_{2} O) \), \( C_{3} AH_{6} \) for calcium aluminate hydrate \( (3CaO \cdot Al_{2} O{}_{3}.6H_{2} O) \) and \( C_{3} FH_{6} \) for calcium ferrite hydrate \( (3CaO \cdot Fe_{2} O{}_{3}.6H_{2} O) \). They are summarized in Table 1.

2.2 Hydration, Pozzolanic Reactions and Stoichiometry

2.2.1 Hydration

-

(1)

Hydration of Tricalcium Silicate \( (C_{3} S) \)

$$ 2(3CaO \cdot SiO{}_{2}) + 6H_{2} O \to 3CaO \cdot 2SiO_{2} \cdot 3H_{2} O + 3Ca(OH)_{2} $$(1)or

$$ 2C_{3} S + 6H \to C_{3} S_{2} H_{3} + 3CH $$(2) -

(2)

Hydration of Dicalcium Silicate \( (C_{2} S) \)

$$ 2(2CaO \cdot SiO{}_{2}) + 4H_{2} O \to 3CaO \cdot 2SiO_{2} \cdot 3H_{2} O + Ca(OH)_{2} $$(3)or

$$ 2C_{2} S + 4H \to C_{3} S_{2} H_{3} + CH $$(4) -

(3)

Hydration of Tricalcium Aluminate \( (C_{3} A) \)

$$ 3CaO \cdot AlO{}_{3} + 6H_{2} O \to 3CaO \cdot Al_{2} O_{3} \cdot 6H_{2} O $$(5)or

$$ C_{3} A + 6H \to C_{3} AH_{6} $$(6) -

(4)

Hydration of Tetracalcium Alumino Ferrite (\( C_{4} AF \))

$$ \begin{aligned} & 4CaO \cdot Al_{2} O{}_{3} \cdot Fe_{2} O_{3} + 2(Ca(OH)_{2} ) + 10H_{2} O \to \\ & 3CaO \cdot Al_{2} O_{3} \cdot 6H_{2} O + 3CaO \cdot Fe_{2} O_{3} \cdot 6H_{2} O \\ \end{aligned} $$(7)or

$$ C_{4} AF + 2CH + 10H \to C_{3} AH_{6} + C_{3} FH_{6} $$(8)

2.2.2 Pozzolanic Reactions

-

(1)

Additional Calcium Hydroxide from Calcium Oxide \( (CaO) \) in Pozzolan

$$ CaO + H_{2} O \to Ca(OH)_{2} $$(9)or

$$ C + H \to CH $$(10) -

(2)

Pozzolanic Reaction of Silicon Dioxide \( (SiO_{2} ) \)

$$ 3Ca(OH)_{2} + 2SiO_{2} \to 3CaO \cdot 2SiO_{2} \cdot 3H_{2} O $$(11)or

$$ 3CH + 2S \to C_{3} S_{2} H{}_{3} $$(12) -

(3)

Pozzolanic Reaction of Aluminum Oxide \( (Al_{2} O_{3} ) \)

$$ 3Ca(OH)_{2} + Al_{2} O_{3} + 3H_{2} O \to 3CaO \cdot Al_{2} O_{3} \cdot 6H_{2} O $$(13)or

$$ 3CH + A + 3H \to C_{3} AH{}_{6} $$(14)

2.2.3 Rate of Pozzolanic Reactions

Chansawang and Ouypornprasert (2017) studied that rate of pozzolanic reactions of nano silica, nano aluminium oxide, RHA and fly ash by the complexometric titration technique with EDTA (ethylenediaminetetraacetic acid). The indicator was Eriochrome Black T. Figure 1 showed the quantity of Ca2+ reacted in the Ca(OH)2 solution after elapsed time. It could be concluded that RHA could react with Ca(OH)2 much faster than that of fly ash (FA).

2.3 Stoichiometry

Atomic- and molecular weights of all substances related in stoichiometry of hydration- and pozzolanic reactions are summarized in Table 2, 3 and 4. This information will be used throughout the following discussions.

2.4 Optimum Replacement of Cement by Rice Husk Ash and Fly Ash

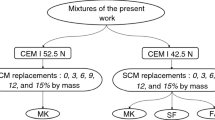

In this technical paper the optimum replacement of cement by rice husk ash (RHA) and fly ash (FA) will be considered by the complete consumption of calcium hydroxide \( (CH) \) from hydration reactions of main minerals in cement by the main chemical compositions in RHA (Table 6).

Let \( fC_{r} \), \( fS_{r} \) and \( fA_{r} \) be the fraction of \( C \), \( S \) and \( A \) in RHA, respectively, \( fC_{f} \), \( fS_{f} \) and \( fA_{f} \) be the fraction of \( C \), \( S \) and \( A \) in FA (Fly Ash), respectively, \( r_{t} \), \( r_{f} \) and \( r_{r} \) be the partial replacement of cement by RHA and FA, by FA and by RHA, respectively. Then the fractional calcium hydroxide \( (fCH) \) from hydration reactions of cement in unit weight replaced by RHA and FA with the ratio \( r_{t} \) would be \( fCH \cdot \left( {1 - r_{t} } \right) \).

Where \( fC_{3} S \), \( fC_{2} S \) and \( fC_{4} AF \) are the fraction of \( C_{3} S \), \( C_{2} S \) and \( C_{4} AF \) in cement per unit weight, respectively. \( r_{{CH - C_{3} S}} \), \( r_{{CH - C_{2} S}} \) and \( r_{{CH - C_{4} AF}} \) are the ratios of \( CH \) from the hydration reactions of \( C_{3} S \), \( C_{2} S \) and \( fC_{4} AF \), respectively. Their values are:

Where \( w_{CH} \), \( w_{{C_{3} S}} \), \( w_{{C_{2} S}} \) and \( w_{{C_{4} AF}} \) are molecular weight of \( CH \), \( C_{3} S \), \( C_{2} S \) and \( C_{4} AF \), respectively (See Table 2 and 3).

Since calcium oxide \( (CaO) \) in RHA and FA can be soluble in water and yield calcium hydroxide as shown in Eqs. (9) and (10) and the \( SiO_{2} \) content in RHA is usually much more than \( CaO \), it might be assumed that amount of \( SiO_{2} \) in RHA and FA is always more than the amount required for the pozzolanic reaction with \( CaO \) in RHA and FA itself, there will be adequate residual amount of \( SiO_{2} \) to react with the residual calcium hydroxide from hydration of cement (see Eqs. (11) and (12)). Aluminum oxide \( (Al_{2} O{}_{3}) \) in RHA and FA can also react with the residual calcium hydroxide from hydration of cement (see Eqs. (13) and (14)).

