Abstract

Here in, we present an experimental investigation using a very simple and low cost technique to provide new properties of AgCl classical materials at the nanometer scale. Indeed, nano-devices, like nano-sensors for example, require miniaturized reference electrodes with high stability. Miniaturization of the reference electrode has a detrimental effect on its desired characteristics, namely on the potential and lifetime. In this work, the Silver chloride wire, also known as a reference electrode, have been produced using the AC mode by electroplating. We analyze the properties of the surface of the wire by changing the applied potential while the other parameters of electrodeposition are kept the same. Then the morphology of the surface is explored at the microscopic scale with SEM. We found that when the potential applied is under 1 V, the morphology of the surface is a globular one, but this surface is also covered by AgCl crystals which grow in spiral fashion from a screw dislocation. This means that the surface is not completely relaxed even if the electric stability of the wire has been shown. If the potential is increased up to 1 V, the surface is covered by nanosheets. Thus, the surface is entirely relaxed and produces a more stable potential. In addition to increased stability of the wire, nanosheets allow to obtain two-dimensional surfaces which could be increased while the thickness still unchanged.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Over the past century, there has been a dramatic increase in the production of very small devices for use in nanotechnology. These devices are made from materials which should have specific properties, especially at the nanometer scale. The properties of such materials depend on the technique used to produce them and the growth mode which may include different interaction parameters. Among these techniques, electrodeposition is starting to be regarded as a viable process for nanofabrication, and even though electrocristallisation has received considerable attention from both the theoretical and experimental viewpoints [1,2,3,4,5]. This technique is typically low-cost and has the possibility to grow nanoscale structures over large areas with fine temporal control [6]. Also, this method has been widely used to create various mesostructures and constrain their shape by modifying the electrochemical growth conditions [7,8,9,10,11]. The growth mechanisms of such structures are still under investigation; however, the capping effect at high growth rates or an oscillatory behavior in nucleation kinetics has been postulated as the possible reasons for shape modification [12, 13].

Recently, using the electrodeposition technique, a crystalline growth of silver nanodiscs was obtained on a sacrificial copper cathodic substrate [14]. The anisotropic growth was attributed to the higher concentration of the copper ions close to the surface due to their sacrificial release from the cathode. Nanostructures such as nanorods [15], nanosheets [16] and nanotubes [17] typically have a high-aspect ratio and can provide this fractal-like topology. Several methods such as chemical vapor deposition, epitaxy and plasma processing or cluster growth have been developed to create these kinds of nanostructures [18,19,20].

However, few studies have been focused on developing this type of structure based on the presence of dislocations at the interface [21, 22]. Some works are limited to buried dislocation networks at the interface and to modeling the surface obtained by epitaxy [23,24,25].

In this paper, we investigate the growth of silver chloride on silver wires under low AC potential. The AC potential provides a more elegant control over the parameters that govern the growth process and helps in understanding the dynamics of this process better. We noted that when the potential applied is under 1 V, AgCl grows in spiral fashion from a screw dislocation. The mixture of globular and spiral aspects means that the surface of silver chloride is not completely relaxed. If the potential exceeds 1 V, the globular form disappeared and two-dimensional growth takes place leading to nanosheets. Then, the surface is completely relaxed. Furthermore, the surface of the wire could be increased by this process and new properties should be identified to make the most of in some applications of nanotechnology.

2 Experimental Details

In our beautiful experimental AC anodization, we use a function generator (Tektroix AFG 3022B) which can generate rectangular potential waveforms of various frequencies and duty cycles. The power source is connected to an electrochemical cell, which contains a cathode platinum wire (diameter of 250 µm) and Ag anode wire (diameter of 200 µm). The two electrodes are immersed in 1 M KCl and the distance between them is 1 cm.

Prior to the deposition, the Ag wire was rinsed with acetone, then DI water, followed by diluted HCl and then DI water again. The rinse is used to remove organic and inorganic residues on the wire’s surface. The electrochemical conversion of the Ag to AgCl was carried out on a predefined portion of the Ag wire (1 cm) dipped in KCl at room temperature using asymmetric square waveforms of 50% duty cycle with various frequencies and amplitudes (AC mode).

3 Results and Discussion

The first stage of electrodeposition on an extraneous substrate is of course the formation of a thin film of the metal being deposited. The crystallographic nature, the thickness and the continuity of this layer is a function of the plating system. The exchange current density is actually the main reason for grain growth, also driving the growth of larger grains at the expense of smaller ones. Our measured lattice parameters are respectively 5.5494 Å for AgCl [26] and 4.086 Å for Ag. AgCl and Ag have FCC structure. The lattice mismatch between the two cystals is high which explains the presence of dislocations at the interface. The presence of dislocations may be the controlling factor in crystal growth. In FCC cubic metals, the screw dislocations move in {111} type planes, but can switch from one {111} type plane to another. It is well known that a large lattice mismatch expresses the difficulty of nucleating a new monolayer on a completed surface of an ideal crystal. But if a screw dislocation is present, it is never necessary to nucleate a new layer; the crystal will grow in spiral fashion at the edge of the discontinuity as shown in Fig. 1. An atom can be bound to a step more strongly than to a plane. If the growth rate is independent of the direction of the edge in the plane of the surface, the growth pattern is an Archimedean spiral:

where a is a constant

If the radius of curvature r is too small, atoms on the curved edge move until the equilibrium curvature is attained (see Fig. 2). Away from the origin, each part of the step acquires new atoms at a constant rate, so that:

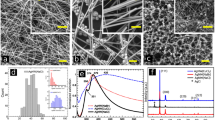

SEM images (see Fig. 3) show that the AgCl film contains a low density of axial screw dislocations that helps their essentially one-dimensional growth. Their density is so low that the crystal retains its theoretical elastic properties. From the absence of dislocations we would expect this AgCl film to have high yield strengths. That is, the stress is not in a direction that can cause slip but the stress caused by the electric field is the force under which the process of growth begins. A particular crystalline growth has been observed when using a potential of about 0.7 V (see Fig. 4).

The chemical composition of AgCl crystals (black in Fig. 4) is reported on Table 1. It is clear that once the dislocations are formed, the tabular growth of the crystals proceeds. The direction of the dislocations does not change very much, except for a few short segments. The origin of these dislocations is related to the addition of chloride after the nucleation phase, which induces lattice strains. The growth process occurs under a potential ≤0.5 V. Unfortunately, there is no mean to correlate the potential applied more firmly with the helicoidally growth and there is no theoretical evidence of this phenomena up to now; moreover, it is not so easy to exactly control the growth process with different parameters.

On the other hand, we think that the application of a potential which is over 1 V introduces a quick depletion of the chlorine concentration close to AgCl surface wire. The helical crystalline form disappears completely and the film seems completely relaxed.

At 1.5 V anodic potential, the silver wire is covered mostly by the nanosheets which are 300–400 nm thick, 5–10 μm high and 10–20 μm long (see Fig. 5b). These results indicate that the growth of the nanosheet AgCl structure over the conventional globular structure is increasingly preferred at higher anodic potentials.

As it demonstrated in a previous work [27], increasing the anodic potential results in increases in the length and height of the nanosheet, while the thickness remains constant (see Fig. 5). We note that when the potential exceed 1 V, the atoms Cl− arrive from NaCl solution with a high rate which could be expressed in mono layers. For simplicity, we assume that the surface temperature is low enough so that only Cl− diffuse on the surface and that Ag remain immobile. As deposition proceeds, the number of Ag+ cations will increase roughly linearly until their concentration becomes comparable to the density of Cl−.

From there on, the probabilities of a diffusing Cl− anions to encounter one of its own or an Ag+ cation become comparable and sheet growth competes with the creation of new stable nuclei. At the saturation nanosheets density, the frequency influences the diffusion of atoms until the size of grains is equal to the mean sheet separation and grains will attach themselves with much higher probability to existing grains than to create new ones. If the deposition continues the nucleation centers become more numerous and coalescence of 2D nanosheets occurs.

4 Conclusions

Silver chloride wires are commonly used as reference electrode, which is why research to date has tended to focus on the stability of AgCl rather than its morphology. Nevertheless, few papers have consistently shown that the morphology of the AgCl surface produced in general is a globular one. This work is an attempt to analyze the new morphology of silver chloride surfaces obtained through an electrochemical process at room temperature. To achieve this aim, wires of Agcl are produced under low potentials in AC mode and the growth is tested under different applied potential.

Microscopic investigations by SEM reveal clearly a new morphology of the silver chloride surface which may be described as random nanosheets. This morphology related to new properties depends on the potential applied and allows to increase the surface wire at nanometer scale. When the potential is under 1 V, the surface of AgCl has a mixture aspect; globular and in spiral fashion. If the potential exceed 1 V, the mosaic appearance of nanosheets is obtained and it would have remained unchanged during the major period of layer growth. In this case, we could confirm that the AgCl surface is completely relaxed and produces a more stable potential.

References

Yu Huang I, Huang Ruey-Shing (2002) Fabrication and characterization of a new planar solid-state reference electrode for ISFET Sensors. Thin Solid Films 406:255–261

Ardizzone1 S, Cappelletti1 G, Mussini1 PR, Rondinini1 S, Doubova LM (2003) Electrodeposited polycristalline silver electrodes: Surface control for electrocatalysis studies. Russ J Electrochem 39(2):170–176

Bozzini Benedetto, Giovannelli Giuseppe, Mele Claudio (2007) Electrochemical dynamics and structure of the Ag/AgCl interface in chloride-containing aqueous solutions. Surf Coat Technol 201:4619–4627

