Abstract

Enhanced oil recovery (EOR) implementation arises as a supplementary technology to conventional ones, optimizing the not-easily recoverable oil phase. Estimation of oil remnant in reservoirs approaches to seven billion of barrels, after primary and secondary recoveries. One of the EOR strategies implies the use of displacing fluids, such as water-soluble polymers, which are pumped into the reservoir forcing the oil to flow toward the production wells. Thus, the state of the art related to the use of different starch derivatives in EOR is included in this chapter. Besides, diverse synthesis methodologies of the modified starches are presented, analyzing the optimal conditions of each reaction. Particularly, the synthesis of cationic starches is reported since they are the most used in EOR. Modification degree and physicochemical properties of the derivatives are included. Rheological and flow properties of displacing fluids are also discussed as a function of starch concentration.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Enhanced oil recovery (EOR)

- Starch derivatives

- Cationic and cross-linked starches

- Chemical synthesis

- Modification degree

- Physicochemical properties

- Rheological and flow properties

1 Introduction

Nowadays, conventional oil recovery involves mainly three phases named primary, secondary, and tertiary, respectively. In the primary phase, the natural pressure of the reservoir is employed to push crude oil to the surface, allowing a yield up to 10%. In the secondary one, pressurized gas and water are injected to recover part of the remnant oil (~30%). Secondary extraction, which involves mainly the injection of water into oil wells, is the most used methodology due to its low complexity and cost, recovering less than 50% of the original oil. However, several difficulties are found along its application related to the water cut (or water channeling) phenomena and the consequently low oil recovery yield, making this process noneconomically attractive. Within this context, even if the oil recovery is improved in 1%, this increment represents hundreds of millions of tons without any exploration and development investment (Shi et al. 2015). However, heterogeneous nature of the reservoirs hinders the complete oil phase extraction by water flooding.

The non-homogeneity within reservoir structure is due to variations in permeability and porosity and to the existence of different fracture orientations (Van den Hoek 2004). As a solution of these drawbacks, a tertiary phase has emerged, known as enhanced oil recovery (EOR). EOR is considered a multidisciplinary area, which involves not only scientific but also technological concepts for developing new methodologies to enhance crude oil extraction and to extend the production life of oil fields. EOR implementation arises as a supplementary technology to conventional ones, optimizing the not-easily recoverable oil phase. To have an idea, the estimation of the crude oil remnant in reservoirs after primary and secondary recoveries approaches to seven billion of barrels. This number is a good reason for searching alternative methodologies in order to maximize crude oil recovery. Within this context, one of the strategies proposed for EOR implies the use of sophisticated displacing fluids, which are pumped into the reservoir forcing the oil to flow toward the production wells. For such a purpose, fluids must be more viscous than water, like the well-known solutions based on water-soluble polymers . The use of water-soluble additives for EOR has been discussed during the last years, considering certain limitations associated with rheological properties of their suspensions. It is important to note that fluid flow behavior is directly related to the chemical structure of the used polymers, as well as the influence of external parameters, such as salts and surfactant concentrations, and temperature, among others (Wever et al. 2011; Gao 2015). Polymer flooding is the common name used for the injection of a polymer solution into petroleum reservoirs and has been successfully applied in several countries (Sorbie 2000; Silva et al. 2007; Morel et al. 2010; Nezhad and Cheraghian 2015). The most crucial criteria to select the appropriate polymer are its ability to generate a viscous solution at the minimum concentration (Shi et al. 2015). Besides, since this method relies on polymer adsorption on pores located at the rock walls, it is therefore important to consider this capacity in the selection of the polymer employed for injection purposes (Leslie et al. 2005). Among the polymers studied, one of the most water-soluble polymers used is partially hydrolyzed polyacrylamides (HPAM) because it increases significantly the fluid displacement viscosity, allowing a higher sweep of the oil phase. Nevertheless, since the interaction between polymers and salts present into reservoirs produces changes in the rheological behavior of the solution, this issue is also relevant for the proper selection of the additive. The experience has shown that large periods of successive flooding lead to a more marked heterogeneous reservoir by increasing the number of big-sized pores and the wellbore permeability. Consequently, the injected polymer suffers from the channeling phenomena in high permeability areas (Daripa and Pasa 2004; Bao et al. 2009).

Considering the water-soluble character of starch, this biopolymer can be used as an additive in EOR technologies. During the last six decades, starch has been modified by different physical and chemical methods obtaining derivatives for oil field applications. Nowadays, some of these modified starches are commercially available. Within this context, the low cost, worldwide availability, and high eco-friendly character make starch as a good candidate for developing additives to be used in the oil industry, an activity that consumes millions of pounds of starch and their derivatives per year (Qiao and Zhu 2010). At this point, it is important to note that additives obtained from natural polymers compete with those derived from synthetic ones. Thus, the selection of additives to be used in EOR technologies must be based not only on its functional properties but also on its price and availability. Particularly, in the case of the modified starches, their price is mainly associated to their production costs. In this sense, reaction selectivity (fraction of reagent which reacts with starch) and starch reactivity (amount of modified starch that can be produced in certain reaction conditions) mostly determine the commercial cost of these derivatives.

Oil field applications of starch and their derivatives include filtrate-loss control, mud-rheology modification, shale stabilization, drag reduction, water shutoff, and EOR. For such a purpose, some characteristics of starch such as molar mass, chemical structure, and solubility, as well as reservoirs’ salinity and temperature, influence the oil recovery efficiency (Zhang 2001). In this chapter, we will discuss the state of the art related to the use of different starch derivatives in EOR. Besides, diverse methodologies developed to synthesize modified starches are also presented, by analyzing the optimal conditions of each reaction. The degree of modification and the physicochemical properties of the derivatives are also included and discussed along the chapter, hoping that this interchange of ideas and methodologies will contribute to a better understanding of the use of modified starches for EOR.