The residual \( CH \) from Eq. (15) can be completely consumed in pozzolanic reactions with \( SiO_{2} \) and \( Al_{2} O{}_{3} \) as shown in Eq. (19).

Let

and

Where \( r_{CS} \) is the ratio by weight of \( C \) to \( S \) for complete pozzolanic reactions of \( SiO_{2} \) whose value is given in Eq. (22).

Where \( w_{C} \) and \( w_{S} \) are the molecular weights of \( C \) and \( S \), respectively (see Table 2).

Then Eq. (19) reduces to:

Where \( r_{SCH} \) and \( r_{ACH} \) are the ratios of molecular weights that calcium hydroxide reacts with silicon dioxide and aluminium oxide, respectively. Their values are shown in Eqs. (25) and (26), respectively.

Then \( r_{f} \) can be rewritten from Eq. (23) as shown in Eq. (27).

Similarly \( r_{r} \) can be rewritten from Eq. (24) as shown in Eq. (28).

In the case of cement is replaced by RHA only (no FA) \( r_{r} = r_{t} \) and \( r_{f} = 0 \):

In the case of cement is replaced by FA only (no RHA) \( r_{f} = r_{t} \) and \( r_{r} = 0 \):

Optimum partial replacement of cement by mixed ash of RHA and FA is shown in Fig. 2. It can be seen that the optimum fractional replacement of cement by rice husk ash is much lower than that of fly ash. There is a straight line connected between the two optimum points. The diagonal lines show the fractional replacement for each type of pozzolan.

2.5 The Whole Range of Cement Replacement by Rice Husk Ash and Fly Ash

For the practical application it is also interesting to determine the chemical reactions and the consequences in the range of the cement replacement below and above the point of complete consumption of calcium hydroxide (CC). For the sake of further discussions the fractional replacement of cement by ash below the point of complete consumption should be called the state of the incomplete consumption (IC); whereas the fractional replacement of cement by ash beyond the point of complete consumption should be called the state of the beyond-complete consumption (BC). In the range of IC until CC all ash should be consumed. Otherwise ash should be partially consumed.

3 Strength Activity Index

3.1 Long-Term Strength Activity Index

3.1.1 Complete Consumption of Calcium Hydroxide

Strength of cement paste is mainly contributed by C-S-H from \( C_{3} S \) and \( C_{2} S \). Additional contributions are from \( C_{3} AH_{6} \), the product of \( C_{3} A \) and \( C_{4} AF \). With rice husk ash and fly ash in binder C-S-H and \( C_{3} AH_{6} \) from pozzolanic reactions have not been clearly understood in the term of rate of reactions as well as the strength development. It was concluded that C-S-H from pozzolanic reactions had the same structure as C-S-H from hydration of cement (Taylor 1997). However, at the early age of cement paste the rate of hydration of \( C_{2} S \) as well as the strength development is much slower than developed from \( C_{3} S \). Fortunately the long-term strength of C-S-H developed from \( C_{2} S \) is insignificantly lower than that from \( C_{3} S \), the long-term strength of C-S-H from the pozzolanic reaction could be assumed to be the average strength of C-S-H from \( C_{3} S \) and \( C_{2} S \) without significant errors. Furthermore the contribution of \( C_{3} AH_{6} \) from the hydration of cement and pozzolanic reactions take minor contribution to the overall strength of binder. Therefore the strength of \( C_{3} AH_{6} \) can be assumed equal for both type of reactions. Based on the reasons mentioned above and the given values of strength for the age of 360 days (Bogue 1955) the long-term strength activity index \( (SAI) \) can be defined as the strength of binder paste over the strength of cement paste at the age of 360 days as shown below:

Where \( \alpha s = 72.0 \), \( \beta s = 71.265 \), \( \gamma s = 8.082 \) and \( \delta s = 5.143 \). Ouypornprasert et al. (2016) suggested that for long-term strength activity index \( \alpha \beta \) could be determined by taking the average of without a significant error i.e. \( \alpha \beta = 71.6325 \), since the long-term values of \( \alpha s \) and \( \beta s \) are very close to each other.

3.1.2 Incomplete Consumption of Calcium Hydroxide

In this range of replacement all ash should be consumed. Equations (31) and (32) are still valid for determining the values of strength activity index.

3.1.3 Beyond-Complete Consumption of Calcium Hydroxide

In this range of replacement not all ash should be consumed. Again, only Eq. (32) is still valid for determining the contribution of \( SAI \) from cement, but \( SAI \) should be determined from different conditions based on: (1) the total pozzolan and the calcium hydroxide remained from hydration of cement plus additional calcium hydroxide produced from pozzolan (CHc), (2) calcium oxide content from pozzolan (CHC), (3) aluminium oxide from pozzolan (CHA) and (4) the total pozzolanic content from pozzolan (CHP). These quantities can be determined from Eqs. (33)–(36), respectively.

-

(i)

For \( CHC \le CHc \) and \( CHA \le CHc - CHC \), \( SAI \) should be determined from Eq. (37).

$$ SAI = \frac{{fa \cdot \left( {1 - r_{t} } \right) + \frac{1}{3} \cdot CHC \cdot \alpha \beta + \frac{1}{3} \cdot CHA \cdot \gamma }}{fa} $$(37) -

(ii)

For \( CHC \le CHc \) and \( CHA > CHc - CHC \), \( SAI \) should be determined from Eq. (38).

$$ SAI = \frac{{fa \cdot \left( {1 - r_{t} } \right) + \frac{1}{3} \cdot CHC \cdot \alpha \beta + \frac{1}{3} \cdot \left( {CHc - CHC} \right) \cdot \gamma }}{fa} $$(38) -

(iii)

For \( CHC \ge CHc \), \( SAI \) should be determined from Eq. (39).

$$ SAI = \frac{{fa \cdot \left( {1 - r_{t} } \right) + \frac{1}{3} \cdot CHc \cdot \alpha \beta }}{fa} $$(39)

3.2 Diagram of the Long-Term Strength Activity Index

Based on \( SAI \) at state of IC (Incomplete Consumption), CC (Complete Consumption) and BC (Beyond-Complete Consumption) using Eqs. (31)–(39) a diagram for the long-term strength activity index with respect to the fractional replacement of cement by ash could be constructed.