Jin X, Lu J, Liu P, Tong H (2003) The electrochemical formation and reduction of a thick AgCl deposition layer on a silver substrate. J Electroanal Chem 542:85–96

Tiwari JP, Rao Chepuri RK (2008) Template synthesized high conducting silver chloride nanoplates. Solid State Ion 179:299–304

Gurrappa I, Binder L (2008) Electrodeposition of nanostructured coatings and their characterization. A review Sci Technol Adv Mater 9:043001

Pradhan D, Kumar M, Ando Y, Leung KT (2008) One-dimensional and two-dimensional ZnO nanostructured materials on a plastic substrate and their field emission properties. J Phys Chem C 112:7093–7096

Cao BQ, Teng XM, Heo SH, Li Y, Cho SO, Li GH, Cai WP (2007) Surfactant-assisted in situ chemical etching for the general synthesis of ZnO nanotubes array. J Phys Chem C 111:2470–2476

Sajanlal PR, Sreeprasad TS, Samal AK, Pradeep T (2011) Anisotropic nanomaterials: structure, growth, assembly, and functions. Nano Rev 2(1):5883

Xu LF, Guo Y, Liao Q, Zhang JP, Xu DS (2005) Morphological control of ZnO nanostructures by electrodeposition. J Phys Chem B 109:13519–13522

Martin-Gonzalez M, Snyder GJ, Prieto AL, Gronsky R, Sands T, Stacy AM (2003) Direct electrodeposition of highly dense 50 nm Bi2Te3-y Se y nanowire arrays. Nano Lett 3:973–977

Xiao ZL, Han CY, Kwok WK, Wang HW, Welp U, Wang J, Crabtree GW (2004) Tuning the architecture of mesostructures by electrodeposition. J Am Chem Soc 2316–2317:126

Fleury V (1997) Branched fractal patterns in non-equilibrium electrochemical deposition from oscillatory nucleation and growth. Nat 390:145–148

Zhu YC, Geng WT (2008) Three-dimensional self-assembly of Ag nanodisks in crystallography orientations by modified electrochemical deposition. J Phys Chem C 112:8545–8547

Xia YN, Yang PD, Sun YG, Wu YY, Mayers B, Gates B, Yin YD, Kim F, Yan YQ (2003) One-dimensional nanostructures: synthesis, characterization, and applications. Adv Mater 15:353–389

Law M, Goldberger J, Yang PD (2004) Semiconductors nanowires and nanotubes Annu. Rev Mater Res 34:83–122

Wu YH, Yu T, Shen ZX (2010) Two-dimensional carbon nanostructures: Fundamental properties, synthesis, characterization and potential applications. J Appl Phys 108:071301

Knez M, Niesch K, Niinisto L (2007) Synthesis and surface engineering of complex nanostructures by atomic layer deposition. Adv Mater 19:3425–3438

Gonzalez-Aguilar J, Moreno M, Fulcheri L (2007) Carbon nanostructures production by gas-phase plasma processes at atmospheric pressure. J Phys D Appl Phys 40:2361–2374

Jensen P (1999) Growth of nanostructures by cluster deposition: experiments and simple models. Rev Mod Phys 71:1695

Morin SA, Forticaux A, Bierman MJ, Jin S (2011) Screw dislocation-driven growth of two-dimensional nanoplates. Nano Lett 11:4449–4455

Hacialioglu Salih, Meng Fei, Jin Song (2012) Facile and mild solution synthesis of Cu2O nanowires and nanotubes driven by screw dislocations. Chem Commun 48:1174–1176

Derardja A (2010) Anisotropic elastic distorsions of a buried dissociated hexagonal network of dislocations in a Nickel based superalloys. Adv Mater Res 83–86:289–294

Lashmore DS, Thompson R (1992) Cracks and dislocations in face-centered cubic metallic multilayers. J Mater Res 7:2379

Bonnet R (2000) Evaluation of surface strain due to the reconstruction of atomically close-packed crystalline surfaces. Phys Rev B 61:14059–14065

Plendl JN, Mansur LC (1972) Anomalous thermal expansion with infrared spectroscopy. Appl Opt 11:1194–1999

Safari S, Selvaganapathy PR, Derardja A, Deen MJ (2011) Electrochemical growth of high-aspect ratio nanostructured silver chloride on silver and its application to miniaturized reference electrodes. Nanotechnol 22(31):315601–315608

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this chapter

Cite this chapter

Mechaour, S.S., Derardja, A., Deen, M.J., Selvaganapathy, P.R. (2018). New Morphology of a Silver Chloride Surface Grown on Silver Wires. In: Öchsner, A., Altenbach, H. (eds) Improved Performance of Materials. Advanced Structured Materials, vol 72. Springer, Cham. https://doi.org/10.1007/978-3-319-59590-0_6

Download citation

DOI: https://doi.org/10.1007/978-3-319-59590-0_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-59589-4

Online ISBN: 978-3-319-59590-0

eBook Packages: EngineeringEngineering (R0)