2 Modified Starch for Oil Field Applications

Native starch has a granular morphology with special functional properties. In this sense, starch is slightly soluble in cold water and forms colloidal suspensions under heating. Besides, due to the high viscosity of starch pastes, this polysaccharide is usually used as adhesive, for thickening purposes, and as a texturing agent (Jaspreet et al. 2007). Tailor-made starches have been synthesized for specific applications in order to widen its application fields. These modifications involve changes in the granular structure, by modifying its gelatinization behavior, swelling degree, and solubility capacity (Barrios et al. 2012). Thus, it is possible to synthesize modified starches with different hydrophilic/hydrophobic characters, depending on the nature of the reactive agent as well as the medium and the reaction conditions (Heinz and Koschell 2005; Jaspreet et al. 2007). Among these derivatives, pre-gelatinized, etherified, grafted copolymers and cross-linked and blended starches can be mentioned. Considering their abundance, stability, and the inherent eco-friendly character, Leslie et al. (2005) reported the importance of using modified cationic polysaccharides and branched polymers based on cyclodextrins in EOR technologies. Within this context, it is relevant to evaluate the adsorption of these additives on core samples extracted from hydrocarbon reservoir rocks, considering charge density and molar mass of the polysaccharides . These authors found that polymer absorption is strongly dominated by a combination of electrostatic interactions between polymer and rock surfaces, as well as the size of the polymer.

Table 1 summarizes different modified starches used in the petroleum industry, especially in EOR.

3 Cationic Starches

Within starch derivatives, cationic-modified polymers have been used as functional additives in the petroleum industry (Fu et al. 2013). The modification is based on the substitution of starch hydroxyl groups by functional groups with positive charges, by employing different chemical reagents. In this sense, it is possible to introduce sulfonium, ammonium, amino, imino, or phosphonium groups (Bertolini 2009; Kuo and Lai 2009). These derivatives present a wide range of degree of substitution (DS), and they are usually synthesized by using starches from different botanical sources as substrates and several modifying agents. Concerning the methods employed, they are divided into batch and continuous processes. Regarding the first ones, they can be carried out via granular slurry, semidry, or solubilized paste; on the other hand, in the continuous processes, reactive extrusion is generally employed (Bertolini 2009).

Cationic starch moieties can be synthesized by employing a quaternary ammonium reactive (Pal et al. 2005), but in the last years, the chemical group most currently incorporated is 2-hydroxy-3-(trimethylammonium)propyl by etherification with 2,3-epoxypropyltrimethylammonium chloride (glycidyltrimethylammonium chloride , EPTAC) (Prado and Matulewicz 2014). EPTAC can be acquired commercially, but it is toxic and has a low chemical stability and a high cost. An alternative to overcome these limitations, especially at industrial scale, is the synthesis of this reagent in situ by using 3-chloro-2-hydroxypropyltrimethylammonium chloride (CHPTAC) , which is also a commercially available reagent. A simple procedure for the synthesis of EPTAC is shown in Fig. 1.

Concerning the functionalization process , Prado and Matulewicz (2014) reported a two-step mechanism. In the first step, an alkoxide is formed, in an alkaline medium, from a starch hydroxyl group as it is shown in Fig. 2. Then, this alkoxide reacts with the EPTAC by a nucleophilic attack, by opening the epoxide group.

Considering batch processes employed to obtain these starch derivatives, the semidry and wet methods are the most used. Regarding the semidry technique, the reactive agents are spread over starch and submitted to an optimized time–temperature routine (Zhang et al. 2007). Meanwhile, the wet method can be performed in homogeneous as well as in heterogeneous conditions (Haack et al. 2002; Heinze et al. 2004; Sableviciene et al. 2005). In the homogeneous wet option, dimethyl sulfoxide (DMSO) is used as the reaction medium. On the other hand, in the heterogeneous wet process, suspensions, mainly based on water or alcohols under basic medium, are usually employed. Concerning continuous processes, reactive extrusion is one of the most used methods at industrial scale. It is important to highlight that this process allows obtaining not only a functionalized starch but also a thermoplastic derivative. This material results from the reactive conditions (high shear stress and temperature) and the incorporation of a plasticizer during the extrusion process, improving starch processability (Ayoub and Bliard 2003; Ayoub et al. 2004; Tara et al. 2004). The most important advantage associated to both, semidry and extrusion techniques, is their easy procedure (the lack of additional steps which could lead to a partial loss of the synthesized derivative is their characteristic). However, the presence of some chemical products such as salts, reactive agents, and by-products influences reaction yield, as well as the quality of modified starches (Radosta et al. 2004).

The method that guarantees the production of derivatives with a high purity is the wet one, because reaction conditions preserve the integrity of the starch granules. Consequently, these functionalized starches play an important role as adsorbents and flocculants (Sableviciene et al. 2005; Klimaviciute et al. 2007). Despite these advantages, the problems associated to heterogeneous method are related to the incorporation of inorganic salts which are used for reducing the phenomenon of the swelling of the granules (Huber and BeMiller 2001; Butrim et al. 2008).

Scientific literature reports several works regarding the synthesis of cationic starches by wet process under homogeneous and heterogeneous conditions (Kuo and Lai 2007, 2009; Kavaliauskaite et al. 2008; Pi-xin et al. 2009; Hebeish et al. 2010; Wang and Xie 2010). By analyzing the open literature , it can be noticed that reaction efficiency, degree of substitution, and granule preservation, as well as functional properties of starch derivatives, depend on diverse factors, such as chemical reagents, molar ratio of reactive agents, and medium conditions, among others.

Regarding the synthesis of hydrosoluble derivatives based on starch, Heinze et al. (2004) studied three methods to obtain 2-hydroxy-3-(trimethylammonium)propyl starch (HTPS) . These authors assayed different media and reaction conditions and the same reagent (2,3-epoxypropyltrimethylammonium chloride, EPTAC ) for functionalization purposes. They employed several native starches from diverse botanical sources and variable amylose content. Particularly, the methods proposed for synthesizing modified starches involved heterogeneous, homogeneous, and pseudo-heterogeneous cationization. Figure 3 shows the reaction pathways used by Heinze et al. (2004) to obtain HTPS. In this sense, the effect of different variables, such as reaction medium, synthesis conditions, and properties of native starch over the DS of the obtained derivative was evaluated. From the analysis of the results derived from this study, it is possible to infer that, generally, the DS does not depend on the botanical source or the amylose content of the native starch. However, a significant effect on the DS was observed for those starches containing a low amylose proportion, which were submitted to heterogeneous cationization.