Within the range of IC the calcium hydroxide produced by hydration and dissolution of CaO in ash will not be used up. The values of \( SAI \) can be determined by Eq. (31). It could be observed that once \( r_{t} \begin{array}{*{20}c} {} \\ \end{array} or\begin{array}{*{20}c} {} \\ \end{array} r_{r} + r_{f} \) is fixed, Eq. (31) is linear with respect to \( r_{t} \) up to the point of CC.

Within the range of BC additional pozzolanic reaction is still possible. A typical diagram for the long-term \( SAI \) can be shown in Fig. 3. For the ash with high silica content the contributions of CaO and Alumina to \( SAI \) approaches zero. The values of \( SAI \) determined from Eqs. (37), (38) and (39) are nearly equal. Therefore the value of \( SAI \) will decrease linearly with respect to the fractional replacement of cement by ash. For the ash with high content of CaO the point of CC will shift to the right considerably. Just right to the point of CC the value of \( SAI \) will drop abruptly. Within the range of BC, again the value of \( SAI \) will change linearly with respect to the fractional replacement of cement by ash.

3.2.1 Effects of Silica Content on the Long-Term \( SAI \) Diagram

It should be noted that rice husk ash can contain very high content of reactive silica, but very low contents of calcium oxide and alumina. Furthermore its chemical composition is quite similar to silica fume. A set of hypothetical ashes with high content of silica are assumed. Thus, the effects of silica content in ash can be shown in Fig. 5. It could be observed that the higher the silica content in ash, the higher the peak of the strength activity index at CC, the steeper the slope of the \( SAI \) curve in the IC range, but the lower the fractional replacement of cement by ash at CC with the constant slope of \( SAI \) curve within the BC range.

3.2.2 Effects of Calcium Oxide Content on the Long-Term \( SAI \) Diagram

Class F fly ash may contain small CaO content; whereas Class C fly ash may contain high content of CaO. Therefore a set of hypothetical ashes with various contents of silica are assumed. Thus, the effects of CaO content in ash can be shown in Fig. 6. It could be observed that the higher the CaO content in ash, the higher the peak of the \( SAI \) at CC, the higher the fractional replacement of cement by ash at CC, the wider the range of possible replacement, the flatter the slope of the \( SAI \) curve in the IC range and the BC range.

3.2.3 \( SAI \) Diagram for Rice Husk Ask, Fly Ash and Mixed Ashes

Figure 7 compares the diagrams of the long-term \( SAI \) with respect to the total fractional replacement of cement by rice husk ash, fly ash and mixed ashes of rice husk ash and fly ash. It should be observed that the peak value of \( SAI \) for the cement replacement by rice husk ash is higher than that of fly ash, but the fractional cement replacement by rice husk ash is much lower than that of fly ash. There is a line connecting these two peaks. This line represents the point of CC for mixed ashes of rice husk ash and fly ash. For a given value of the total fractional cement replacement by mixed ashes the optimum ratio of rice husk ash and fly ash can be determined from Eqs. (28) and (27), respectively.

Since any type of ash may contain some amount of CaO, silica and alumina, it should be represented best in term of mixed ash. Thus, the typical diagram for the long-term \( SAI \) of mixed ash may have the shape like that shown in Fig. 4.

3.3 Strength Activity Index for Any Age

The long-term strength activity index can be extended for predicting strength activity index for different ages and different surface areas. The coefficients could be obtained by curve fitting of data from tests carried out by many investigators such as Habeeb and Mahmud (2010), Le and Ludwig (2016), Khalil et al. (2014), Nawaz et al. (2016) and Chatveera and Nimityongskul (1994). Details will be out of the scope of this technical paper and will be discussed in the authors’ complete research project (2017).

For the strength activity index at other ages the values of strength of C-S-H from \( C_{3} S \) and \( C_{2} S \) are rather different at early ages. However the difference in values would decrease with the increasing age. Since the development of strength of C-S-H products from pozzolanic reactions of pozzolan is still not clear, it should be studied extensively so that we can use rice husk ash and fly ash in partial replacement of cement more appropriately and with more confidence. To demonstrate how the strength activity index at other ages could be extended, again the values of strength of main minerals in cement were measured directly from Bogue’s curve (Bogue 1955). For the short-term cases, however, \( \beta s \) could be much lower than \( \alpha s \), for example at the age of 28 days \( \alpha s = 47.76 \), \( \beta s = 5.89 \), \( \gamma s = 4.58 \) and \( \delta s = 2.77 \). Therefore a closer look for the value of \( \alpha \beta \) should be considered.

3.3.1 Effects of CaO/SiO2 Ratio on Nano-structures of C-S-H and Strength Activity Index

Taylor (1986) showed that the Ca/Si ratio effected on the form of nanostructure of C-S-H. The chain of Jennite would be formed with the Ca/Si ratio in the range of 1.6–2.2. Whereas the chain of Tobermorite could be formed with the Ca/Si ratio in the range of 0.8–1.2. Taylor (1997) summarized from results of many researchers that C-S-H type I was the fibrous nanostructure and C-S-H type II was the honeycombs nanostructure. From the compositional standpoint Jennite and the C-S-H (II) are closer to C-S-H gel than 1.4 nm Tobermorite and C-S-H (I). Skinner et al. (2010) concluded from the total X-ray scattering measurements for the nanostructure of C-S-H in cement that the C-S-H component in hydrated tricalcium silicate was similar to C-S-H (I).

Furthermore James and Rao (1986) claimed that the CaO/SiO2 ratio of 0.65 was the lower limit for the forward pozzolanic reaction. Based on the concept of complete consumption of calcium hydroxide proposed by the authors the CaO/SiO2 ratio of 1.40 is within the forward pozzolanic reaction. For the sake of further discussions we should convert the Ca/Si ratios to the CaO/SiO2 ratios by the factor of 0.654. The relationship between CaO/SiO2 and the fractional replacement of cement by ash – nanostructures of C-S-H is shown in Fig. 8. Based on the reasons shown above the αs strength activity index \( (SAI) \) will be selected to represent tricalcium silicate, C-S-H (I), and Tobermorite. Whereas the βs \( SAI \) will be selected to represent dicalcium silicate, C-S-H (II), and Jennite.

