Abstract

Non-metallic carbon electrodes are widely used in the construction of Microbial Fuel Cells (MFCs) mainly due to their high conductivity and low cost. The objective of this work was to determine the effect of increasing the surface area of the electrodes (with values of R1 = 241 and R2 = 205 cm2, achieved by making several spherical indentations on them) on the voltage generated in the MFC while treating residual wastewater. The MFC consisted of a chamber provided with four graphite electrodes connected each other by an electric circuit and a resistance of 10 Ω. The device was tested with three different initial organic matter concentrations in the wastewater (389.6, 428.6 and 453.6 mg L−1) and a total process time of 8 days. The voltage generation rates were 0.29 and 0.25 mV·day−1 (between the 2nd and 5th day) and the maximum values of voltage registered (at 5th day) were 1.9 and 1.5 mV for R1 and R2 respectively. The organic matter removal rates were also dependent of the electrodes surface area; we obtained values of 49.6 mg.L−1/day for R1 and 34.5 mg.L−1/day for R2.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

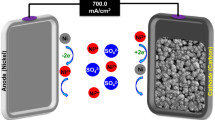

A Microbial Fuel Cell (MFC) is a biochemical reactor that generates electrical energy by the oxidation of organic matter in the presence of fermentative bacteria. There is a considerable quantity of reports in which the characterization of the performance of MFCs is made; in these reports, a wide variety of substrates, such as glucose, acetate, lactate or wastewater are employed (Baranitharan et al. 2014). The use of wastewater as a substrate for electricity generation is seen as a promising approach because it is a renewable energy source; nevertheless, this technology is currently in an early stage of research and development since its implementation on an industrial scale still faces technical and economic difficulties (Gonzalez et al. 2014).

As in a MFC, the microorganisms act as a catalyst in the transfer of electrons from the substrate to the anode; as a consequence, the selection of the microbial strain (either pure or in consortium) has a paramount importance in its performance. Also, the different aspects related to the design of a MFC, such as, the efficient assembly of electrodes, the use of a membrane to decrease the resistance associated with proton transfer, the effective interaction of the substrate with the microbial consortium, the surface area suitable for the microbial growth in the electrodes and the ideality of the catholyte, among others, are important parameters on which the generation of electricity in the MFC depends (Kim et al. 2015).

2 Materials and Methods

The experimental device consisted of a single chamber MFC built with 3 mm-thick acrylic walls. Four graphite electrodes (2.8 × 8 × 0.3 cm) were placed equidistant to each other inside the reactor. They were connected each other by an external circuit with copper wire (awg 16 gauge) and a resistance of 10 Ω. In order to increase the surface of the electrodes, spherical indentations were made.

The process was evaluated for 8 days, at a temperature of 35 ± 0.5 °C, the cell volume was 1.6 L and a recirculation flow rate of 7.8 L·h−1 was maintained with a peristaltic pump (MasterFlex L/S, Easy–Load II). Domestic wastewater was collected in the septic tank of the University, the MFC was filled using a residual water/sludge ratio of 2:1. Electricity production was monitored daily by a discrete 3-point sampling of the voltage generated, reporting a daily average, using a Fulgore® digital multimeter, model FU0233 for this measurement. Organic matter consumption was determined indirectly by measuring the Chemical Oxygen Demand (COD) (NMX-AA-030-SCFI 2001), every 24 h.

Statistical analysis was carried out using a complete factorial design of two factors (the total area of the electrodes and the initial concentration of organic matter present in the water samples). Two levels were tested to evaluate the influence of the electrode surface area (R1 = 241 and R2 = 205 cm2) and three initial concentrations of organic matter (389.6, 428.6 and 453.6 mg·L−1). The experiments were performed in triplicate and an analysis of variance with α < 0.05 was performed using Stats pad software version 2.0.2 to determine significant statistical differences among the experimental conditions.

3 Results and Discussions

The voltage generated in both reactors throughout the experiment showed a Gaussian behavior (Fig. 1a). In the first two days, the voltage increase observed remained essentially constant because the bacteria are adapting to the operating conditions of the reactor. From day 2, the rate of voltage production increased (R1 = 0.29 and R2 = 0.25 mV·day−1) and the highest measured voltage was observed on day 5 in all the treatments tested (R1 = 1.9 mV and R2 = 1.5 mV). From day 5 until the end of the experiment, the voltages measured in the different treatments decreased and returned to their initial value, These results may be related to the consumption of organic matter during the process (Fig. 1b); the first two days, a lower rate of degradation was observed, 23.3 mg·L−1/day for R1 and 15.23 mg·L−1/day for R2; However, from day 3, the degradation rate doubled to 49.6 for R1 mg·L−1/day and 34.5 mg·L−1/day for R2.

According to the data presented in Fig. 2a, it is observed that there is a directly proportional relationship between the area of the electrodes and the rate of voltage production; it is noted that the initial concentration of organic matter of 428.6 mg·L−1 is the one that reaches a higher rate of voltage production. Figure 2b shows a directly proportional effect between the area of the electrodes and the maximum voltage value reached at day 5; however, the initial concentration of organic matter has not a statistically significant effect on this parameter.