Scheme of reaction used to synthesize 2-hydroxy-3-(trimethylammonium) propyl starch (HTPS) under different media and conditions (Taken from Heinze et al. 2004)

It was demonstrated that modified derivatives with high DS values (up to 1) could be obtained by one-step homogeneous method using a molar ratio equal to 2 between the cationization agent and the anhydroglucose unit. According to the comparison made between homogenous and heterogeneous methods, the first one resulted in being more efficient. In the heterogeneous method, the impeded diffusion of the reagent by the presence of positive groups located on the surfaces of starch granules obstructs the cationization reaction. On the other hand, homogeneous methods offer a less hindered surface thanks to the solubilization of the starch granules by enhancing the diffusion of the cationization agent. Despite homogeneous reaction is the most efficient method for synthesizing cationic starches, it is important to mention that employs more liquid than the heterogeneous technique. In order to reach a DS between 1.0 and 1.5, Heinze et al. (2004) proposed the use of an additional cationization stage. In that work, it is reported a complete structural characterization of the synthesized cationic starches from the aforementioned method, revealing that these derivatives resulted soluble in cold water. Taking into account that cationic starches could be used as additives in EOR technologies, solubility data are a relevant issue to be considered.

According to Siau et al. (2004), the cationization process increases the disruption of starch crystalline structure, by enhancing significantly the water uptake of the polymer and its thermal properties. The feasibility of using starch derivative solutions as oil displacement fluids is based on different aspects such as their high salt tolerance, their capacity to reduce the water cut phenomenon, and their adsorption properties on sand particles of oil reservoirs (Fu et al. 2013). It is possible to tailor the structural characteristics and functional properties of cationic starches by selecting the proper method of synthesis and by adjusting the optimal reaction conditions. In this regard, Bendoraitiene et al. (2012) stressed that derivatives with high sorption properties can be obtained with the aid of organic bases in the reaction system. On the other hand, it has been established that exposition to microwave radiation during the cationization reaction favors the production of starch derivatives with specific characteristics (Wei et al. 2008; Singh et al. 2013).

As it was aforementioned, even though HPAM flooding is one of the most used techniques in EOR processes, some disadvantages have been found (Daripa and Pasa 2004; Hou et al. 2009). Concerning advantages of the HPAM flooding, it can be mentioned a higher oil yield and a reduction of the water cut phenomenon. Reservoir flooding during long periods increased the stratum heterogeneity and the presence of big pores, conforming a more permeable region. Consequently, HPAM channeling takes place in this high permeability zone and a premature polymer loss from the wellbore occurred, affecting the oil phase displacement. Qiao and Zhou (2010) and Qiao et al. (2012) proposed an alternative to enhance the sweep efficiency, through sealing the big pores using the HPAM retained in the reservoir. These authors proposed the use of 2-hydroxy-3-(trimethylammonium)propyl starch (HTPS) in EOR technology, obtained from native corn starch and EPTAC as reagent. Thus, the injection of HTPS solutions after HPAM flooding allows reacting with the remnant polymer located in the high permeability regions, producing an in situ gelling system by electrostatic forces (Al-Muntasheri et al. 2007). This process offers a more economical option in order to replace other conventional additives such as metallic or organic cross-linking agents (Wang et al. 2003; Jeon et al. 2008; Chang et al. 2010). These gel-type structures act like profile modification agents since they reduce the reservoir permeability, blocking and plugging the big pores. Along a cross-linking reaction, the HPAM–HTPS liquid phase is transformed into a viscoelastic solid, increasing the system strength. Firstly, the low strength of this cross-linked gel is responsible to reach deeper breakthrough into reservoir channels. However, when this reaction takes place, three-dimensional molecules are formed, increasing the viscosity and strengthening of gel system. The physical properties of this final cross-linked material lead to an obstruction and sealing of the channels and pores, reducing the reservoir permeability. The result of alternating injections of HPAM and HTPS solutions before water flooding improves oil production since water can displace the oil phase present in mid-low permeability regions (Sabhapondit et al. 2003; Wang et al. 2003).

In order to evaluate the viscoelastic behavior of HPAM–HTPS cross-linked gels, Qiao and Zhu (2010) and Qiao et al. (2012) performed rheological studies working on systems obtained from reactions of cationic starches and HPAM solutions with different concentrations. Rheological curves obtained from steady shear tests carried out at 25 °C for HPAM solution (1,500 mg/L) and a HPAM–HTPS gel system (prepared by mixing in equal volumetric proportion of 1,500 mg/L HPAM and 5,000 mg/L HTPS) are shown in Fig. 4. A pseudoplastic behavior for both HPAM solutions and gel systems at high shear rate values was evidenced. As it can be observed, the viscosity of HPAM and HPAM–HTPS gels decreased with an increase in shear rate. This tendency is associated to the shear thinning phenomenon and to cross-linking points shearing off. Thus, the flow resistance and, consequently, the viscosity are reduced. It is important to highlight that viscosity values of HPAM–HTPS gels were found to be higher than those corresponding to HPAM solutions over the shear rate range studied.

Rheological curves of HPAM solution (1500 mg/L) and HPAM–HTPS gel system (1,500 mg/L HPAM and 5,000 mg/L HTPS). Symbols: (▲) HPAM solution and (△) HPAM–HTPS gel system (Taken from Qiao et al. 2012)

Qiao and Zhu (2010) and Qiao et al. (2012) also prepared formulations from HTPS and HPAM solutions with different concentration in order to evaluate the gel strength. As it can be observed in Fig. 5, as concentrations of the two fluids decrease, this viscoelastic property of the resulting gel is diminished.