Figure 8 showed the relationship between the CaO/SiO2 ratio and the fractional replacement of cement by ash in view of the consumption of calcium hydroxide. At the point of the complete consumption (CC) of calcium hydroxide (CH) the CaO/SiO2 ratio = 1.4 corresponds clearly to the Tobermorite and \( SAI \). With the CaO/SiO2 ratio above this point the CaO/SiO2 ratio increases rapidly with the decrease of the replacement of cement and the pozzolanic reaction proceed rapidly and the \( SAI \) is, again, βs. Above the upper limit of the CaO/SiO2 ratio = 1.439 the \( SAI \) is assumed constant at βs. This interval of CaO/SiO2 ratio above CC should be called the interval of incomplete consumption of calcium hydroxide (IC). Below the complete consumption of CH the CaO/SiO2 ratio decreases slowly with the increment of the cement replacement by ash. This interval should be called beyond-complete consumption of CH (BC). The lower bound for the βs \( SAI \) occurs at the CaO/SiO2 ratio = 1.047. The αs \( SAI \) is in the interval of the CaO/SiO2 ratio of (0.523, 0.785). It is interesting to note that the lower bound of forward pozzolanic reaction of 0.65 lies within this interval. The practical values of cement replacement by ash are far above this limit. The linear extension is assumed for the αβ \( SAI \) for the gap of the CaO/SiO2 ratios of (0.785,1.047). Based on these assumptions the average αβ \( SAI \) for the whole range of the pozzolanic reaction for ash or mixed ashes could be determined. The relationship of the αβ \( SAI \) and C-S-H \( SAI \) to the fractional replacement of cement by ash could be depicted in Figs. 9 and 10, respectively.

3.3.2 Other Factors Effecting Strength Activity Index

Hydration reaction, formation of calcium hydroxide by dissolving calcium oxide (quicklime) in water and pozzolanic reactions of silica and alumina are all exothermic reactions. Langan et al. (2002), Tokyay et al. (2010) and Över (2012) concluded that the presence of silica fume, fly ash, rice husk ash and other types of pozzolan could accelerate or retard heat evolution in hydration of Portland cement at the early age. Therefore it may result in increasing and decreasing of strength activity index at the early age. A diagram for the long-term strength activity index with respect to the fractional replacement of cement by ash could be compared with the corresponding diagrame for the earlier ages as shown in Fig. 11.

Many other factors may also effect on the strength activity index of cement paste mixed with ash such as chemical composition of and Portland cement and ash, physical properties of ash such as shape of particles, particle size distribution, fineness modulus or surface area of cement and ash, heat evolution of hydration, type and dose of superplasticizer and environmental conditions. All these factors are, however, out of scope of this technical paper.

Uncertainty in chemical composition of and Portland cement and ash can also effect on the strength activity index and will be discussed in a following subsection.

3.4 Short-Term and Long-Term SAI Diagrams for Rice Husk Ask, Fly Ash and Mixed Ashes

Long-term SAI for rice husk ash and fly ash could be understood in view of diagrams shown in Figs. 3 and 4, respectively. Furthermore the scenario of SAI diagrams at several ages for rice husk ash or fly ash or any type of pozzolan is depicted in Fig. 11. It can be seen clearly that the older the age, the higher would be the values in the SAI diagram.

3.5 Results from the Authors

A series of tests for specimens of cement mortars mixed with silica fume, rice husk ash and fly ash have been carried out. The ordinary Portland cement type I was used. The range of fractional replacement of cement by pozzolan covered IC, CC and BC. The water binder ratios were in the range of 0.4–0.5. The mortar specimens were in the size of a 50×50×50 mm3 cube. All specimens were controlled by 110 + 5% of the flow table test. No high range reducing is added for the controlled specimens and the specimens with cement replacement by fly ash. However, small amount of high range water reducing agent were added for the specimens with cement replacement by silica fume or rice husk ash to achieve the controlled flow. All specimens were cured in filtered underground water.

The main chemical compositions of cement were C3S (60.88%), C2S (14.86%), C3A (8.47%) and C4AF (10.29%). Three ash samples SF, RHA and FA composed of silica (SiO2) 89.36, 74.64 and 35.83%, respectively, alumina (Al2O3) 0.42, 0.21 and 21.27%, respectively, and CaO 0.45, 0.74 and 16.17%, respectively.

Some of these results within the range of IC were plotted against the short-term – and long-term \( SAI \) diagrams as shown in Figs. 12, 13 and 14 for silica fume, rice husk ash and fly ash, respectively. More results within the range of BC were referred to Ouypornprasert et al. (2017).

It should be observed that the values of \( SAI \) for the tested results could be a slightly higher or lower than the corresponding predicted values at the same age from the models. However, all the actual values of \( SAI \) were still far below the corresponding long-term predicted values from the models. The deviations from the proposed SAI diagrams could be explained by results from other researchers, some of which were summarized in the following.

3.6 Results from Other Researchers

Results from other researchers could be compared only in cases that enough necessary data for analyses were given. Some results of comparisons were discussed below.

3.6.1 Cement Paste - Barley Husk Ash, Rice Husk Ash and Coal Fly Ash

Khalil et al. (2014) tested a series of cement paste specimens of \( 1^{\prime \prime } \times 1^{\prime \prime } \times 1^{\prime \prime } \) cubes. The water content of consistency was determined for each set of the specimens. The ordinary Portland cement Type I was used. No high range water reducing agent was added. Barley husk ash, rice husk ash and coal fly ash was screened through 0.125 mm standard sieve. The consistency and the setting time of fresh pastes were tested according to ISO 9597:1989. The fractional replacement of cement by barley husk ash (BHA), rice husk ash (RHA) or coal fly ash (CFA) was in the range of 0.05–0.30. The water demand for standard consistency linearly increased with an increment of cement replacement level by BHA, RHA, or CFA, this was due to the relatively higher specific surface area of the ashes (11,000–12,000 cm2/g) than the OPC (3,100 cm2/g) in addition to the hygroscopic nature of the ashes which consume relatively higher amounts of mixing water.

The main chemical compositions of cement necessary for Bogue’s equation were CaO (64.62%), SiO2 (20.63%), Fe2O3 (6.88%), Al2O3 (1.54%) and SO3 (1.21%). Three ash samples BHA, RHA, and CFA composed mainly of silica (SiO2) 79.298, 64.948 and 60.402%, respectively, and alumina (Al2O3) 8.775, 11.830 and 11.00%, besides little content of CaO.

At a fixed fractional replacement of cement by ash a noticeable improvement in compressive strength was observed as the curing time (age of hydration) increased from 3 to7 to 28 days, beyond which (at 90 days) the improvement in strength was less significant. The values of the strength activity index for the specimens at the age of 90 days were plotted against the short-term and long-term \( SAI \) diagrams proposed as shown in Figs. 15, 16 and 17 for barley husk ash, rice husk ash and coal fly ash, respectively. It could be observed that the values of SAI from tested results were much higher than the corresponding values from the model within the range of IC, but much lower in the range of BC.