The maximum voltage generated was 1.9 mV for R1 and 1.5 mV for R2 (day 5), with an initial organic matter concentration of 428.6 mg·L−1; these results are similar to those obtained by Penteado et al. (2016), who recorded values ranging from 0.2 to 72 mV (day 9), using waste water from a winery with an initial organic matter concentration of 6,850 mg·L−1 and carbon paper and carbon fiber electrodes in a double chamber MFC. They concluded that the maximum amount of voltage generated depends on the material of the electrodes. Other authors have considered increasing the ratio of the electrode surface area to the reactor volume to improve the electrical efficiency of the cells. Kim et al. (2015), reported a production of 634 mV·m−3 in a 9-day process within 2.2 h using a 0.1 L cathode MFC with graphite fiber brush anodes (0.57 cm2) and residual water with 400 mg·L−1 of initial organic matter. The results obtained were similar with those observed in this study, in which we produced a higher ratio 1,187 mV·m−3, under the tested conditions. Likewise, Sciarria et al. (2013), reported that when using one-chamber reactors (0.028 L) with graphite fiber brush electrodes (0.22 m2), they obtained 1,428.5 mV·m−3 at day 5 (12.5 total days), with an initial concentration of organic matter of 2,600 mg·L−1; which exemplifies how the increase of the area, the use of different materials to build the electrodes in the anode chamber and the increase of the organic matter concentration, are intimately related to the amount of voltage generated in an MFC.

Zhao et al. (2016), analyzed the relationship between the electricity production and initial organic matter concentration in an MFC; in this work, they found that when the organic matter content was high (10–16% w/w), the rate and the maximum voltage produced were higher; nevertheless, in this cases, voltage production tended to be unstable mainly due to the generation and accumulation of bubbles related to fermentation and methanogenesis processes. This was also observed in this work, in which the total organic matter inside the MFC (including the organic matter present in the water and the sludge) ranged from 8 to 21% w/w; for this reason, we implemented a gas purge at the top of the reactor.

In this work an average organic matter removal of 65 and 52% were obtained for R1 and R2, respectively. Increasing the electrode surface (an amount of 18%) had a statistically significant effect on the rate of removal of organic matter, which augmented by about 20% (Fig. 3), with an average removal rate of 36.86 mg·L−1/day for R1 and 29.47 mg·L−1/day for R2. In addition, it was observed that the initial concentration of organic matter in the wastewater has a directly proportional relation (α < 0.5) with the organic matter removal rate; the higher initial organic matter concentration (453.66 mg·L−1), the higher its removal rate.

4 Conclusions

It was determined that the surface of the electrode had a direct relationship with the amount of the generated voltage in the MFC; the higher voltage production corresponded to the reactor having greater surface area. Likewise, it was also observed that the initial concentration of organic matter present in the substrate has a directly proportional effect on the amount of voltage generated in the studied conditions.

References

Baranitharan E, Khan R, Prasad DMR, Teo W, Tan G, Jose R (2014) Effect of biofilm formation on the performance of microbial fuel. Bioproc Biosyst Eng 38:15–24

Gonzalez A, Perez J, Cañizares P, Rodrigo M, Fernandez F, Lobato J (2014) Study of a photosynthetic MFC for energy recovery from synthetic industrial fruit juice wastewater. Int J Hydrogen Energ 39:21828–21836

Kim K, Yang W, Logan B (2015) Impact of electrode configurations on retention time and domestic wastewater treatment efficiency using microbial fuel cells. Water Res 80:41–46

NMX-AA-030-SCFI, 2001 Análisis de Agua. Determinación de la Demanda Química de Oxígeno en aguas naturales, residuales y residuales tratadas. Métodos de prueba, México: Secretaría de Comercio y Fomento Industrial

Penteado E, Fernandez C, Zaiat M, Gonzalez E, Rodrigo M (2016) Influence of carbon electrode material on energy recovery from winery wastewater using a dual-chamber microbial fuel cell. Environ Technol 12:1–9

Sciarria T, Tenca A, D’Epifania A, Mecheri B, Merlino G, Barbato M, Borin S, Licoccia S, Garavaglia V, Adani F (2013) Using olive mill wastewater to improve performance in producing. Bioresour Technol 147:246–253

Zhao Q, Li R, Ji M, Ren J (2016) Organic content influences sediment microbial fuel cell performance and community structure. Bioresour Technol 220:549–556

Acknowledgments

We want to acknowledge PhD Dimas Talavera Velázquez for his valuable collaboration in the construction of the carbon electrodes.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Villarreal-Martínez, D., Arzate-Martínez, G., Reynoso-Cuevas, L., Salinas-Martínez, A. (2017). Effect of Increasing the Surface Area of the Graphite Electrodes on Electricity Production in a Microbial Fuel Cell (MFC) Fed with Domestic Wastewater. In: Mannina, G. (eds) Frontiers in Wastewater Treatment and Modelling. FICWTM 2017. Lecture Notes in Civil Engineering , vol 4. Springer, Cham. https://doi.org/10.1007/978-3-319-58421-8_55

Download citation

DOI: https://doi.org/10.1007/978-3-319-58421-8_55

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-58420-1

Online ISBN: 978-3-319-58421-8

eBook Packages: EngineeringEngineering (R0)