Effect of solution concentration on storage moduli (G′) of HPAM–HTPS gel systems. Symbols: (▲) 5,000 mg/L HTPS +1,500 mg/L HPAM, (△) 5,000 mg/L HTPS +1000 mg/L HPAM, (▼) 3,000 mg/L HTPS +1,500 mg/L HPAM, and (▽) 3000 mg/L HTPS +1000 mg/L HPAM (Taken from Qiao et al. 2012)

It is well known that the efficiency of oil displacement is strongly influenced by the wettability of reservoir soils. In this sense, to analyze the capacity of cationic starch solutions for improving the oil phase recovery in EOR technologies, the wettability of a model soil is usually determined (Karabakal and Bagci 2004). Within this context, Qiao et al. (2012) studied the effect of using HTPS as EOR additive on the wettability of a montmorillonite-based reservoir (Mt). This property of the surface was evaluated comparatively between Mt-HTPS and Mt-HPAM systems, through measurements of contact angle values. The preparation of both systems was carried out by adding Mt to HTPS or HPAM solutions, and samples so obtained were submitted to several experimental steps (filtration, washing, drying, grinding, and sifting). The resulting wetting curves of Mt-HTPS and Mt-HPAM systems, as well as for the neat Mt in water are shown in Fig. 6.

Wetting curves of HTPS-Mt, HPAM-Mt, and raw Mt in water (Taken from Qiao et al. 2012)

For Mt-HTPS and Mt-HPAM, an opposite behavior was observed. The presence of HTPS on Mt increases the hydrophilic character of this substrate and, consequently, the soil wettability in water. On the other hand, the addition of HPAM slightly increases the hydrophobic nature of the Mt particles. Taking into account these results, it is expected that the use of solutions based on HTPS would enhance oil displacement, by modifying soil wettability. The fact that the reservoir surface turned to a more marked hydrophilic character would facilitate taking off the oil layer adhered to the rock and would increase the flow resistance of ulterior water injections. As a consequence, water channeling would be reduced, improving the efficiency of the oil displacement.

Qiao and Zhu (2010) also carried out several simulations in order to evaluate if HPAM–HTPS gel systems were able to plug high permeable pores. In this sense, sand-pack core-flood assays were performed determining the influence of gel presence on water permeability of the reservoir. From the results derived from those tests, it was evidenced that an intermediate injection of the HTPS solution between two HPAM flooding reduced the polymer fingering, as well as its loss. Besides, Qiao and Zhu (2010) claimed that the use of HTPS solutions reduced significantly water cut phenomenon, by enhancing oil recovery.

4 Anionic Starches

Another alternative for EOR technologies are additives based on anionic modified starches. These derivatives are obtained through the incorporation of functional groups with negative charge, such as carboxymethyl and sulfonic groups (Chen et al. 2015). Modification provides anionic starches with enhanced functional properties such as solubility, hydrophilicity, and flocculation. The most studied derivative is the carboxymethyl starch (CMS) , which is an attractive modification not only for academic but also for industrial fields (Kittipongpatana et al. 2006; Lawal et al. 2007; Zhou et al. 2010). Among CMS derivatives, the sodium carboxymethyl starch (CMS-Na, anionic) can be mentioned.

Carboxymethylation process allows the synthesis of modified starches with useful functional properties for a wide variety of industries, including those related to oil recovery (Zhang 2001; Lazik et al. 2002; Jie et al. 2004; Volkert et al. 2004; Kittipongpatana et al. 2006; Moorthy et al. 2006; Zhou et al. 2007). Figure 7 shows the reaction scheme employed for carboxymethylation of starch molecules, based on Williamson’s ether synthesis (Tijsen et al. 2001). As it can be observed, the anionization process involves the incorporation of carboxymethyl moieties to anhydroglucose units of starch molecules, obtaining more hydrophilic derivatives. This modification improves some functional properties of the resulting starch, such as stability in aqueous solutions and retrogradation at low temperatures (Barrios et al. 2012).

Reaction scheme to synthesize sodium carboxymethyl starch (CMS-Na, anionic) (Taken from Barrios et al. 2012)

The mechanism involves two consecutive reactions. In the first stage, NaOH reacts with starch hydroxyl groups located at C2, C3, or C6. Then, the substitution reaction is carried out by the presence of the reactive agent, monochloroacetic acid (MCAA) or sodium monochloro acetate (SMCA) .

Barrios et al. (2012) studied the carboxymethylation process as a way of synthesizing anionic starches using diverse reaction media as well as different reagents. In this sense, these authors proposed the use of isopropanol (IP) , dimethyl sulfoxide (DMSO) , and water as reaction solvents. Concerning modifying agents, the abovementioned MCAA and SMCA were employed. Besides, the carboxymethylation process was optimized by adjusting the reaction conditions, such as starch/reagent molar ratio, temperature, and time in order to obtain derivatives with high DS values. Additionally, one of the aims of the research was the synthesis of modified starches with high zero-shear viscosity in aqueous suspensions. At this point it is important to mention that the best reaction condition for producing starch derivatives with high DS usually favors the degradation of starch and, consequently, the decrease of solution viscosity (Jie et al. 2004; Sangseethong et al. 2005). Thus, Barrios et al. (2012) proposed an alternative strategy in order to optimize the anionization method that involved three steps: (i) the selection of the solvent by using the reaction conditions already employed by several authors (Heinz and Koschell 2005; Flores 2006; Mollega et al. 2011); (ii) the selection of the reagent among the most reported in the specific literature, taking into account the solvent previously chosen (Jie et al. 2004; Heinz and Koschell 2005; Sangseethong et al. 2005; Stojanovic et al. 2005; Mollega et al. 2011; Flores 2006); and (iii) the selection of the optimal anhydroglucose unit/reagent molar ratio, reaction temperature, and time for the anionization process.

Concerning the reaction medium, authors concluded that starch derivatives obtained by using DMSO or water resulted soluble in water. Meanwhile, those synthesized in IP were insoluble because a heterogeneous anionization process took place, since the modification process was observed only at the surface of starch granules. In order to select the best reactive agent, carboxymethylation process was carried out in a homogeneous medium, employing water as solvent, at 75 °C and 4 h. Obtained derivatives were tested through rheological assays in order to determine the zero-shear rate viscosity. In this sense, the use of SMCA led to derivatives with higher viscosity than those obtained by employing MCAA under the same reaction conditions (Sangseethong et al. 2005). The viscosity increment could be related to the electrostatic repulsion among carboxymethyl groups that would favor the expansion of the molecular structure of the starch. Consequently, a more hindered movement of starch chains is expected. From this result, it could be inferred that sodium carboxymethyl starches synthesized by using SMCA present a high DS value.