Comparison between the tested results by Khalil et al. (2014) with the SAI diagram - barley husk ash

Comparison between the tested results at the age 90 days by Khalil et al. (2014) with the SAI diagram - rice husk ash

Comparison between the tested results at the age 90 days by Khalil et al. (2014) with the SAI diagram – coal fly ash

3.6.2 Cement Paste – Nanosilica and Silica Fume

Qing et al. (2007) tested a series of cement paste specimens of 25 mm × 25 mm × 25 mm cubes. The water content of consistency was determined for each set of the specimens. The ordinary Portland cement (42.5 grade, Blaine specific surface 310 m2/kg) complying with Chinese standard (GB 175) was used. A commercial sulphonated melamine formaldehyde polymer (liquid solution, water content 70%) with special gravity 1.2 g/cm3 and water reduction up to 20% was used. Tap water was used in all experiments. For all the pastes, a cement plus addition:water:superplasticizer ratio of 1:0.22:0.025 was used. The fractional replacement of cement by pozzolan was not greater than 0.05.

The main chemical compositions of cement necessary for Bogue’s equation were CaO (64.27%), SiO2 (21.05%), Fe2O3 (4.03%), Al2O3 (5.56%) and SO3 (0.75%). Two pozzolan samples nanosilica and silica fume composed mainly of amorphous state of silica (SiO2) 99.9 and 92.1%, respectively. They possessed variable contents of alumina (Al2O3) 0 and 2.04%, besides negligible content of CaO.

The values of the strength activity index for the specimens at the age of 1, 3, 28 and 60 days were plotted against the short-term and long-term \( SAI \) diagrams as shown in Figs. 18 and 19 for nanosilica and silica fume, respectively. It should be observed that the values of SAI from the tested results were much higher than the corresponding values. These might be due to the addition of high amount of superplaticizer as shown by Chatveera and Nimityongsakul (1994b). Furthermore the particle size of silica fume was much smaller than OPC and the filler effect occurred. This effect was more pronounced in the case of nanosilica.

Comparison between the tested results at the age 1, 3, 28 and 60 days by Qing et al. (2007) with the SAI diagram – nanosilica

Comparison between the tested results at the age 1, 3, 28 and 60 days by Qing et al. (2007) with the SAI diagram – silica fume

Comparison between the tested results at the age 3, 7, 28 and 56 days by Chatveera and Nimityongskul (1994a) with the SAI diagram – rice husk ash

Comparison between the tested results at the age 3, 7, 28 and 56 days by Chatveera and Nimityongskul (1994a) with the SAI diagram – fly ash

3.6.3 Mortar - Rice Husk Ash and Fly Ash

Chatveera and Nimityongskul (1994a) studied the influence of artificial pozzolanas on mechanical behavior of high strength concrete. Two sources of river sand were used. The values of fineness modulus were 3.37 and 2.39.

The main chemical compositions of cement necessary for Bogue’s equation were CaO (63.8%), SiO2 (20.2%), Fe2O3 (2.9%), Al2O3 (5.4%) and SO3 (2.6%). Two ash samples RHA, and FA composed mainly of silica (SiO2) 97.27 and 33.62%, respectively, alumina (Al2O3) 0.54 and 15.08%, respectively, and CaO 1.09 and 23.96%, respectively.

The fractional replacement of cement by rice husk ash or fly ash was fixed to 0.30. The water-binder ratios for the ordinary cement, cement mixed with RHA and cement mixed with FA were 0.28, 0.42 and 0.38, respectively.

The values of the strength activity index for the specimens without superplaticizer at the age of 3, 7, 28 and 56 days were plotted against the short-term – and long-term \( SAI \) diagrams for rice husk ash and fly ash as shown in Figs. 22 and 23, respectively.

Comparison between the tested results at the age 28 days by Jaturapitakkul et al. (1999) with the SAI diagram – fly ash

Comparison between the tested results at the age 28 days by Chatveera and Nimityongskul (1994b) with the SAI diagram – rice husk ash

It should be observed from Fig. 20 that the fractional replacement of cement by RHA = 0.3 was in the range of BC and the values of SAI of mortars mixed with RHA agreed very well with the corresponding values from the model. These results confirmed the claim of no forward pozzolanic reaction of silica at the Cao/SiO2 ratio of 0.65. From Fig. 21, however, the values of SAI from the tested results for cement mixed with FA were quite scattered. The values of the compressive strength of the specimens with higher value of fineness modulus were much lower than those with the lower value of fineness modulus. On the contrary the values of SAI of the specimens with higher value of fineness modulus were much higher than those with the lower value of fineness modulus.

3.6.4 Mortar - Effect of Particle Size of Fly Ash

Jaturapitakkul et al. (1999) studied the strength activity index of ground coarse fly ash with cement. The ordinary Portland cement Type I was used. The control samples were prepared with the proportion cement to sand of 1:2.75 by weight and with the water to cement ratio of 0.64. For the other samples the cement was replaced by fly ash 20% by weight. The ratios of water to cementitious material (cement+fly ash) for the other samples were varied between 0.60–0.69, depending on the fineness of fly ash, to maintain flow of mortar between 110 ± 5% in accordance with ASTM C 230. The standard mortar cubes of 50 × 50 × 50 mm3 were cast in brass molds and the mortars were removed from the molds after 24 h. The compressive strength of the mortars was performed as prescribed by ASTM C 109 at 24 h, 3, 7, 14, 28, 60, and 90 days of curing.

The main chemical compositions of cement necessary for Bogue’s equation were CaO (64.99%), SiO2 (20.62%), Fe2O3 (3.1%), Al2O3 (5.22%) and SO3 (2.7%). The original coarse fly ash from Mae Moh Amphur composed of silica (SiO2) 45.94%, alumina (Al2O3) 25.62% and CaO 9.39%. The original coarse fly ash was grounded, processed and classified with respect to the processes. The major change was the particle size distributions, not the chemical composition. The mean particle size of OPC was 16.0 µ. Whereas the mean particle sizes for the original fly ash (O), Fly Ash (CFC), Fly Ash (F) and Fly Ash (CFF) were 50.0, 19.5, 18.0 and 5.0 µ, respectively.

