Abstract

The finite element analysis is used to investigate the sensitivity of the effective transverse thermal conductivity of polymeric composites reinforced with Manila hemp fibers in terms of their degree of saturation. It is predicted that the hierarchical structure of the fiber bundle will highly magnify the rate of water absorption and in consequence, the effective transverse thermal conductivity of the composite is altered. This influence is quantized in terms of the volume fraction of the fiber bundle and the lumen to produce a homogenized representative continuum. It was found that increasing the fiber volume fraction in a dry medium results in a decrease in the thermal conductivity whereas an increase of conductivity will be evident in a wet condition. Furthermore, the increase in the volume fraction of the lumen enhances the thermal conductivity by retaining more water during saturation which supports the developed hypothesis.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Natural fibers are widely used in various polymeric media for their typical low density, moderate cost, good specific strength, abundance and renewability of resources, and biodegradability among other favored qualities. Nevertheless, the natural variability of properties, deficient fiber-to-matrix bonding, and more importantly their hydrophilic character introduce some challenges to their application. For instance, outdoor usage of natural composites is limited because of the susceptibility of their fiber reinforcements to some environmental factors [1, 20].

The porous structure of natural fibers makes them better thermal insulators compared to synthetic fibers such as glass or carbon [16]. On the other hand, their relatively low thermal conductivity may cause heat dissipation difficulties in some cases [13]. This trade-off attracted researchers in the past decades to investigate the naturally anisotropic thermal behavior of these composites in terms of their volumetric composition [24], volume fraction of fibers [14], fiber orientation [3], and thermal diffusivity [13, 17] among other effective parameters.

The mechanical properties of cellulose fibers are sensitive to the moisture content, particularly when incorporated into polymeric resins [7]. Namely, the hygroscopic behavior of natural fibers results in dimensional instabilities, i.e., swelling and shrinkage, which may induce residual stresses and microcracks into the composite as well as the debonding of the fibers [4, 21]. From a macroscopic point of view, moisture initiates the degradation process of the natural fibers which in consequence, affects the properties of the composite. For instance, reduction of the elastic modulus and tensile strength [5, 6], fluctuation of the impact strength [2], and even the initiation of a fungal decay process [23] is foreseeable. Moreover, considering the porosity of the fibrous structure, the thermal conductivity of natural fibers is predicted to be affected by the presence of water.

Various theoretical and experimental methods were used to predict the thermal behavior of natural fibers but the scarcity of the research on the effect of saturation motivated the current work which is basically a computational effort to envision the big picture of the saturation process. In the current study, the effect of water content on the insulation role of a composite—reinforced with Manila hemp fibers in a high density polyethylene (HDPE) matrix—is investigated using the finite element method. A list of the used symbols in the current work is also provided (see Table 1).

2 Methodology

In the current study, the finite element method [18, 19] was used to estimate the effective thermal conductivity of unidirectional Manila hemp fiber bundles in the transverse (i.e., perpendicular to the principal fiber axis) direction. A four-phase continuum was created using the MSC Marc (version 2014.2) commercial finite element package. This software was selected due to its capability of incorporating user-written pieces of code into its core algorithm. Namely, the customized procedures can be carried out using the subroutines written in the Fortran programming language [10]. This facility—along with the provided Python scripting tool—makes it possible to fully automatize the parametric study [11, 12].

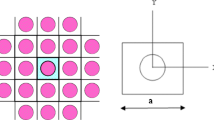

The composite is assumed to be made up of unidirectional hemp fiber bundles (see Fig. 1). Each fiber bundle consists of a set of lumens which are basically slender tubular structures that provide the air cavities [26]. Since the porosity of a natural fiber defines its capacity to hold water [21], the storage of moisture is done by filling the tubes with water and creating a wet lumen.

A recent research shows that the bulk property of the fibrous structure can be properly modeled, within an acceptable margin of error, irrespective of the exact micro-level structure [15]. Therefore, a unit cell of the composite is selected as the RVE of the whole composite. In order to capture the hierarchy of the structure, the accumulated effect of the individual sub-structures are considered in four distinct layers:

-

1.

a polymeric matrix of HDPE,

-

2.

the solid part of the Manila hemp fiber bundle,

-

3.

the water contained in the lumens, and

-

4.

the air which fills the remaining volume.

These four phases take part in the occurring conduction process within the composite (see Fig. 2). The thermal conductivities of these individual components are listed in Table 2. This implies the fact that since the encapsulated water is stationary, no convection is taking place and the only means of heat transfer is the conduction mechanism [21].

A 2D finite element model, with a thickness of the unit length, was created using a uniform mesh of elements of type 39, i.e., the 4-node bilinear isoparametric planar heat transfer elements. The uniform mesh density \( (\gamma ) \) is defined using the following equation:

where a is the characteristic dimension of the element, i.e., the edge length of each square element. Following several sensitivity analyses, it was observed that the mesh sensitivity was diminished for mesh densities over 300, and thus a mesh density of 400 is used in the simulations.