Regarding the optimal reaction conditions, Barrios et al. (2012) observed that higher values of DS and solution viscosity were obtained by employing water as solvent and by carrying out the reaction at 60 °C during 6 h, with the addition of an excess of SMCA. Besides, under the same conditions, modified starches obtained by using DMSO as solvent led to solutions with lower viscosity. This result could be associated to the degradation process of starch during the carboxymethylation reaction in DMSO . Finally, it should be mentioned that the use of CMS-Na presents limitations associated with troublesome shales in certain reservoirs with specific soil properties. Zhang (2001) proposed an alternative to overcome this drawback by employing sodium-free derivatives as drilling fluids, such as potassium-based starches (CMS-K) .

5 Nonionic Starches

Alkyl ether starch derivatives were also investigated as additives for oil field applications, mainly because they can reduce the fluid loss and increase the viscosity of the fluid displacement. These derivatives are synthesized by incorporating nonionic functionalities such as hydroxyethyl and hydroxypropyl groups . The industrial relevance of this kind of chemical modification relies on the stabilization of starch aqueous solutions, widening their applications in petroleum industry. According to Datta et al. (2014), hydroxyethyl starches (HES) have been one of the cornerstones in fluid management for over four decades. These modified starches are considered semisynthetic polymers that form polydisperse colloidal solutions conformed by polymerized amylopectin molecules with a high degree of ethylation. Figure 8 shows the chemical structure of HES derivative.

Chemical structure of HES derivative (Taken from Datta et al. 2014)

Modified starches are commercially available with different average molecular weights (MW) . Derivatives with MW ranging from low (70–130 kg/mol), middle (~00 kg/mol) to high (>450 kg/mol) values are commercially available. Table 2 presents the main trade names of commercial HES, showing their DS and MW.

The industrial production of these derivatives is frequently carried out by an aqueous slurry phase process, by employing starches from different botanical sources. Besides, a two-phase gas–solid method can also be employed. Regarding slurry technology, HES are prepared by the reaction of starch with ethylene oxide in alkaline media through a batchwise process. An advantage of the slurry method is the relatively easy separation of starch granules in the downstream processing. The starting material may be native starch in its granular form or gelatinized in aqueous solutions. Modification of granular starch can be performed using three different reaction media: (i) water, (ii) organic solvents, and (iii) gaseous ethylene oxide. Regardless the media, this modification method involves the use of catalysts such as hydroxides or basic salts. DS and solubility properties are dependent on reaction conditions. Generally, the application of those methods which involve reactions using starch in granular form and in the absence of organic solvents is preferred. In this way, additional reaction stages such as purification after starch modification are avoided, reducing the cost of production of the derivatives. Figure 9 shows the reaction mechanism involved for HES synthesis. However, undesired side reactions like those involving the hydrolysis of ethylene oxide to ethylene glycol can also take place (Fig. 10).

Whether starch modifications are catalyzed or not, the glycol-forming reaction is always carried out. The low selectivity of the slurry process is mainly due to the occurring of this undesired side reaction, which is favored by the large amount of water. Another disadvantage of the suspension process is the long time required to perform the hydroxyethylation of starch. In order to prevent the gelatinization process, starch can be cross-linked before or during the modification. Due to the low starch reactivity, it is necessary to use a reaction temperature that favors the gelatinization of the polysaccharide. Meanwhile, sodium sulfate and sodium chloride are usually added to the reaction media in order to avoid the swelling of starch granules. Then, part of the ethylene oxide becomes ineffective because it reacts with the anion coming from the salt dissolution, as it is shown in Fig. 11.

Usually, this abovementioned reaction is not desired in the slurry process. In fact, it is an expensive way to create hydroxyl ions to act as basic catalyst in the slurry media. Regarding the use of sodium sulfate or sodium chloride inhibitors for the swelling process of the granules, the second one is the most appropriate since the hydrolysis of ethylene oxide scarcely occurs.

An alternative to reduce the aforementioned drawbacks is the so called “dry, gas–solid” process. Even though the use of gaseous ethylene oxide plus the low moisture in the medium favors the hydrolysis of the reagent, starch reactivity can be enhanced by using higher reaction temperatures. Since starch derivatives can be used in petroleum industry, it is relevant to evaluate not only their efficiency as EOR additives but also their cost of production. In this sense, the selection of a hydroxyethylation method between the two aforementioned processes (slurry versus “dry, gas–solid” processes, by taking into account the optimized conditions and derivative properties) should be focused on the cost reduction associated to the synthetic pathway.

Similarly to hydroxyethyl starches, hydroxypropyl ones can be obtained by the alkaline addition of propylene oxide (Gonera 2004). Figure 12 shows the chemical structure of this starch derivative usually employed in EOR technologies.

Chemical structure of hydroxypropyl starch. R: -CH2-CH2-CH3 (Taken from Gonera 2004)

According to Mark (2013), this derivative is one of the more produced, among starch hydroxyalkyl ethers, at industrial scale. Aqueous as well as alkaline slurry processes allow obtaining hydroxypropyl starches with low degree of modification (<0.1). On the other hand, starch etherification with propylene oxide in alcohol slurry and alkaline conditions represents the most suitable media reaction to synthesize derivatives with a high degree of modification. It is important to note that functional properties of these derivatives (such as solubility, pasting temperature, and viscosity stability) mainly depend on the degree of modification (Mark 2013).