The values of the strength activity index for the specimens at the age of 28 days were plotted against the short-term – and long-term \( SAI \) diagrams for fly ash as shown in Fig. 22. It should be observed that the value of SAI for Fly Ash (O) was very close to the corresponding value from the model. Whereas the values of SAI for the other classes of Fly Ash were much higher than the corresponding value from the model. The main reason was the mean particle sizes of Fly Ash were nearly equal or lower than that of OPC. In these cases filler effect of fly ash accelerated the precipitation of C-S-H gel on the interface surface area.

3.6.5 Mortar – High Volume Cement Replacement and Effect of Superplasticizer - Rice Husk Ash and Fly Ash

Chatveera and Nimityongskul (1994b) studied the strength activity index for high volume replacement of cement by rice husk ash and fly ash as well as for the effect of superplasticizer. The ordinary Portland cement Type I was used. The control samples were prepared with the proportion cement to sand of 1:2.75 by weight and with the water to cement ratio of 0.64. The flow of mortar was controlled between 110 ± 5% in accordance with ASTM C 230. The standard mortar cubes of 50 × 50 × 50 mm3 were cast in brass molds and the mortars were removed from the molds after 24 h. The compressive strength of the mortars was performed as prescribed by ASTM C 109 at the age of 7, 14, 28, 60 and 90 days. The fractional replacement of cement by ash or mixed ash was in the range of 0–0.6. In this studied the original rice husk ash was grounded and the particle size of RHA was much lower than that of OPC.

The main chemical compositions of cement necessary for Bogue’s equation were CaO (63.8%), SiO2 (20.2%), Fe2O3 (2.9%), Al2O3 (5.4%) and SO3 (2.6%). Two ash samples RHA, and FA composed mainly of silica (SiO2) 89.9 and 15.1%, respectively, alumina (Al2O3) 0.5 and 7.0%, respectively, and CaO 0.5 and 33.0%, respectively.

The values of SAI for the specimens without superplaticizer were plotted against the short-term and long-term \( SAI \) diagrams for rice husk ash and fly ash as shown in Figs. 23 and 24, respectively.

Comparison between the tested results at the age 28 days by Chatveera and Nimityongskul (1994b) with the SAI diagram – fly ash

It could be seen clearly from Fig. 23 that at the cement replacement of 0.20 the values of SAI of the tested results were much higher than the corresponding values from the model. For the cement replacement at 0.4 and 0.6, the values of SAI from the results at the early ages of 3 and 7 days. Again this fact confirmed the threshold of forward pozzolanic reaction of silica. The tested results at the older age, however, showed that pozzolanic reaction of silica could move forward.

In Fig. 24 the predicted values of SAI tended to overestimate at the early ages; whereas they tended to underestimate at the older ages.

Sulphonated naphthalene formaldehyde condensed polymer was used as superplasticizer with the dose 1.25% of cement by weight. The specimens were tested at the age of 7, 14, 28, 60 and 90 days. The values of SAI for the specimens with superplaticizer were plotted against the short-term and long-term \( SAI \) diagrams for rice husk ash and fly ash as shown in Figs. 25 and 26, respectively. These two figures showed clearly that specimens with superplasticizer resulted in much higher values of compressive strength as well as SAI than those values of the corresponding specimens without superplasticzer. Furthermore with superplasticizer the pozzolanic reaction of silica could move forward beyond the threshold even at the early age.

Comparison between the tested results at the age 28 days by Chatveera and Nimityongskul (1994b) with the SAI diagram – rice husk ash

Comparison between the tested results at the age 28 days by Chatveera and Nimityongskul (1994b) with the SAI diagram – fly ash

3.6.6 Concrete - Rice Husk Ash

Habeeb and Mahmud (2010) studied the strength of concrete mixed with rice husk ash. The values of fractional replacement of cement were 0.05, 0.10, 0.15 and 0.20. The given contents of CaO, SiO2 and Al2O3 for rice husk ash and fly ash could be taken directly. The fractional contents of C3S, C2S, C3A and C4AF could be converted by Bouge’s equation. However, for the sake of comparison, the optimum SAI indices for the compressive strength of concrete from the study at the ages of 28 days and 90 days were plotted against the corresponding SAI diagrams proposed the authors as shown in Fig. 27. It should be observed that the values of fractional replacement of 0.05, 0.10 and 0.15 lied within the range of incomplete consumption of calcium hydroxide, but the replacement 0.20 lied far beyond the complete consumption. The predicted values of the strength activity index at the age of 28 days were consistent with the tested results of concrete mixed with rice husk ash carried out by the researchers. It should be noted that the surface area of the grounded rice husk ash of the data points marked by solid squares (180 min.), solid asterisks (270 min.) and solid circles (360 min.) were lower in order, respectively. The values of SAI from the tested results were much higher than the corresponding values for the model for all cases. In cases of concrete the higher values of SAI from tested results might be much higher values of modulus of elasticity and strength of coarse aggregate than the corresponding values of the binder, especially at the early age.

Comparison of strength activity index with tested data by Habeeb and Mahmud (2010) - concrete mixed with rice husk as at the age of 28 days

The same trends were also observed from the studies of the other researchers such as results from Xu et al. (2016) as shown in Fig. 28.

4 Propagation of Uncertainty

4.1 Linear Functions

For a linear function of n random variables in form of:

The correlation matrix of \( \underline{X} \) is symmetric in form of:

Where \( \rho_{ij} \) is the correlation coefficient between \( X_{i} \) and \( X_{j} \). The covariance term \( \sigma_{ij} \) can be expressed in terms of the correlation coefficients:

Where \( \sigma_{i} \) and \( \sigma_{j} \) are standard deviations of variables \( X_{i} \) and \( X_{j} \) respectively. Thus \( \sigma_{i}^{2} \) and \( \sigma_{j}^{2} \) are variance of variables \( X_{i} \) and \( X_{j} \), respectively.

Then the variance of \( g\left( {\underline{X} } \right) \) is:

In the case that variables \( \underline{X} \) are uncorrelated variables the variance and the standard variation of \( g\left( {\underline{X} } \right) \) are reduced to:

4.2 Nonlinear Functions and Monte-Carlo Simulations

For a nonlinear function of n uncorrelated random variables, the standard deviation of \( g\left( {\underline{X} } \right) \) \( (\sigma_{g} ) \) to calculate error propagation, the variance formula (Ku 1966):

For other cases Monte-Carlo simulations may be applied. Then the suitable distributions for \( g\left( {\underline{X} } \right) \) can be obtained by Goodness-Of-Fit Tests e.g. Chi-Square Errors Test and K-S Test (Ouypornprasert 2002).