It is worth emphasizing that only one type of element was used with four different material properties which represented the four distinct phases of the problem. Based on the volume fraction values of fiber bundle and lumen plus the degree of saturation of the fiber, the occupied volume of each phase was calculated at the beginning of each analysis. In the next step, different properties were assigned to the elements by means of the ANKOND user subroutine. This subroutine is responsible for the anisotropic thermal behavior of the material and it was called upon the material assignment stage of the finite element analyses.

Inasmuch as the prescribed temperature boundary conditions provide the most precise results in thermal conductivity analyses [9], two set of prescribed temperatures were assigned to the left- and right-hand nodes of the RVE. Namely, a high temperature of 20℃ and a lower temperature of 0℃ was assigned as the boundary conditions. This established a temperature gradient which was followed by a heat flux in the transverse direction (see Fig. 3). The reaction heat flux of the lower temperature region was summed up and used to calculate the effective transverse thermal conductivity of the composite by means of the Fourier’s law [8]:

where \( k_{\text{eff}} \) is the effective thermal conductivity of the composite, \( \dot{Q} \) is the total reaction flux in the top boundary conditions, \( A_{0} \) is the cross-sectional area perpendicular to direction of the flux, \( w \) is the width of the RVE (distance between the boundary faces), and \( \Delta{T} \) is the prescribed temperature difference.

To represent the water content of the specimens, the degree of saturation \( (S_{\text{w}} ) \) was used, which can be defined as follows:

where \( V_{\text{w}} \) is the volume of the water, and \( V_{\text{void}} \) is the total volume of the voids.

Finally, in the current study, the assumptions can be summarized into the following points:

-

the porosity of the matrix is neglected,

-

the effect of the thermal barrier resistance is neglected,

-

it is assumed that the thermal conductivity of the solid portion of hemp fiber bundles is independent of the lumen size,

-

the thermal conductivity of all the components is assumed to remain constant by increasing the temperature, and

-

the solid portion of the hemp fiber bundle is assumed to have no porosity and all the porosity is provided by the lumens.

3 Results and Discussion

In a typical hemp fiber, the average diameter of the fiber bundle and lumens are 213 and 16.5 microns, respectively. Also an average number of 137 lumens exists in every fiber bundle which results in an average lumen volume fraction of 30.87% [15]. The saturation of this typical hemp fiber is simulated and the effective transverse thermal conductivity is calculated using the accumulated reaction heat fluxes (see Fig. 4). It can be noted that by increasing the degree of saturation, the effective thermal conductivity experiences an increase which happens in a higher rate for the higher fiber bundle volume fractions. For instance, for a fiber bundle volume fraction of 60%, the saturation causes an increase of the thermal conductivity by 25.79% whereas the same value was only improved by 3.79% for a volume fraction of 10%. In other words, although the lumen fraction is kept constant, the amount of absorbed water increases due to the overall increase in the cross-sectional area of the fiber bundle.

The effect of lumen volume fraction is investigated for two extreme fiber bundle volume fractions, i.e., a high volume fraction of 60% and low volume fraction of 10% (see Figs. 5 and 6). Increasing the lumen volume fraction in either case results in an increase in the effective thermal conductivity due to saturation. This effect is augmented in higher fiber bundle volume fractions. For example, the complete saturation of a low fiber content composite with a small lumen volume fraction increases the transverse thermal conductivity by only 1.24% whereas a high content fiber with a high lumen volume fraction undergoes a 44.61% improvement.

In the dry composite samples, increasing the fiber bundle volume fraction reduces the effective thermal conductivity for a specific lumen volume fraction. Similarly, increasing the lumen volume fraction for a specific fiber bundle volume fraction, decreases the thermal conductivity of the specimen (see Fig. 7). On the other hand, in a fully saturated composite sample, the effect is opposite to that of the dry sample due to the higher thermal conductivity of the absorbed water compared to air (see Fig. 8).

4 Conclusion

In summary, the porosity of the Manila hemp fiber bundles affected the effective transverse thermal conductivity of the natural composite. Namely, a decrease was observed in the dry samples whereas an improvement in the effective thermal conductivity of the composite happened for the fully saturated samples. This effect was highly augmented in high fiber bundle volume fractions or high lumen volume fractions. In either case, the amount of water absorption was increased due to increased volume of the voids within the fiber bundle and in consequence, increased the effective transverse thermal conductivity of the composite.