6 Grafted Starches

Starch grafting is another strategy that produces derivatives with potential application in the petroleum industry (Kalia and Sabaa 2013). Thus, the use of this kind of modified starches as components of drilling fluids is mainly based on their capacity to control the filtrate loss and to act as thickener agents, as well as for stabilizing the soil of oil reservoirs. In this sense, it was demonstrated that these starch derivatives resulted in being more efficient than anionic or nonionic starches for inhibiting clay and shale hydration process. Furthermore, these derivatives can modify the fluid viscosity and reduce the oil field drag, being suitable as additives in EOR technologies. Kalia and Sabaa (2013) stressed that grafted starches presented a better thermal stability and shear rate than HPAM, the hydrosoluble polymer usually employed as additive in EOR technologies. For these reasons, grafted starches have received special attention not only at academic research but also at industrial level. Table 3 includes some grafted starches usually employed in the petroleum industry.

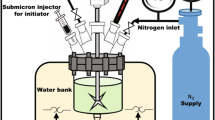

Among vinyl monomers, acrylamide and vinyl alcohol are the most extensively employed for grafting onto starch molecules, which allow obtaining nonionic products for drilling fluids. Starch-g-poly(acrylamide) derivatives are composed of acrylamide or acrylamide–acrylic acid branches from a starch main chain. Their use as additives in EOR processes is mainly associated to the capacity of these derivatives to form highly viscous aqueous suspensions. Singh et al. (2006) reported the synthesis of this derivative by using microwave irradiation. The synthesis of grafted starches by this non-conventional method presents some advantages: heating is direct and highly selective, avoiding thermal inertia and heat exchange within the medium (Wiesbrock et al. 2004). In addition, the use of microwave radiation could be performed either in absence or with very low concentration of initiator (Singh et al. 2004, 2006). Figure 13 shows the starch grafting reaction with acrylamide, as well as the reaction conditions. Singh et al. (2006) demonstrated that this monomer was successfully grafted onto potato starch employing a little amount of potassium persulfate as initiator.

Acrylamide grafting onto potato starch under microwave irradiation (Taken from Singh et al. 2006)

Grafting of acrylamide monomers onto starch molecules was corroborated by infrared spectroscopy (IR) . In this sense, the detection of bands associated to N-H and C=O functional groups in the grafted starch was a clear evidence of the grafting process. Besides, microwave irradiation favored the reduction of the degree of crystallinity of potato starch, which is an indicative of an effective grafting. Singh et al. (2006) reported a high-yield reaction by carrying out the grafting process under the following conditions: 0.10 M acrylamide, 0.0025 M potassium persulfate, 0.1 g/25 mL potato starch, 720 W microwave power, 60 s exposure, and 25 mL of total reaction volume. In addition, it was demonstrated that an inert atmosphere was not a conditioning factor to perform the starch grafting by microwave irradiation.

On the other hand, Song et al. (2007) synthesized a starch derivative by a graft copolymerization with acrylamide (AM) and 2-acrylamido-2-methylpropane-sulfonic acid (AMPS) . These authors reported the use of a complex initiation system of ceric sulfate (CS) and ammonium persulfate (APS) to favor the grafting reaction. Besides, they studied the influence of reaction conditions on yield and final properties of obtained derivatives, proposing these modified starches as a flooding additive for EOR technologies. When 0.2% of grafted starch [Starch-g-p(AM-co-AMPS)] was used as flooding agent, a higher enhanced oil recovery rate was obtained compared to HPAM. Results showed that the novel graft polymer exhibited a much better resistance to temperature and shear rate than HPAM, having potential application in EOR processes.

Eutamene et al. (2009) also studied starch-grafted polyacrylamide copolymers and evaluated their rheological properties, either in water or in water-based muds. Several grafted starches were synthesized by free-radical grafting of acrylamide onto starch, employing ceric ammonium sulfate (CAS) as initiator. These authors stressed that intrinsic viscosity and molar mass of starch derivatives are mainly conditioned by the concentration of both CAS and monomer. Additionally, the behavior of obtained grafted starches under different oil field conditions was predicted, by evaluating the properties of their aqueous solutions. In this sense, water solubility, viscosity, and shear rate as function of temperature, salt concentration and type, and aging time were studied. It is important to highlight that the understanding of these properties is relevant for using grafted starches in drilling muds. Comparing grafted starches with acrylamide to the unmodified starch substrate, the first ones behaved as shear thinning and salt resistant; and their rheological properties were more stable with time.

7 Concluding Remarks

Along the previous sections, the synthetic pathways developed for producing modified starches susceptible to be employed as EOR agents were discussed. Then, an outlook of the research works provided by the scientific literature was provided. The synthesis of cationic, anionic, nonionic, and grafted starch derivatives was presented, with the inherent particularities regarding each kind of modification. Each type of synthesis depends on many reaction parameters (such as temperature, medium, or the presence of coagents as additives) as well as the technical methodology employed (homogeneous or heterogeneous slurry, microwave assisted, among others). In addition, the resulting product must present several particularities for its use in EOR technologies. For example, the interaction between modified starches and soil and the viscosity of the resulting starch solutions are critical parameters to take into account in order to achieve the objectives planned for the recovery. In such a sense, the research regarding this subject will increase in the next years for two main reasons: the availability of raw starch (as a commodity easily obtained from the biomass) and the increasing interest in novel technologies for oil recovery purposes. We hope that, in the near future, the data presented in the present work will be largely exceeded.

References

Al-Muntasheri G, Nasr-El-Din H, Hussein I (2007) A rheological investigation of a high temperature organic gel used for water shut-off treatments. J Pet Sci Eng 59(1–2):73–83

Ayoub A, Bliard C (2003) Cationisation of glycerol plasticised wheat starch under microhydric molten conditions. Starch/Stärke 55:297–303

Ayoub A, Berzin F, Tighzert L et al (2004) Study of the thermoplastic wheat starch cationisation reaction under molten condition. Starch/Stärke 56:513–519

Bao M, Kong X, Jiang G et al (2009) Laboratory study on activating indigenous microorganisms to enhance oil recovery in Shengli oilfield. J Pet Sci Eng 66:42–46

Barrios S, Contreras J, López-Carrasquero F et al (2012) Chemical modification of cassava starch by carboxymethylation reactions using sodium monochloro acetate as modifying agent. Revista de la Facultad de Ingeniería UCV 27(2):97–105

Bendoraitiene J, Klimaviciute R, Zemaitaitis A (2012) Preparation of high substituted cationic starch in presence of organic bases. Starch/Stärke 64:696–703