4.3 Optimum Replacement of Rice Husk Ash for Cement

For the sake of further discussions: Let the value of a reduced variable \( y_{i} \) of a random variable \( X_{i} \) with mean \( (\mu_{{X_{i} }} ) \) and standard deviation \( (\sigma_{{X_{i} }} ) \) be:

The partial derivative of a function \( g\left( {\underline{X} } \right) \) with respect to a reduced variable \( y_{i} \) is \( \frac{{\partial g\left( {\underline{x} } \right)}}{{\partial y_{i} }} \). By applying the chain rule this term may be rewritten as:

From Eq. (29):

Thus:

Where \( y_{i} = yfC_{3} S,\,yfC_{2} S,\,yfC_{4} AF,\,yfC_{r} ,\,yfS_{r} ,\,yfA_{r} ,\;for\,i = 1, \ldots ,6 \), respectively.

4.4 Optimum Replacement of Fly Ash for Cement

Similarly from Eq. (30):

Thus:

Where \( y_{i} = yfC_{3} S,\,yfC_{2} S,\,yfC_{4} AF,\,yfC_{f} ,\,yfS_{f} ,\,yfA_{f} ,\;for\,i = 1, \ldots ,6 \), respectively.

5 Reliability Analyses

5.1 Linear Limit-State Functions

For a linear function of n random variables \( g(\underline{X} ) \) as in form of Eq. (40), the mean \( (\mu_{g} ) \) and the standard deviation \( (\sigma_{g} ) \) of a vector of normal variables \( X \) can be calculated from the equations below:

Then the reliability index \( (\beta ) \) may be defined as:

Thus the failure probability \( (p_{f} ) \) can be calculated from the equation below:

Where \( \varPhi \left( z \right) \) is the cumulative probability of the standard normal variable of a z-score. For more details about reliability analyses it is referred to Ouypornprasert (1988).

5.2 Nonlinear Limit-State Functions and Monte-Carlo Simulations

For general applications where the functions \( g(\underline{X} ) \) are nonlinear and/or random variables are non-normal, then the statistical representation of a limit-state function may be obtained by Monte-Carlo simulations as discussed earlier. However the failure probability may be estimated efficiently by Monte-Carlo simulations together with an advanced variance reduction technique such as Importance Sampling Technique as shown below:

Where \( N \) is the number of simulations, \( f_{{\underline{X} }} \left( {\underline{x} } \right) \) is the joint probability density function, \( h_{{\underline{Y} }} \left( {\underline{x} } \right) \) is an importance sampling density function, \( I\left( {g\left( {\underline{x} } \right)} \right) \) is an indicator function whose value equals 1 when \( g\left( {\underline{x} } \right)\, \le \,0 \) and equals 0 otherwise.

6 Mass Production of Precast Concrete

The statistical data of cement, rice husk as and fly ash available in hands showed significant variation. On one hand the mass production of precast products should be of optimum cost. On the other hand the products should be qualified for all specifications with pre-specified criteria. Therefore the statistical data should be analyzed in advance. For a concrete cast of cement mixed with rice husk ash, the statistical data available of the materials are summarized in Table 5.

7 Discussion

For preliminary analyses all related variables are assumed uncorrelated and normally distributed. The optimum fractional replacement of cement by rice husk ash is 0.1777.

The long-term strength activity index of the optimum replacement of cement by rice husk ash is 1.4252. The uncertainty of the long-term strength activity index can be obtained by simple Monte-Carlo simulations. Goodness-Of-Fit tests revealed that the long-term strength activity index can be represented well by normal distribution. For optimum replacement of cement by rice husk ash only the long-term strength activity index based on 8192 simulations can be represented well by normal distribution with mean value and standard deviation = 1.1232 and 0.0113, respectively. The goodness of fit is shown in Fig. 29.

For the decision based on strength of the concrete the values of failure probability may play an important role. If the failure of the binder paste is defined as the value of the long-term strength activity index less than 1.1 (see Fig. 30), then the value of failure probability can be estimated. It can be seen from Eq. (31) that the cross multiplication for \( SAI = 1.1 \) and forming the limit-state function from the difference of both sides of the equation, then the limit-state function is linear in term of related random variables. Since all these variables are assumed normally distributed, then the reliability index and the corresponding value of failure probability can be obtained easily by using Eqs. (65) and (66), respectively. In other cases the Monte-Carlo simulations together with an Importance Sampling technique may be applied.

For this particular case the reliability index (Fig. 30) and the value of failure probability for the optimum replacement of cement by rice husk ash are 2.021 and \( \Phi \left( { - 2.021} \right) = 2.165 \times 10^{ - 2} \), respectively. Theoretically \( SAI \) of the optimum replacement should yield the maximum \( SAI \). Since the failure probability in term of \( SAI \) is very low for this particular case, a higher or lower value of replacement of cement by rich husk ash might be possible so that products could be qualified for all specifications.

Once this optimum replacement of cement by rice husk ash = 0.1777 is selected, then the propagation of uncertainty in terms of optimum ratio should be also considered. The corresponding standard deviation of this ratio is 0.0035. Again if the ratio is assumed normally distributed, then the interval of the applied ratio should be [0.1708,0.1846] with the confidence interval 95% (0.1777 + 1.96 × 0.0035). The more precise conclusion may be, again, estimated from Monte-Carlo Simulations and Goodness-Of-Fit tests.

The reliability indices based on long-term SAI = 1 within the range of partial replacement of cement by mixed ash of rice husk ash and fly ash were in the close interval of [0.753,10.862] and the corresponding values of failure probability were in the close interval of [8.75 × 10−28, 2.26 × 10−1]. The relationship between the reliability index and the fractional replacement of cement by mixed ash was shown in Fig. 31.

8 Conclusions

-

(1)

Hydration of main chemical compositions of cement and pozzolanic reactions of minerals in rice husk ash and fly ash were reviewed. Data necessary for stoichiometry of hydration- and pozzolanic reactions were also given,

-

(2)

Formula for the optimum replacement of cement by rice husk ash and fly ash based on the complete consumption of calcium hydroxide from hydration of cement was derived,

-

(3)

The long-term strength activity index \( (SAI) \) for the age of 360 days based on equivalent calcium silicate hydrate was proposed and the SAI diagrams could be constructed,

-

(4)

The strength activity index at any age could be modeled based on nano-structures depending on the CaO/SiO2 ratio and the scenario of \( SAI \) diagrams could be seen.