References

Assarar M, Scida D, El Mahi A, Poilâne C, Ayad R (2011) Influence of water ageing on mechanical properties and damage events of two reinforced composite materials: flax–fibres and glass–fibres. Mater Des 32(2):788–795

Athijayamani A, Thiruchitrambalam M, Natarajan U, Pazhanivel B (2009) Effect of moisture absorption on the mechanical properties of randomly oriented natural fibers/polyester hybrid composite. Mater Sci Eng, A 517(1–2):344–353

Behzad T, Sain M (2007) Measurement and prediction of thermal conductivity for hemp fiber reinforced composites. Polym Eng Sci 47(7):977–983

Célino A, Freour S, Jacquemin F, Casari P (2014) The hygroscopic behavior of plant fibers: a review. Front Chem 1:1–12

Chow CPL, Xing XS, Li RKY (2007) Moisture absorption studies of sisal fibre reinforced polypropylene composites. Compos Sci Technol 67(2):306–313

Dhakal H, Zhang Z, Richardson M (2007) Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos Sci Technol 67(7–8):1674–1683

Faruk O, Bledzki AK, Fink HP, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37(11):1552–1596

Fiedler T, Hosseini S, Belova IV, Murch GE, Öchsner A (2009) A refined finite element analysis on the thermal conductivity of perforated hollow sphere structures. Comput Mater Sci 47(2):314–319

Islam MR, Pramila A (1999) Thermal conductivity of fiber reinforced composites by the fem. J Compos Mater 33(18):1699–1715

Javanbakht Z, Öchsner A (2017) Advanced finite element simulation with MSC Marc: application of user subroutines. Springer, Cham

Javanbakht Z, Hall W, Öchsner A (2016a) Automatized estimation of the effective thermal conductivity of carbon fiber reinforced composite materials. Defect Diffus Forum 370:177–183

Javanbakht Z, Hall W, Öchsner A (2016b) Finite element evaluation of effective thermal conductivity of short carbon nano tubes: a comparative study. Defect Diffus Forum 372:208–214

Kalaprasad G, Pradeep P, Mathew G, Pavithran C, Thomas S (2000) Thermal conductivity and thermal diffusivity analyses of low-density polyethylene composites reinforced with sisal, glass and intimately mixed sisal/glass fibres. Compos Sci Technol 60(16):2967–2977

Li X, Tabil LG, Oguocha IN, Panigrahi S (2008) Thermal diffusivity, thermal conductivity, and specific heat of flax fiber–hdpe biocomposites at processing temperatures. Compos Sci Technol 68(7–8):1753–1758

Liu K, Takagi H, Yang Z (2011) Evaluation of transverse thermal conductivity of manila hemp fiber in solid region using theoretical method and finite element method. Mater Des 32(8–9):4586–4589

Liu K, Takagi H, Osugi R, Yang Z (2012) Effect of lumen size on the effective transverse thermal conductivity of unidirectional natural fiber composites. Compos Sci Technol 72(5):633–639

Mangal R, Saxena NS, Sreekala MS, Thomas S, Singh K (2003) Thermal properties of pineapple leaf fiber reinforced composites. Mater Sci Eng, A 339(1–2):281–285

Öchsner A (2016) Computational statics and dynamics: an introduction based on the finite element method. Springer, Singapore

Öchsner A, Merkel M (2013) One-dimensional finite elements: an introduction to the FE method. Springer, Berlin and Heidelberg

Placet V (2009) Characterization of the thermo-mechanical behaviour of hemp fibres intended for the manufacturing of high performance composites. Compos A Appl Sci Manuf 40(8):1111–1118

Rakovsky SK (2014) Analytical tools and industrial applications for chemical processes and polymeric materials. Apple Academic Press, Point Pleasant

Rauwendaal C (2014) Polymer extrusion, 5th edn. Hanser Publications and Hanser Publication, Munich and Cincinnati

Schirp A, Wolcott MP (2007) Influence of fungal decay and moisture absorption on mechanical properties of extruded wood-plastic composites. Wood Fiber Sci 37(4):643–652

Shah DU, Bock MCD, Mulligan H, Ramage MH (2016) Thermal conductivity of engineered bamboo composites. J Mater Sci 51(6):2991–3002

Singh RP, Heldman DR (2014) Introduction to food engineering, 5th edn. Food science and technology international series. Elsevier Academic Press, Amsterdam

Wang H, Xiao Y, Qin QH (2016) 2D hierarchical heat transfer computational model of natural fiber bundle reinforced composite. Scientia Iranica Trans B, Mech Eng 23(1):268

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this chapter

Cite this chapter

Javanbakht, Z., Hall, W., Öchsner, A. (2018). Computational Evaluation of Transverse Thermal Conductivity of Natural Fiber Composites. In: Öchsner, A., Altenbach, H. (eds) Improved Performance of Materials. Advanced Structured Materials, vol 72. Springer, Cham. https://doi.org/10.1007/978-3-319-59590-0_16

Download citation

DOI: https://doi.org/10.1007/978-3-319-59590-0_16

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-59589-4

Online ISBN: 978-3-319-59590-0

eBook Packages: EngineeringEngineering (R0)