Bertolini A (2009) Trends in starch applications. In: Bertolini A (ed) Starches: characterization, properties, and applications. CRC Press, Boca Raton, pp 1–19

Butrim S, Butrim N, Bil’dyukevich T et al (2008) Synthesis and physicochemical properties of low-substituted cationic ethers of starch. Russ J Appl Chem 81:2026–2032

Chang Y, Eom J, Kim J et al (2010) Preparation and characterization of shape memory polymer networks based on carboxylated telechelic poly(ε-caprolactone)/epoxidized natural rubber blends. J Ind Eng Chem 16:256–260

Chen Q, Yu H, Wang L et al (2015) Recent progress in chemical modification of starch and its applications. RSC Adv 5:67459–67474

Daripa P, Pasa G (2004) An optimal viscosity profile in enhanced oil recovery by polymer flooding. Int J Eng Sci 42:2029–2039

Datta R, Nair R, Pandey A et al (2014) Hydroxyeyhyl starch: controversies revisited. J Anaesthesiol Clin Pharmacol 30:472–480

Eutamene M, Benbakhti A, Khodja M et al (2009) Preparation and aqueous properties of starch-grafted polyacrylamide copolymers. Starch/Stärke 61(2):81–91

Fink J (2015) Petroleum engineer’s guide to oil field chemicals and fluids, 2nd edn. Elsevier, Oxford

Flores R (2006) Desarrollo de almidones funcionalizados y evaluación de las propiedades reológicas para su aplicación en la industria petrolera. Undergraduate Thesis, Simón Bolívar University, Caracas

Fu J, Qiao R, Zhu L et al (2013) Application of a novel cationic starch in enhanced oil recovery and its adsorption properties. Korean J Chem Eng 30(1):82–86

Gao C (2015) Application of a novel biopolymer to enhance oil recovery. J Pet Explor Prod Technol 6(4):749–753

Gonera A (2004) Aminofunctional starch derivatives: synthesis, analysis, and application. Cuvillier Verlag, Göttingen

Haack V, Heinze T, Oelmeyer G et al (2002) Starch derivatives of high degree of functionalization, 8. Synthesis and flocculation behavior of cationic starch polyelectrolytes. Macromol Mater Eng 287:495–502

Hebeish A, Higazy A, El-Shafei A et al (2010) Synthesis of carboxymethyl cellulose (CMC) and starch-based hybrids and their applications in flocculation and sizing. Carbohydr Polym 79:60–69

Heinz T, Koschell A (2005) Carboxymethyl ethers of cellulose and starch – a review. Macromol Symp 223:13–39

Heinze T, Haak V, Rensing S (2004) Starch derivatives of high degree of functionalization. 7. Preparation of cationic 2-hydroxypropyltrimethylammonium chloride starches. Starch/Stärke 56:288–296

Hou J, Li Z, Cao X et al (2009) Integrating genetic algorithm and support vector machine for polymer flooding production performance prediction. J Pet Sci Eng 68:29–39

Huber K, BeMiller J (2001) Location of sites of reaction within starch granules. Cereal Chem 78:173–118

Jaspreet S, Lovedeep K, Mccarthy O (2007) Factors influencing the physico-chemical, morphological, thermal and rheological properties of some chemically modified starches for food applications – a review. Food Hydrocoll 21:1–22

Jeon Y, Lei J, Kim J (2008) Dye adsorption characteristics of alginate/polyaspartate hydrogels. J Ind Eng Chem 14:726–731

Jie Y, Wem-Ren C, Manurung R et al (2004) Exploratory studies on the carboxymethylation of cassava starch in water-miscible organic media. Starch/Stärke 56:100–107

Kalia S, Sabaa M (eds) (2013) Polysaccharide based graft copolymers. Springer, Berlin Heidelberg

Karabakal U, Bagci S (2004) Determination of wettability and its effect on waterflood performance in limestone medium. Energy Fuel 18:438–449

Kavaliauskaite R, Klimaviciute R, Zemaitaitis A (2008) Factors influencing production of cationic starches. Carbohydr Polym 73:665–675

Kittipongpatana O, Sirithunyalug J, Laenger R (2006) Preparation and physicochemical properties of sodium carboxymethyl mungbean starches. Carbohydr Polym 63:105–112

Klimaviciute R, Riauka A, Zemaitaitis A (2007) The binding of anionic dyes by cross-linked cationic starches. J Polym Res 14:67–73

Kuo W, Lai H (2007) Changes of property and morphology of cationic corn starches. Carbohydr Polym 69:544–553

Kuo W, Lai H (2009) Effects of reaction conditions on the physicochemical properties of cationic starch studied by RSM. Carbohydr Polym 75:627–635

Lawal O, Lechner M, Hartmann B et al (2007) Carboxymethyl cocoyam starch: synthesis, characterisation and influence of reaction parameters. Starch/Stärke 59:224–233

Lazik W, Heinz T, Pfeiffer K et al (2002) Starch derivatives of a high degree of functionalization. VI multistep carboxymethylation. J Appl Polym Sci 86:743–752

Leslie T, Xiao H, Dong M (2005) Tailor-modified starch/cyclodextrin-based polymers for use in tertiary oil recovery. J Pet Sci Eng 46:225–232

Mark H (2013) Encyclopedia of polymer science and technology, concise, 3rd edn. Wiley, New Jersey

Mollega S, Barrios S, Freijoo J et al (2011) Modificación química de almidón de juca nativo mediante la reacción de carboximetilación en medio acuoso. Revista de la Facultad de Ingeniería de la Universidad Central de Venezuela 26(1):117–128

Moorthy S, Andersson L, Eliasson A et al (2006) Determination of amylose content in different starches using modulated differential scanning calorimetry. Starch/Stärke 58:209–214

Morel D, Vert M, Bouger Y (2010) First polymer injection in deep offshore field Angola. In: Abstracts of the Annual Technical Conference and Exhibition, Florence, Italy, 19–22 Sept 2010