-

(5)

The proposed \( SAI \) diagrams were verified by a series of tests for specimens of mortars mixed with silica fume, rice husk ask and fly ash carried out by the authors, and were validated by results by other researchers. It should be noted that the proposed model was based on main chemical compositions in cement and ash only. Although other factors such as engineering properties of ash, heat evolution of hydration, relative mean particle size of cement to that of ash, type and dose of superplasticizer etc. showed influences on \( SAI \), they were out of the scope of this technical paper. However they should be included in the refined models in the authors’ prospective research projects.

-

(6)

The propagation of uncertainty of the partial replacement of cement by rice husk ash and fly ash in term of variation of main chemical compositions in cement and rice husk ash and fly ash were formulated.

-

(7)

Reliability analyses for utilizing the optimum replacement of cement by rice husk ash and fly ash were reviewed,

-

(8)

The applicability of the proposed concepts was demonstrated based on statistical data of materials available in hands,

-

(9)

All the concepts mentioned above could be extended to one other type of pozzolan as well as mixed pozzolan.

References

Bogue, R.H.: Chemistry of Portland Cement. Reinhold, New York (1955)

Chansawang, S., Ouypornprasert, W.: Rate of pozzolanic reactions of rice husk ash and fly ash. Intl. J. Mater. Struct. Reliab. (2017, Submitted for publication)

Chatveera, B., Nimityongskul, P.: Influence of artificial pozzolanas on mechanical behavior of high strength concrete, Khonkaen Univ. J. Eng. 21 pp. 59–71 (1994a). (in Thai)

Chatveera, B., Nimityongskul, P.: Portland cement containing rice husk ash, fly ash and superplasticzer. Suranaree J. Sci. Technol. 1, 109–122 (1994b)

Dumrongsil, S., et al.: Stiochiometry of pozzolanic reaction. J. Res. Training Rajmangala Inst. Technol. 4(1), 28–34 (2000)

Habeeb, G.A., Mahmud, H.B.: Study on properties of rice husk ash and its use as cement replacement material. Mat. Res. 13(2), 185–190 (2010)

James, J., Rao, M.S.: Reactivity of rice husk ash. Cement Concr. Res. 16(3), 296–302 (1986)

Jaturapitakkul, C., et al.: A study of strength activity index of ground coarse fly Ash with Portland cement. ScienceAsia 25, 223–229 (1999)

Kamollertvara, K., Ouypornprasert, W.: Determination of mean values of common distributions in civil engineering from the specifications for mass production. In: The Proceedings of the 7th International Conference on Engineering and Technology ICET-2015, Phuket, 19–20 June 2015, pp. 1-4. Prince of Songkla University, Faculty of Engineering, Hat Yai, Songkhla (2015)

Kamollertvara, K., et al.: Statistical analyses of optimum partial replacement of cement by rice husk ash based on complete consumption of calcium hydroxide. In: The Proceedings of RSU International Research Conference 2016, Pathumthani (2016)

Khalil, N.M., et al.: Beneficiation of the huge waste quantities of barley and rice husks as well as coal fly ashes as additives for Portland cement. J. Ind. Eng. Chem. 20, 2998–3008 (2014)

Ku, H.H.: Notes on the use of propagation of error formulas. Natl. Bureau Stand. 70C(4), 262 (1966)

Langan, B.W., et al.: Effect of silica fume and fly ash on heat of hydration of Portland cement. Cem. Concr. Res. 32, 1045–1051 (2002)

Le, H.T., Ludwig, H.M.: Effect of rice husk ash and other mineral admixtures on properties of self-compacting high performance concrete. Mater. Des. 89, 156–166 (2016)

Nawaz, A., et al.: Effect and limitation of free lime content in cement-fly ash mixtures. Constr. Build. Mater. 102, 515–530 (2016)

Ouypornprasert, W.: Methods to calculate structural reliability, Internal Working Report No.18 – Institute of Engineering Mechanics, University of Innsbruck, Austria (1988)

Ouypornprasert, W.: Goodness-of-fit tests for common continuous distributions in civil engineering. In: Proceedings of the International Conference on Computational Mathematics and Modeling (CMM-2002), 22–24 May 2002, pp. 117–126. Mahidol University and Curtin University of Technology, Century Park Hotel, Bangkok (2002)

Ouypornprasert, W., et al.: Statistical analyses of optimum partial replacement of cement by fly ash based on complete consumption of calcium hydroxide. In: The Proceedings of the International Conference of Advanced Engineering and Technoogy (ICAET2016), Bhai Gurdas Institute of Technology, Sangrur, Punjab, India (2016)

Ouypornprasert, W., et al.: The use of rice husk ash and fly ash for partial replacement of cement for mass production of precast concrete products. Internal Working Report No.20 - Asia Research, Development and Innovation Center, Asia Expansion Concrete Product (1993) Co. Ltd., Bangkok (2017)

Över, D.: Early heat evolution in natural pozzolan incorporated cement hydration. In: partial fulfillment of the requirements for the degree of Master of Science in Civil Engineering Department, Middle East Technical University (2012)

Qing, Y., et al.: Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 21, 539–545 (2007)

Skinner, B., et al.: Nanostructure of CSH in cement. Phys. Rev. Letters 104(19), 195502 (2010)

Taylor, H.F.W.: Cement chemistry. J. Am. Ceram. Soc. 69, 614–618 (1986)

Taylor, H.F.W.: Cement Chemistry, 2nd edn. Thomas Telford Publishing, Thomas Telford Services Ltd., London (1997)

Tokyay, M., et al.: Granüle Yüksek Fırın Cürufu,Tras ve Kalker İçeren Çimentolarda Mineral Katkı Türü, Öğütme Yöntemi ve Çimento İnceliğinin Hidratasyon Isısına Etkilerinin Araştırılması. vols. AR-GE 2010/01-A. Turkish Cement Manufacturers Association, Ankara, Turkey (2010)

Acknowledgments

Full financial support and Granting a Professional License of Software Mathcad Prime for calculation throughout the authors’ research projects by Asia Group (1999) Company Limited was cordially acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Ouypornprasert, W., Traitruengtatsana, N., Kamollertvara, K. (2018). Optimum Partial Replacement of Cement by Rice Husk Ash and Fly Ash Based on Complete Consumption of Calcium Hydroxide. In: Struble, L., Tebaldi, G. (eds) Materials for Sustainable Infrastructure. GeoMEast 2017. Sustainable Civil Infrastructures. Springer, Cham. https://doi.org/10.1007/978-3-319-61633-9_10

Download citation

DOI: https://doi.org/10.1007/978-3-319-61633-9_10

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-61632-2

Online ISBN: 978-3-319-61633-9

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)