Nezhad S, Cheraghian G (2015) Mechanisms behind injecting the combination of nano-clay particles and polymer solution for enhanced oil recovery. Appl Nanosci 6(6):923–931

Pal S, Mal D, Singh R (2005) Cationic starch: an effective flocculating agent. Carbohydr Polym 59:417–423

Pi-xin W, Xiu-li W, Xue D et al (2009) Preparation and characterization of cationic corn starch with a high degree of substitution in dioxane–THF–water media. Carbohydr Res 344:851–855

Prado H, Matulewicz M (2014) Cationization of polysaccharides: a path to greener derivatives with many industrial applications. Eur Polym J 52:53–75

Qiao R, Zhu W (2010) Evaluation of modified cationic starch for impeding polymer channeling and in-depth profile control after polymer flooding. J Ind Eng Chem 16:278–282

Qiao R, Zhang R, Zhu W et al (2012) Lab simulation of profile modification and enhanced oil recovery with a quaternary ammonium cationic polymer. J Ind Eng Chem 18:111–115

Radosta S, Vorwerg W, Ebert A et al (2004) Properties of low-substituted cationic starch derivatives prepared by different derivatisation processes. Starch/Stärke 56:277–287

Sabhapondit A, Borthakur A, Haque I (2003) Water soluble acrylamidomethyl propane sulfonate (AMPS) copolymer as an enhanced oil recovery. Energy Fuel 17:683–688

Sableviciene D, Klimaviciute R, Bendoraitiene J et al (2005) Flocculation properties of high-substituted cationic starches. Colloids Surf A Physicochem Eng Asp 259:23–30

Sangseethong K, Ketsilp S, Sriroth K (2005) The role of reation parameters on the preparation and properties of carboxymethyl cassava starch. Starch/Stärke 57:84–93

Shi L, Zhu S, Zhang J et al (2015) Research into polymer injection timing for Bohai heavy oil reservoirs. Pet Sci 12:129–134

Siau C, Karim A, Norziah M et al (2004) Effects of cationization on DSC thermal profiles, pasting and emulsifying properties of sago starch. J Sci Food Agric 84:1722–1730

Silva I, De Melo M, Luvizotto J (2007) Polymer flooding: a sustainable enhanced oil recovery in the current scenario. In: Abstracts of the Latin American Caribbean petroleum engineering conference, Buenos Aires, 15–18 Apr 2007

Singh V, Tiwari A, Tripathi D et al (2004) Microwave assisted synthesis of guar-g-polyacrylamide. Carbohydr Polym 51:1–6

Singh V, Tiwari A, Pandey S et al (2006) Microwave-accelerated synthesis and characterization of potato starch-g-poly(acrylamide). Starch/Stärke 58:536–543

Singh R, Pal S, Rana V et al (2013) Amphoteric amylopectine: a novel polymeric flocculant. Carbohydr Polym 91:294–299

Song H, Zhang S, Ma X et al (2007) Synthesis and application of starch-graft-poly(AM-co-AMPS) by using a complex initiation system of CS-APS. Carbohydr Polym 69(1):189–195

Sorbie K (2000) Polymer-improved oil recovery. CRC Press, Boca Raton

Stojanovic Z, Jeremic K, Jovanovic S et al (2005) A comparison of some methods for the determination of the degree of substitution of carboxymethyl starch. Starch/Stärke 57:79–83

Tara A, Berzin F, Tighzert L et al (2004) Preparation of cationic wheat starch by twin-screw reactive extrusion. J Appl Polym Sci 93:201–208

Tijsen C, Kolk H, Stamhuis E et al (2001) An experimental study on the carboxymethylation of granular potato starch in non-aqueous media. Carbohydr Polym 45:219–226

Van den Hoek P (2004) Impact of induced fractures on sweep and reservoir management in pattern floods. In: Abstracts of the SPE annual technical conference and exhibition, Texas, 24–29 Sept 2004

Volkert B, Loth F, Lazik W et al (2004) Highly substituted carboxymethyl starch. Starch/Stärke 56:307–314

Wang Y, Xie W (2010) Synthesis of cationic starch with a high degree of substitution in an ionic liquid. Carbohydr Polym 80:1172–1177

Wang W, Liu Y, Gu Y (2003) Application of a novel polymer system in chemical enhanced oil recovery (EOR). Colloid Polym Sci 281:1046–1054

Wei Y, Cheng F, Zheng H (2008) Synthesis and flocculating properties of cationic starch derivatives. Carbohydr Polym 74:673–679

Wever D, Picchioni F, Broekhuis A (2011) Polymers for enhanced oil recovery: a paradigm for structure–property relationship in aqueous solution. Prog Polym Sci 36:1558–1628

Wiesbrock F, Hoogenboom R, Schubert U (2004) Microwave assisted polymer synthesis: state-of-the-art and future perspectives. Macromol Rapid Commun 25:1739–1764

Zhang L (2001) A review of starches and their derivatives for oil applications in China. Starch/Stärke 53:401–407

Zhang M, Ju B-Z, Zhang S et al (2007) Synthesis of cationic hydrolyzed starch with high DS by dry process and use in salt-free dyeing. Carbohydr Polym 69:123–129

Zhou X, Yang J, Qu G (2007) Study on synthesis and properties of modified starch binder foundry. J Mater Process Technol 183:407–411

Zhou X, Yang J, Qian F et al (2010) Synthesis and application of modified starch as a shell-core main adhesive in a foundry. J Appl Polym Sci 116:2893–2900

Acknowledgments

Authors wish to thank the Consejo Nacional de Investigaciones Científicas y Técnicas de la República Argentina (CONICET) for the financial support given to this research.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

López, O.V., Castillo, L.A., Ninago, M.D., Ciolino, A.E., Villar, M.A. (2017). Modified Starches Used as Additives in Enhanced Oil Recovery (EOR). In: Goyanes, S., D’Accorso, N. (eds) Industrial Applications of Renewable Biomass Products. Springer, Cham. https://doi.org/10.1007/978-3-319-61288-1_9

Download citation

DOI: https://doi.org/10.1007/978-3-319-61288-1_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-61287-4

Online ISBN: 978-3-319-61288-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)